Used SCHNEIDER DHC20 #9379799 for sale

URL successfully copied!

Tap to zoom

ID: 9379799

Vintage: 2016

Dip coater

Throughput: (20) Lenses / Hour

Automated fast 2-Axis handling

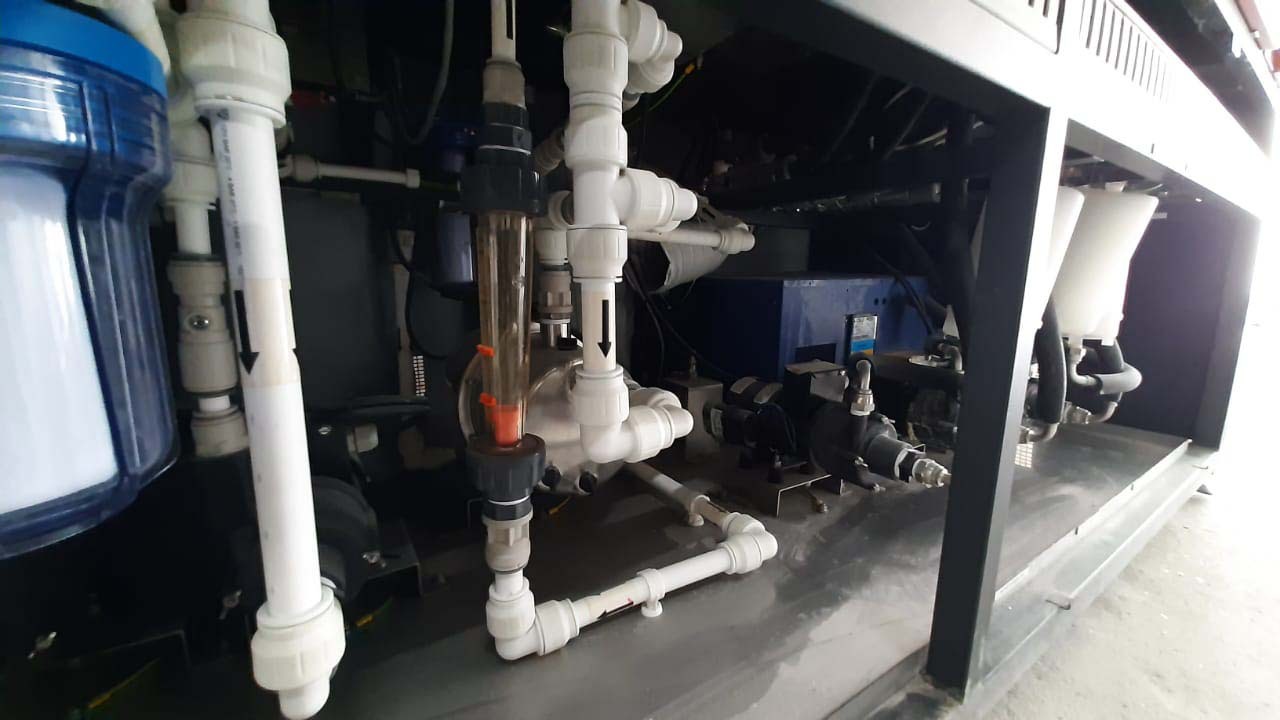

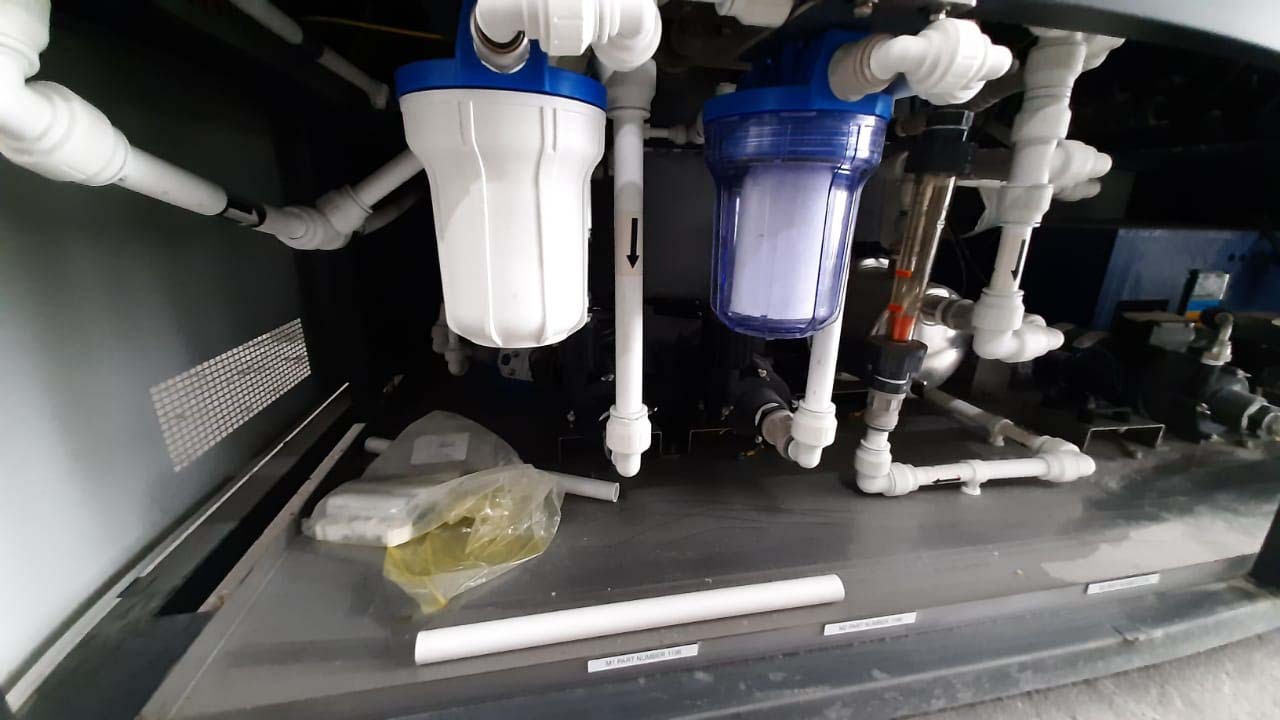

Compact three double-stage cleaning process

Semi automatic fill and level control on tanks

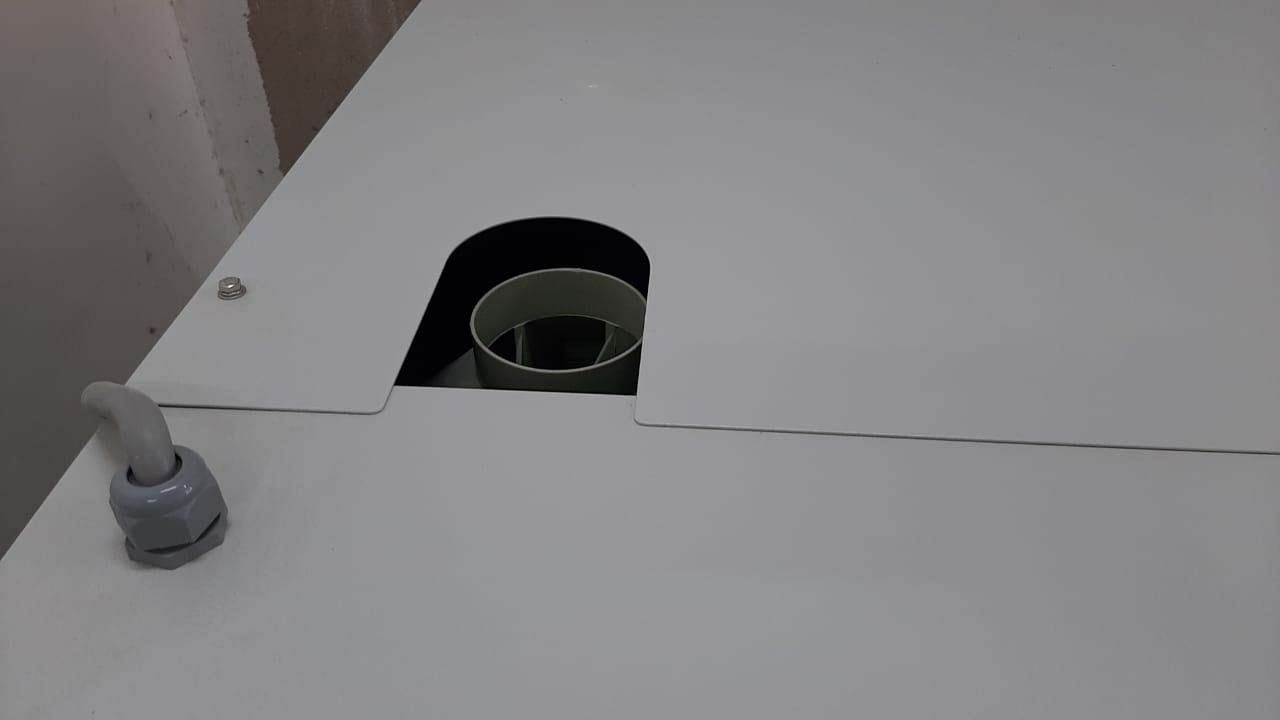

Sliding lid over all coating tanks

Primer stage for polycarbonate lenses

Integrated fire extinguishing system

Ultrasonic cleaning tanks

Hard coating system

With heating and ultrasound

(3) Lacquer tanks

Pre-curing infra-red ovens

Built-in DI water production with conductivity control

Absolute (HEPA) air filter

Comprehensive multistage

Thermal cune clip

Printing stage

(2) Lacquers

(3) Coating tank

ROBOT Handing

Solvent top-up

SCHNEIDER CM / Beckholf control system

Capacity: (20) Lens

Accessories included

2016 vintage.

SCHNEIDER DHC20 photoresist equipment is an advanced tool used in the manufacture of integrated circuits (ICs). It is a wet chemical process that involves the transfer of a precisely patterned film of organic material onto a semiconductor substrate. The photoresist system consists of several components, including a developer, a photoresist mask, a substrate, and the photoresist material. The developer creates a solution of the photoresist material, allowing it to be applied to the substrate. The photoresist mask is then placed on the substrate and the photoresist material is exposed to a focused light source. This process transfers the desired pattern onto the substrate. Once the photoresist material has been transferred onto the substrate, it is then ready to be processed. The processing phase involves a series of steps in order to achieve the desired pattern of the IC design. This includes baking the photoresist material, immersing it in a chemical known as a 'developer', and etching the substrate. During the baking process, the photoresist material undergoes a change in its structure, making it more resistant to the etchant. The developer helps to remove exposed sections of the photoresist material, allowing the pattern of the IC design to be achieved. The etchant is then used to remove unwanted portions of the substrate, leaving behind the desired pattern of the IC design. Finally, the photoresist unit is used to transfer a desired pattern onto the substrate using a photomask. This photomask is then exposed to a high-intensity light source, which further transfers the desired pattern from the photomask to the substrate. In conclusion, DHC20 photoresist machine is an advanced tool used in the manufacture of ICs. It is a wet chemical process that involves the transfer of a precisely patterned film of organic material onto a semiconductor substrate. The photoresist tool consists of several components, including a developer, a photoresist mask, a substrate, and the photoresist material. This asset is used in tandem with the development, baking, and etching processes to achieve the desired pattern of the IC design.

There are no reviews yet