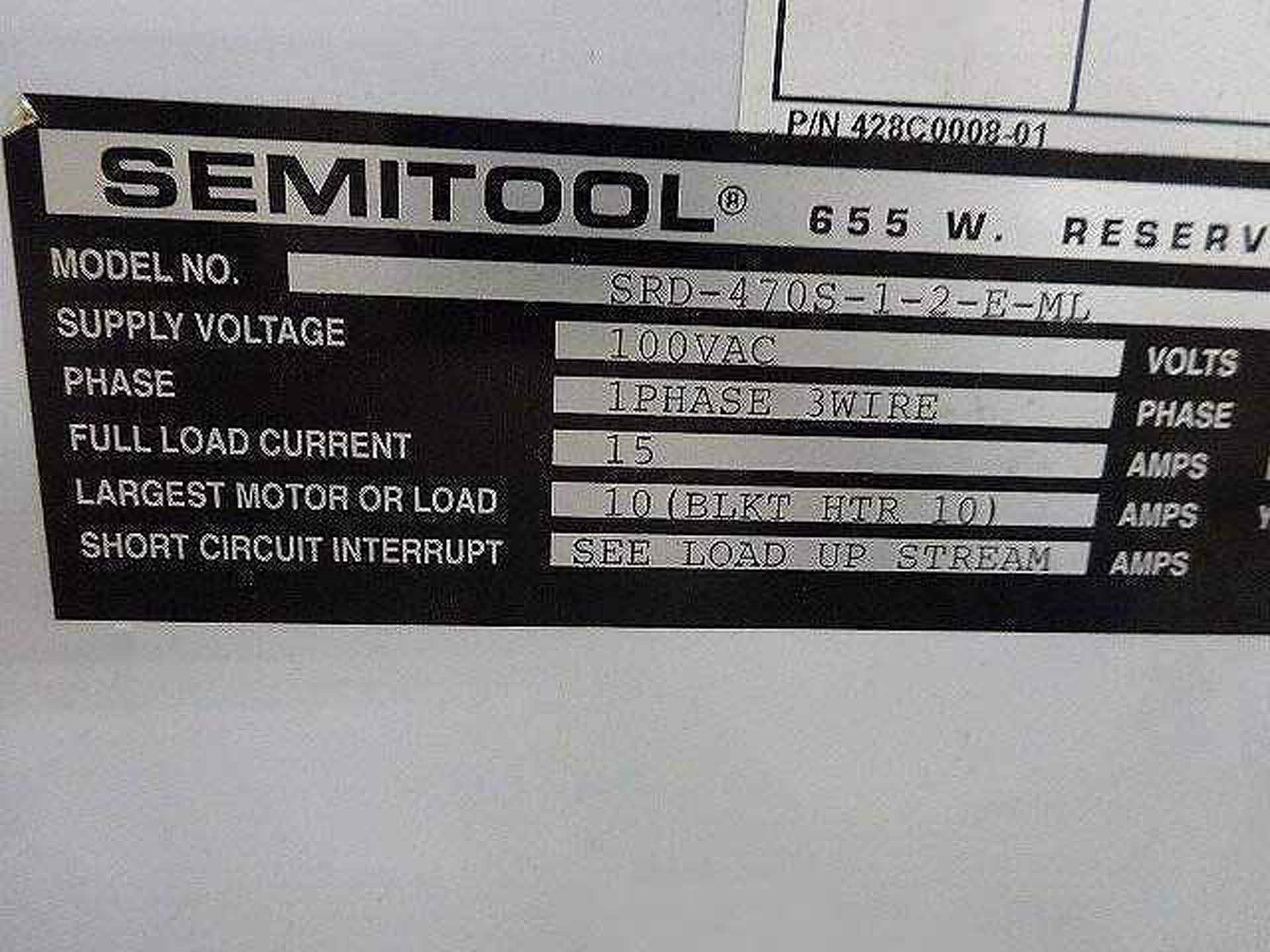

Used SEMITOOL 470S #9254338 for sale

URL successfully copied!

Tap to zoom

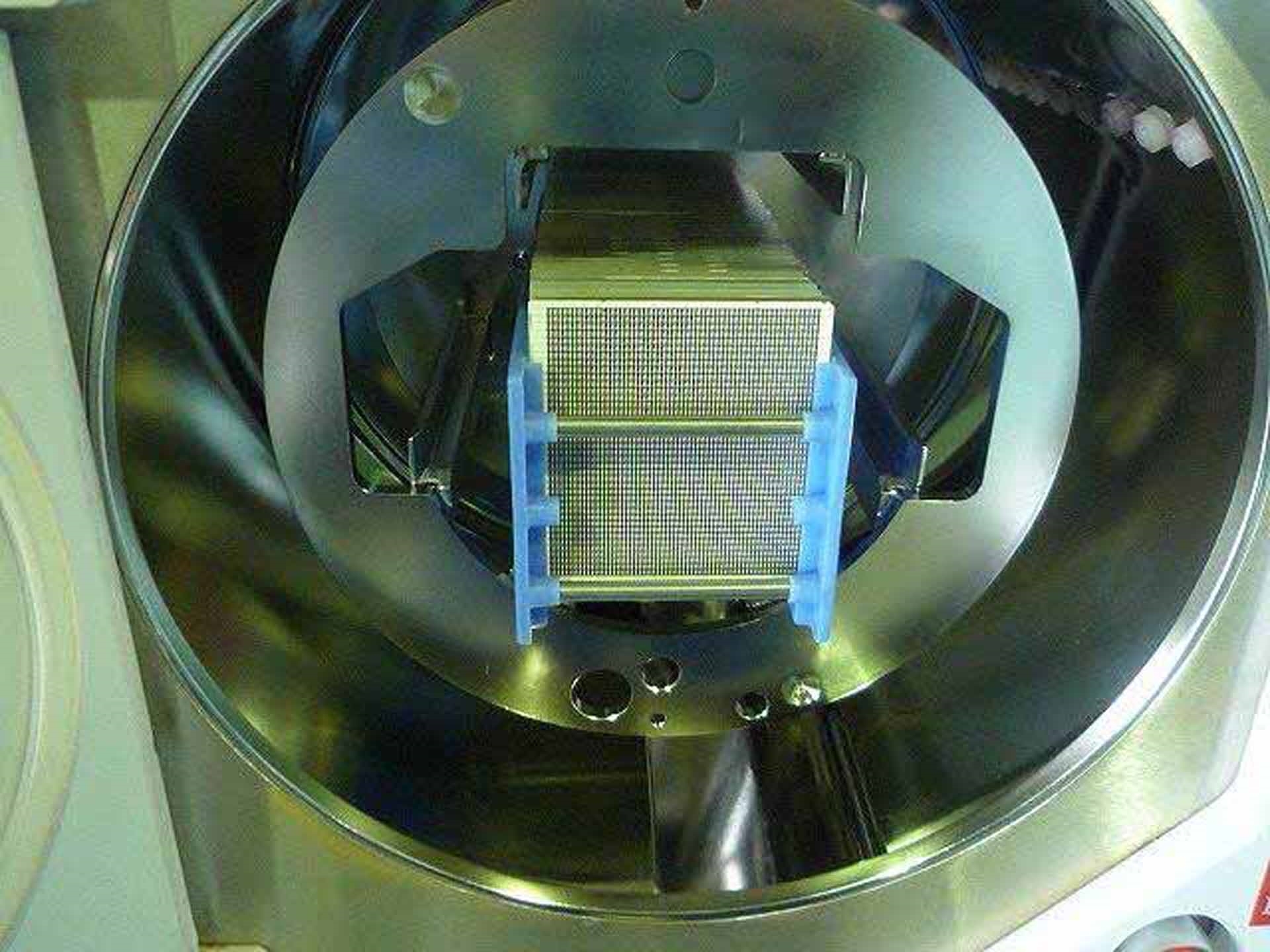

SEMITOOL 470S Photoresist Equipment is a high-performance, automated wet bench designed for use in the photolithographic processes used in the manufacture of semiconductor integrated circuits. The system can apply advanced processing of photoresist materials to semiconductor wafers of various sizes, from 200mm to 500mm, with dielectric and metal deposition. The unit features an automated conveyor that transports wafers between processing steps, a multi-zone temperature-controlled wet bench, and a sophisticated software-based recipe control machine. This combination of advanced features allows the tool to produce uniformly-processed photoresist layer on wafers without manual intervention. SEMITOOL 470 S is designed to deposit advanced photoresist materials that feature eliminating topcoat resist, forming an anti-reflective coating (ARC), building new photoresist layer or replacing existing damaged or defective layer, and increasing or decreasing photoresist thickness. This advanced asset provides high throughput performance and reliable wafer cleaning, critical factors in semiconductor fabrication. The model includes solutions for processing LOR5, LOR6, and LOR7 photoresists, allowing for variations in process module preconditioning and wet bench design. The control equipment of 470S is I/O controlled by an operator platform, allowing for easy setup and adjustment of process parameters. The system is also capable of monitoring the wafer process step by step to provide accurate and dependable results. In addition to the features mentioned, 470 S offers adjustable cleaning parameters and variable module pressure, allowing for improved wafer handling and better control over photoresist quality. The unit is designed to use precision dispensing tools that increase precision during the photoresist layering process. These features, combined with its advanced software-based recipe control machine, enable SEMITOOL 470S to provide an excellent photoresist process for a variety of semiconductor applications.

There are no reviews yet