Used SEMITOOL 430S-5-1-ML-WP #9178866 for sale

URL successfully copied!

Tap to zoom

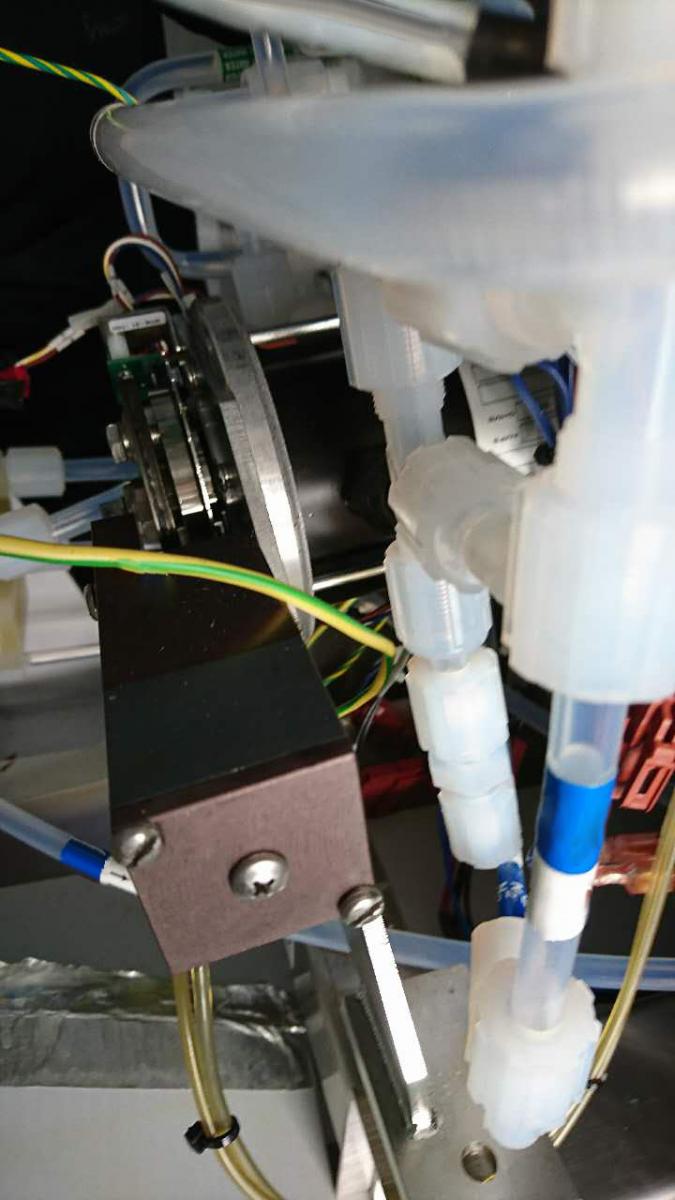

SEMITOOL 430S-5-1-ML-WP Photoresist Equipment is a fully automated and integrated chemistries and processing unit for the application of photoresist materials. It is capable of processing up to 5 115mm wafers per session. The machine is equipped with a series of independent and inter-programmable process chambers, including an external chemical supply cabinet, user-controlled programmable atmospheric control, an RF generator, a PR spraying station, and a rapid thermal curing system, all of which are installed together to create a fully functional processing unit. The photoresist process begins with the pre-treating chamber, which is set up to pre-treat the surface of the wafers. This entails cleaning the wafers to remove any particles, oxides, and/or contaminants that may be present prior to application of the resist material. The pre-treating chamber provides chemical control and precise delivery of a variety of cleaning solutions and etchants to achieve maximum adhesion of the photoresist, depending on the substrate type. The photoresist is then sprayed onto the wafers in the PR spraying station. The spraying station has a motorized precision sprayer, a variable frequency RF generator, and a heated air drying chamber that can couple with external heaters for better control of the resist film dry down times. The RF generator is used to control the deposition of the photoresist for uniformity. Once the photoresist has been applied and dried, the wafers are transferred to the rapid thermal curing (RTC) unit. This unit is equipped with an integrated heater unit and a single chamber with adjustable timing program for precise control of the curing processes. The RTC machine works to precisely regulate the temperature of the wafer per the application. Once the curing process is complete, the wafers are moved into a post-cure chamber, which can provide additional heating or drying cycles when needed to enhance film integrity. 430S-5-1-ML-WP Photoresist Tool features intuitive and user-friendly architecture with clear step-by-step instructions for each step of the photoresist process. The integration of independent process chambers and the precise delivery of cleaning chemicals, resist films, and curing times make it an excellent choice for high-end photolithography applications.

There are no reviews yet