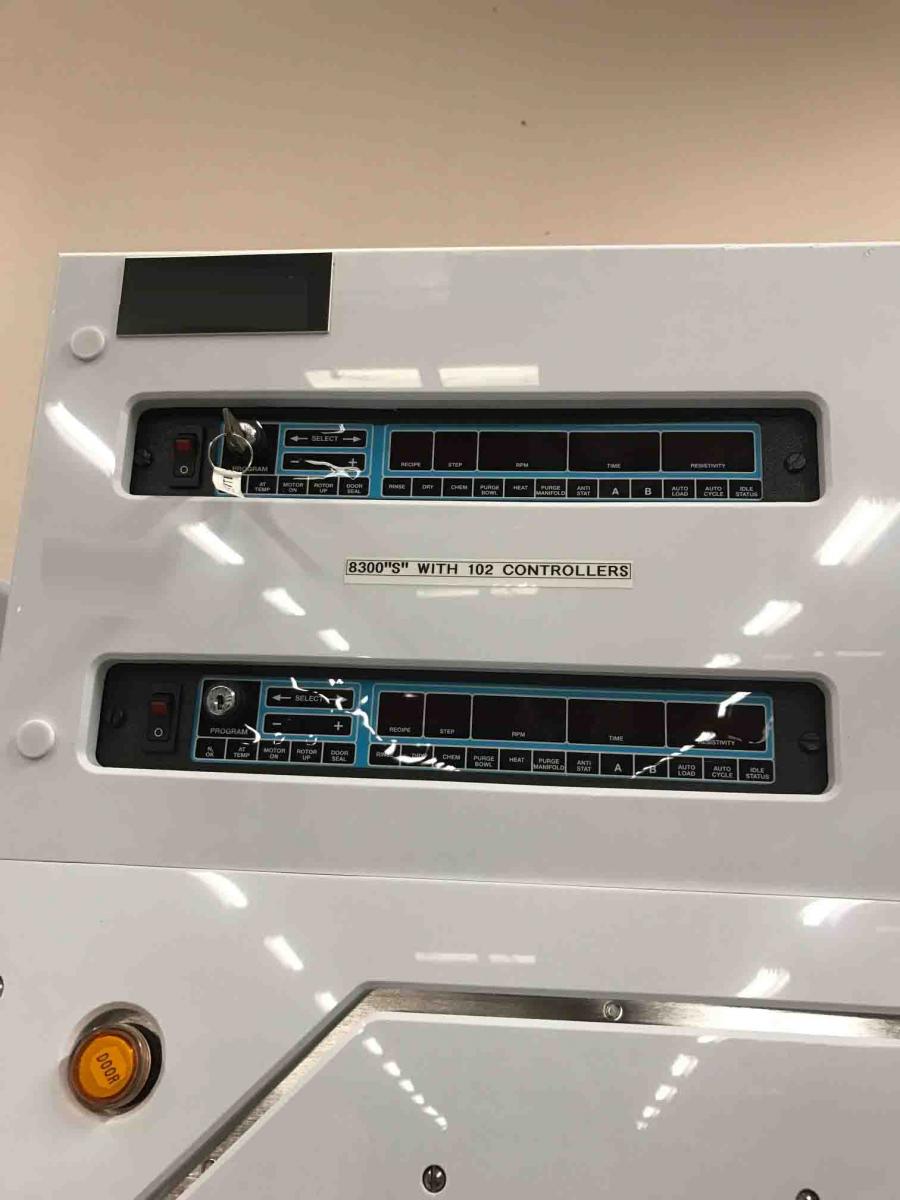

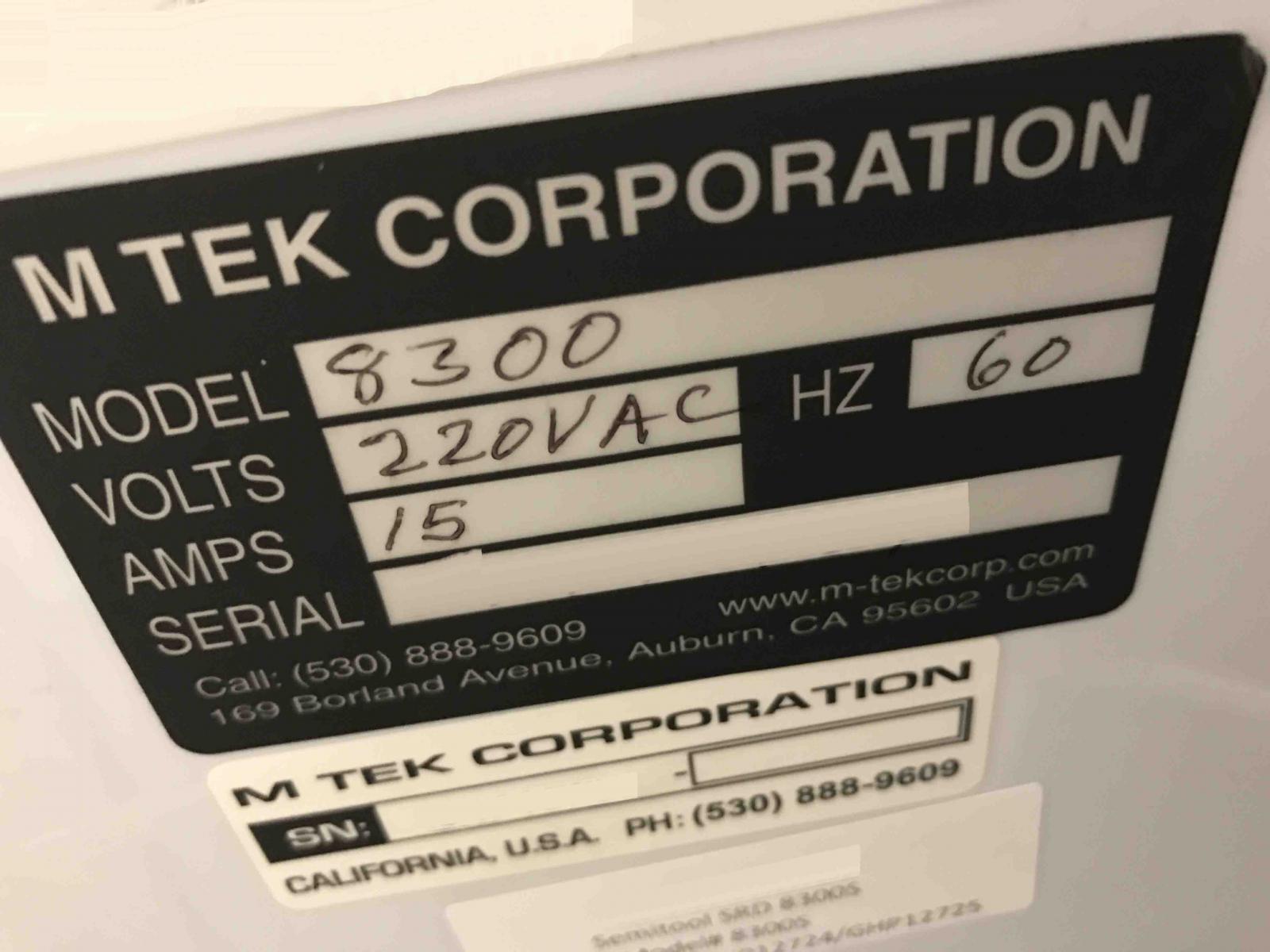

Used SEMITOOL 8300S #9155202 for sale

URL successfully copied!

Tap to zoom

SEMITOOL 8300S Photoresist equipment is a precision machine designed for automated lithography processes used in semiconductor manufacturing. Designed with a modular approach, the system can be easily configured to meet the individual needs of a variety of chip production applications. SEMITOOL 8300 S unit is driven by a Windows-based control machine to ensure programming flexibility, process control and uniformity, and remote access capability. It includes an advanced exposure source and zoom optics, enabling manipulation of the surface of a wafer to enable the printing of fine features of high resolution. The tool is equipped with a software suite, complete with a cross-platform graphical user interface, which allows for the development and optimization of photoresist processes with minimum programming time. This tool set is designed for process optimization and its ability to recognize desired feature sizes is invaluable when dealing with modern integrated circuit designs. The user-friendly interface makes it an ideal asset for automated patterning. In terms of safety and productivity, the model ensures tight safety protocols. It is backed up with a number of safety features such as a wafer presence sensor and is designed to protect against exposure to high light intensities. Furthermore, it features a dual material bulk loading equipment with deposit detection and an integrated isolation visor which keep personnel away from hazardous process conditions. The system is designed to provide an efficient lithography process with a viewing area of 25 cm x 25 cm. It features a field switcher that allows for automatic switching of field sizes and a choice of magnification capacities. A large number of optional features are available with 8300-S, such as vacuum wafer clamping, automatic edge alignment, and cooling jacket. These can be combined to further enhance the performance of the unit. SEMITOOL 8300-S is the ideal machine for a wide range of chip production applications and represents the industry standard for photolithography. It provides flexibility, accuracy and optimized process control for the efficient production of complex chips and boards. Its user friendly interface and advanced process capabilities make it a key component in achieving repeatable and reliable results in high-end chip production processes.

There are no reviews yet