Used PVA 2400 #9215454 for sale

URL successfully copied!

Tap to zoom

ID: 9215454

Vintage: 2012

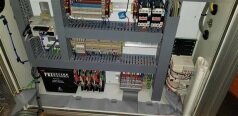

Conformal coating machine

With 360 head

Dual head assembly with 360 rotation

Head 1 with tilt assembly with FCS100 valve

Head 2: No valve

Programming pendant

Flat panel monitor & LCD operator interface

Adjustable SMEMA edge chain conveyor

Computer

Onboard (30) program memories

SMEMA Edge chain conveyor

Access door and exhaust interlocks

Travel speed: 0 to 700 mm/sec (0 to 27.6 in/sec)

Repeatability: ±25 microns (±0.001")

Positional resolution: 0.005 mm (0.0002")

Air supply: 80 PSI Dry, unlubricated air

Power supply: 120V, 220V, +/-10%, 50-60 Hz

Input powers: 115V, 1 Phase, 50/60Hz

2012 vintage.

PVA 2400 is a positive-acting photoresist equipment developed to meet the needs of the microelectronics and high accuracy PCB etching industry. It is a highly stable, long-lasting material that is used for the fabrication of both etched and printed circuit boards. 2400 system is composed of a base resist, a developer, and an anti-reflective layer. The base resist layer is a photopolymer that is exposed to light energy in order to photosensitize it, forming a patternable invisible resist. This layer is highly resistant to etching chemicals and is designed to provide excellent undercutting protection during the etching process. The developer is a mix of chemicals used to further sensitize and harden the exposed areas so that they can be etched without the photosensitive material losing integrity. The anti-reflective layer helps to minimize the reflectivity of the material, thereby improving the accuracy of the etching process. PVA 2400 unit is designed to resist etchants such as hydrochloric acid, hydrofluoric acid, and sulfuric acid. Its superior resistance allows PCBs to be etched using smaller etch depths, thereby increasing the reliability of the etching patterns. 2400 has excellent adhesion, enabling it to effectively protect metal surfaces from damage during etching. A mild alkaline solution is used to remove the un-exposure area of the resist, and a baking process is then used to complete the development of the resist pattern. The final product is a durable, accurately etched board that is ready for use in a circuit board assembly. PVA 2400 photoresist machine is ideal for the fabrication of high-precision printed circuit board designs. Its superior resistance to etchants and its excellent adhesion properties make it an ideal choice for board etching. Its reliable pattern formation and accuracy make it a dependable and cost-effective solution for use in circuit boards.

There are no reviews yet