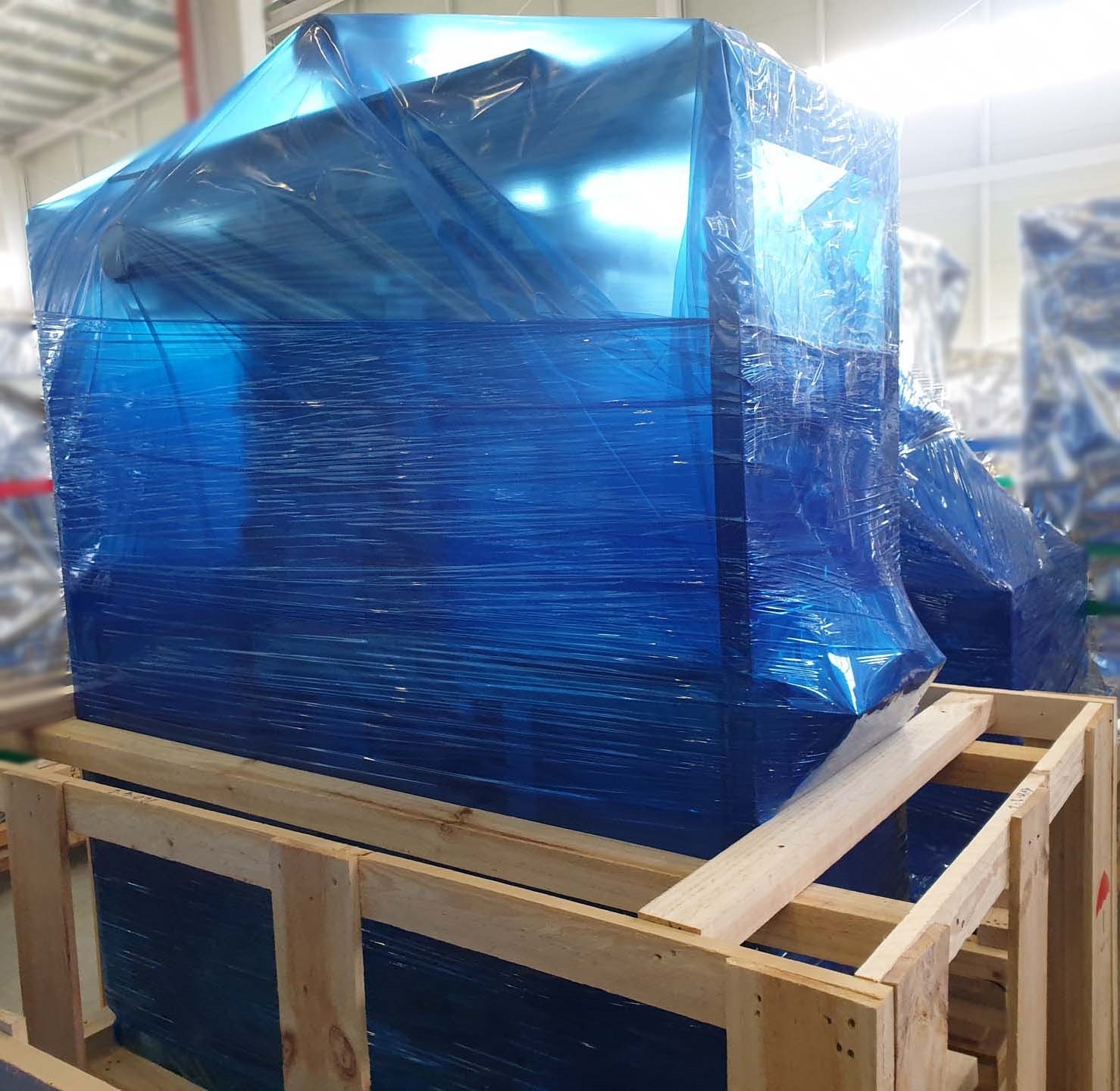

Used SEMES KPS-60V #9265100 for sale

URL successfully copied!

Tap to zoom

SEMES KPS-60V photoresist equipment is a high performance system designed for the creation of photomasks used in a variety of industrial applications, including microelectronics production. Based on a high resolution vacuum evaporation unit, KPS-60V is capable of depositing photosensitive (resist) material in a uniform and repeatable manner to produce highly detailed photomasks with extremely fine features. Part of the major benefit of SEMES KPS-60V machine is its ability to deposit photosensitive Material on silicon wafers, substrates, and other materials with very high precision. Two distinct parts of the tool are involved in the deposition process, the Vacuum Thermal Evaporation unit, and Photo Resist Processing unit. The Vacuum Thermal Evaporation unit is responsible for the uniform deposition of the photosensitive Material, and is capable of producing an extremely uniform build-up of the photoresist material, with a minimum feature size of 0.1 micron. The Photo Resist Processing unit includes a range of additional components, such as a built-in optical head for checking photomask film quality, a laser writer for creating photomask patterns within materials, and an efficient photoetch process in order to accurately apply detailed features to the photomask. In addition, KPS-60V is also capable of fine-tuning the photomask heating and etching process to achieve optimal results. The main focal point of SEMES KPS-60V asset is its ability to produce incredibly accurate photomasks with extremely fine details. This is accomplished through a highly precise monitoring and control of the vacuum process during the deposition of the photoresist. With an extremely fast response time for adjusting parameters, KPS-60V is able to maintain the highest levels of efficiency throughout the entire photomask production process. In conclusion, SEMES KPS-60V photoresist model is a highly advanced equipment designed to create extremely accurate photomasks with high-precision features. Its combination of a vacuum thermal evaporation unit, a laser writer, and a photoetch process make it an industry leader in photomask production technology. The system's highly advanced controls and fast response time ensure that highly accurate and detailed photomasks can be created reliably and quickly.

There are no reviews yet