Used SEMITOOL 870F #9268564 for sale

URL successfully copied!

Tap to zoom

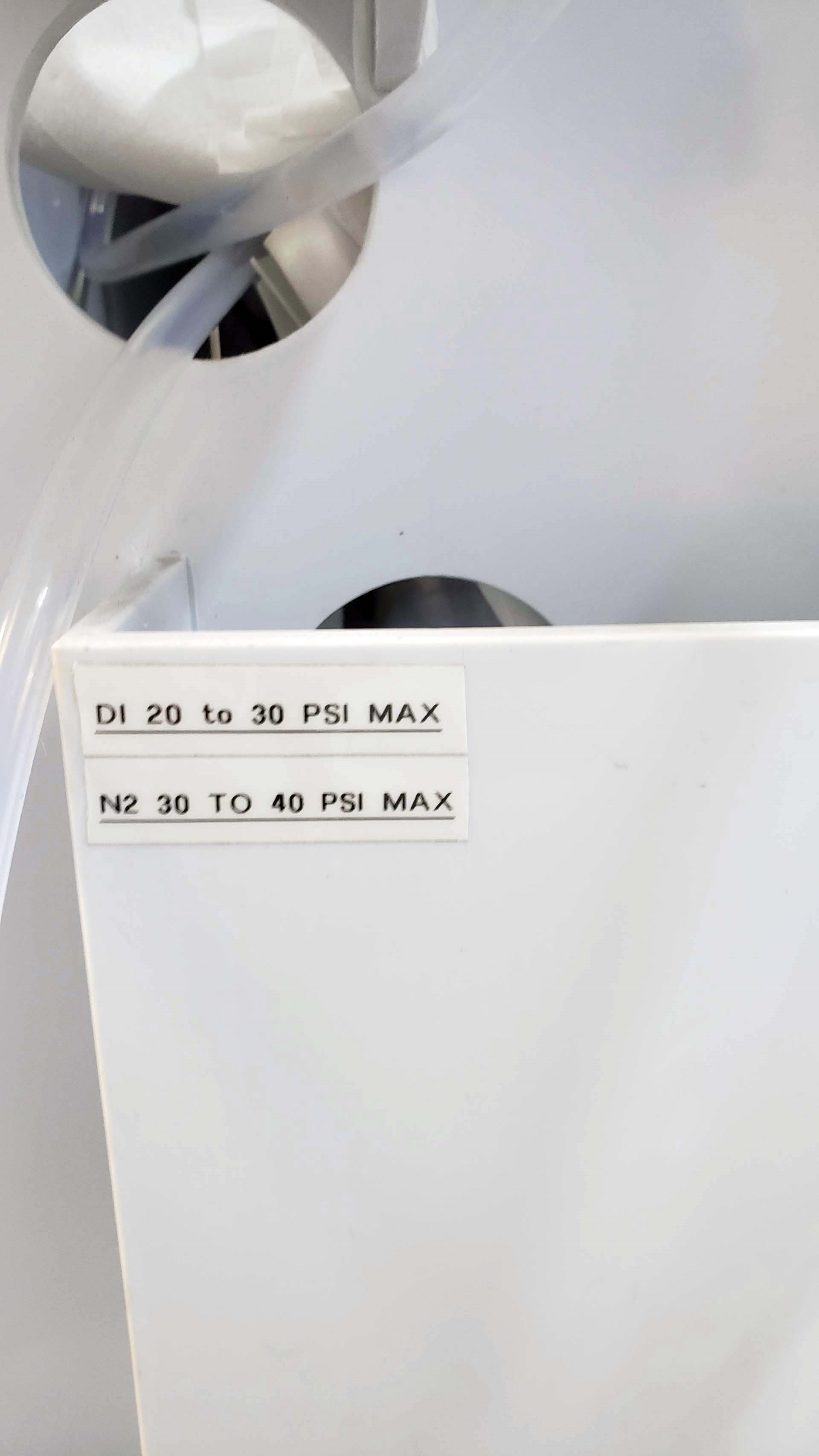

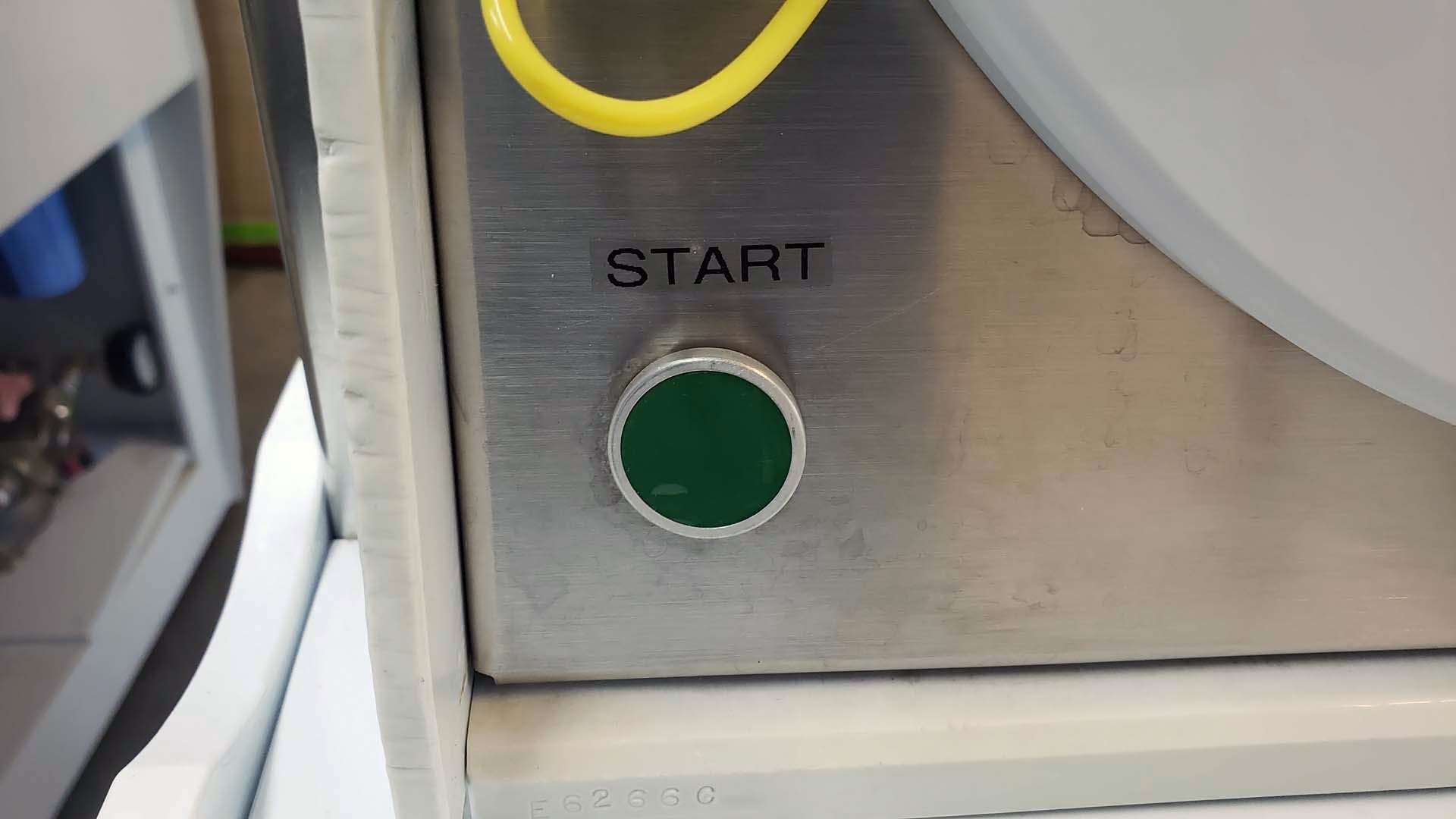

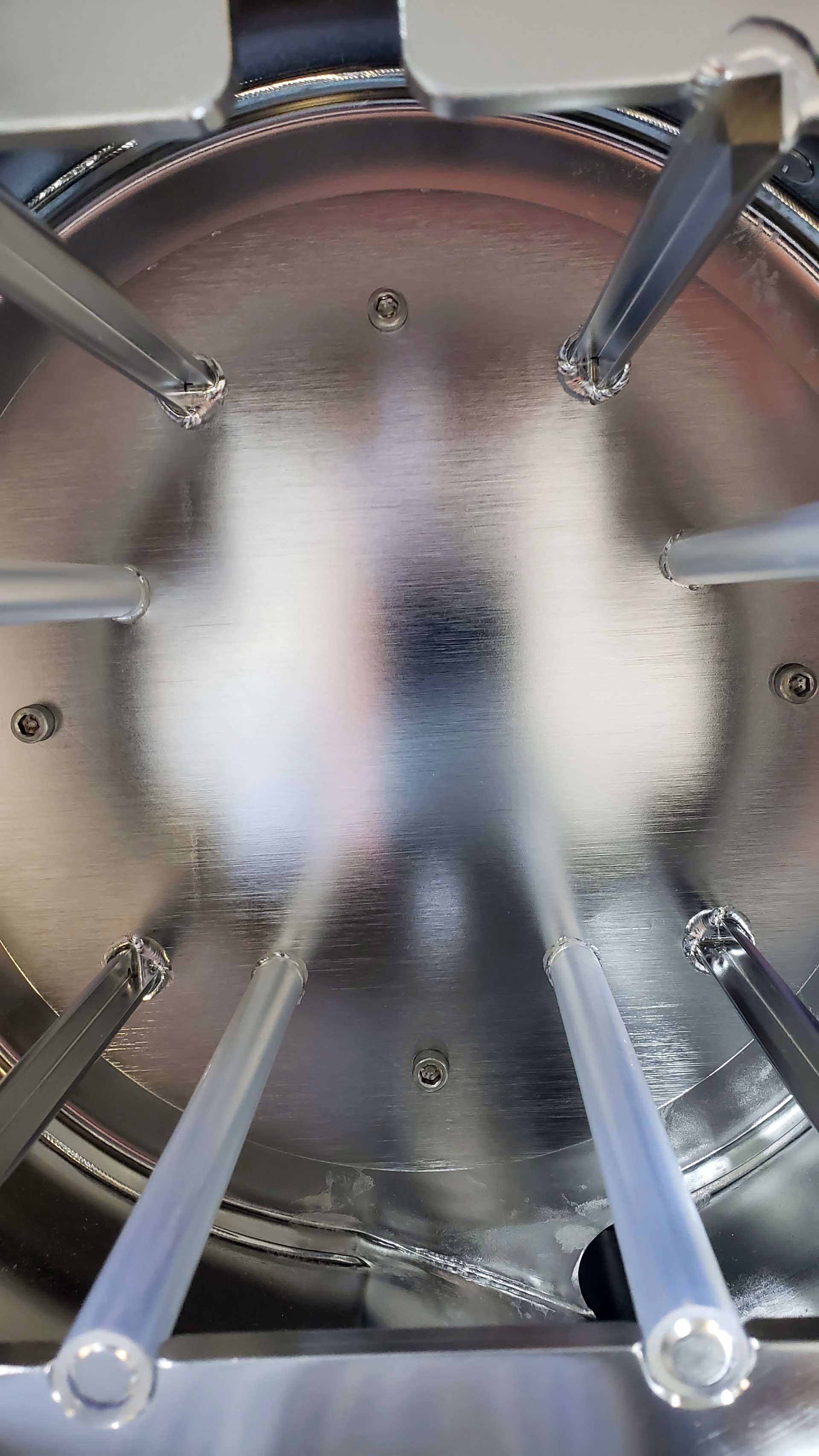

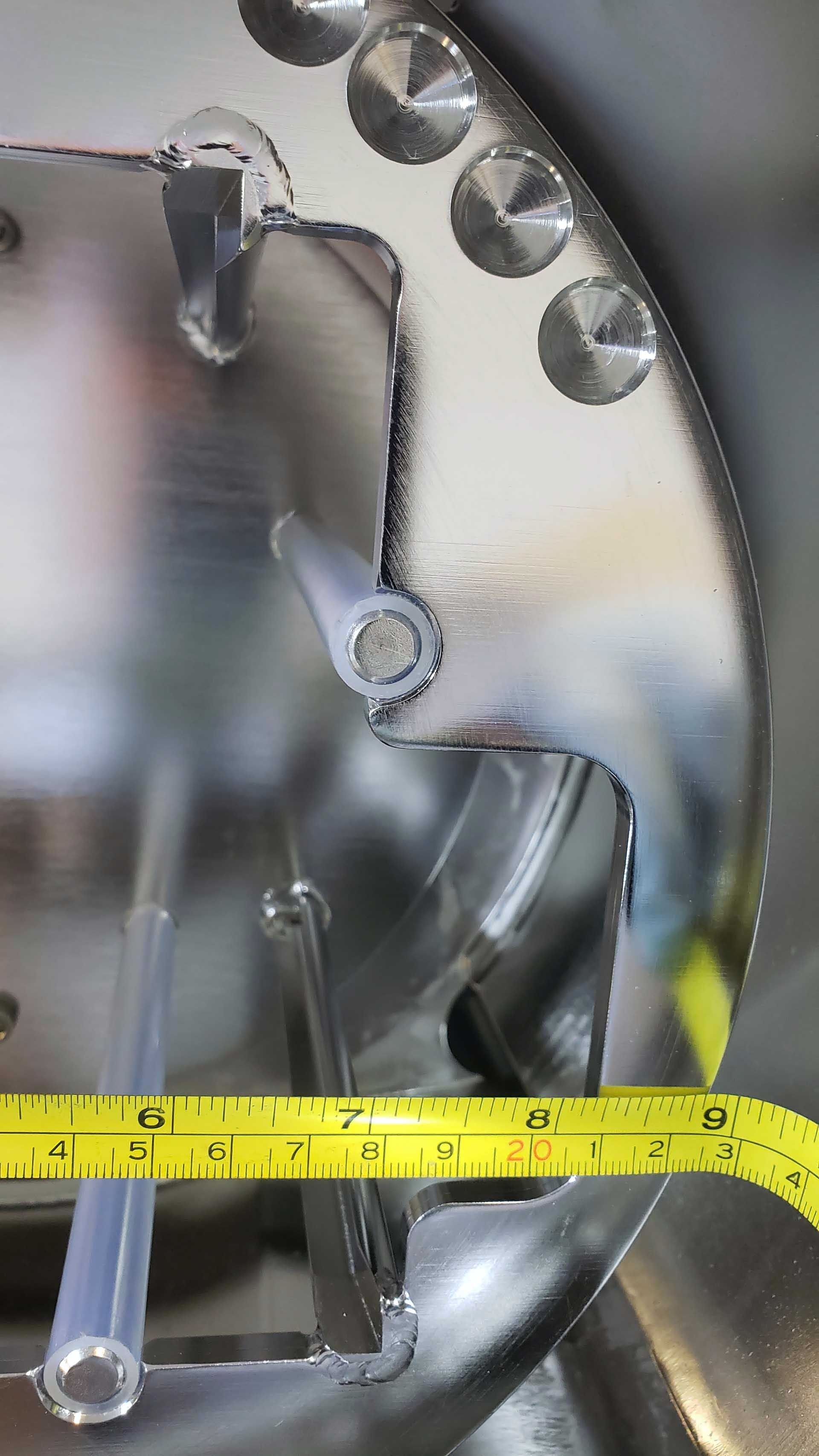

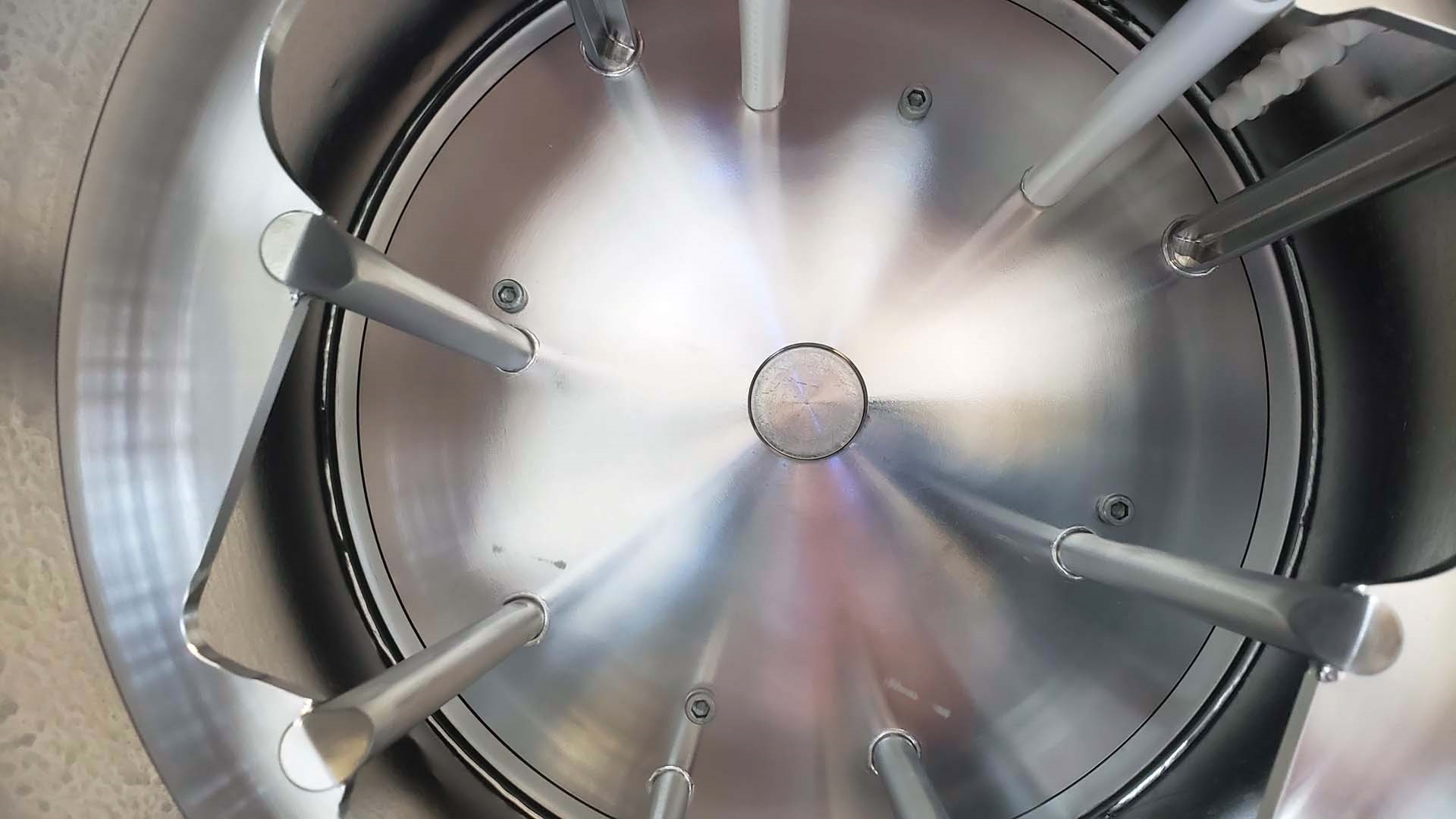

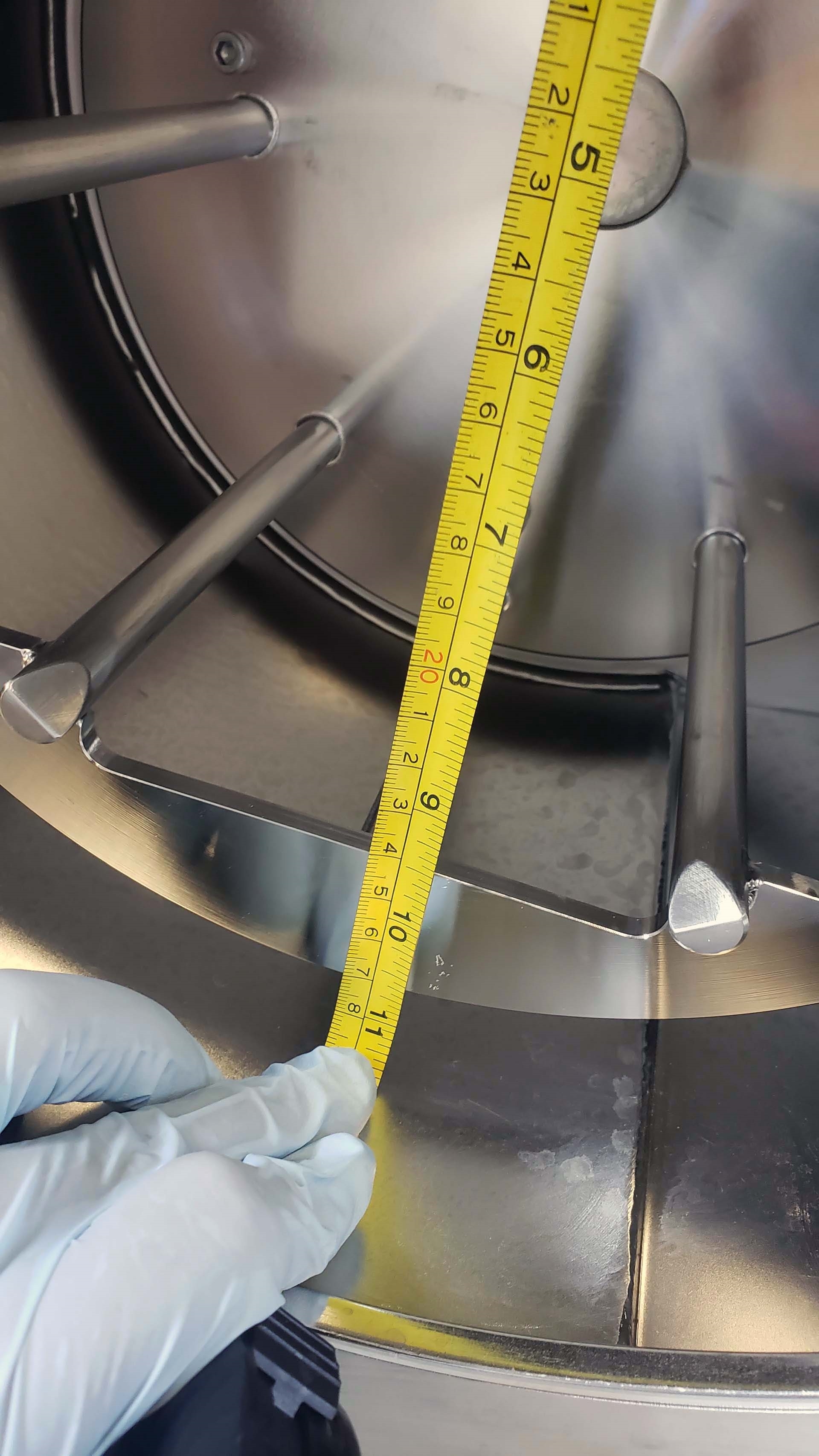

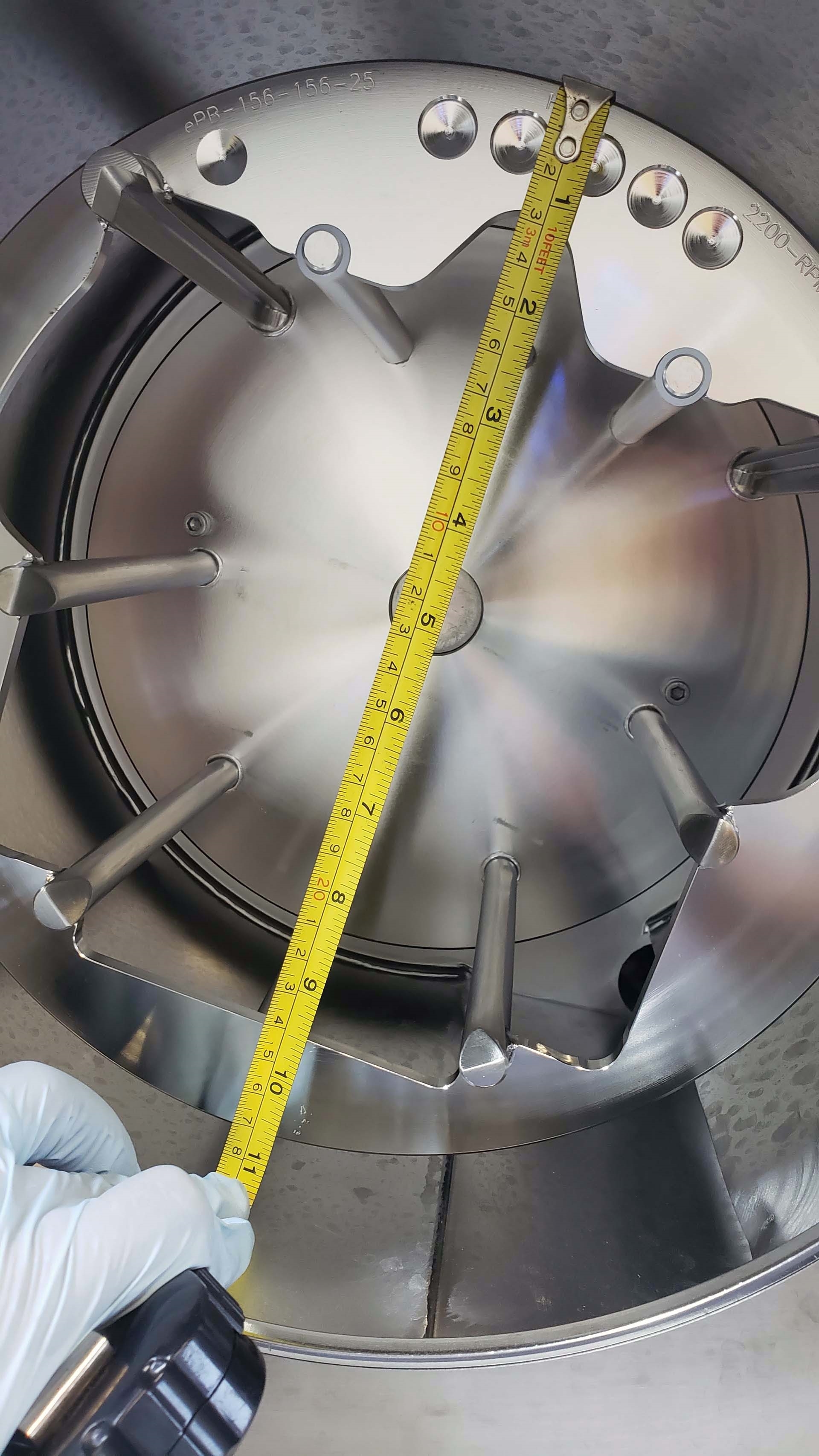

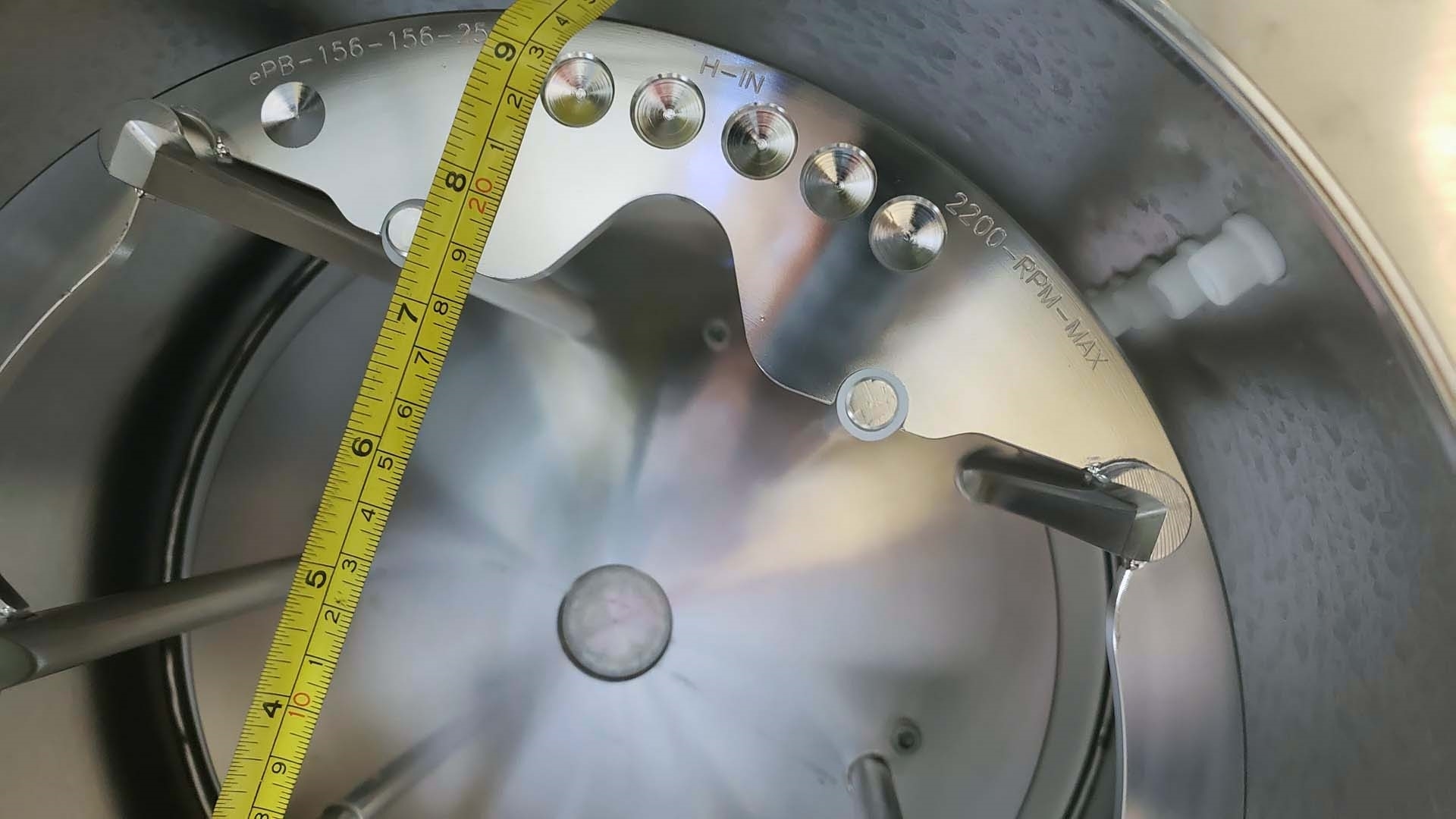

SEMITOOL 870F is a photoresist equipment that is used to pattern layers of photosensitive materials on a substrate surface. It is specifically tailored for the fabrication of semiconductor components and devices. This system can be used to create various types of patterns such as contact openings, gate electrode openings, vias, metal lines and others. 870F is equipped with a digital imaging unit to accurately and precisely render patterns on the substrates. The machine integrates a high-resolution digital camera, high-magnification optics and a zoom mechanism for extremely precise patterning. The camera can be set for a range of resolutions from 0.1 micron to 0.2 micron and x, y and z-axis movement capabilities offer unlimited accuracy. SEMITOOL 870F utilizes a scanning stage to provide precise control of the exposure area with X,Y and Z-axis movement capabilities. This allows precise control over the patterning process, ensuring the desired pattern is formed precisely and consistently. The SCS-211C exposure tool integrates a vacuum/pressure based slide chuck for automatic substrate clamping and a high-precision modular differential drive asset with a maximum accuracy of 5nm for precise substrate movement. 870F also features modular processing chambers which offer a high degree of flexibility for various coating and processing needs. For example, it features an in-situ spin-coating/resist coating chamber which is used to apply patterned materials onto the substrate. The chamber features an integrated resist spin arm, thermocouple, vacuum/pressure based substrate chuck and a pre-set radial spinner head drive model with automatic speed control. SEMITOOL 870F is an efficient photoresist equipment which provides cost-effective solutions for complex semiconductor device fabrication and patterning processes. Its modular architecture offers flexibility for various process steps and its integrated digital imaging system enables high-precision patterning of complicated structures. Furthermore, its automation features and in-situ chamber systems provide consistent process control ensuring maximum yield and output of devices.

There are no reviews yet