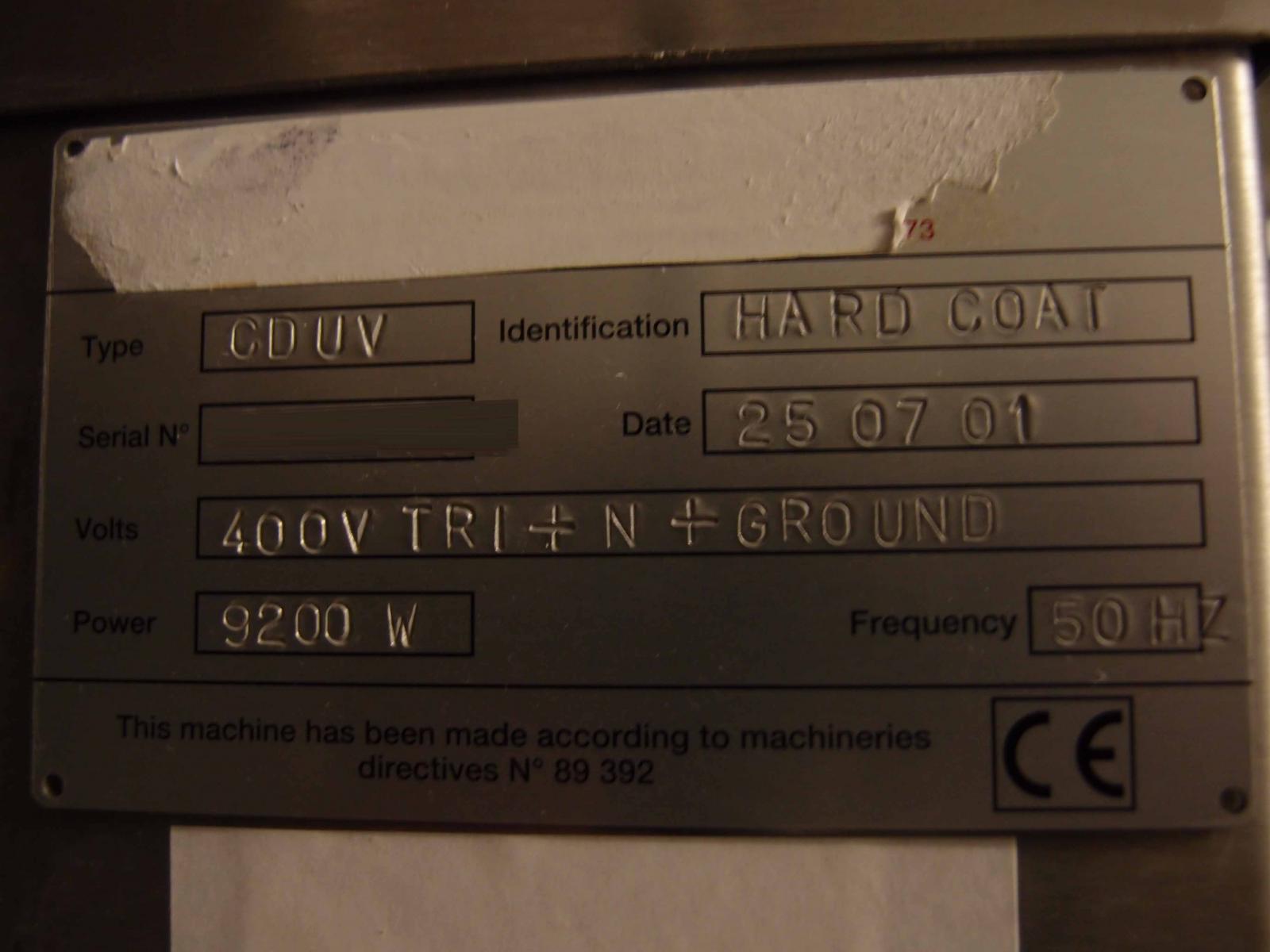

Used SCL CD 200 #9159814 for sale

URL successfully copied!

Tap to zoom

ID: 9159814

Vintage: 2001

Hard coater

CR39

Mid-index material

Hi-index : 1.6, 1.67, 1.74

Trivex

Polycarbonate

Substrate diameter: 50mm - 75mm

Round or elliptical

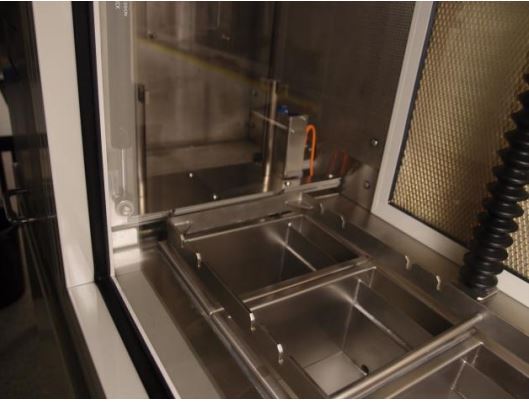

(2) Varnish tanks:

Varnish + varnish

Primer + varnish

Capacity: 170 to 200 per day

(2) Paint tanks:

Lack + Lack

Primer + Lack

Paints / primers are thermally polymerized

Plant capacity about 170-200 glasses / day

2001 vintage.

SCL CD 200 is a photoresist equipment designed for use in the fabrication of integrated circuit components. This system features a light-sensitive liquid coating which hardens upon exposure to light, allowing for the creation of fine patterns on the surface of a substrate. CD 200 utilizes a special light source with adjustable intensity to facilitate exposure of the substrate to light. This light source can be set to different intensities depending on the type of pattern being formed on the substrate. A precise pattern is attained by exposing the substrate to the light source at the desired intensity for a set period of time. By adjusting the intensity as needed, the user can accurately control the amount of thermal and UV energy emitted and the resulting pattern. SCL CD 200 also features a photoresist agent which is mixed with a solvent and sprayed onto the substrate. The photoresist is uniquely formulated to react to the light source which allows it to harden upon exposure, leaving a very precise pattern on the surface of the substrate. These patterns can be used for the purpose of making electrical components, such as integrated circuit boards. CD 200 also features a vacuum chuck which holds the substrate while it is exposed to the light source, as well as a vision unit which facilitates the alignment of the photoresist and light source. This machine provides a very precise and efficient means of etching patterns into the surface of the substrate, allowing for the production of advanced electronic components. SCL CD 200 is an essential tool in the fabrication of integrated circuit components. Its precise light source, photoresist agent, and vision tool make it well suited for creating intricate patterns with a high degree of accuracy. This asset is capable of producing patterns that would otherwise be too difficult to achieve with other methods, allowing for the manufacture of advanced electronics at a much lower cost.

There are no reviews yet