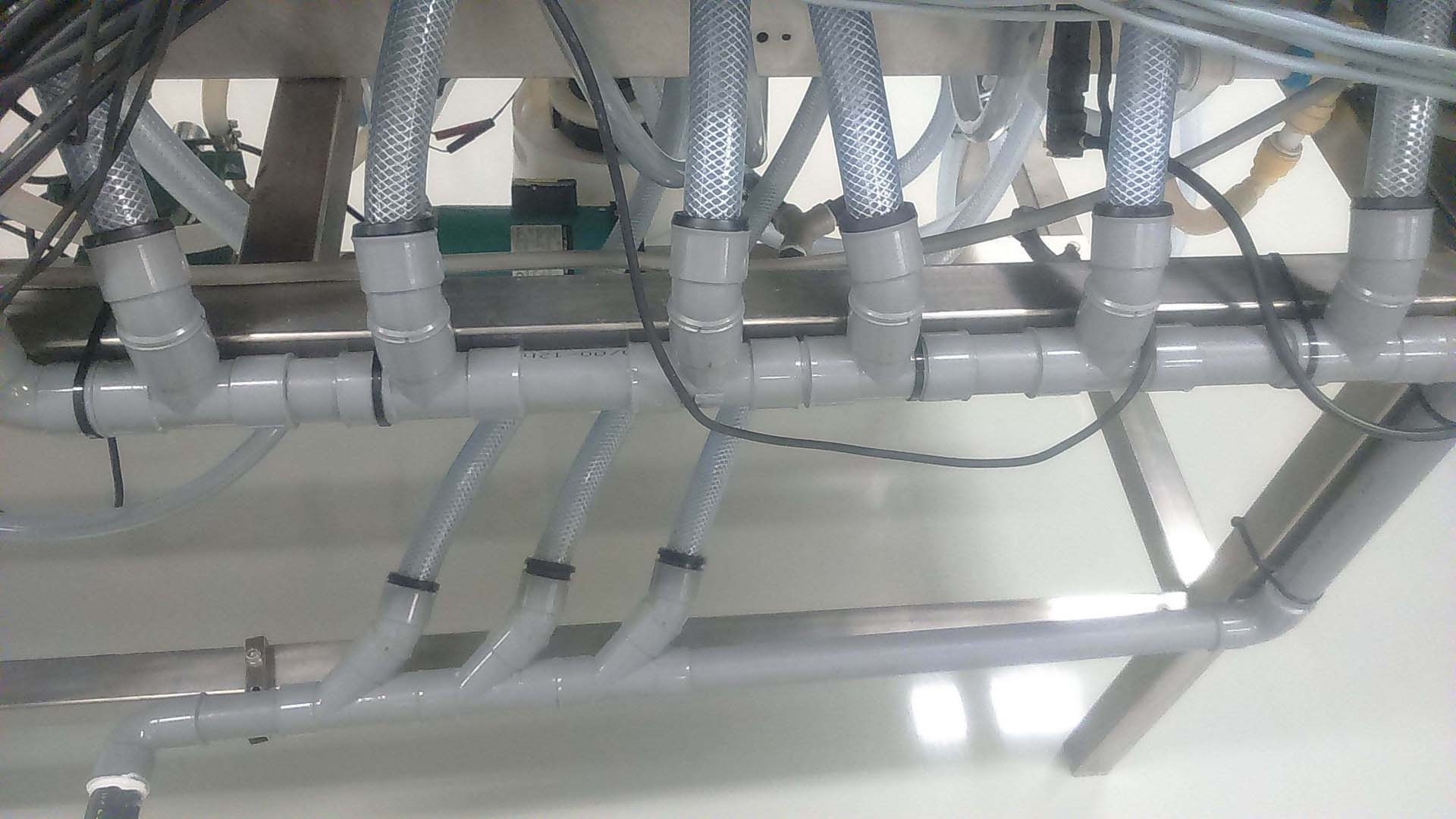

Used SCL CD 400 #9267693 for sale

URL successfully copied!

Tap to zoom

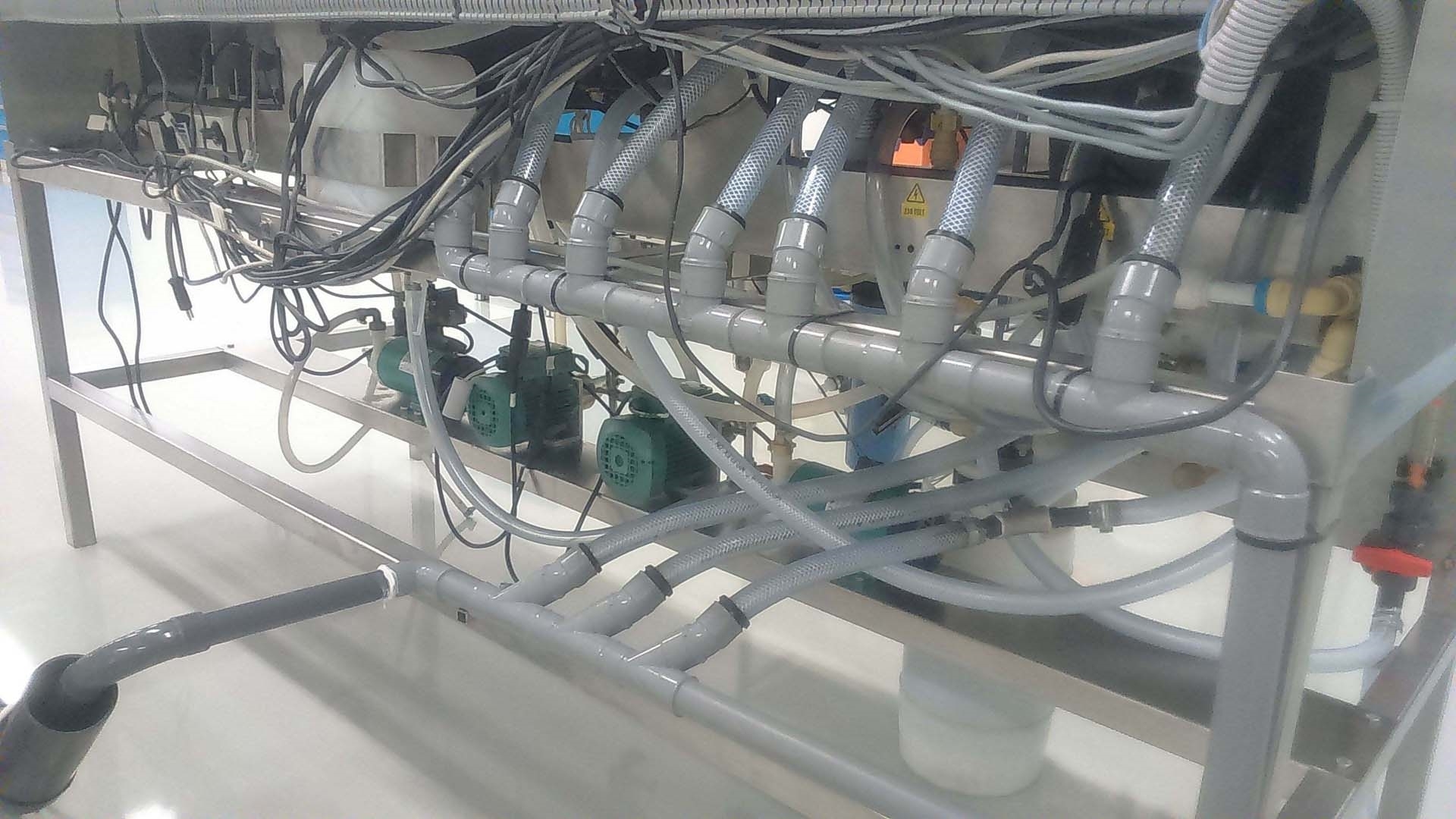

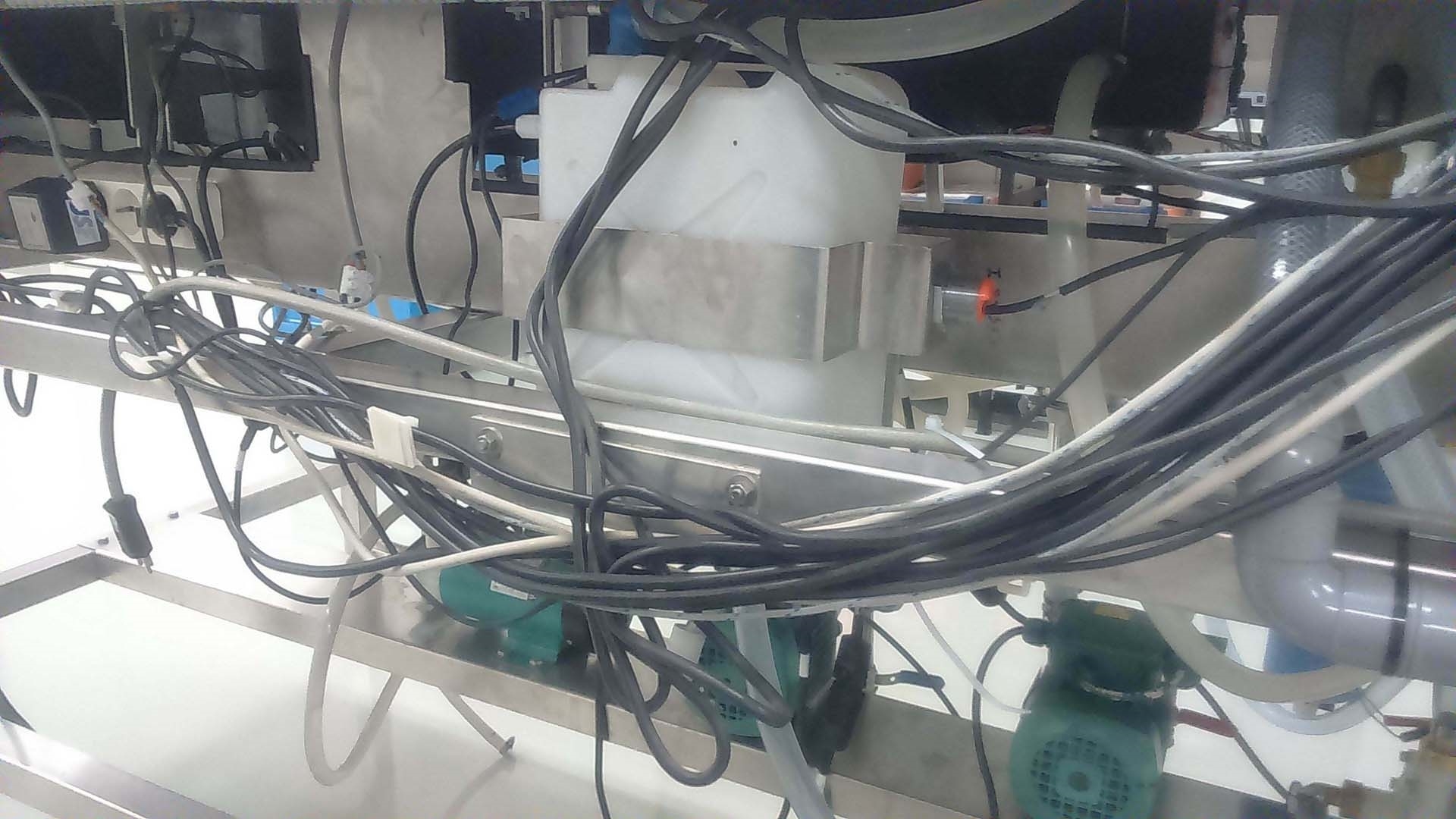

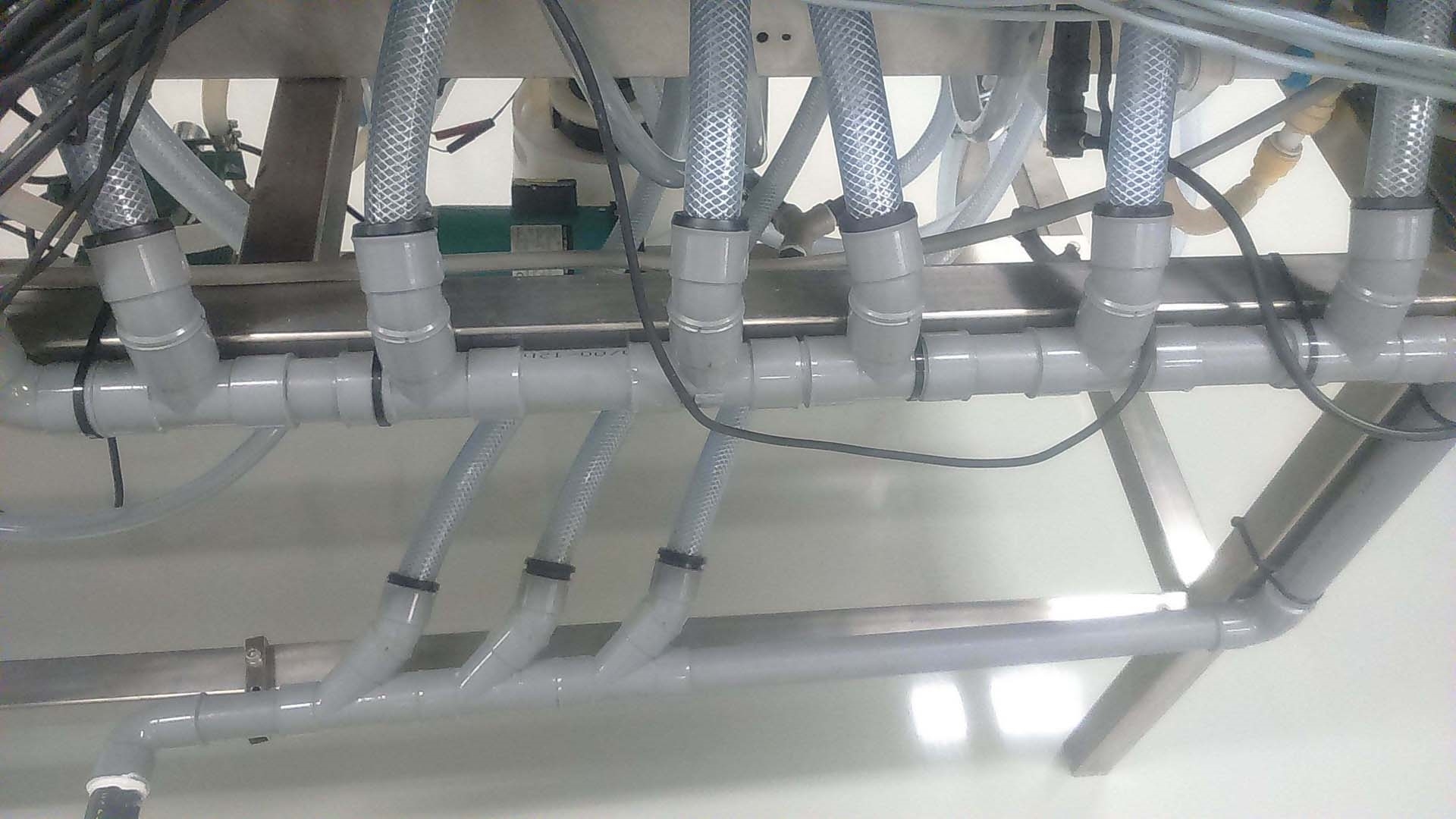

SCL CD 400 is a photoresist system used to process electronic circuits. It is developed based on the optimized UV nanoimprint technology and can be used for both hardbaked and conventional processes. CD 400 uses a photoresist layer in which light sensitive elements are mixed with photopolymersization catalysts. When exposed to ultraviolet light, these elements undergo a process of polymerization. The result is an etch-resistant mask that protects the underlying substrate from chemical etching or physical damage. The photoresist layer is integrated into a specially designed chamber. This chamber is divided into two sections - a pre-engineering section which prepares the photoresist layer and prints the circuit pattern, and a post-processing section which removes the unwanted photoresist layer. The photoresist layer in SCL CD 400 is made of unique elements which provide it with advanced characteristics. It has high resolution, a high contrast index, and low etch resistance. It is also highly reliable and offers high dimensional accuracy when compared with other photoresist systems. CD 400 also has active control measures to ensure that the photoresist layer has optimal uniformity and strength. It adjusts the exposure level of the ultraviolet light to achieve the desired pattern and also provides a high-temperature oven for baking the photoresist material. In addition, SCL CD 400 is very easy to use. It has a simple interface and has multiple functions that are placed within easy reach. It is energy efficient and has a long life, with little maintenance requirements. Finally, CD 400 offers a number of features, such as transparent and opaque sericite substrate option, a multi-speed real-time adaptation exposure system, a patented sipping head for coating, and automated alignment functions. All these features make it the ideal photoresist system for advanced applications.

There are no reviews yet