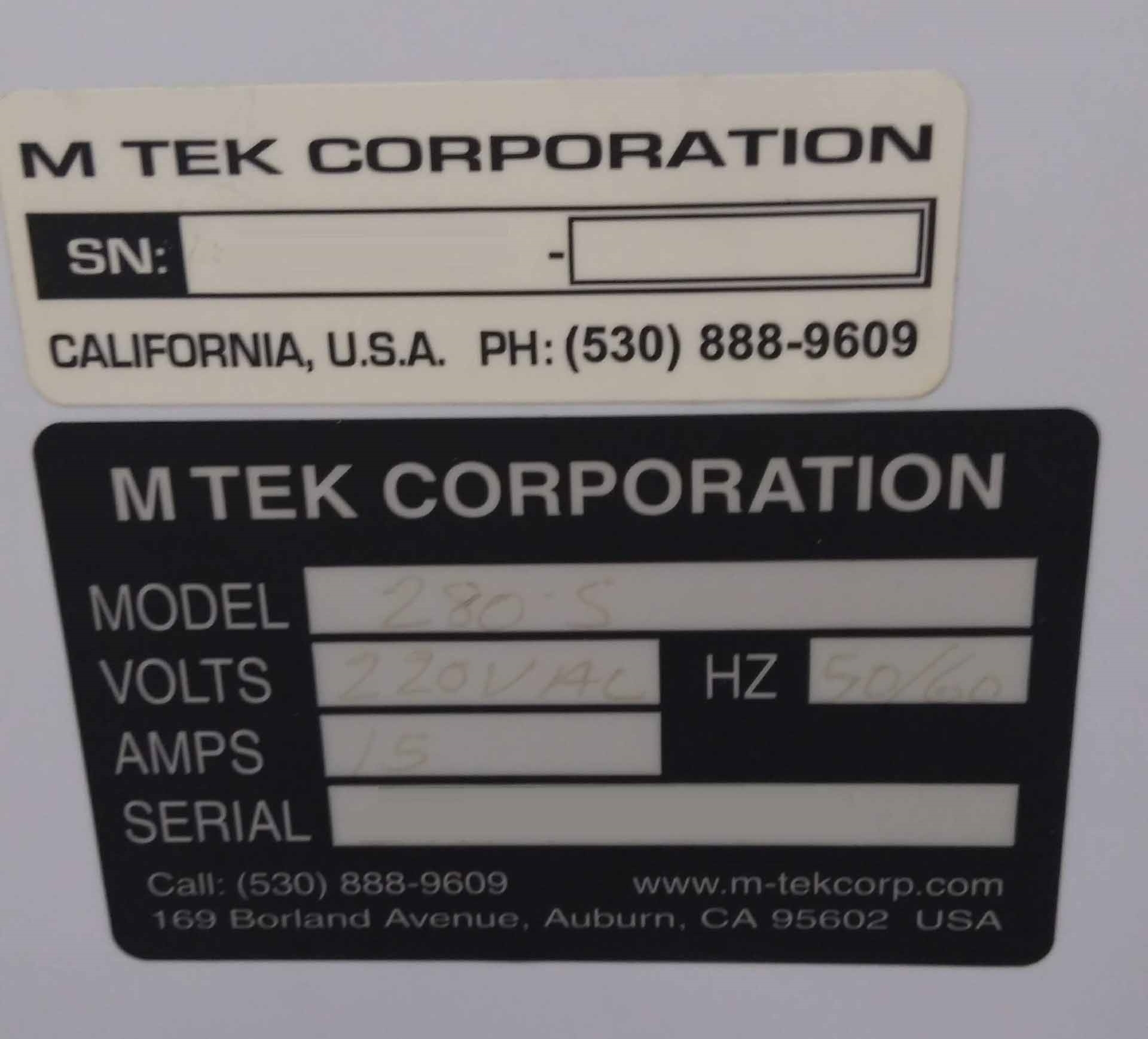

Used SEMITOOL 280S #9255444 for sale

URL successfully copied!

Tap to zoom

SEMITOOL 280S is a photoresist equipment that was developed for wafer fabrication processes. The system can be used to expose and develop chemically-amplified photoresists and is ideal for lithography processes with tight pitches and line widths. The unit is optimized for HDRIP (High Density Release Imprinting) processes, capable of delivering high precision resist profiles with a high resolution of 0.5 microns. The machine comes with a sophisticated UV-camera which can be integrated into the process control for continual monitoring and evaluation of the lithography process. The tool has an optical assembly equipped with two lenses and one condenser lens assembly. The optical assembly is mounted onto a precision high resolution positioning stage which enables high accuracy movement in the XY direction. The stage is also programmable in the Z-axis, enabling precise alignment of the mask and lower lenses, as well as focus control. The asset also has a fully automated mask cassette for loading and unloading masks and substrates, as well as a substrate alignment module which enables precise adjustment of position and orientation for accuracy. Additionally, it has an automatic substrate offload feature and robotic wafer handling with bar-code reading. The photoresist development model uses a batch-processing method, and is a single-chamber design for photoresist processing that enables a vast array of available recipe settings tailored for the appropriate resist chemistry. The equipment has a standard sogginess system which has a cleaning gassing unit, a thin film measurement machine, and adjustable temperature and pressure settings for precise sogginess development. In addition to traditional lithographic and sogginess systems, 280S has a bottom anti-reflective coating (BARC) module which can be used to deposit anti-reflective layers on the bottom side of the wafer for reducing surface reflectance and improving performance. The tool can also be used for post-development treatments, such as baking, sogginess removal, and oxygen or nitrogen annealing. The asset's software control model allows users to customize development recipes and monitor the entire process. It also has a remote diagnosis and repair equipment which can be accessed from any Internet-capable computer to diagnose issues and perform remote maintenance. The entire process can be controlled and monitored through a simple graphical user interface. Overall, SEMITOOL 280S is a powerful and capable photoresist system, capable of producing high-quality lithography with precise focus control within the 0.5 micron pitch range. It comes with a highly advanced automated wafer handling unit and a sophisticated UV-camera for process monitoring and evaluation. The machine can also be used for post-development treatments, such as sogginess removal, baking, and annealing. Additionally, it has a modular software tool which can be customized to optimize results for specific resist chemistries.

There are no reviews yet