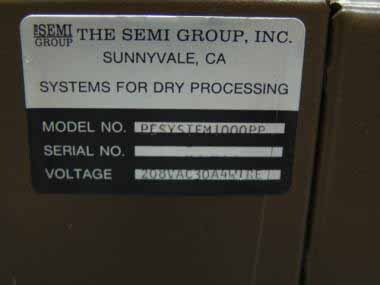

Used SEMIGROUP PP-1000 #9124952 for sale

URL successfully copied!

Tap to zoom

ID: 9124952

RIE system

Microprocessor control: 12" parallel plate

RIE both lower and upper electrodes are temperature controlled

Lower electrode: up to 450 Degrees C

Upper electrode contains a shower head for gas delivery

Power supply: 208 V, 30 A.

SEMIGROUP PP-1000 is a negative photoresist equipment that is primarily used for printed circuit board (PCB) production and other microelectronics applications. It consists of a photoresist which consists of a light-sensitive film that is applied to a substrate. When exposed to UV light, the photoresist hardens and becomes insoluble in developing solvents. After the image has been developed, the photoresist can be removed from the substrate using solvents, leaving the metal circuit exposed. PP-1000 is a negatively-sensitized system, meaning that the exposed areas of the substrate harden upon light exposure while the unexposed areas are less reactive and remain soluble in developing solvents. This unit consists of a photoresist, an activator and, in some cases, a post-exposure bake. When exposed to pure UV-light, the photoresist is hardened and is insoluble in the developing chemicals. After the image has been fully developed, the photoresist can be stripped away from the substrate. This process is used in many PCB production processes for the formation of solder masks, conductor side dry films, and plated through-holes. The photoresist machine used for SEMIGROUP PP-1000 needs to be compatible with the metal layers that will be printed on the substrate. The photoresist should have the ability to promote adhesion between the metal layer and the substrate. Another important factor to consider is the shelf-life of the photoresist, which should be greater than three months to ensure that the photoresist is still intact during processing. The activator used in PP-1000 is the conventional dip-and-dry method. This activator can be applied to the substrate prior to light exposure to as to activate the photoresist material. In some cases, a post-exposure bake may also be required to completely harden the photoresist. This bake can be done at a set temperature and time depending on the requirements In conclusion, SEMIGROUP PP-1000 tool is a negative photoresist asset primarily used for PCB production and other microelectronics applications. It consists of a photoresist, activator, and, in some cases, a post-exposure bake. When exposed to UV light, the photoresist hardens and becomes insoluble in developing solvents. After the image has been developed, the photoresist can be removed from the substrate using solvents, leaving the metal circuit exposed.

There are no reviews yet