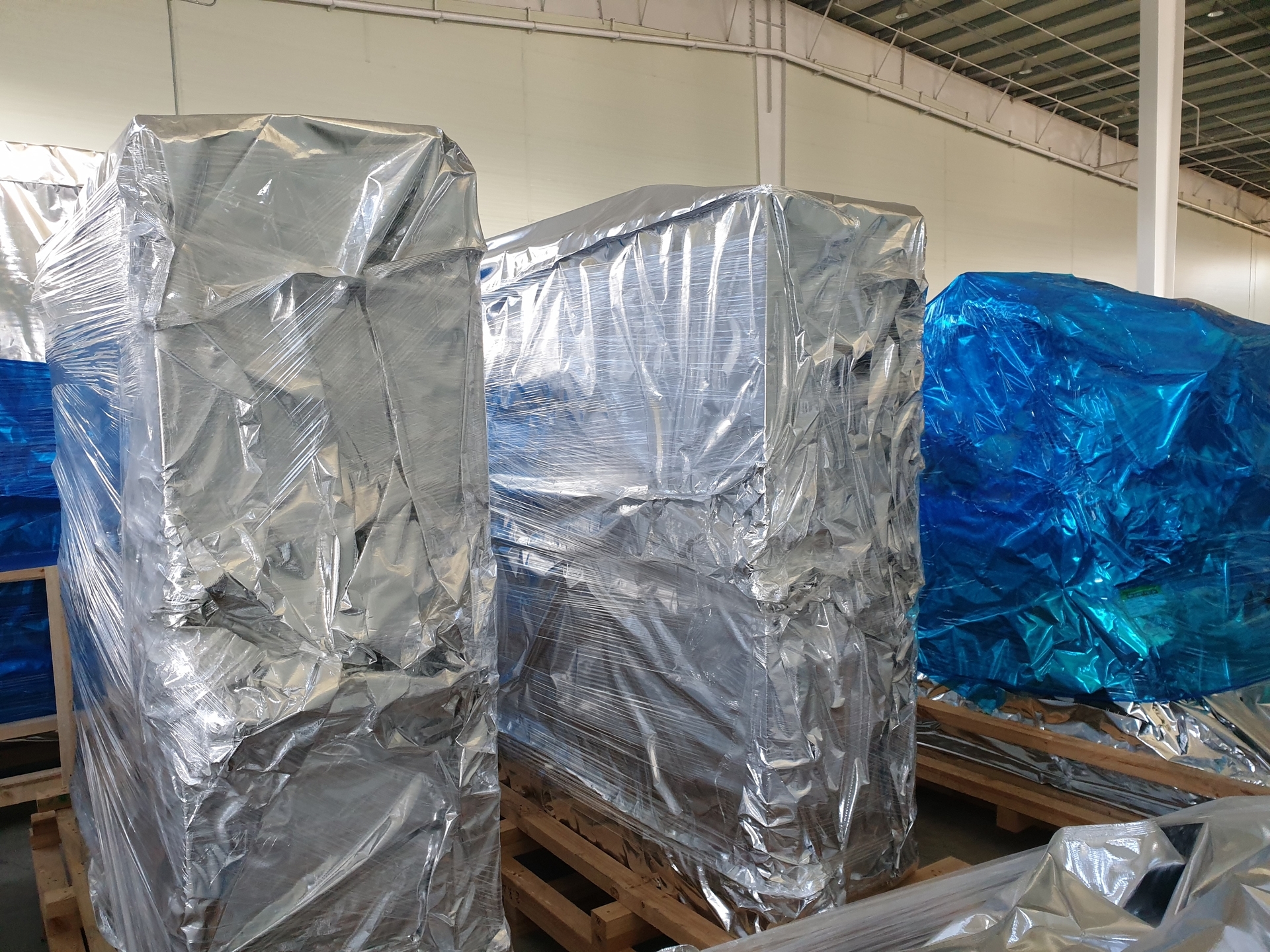

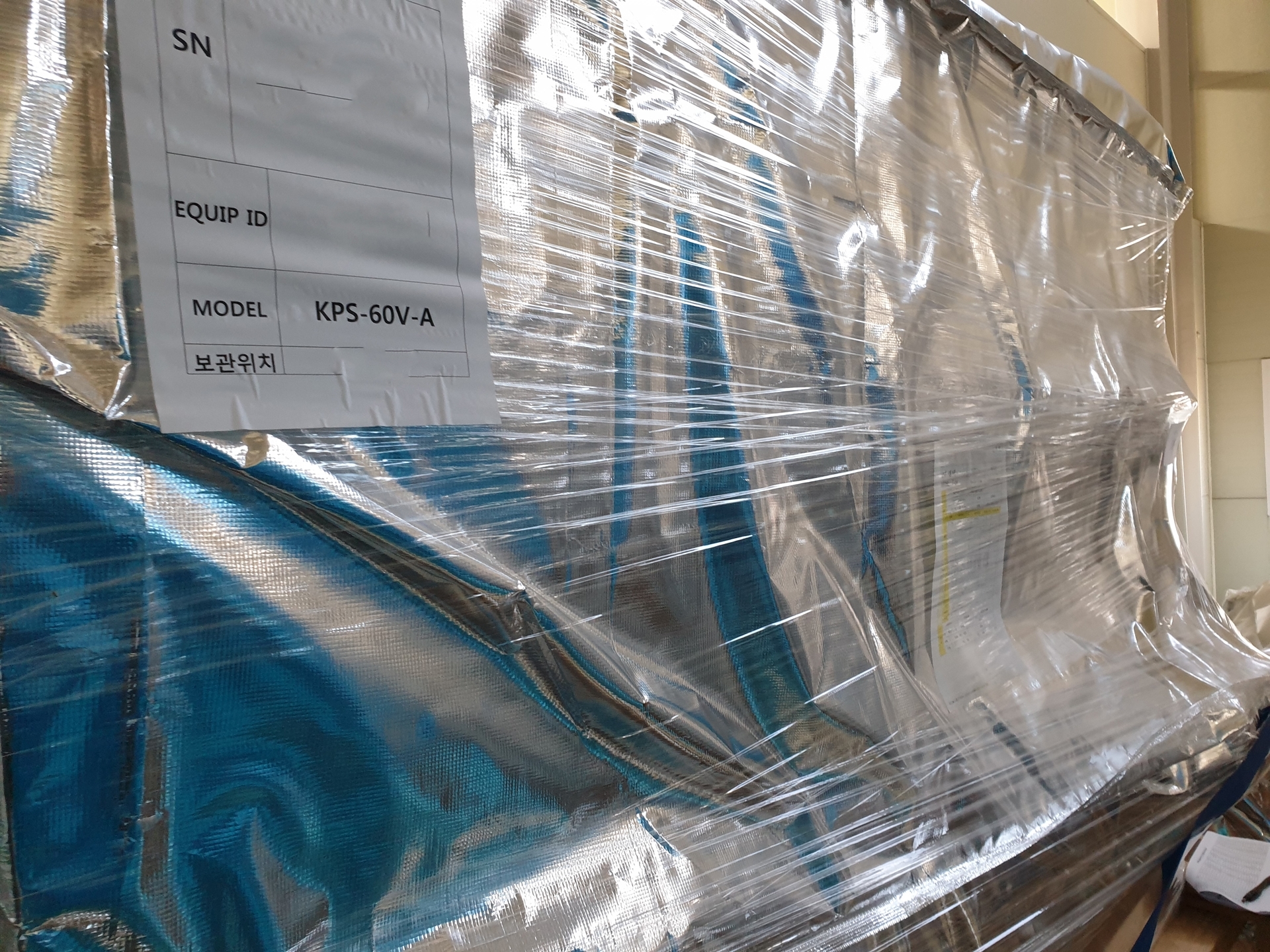

Used SEMES KPS-60V-A #9261448 for sale

URL successfully copied!

Tap to zoom

SEMES KPS-60V-A is a commercially available photoresist equipment designed for general-purpose and high-precision electronic component manufacturing. It utilizes a standard two-step photoresist process to enable accurate and mechanical forming operations. The tool consists of a two-part laminated photoresist sheet containing a photosensitive layer and a substrate layer. The photosensitive layer is initially composed of a thin film of organic material which can be chemically vapor-deposited onto the substrate layer, where it is exposed to a specific wavelength of ultraviolet light. This causes the photosensitive molecules to rearrange themselves and a short-lived polymer network forms. By carefully controlling the exposure time and intensity of the light, the user can create a desired pattern from the photoresist sheet. The second step is the chemical development process. During this step, the sheet is exposed to a developer solution which acts to dissolve the polymeric network, leaving behind only the patterned photoresist. The remaining photoresist can then be passed onto the desired surface or substrate material for further processing. In addition to the main components, the system includes an array of dispensing and imaging tools such as syringes, imaging magnifiers, and colorless markers. These tools are essential for accurately placing the photoresist sheet and ensuring that the exposure times and intensities are properly calibrated. Additionally, the unit is equipped with a thermal control machine which helps to regulate the temperature of the environment and maintain the desired process parameters. Overall, KPS-60V-A tool is an excellent choice for creating intricate electronic components with tight dimensional tolerances due to its precision alignment capability. Furthermore, it is designed for reliable and user-friendly operation, making it a great choice for various industries.

There are no reviews yet