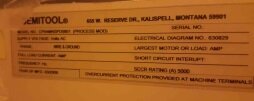

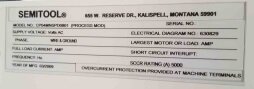

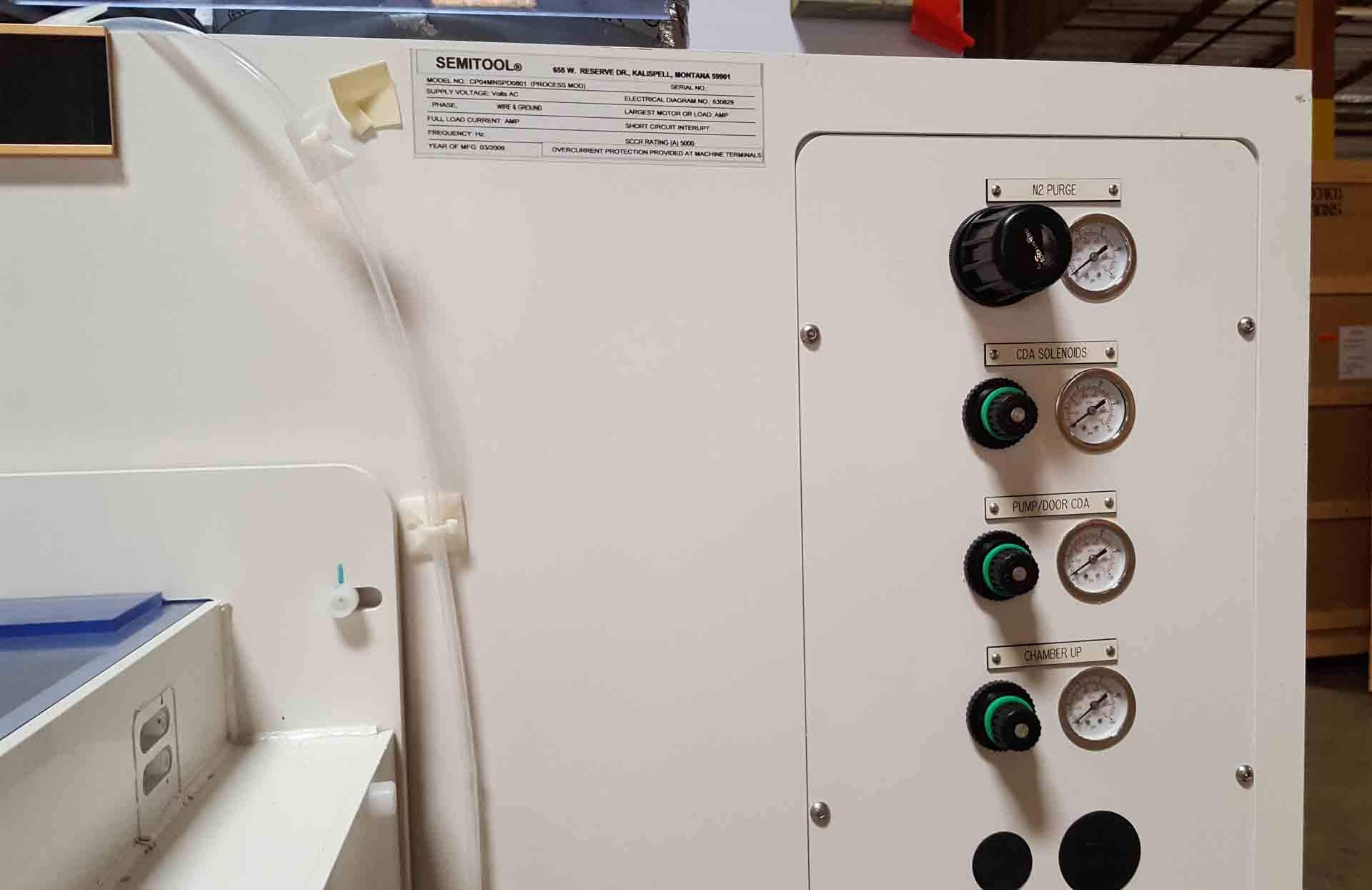

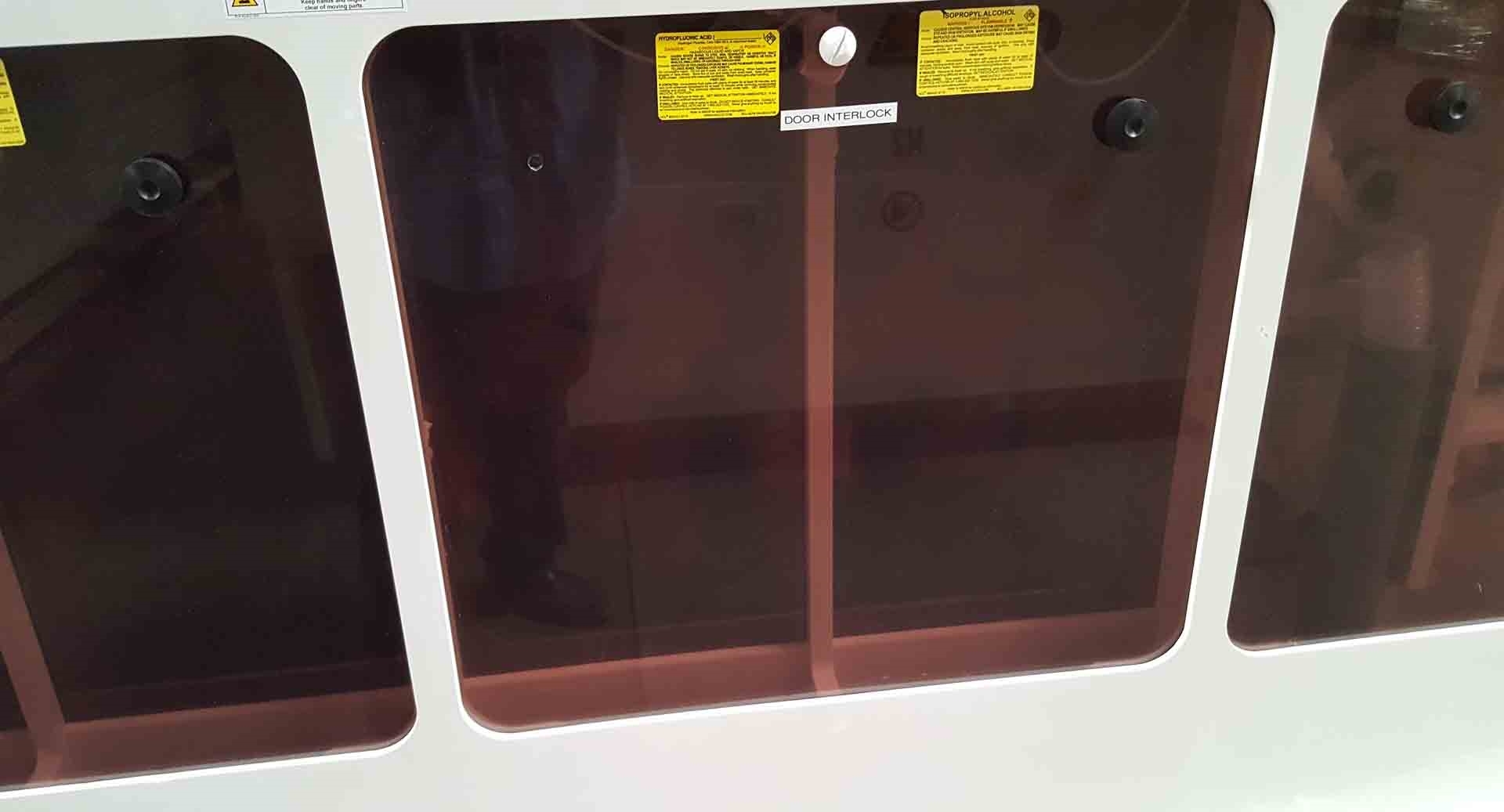

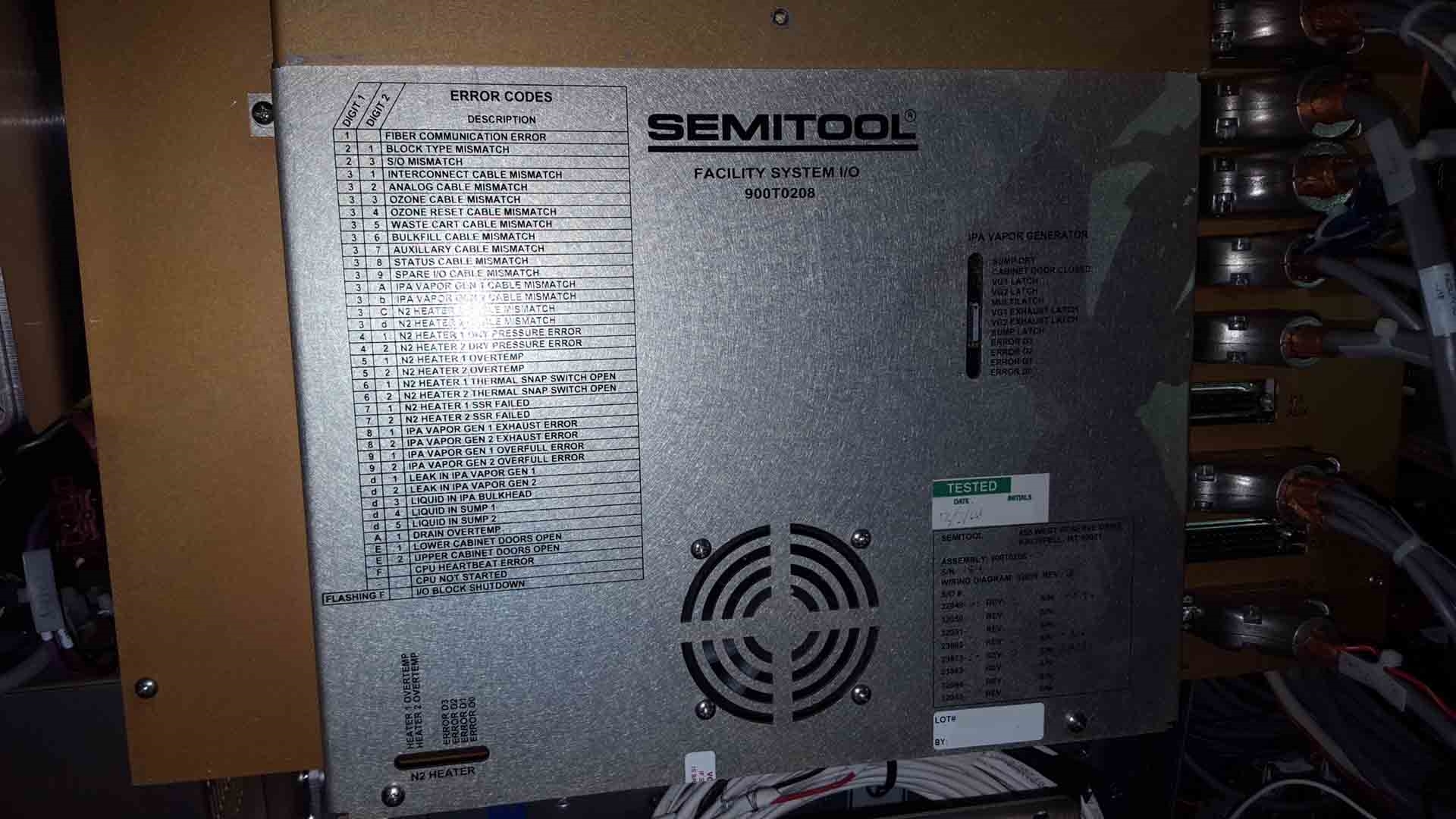

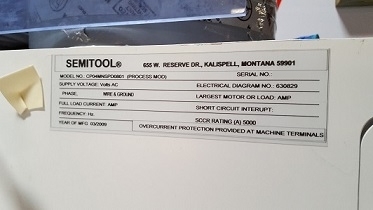

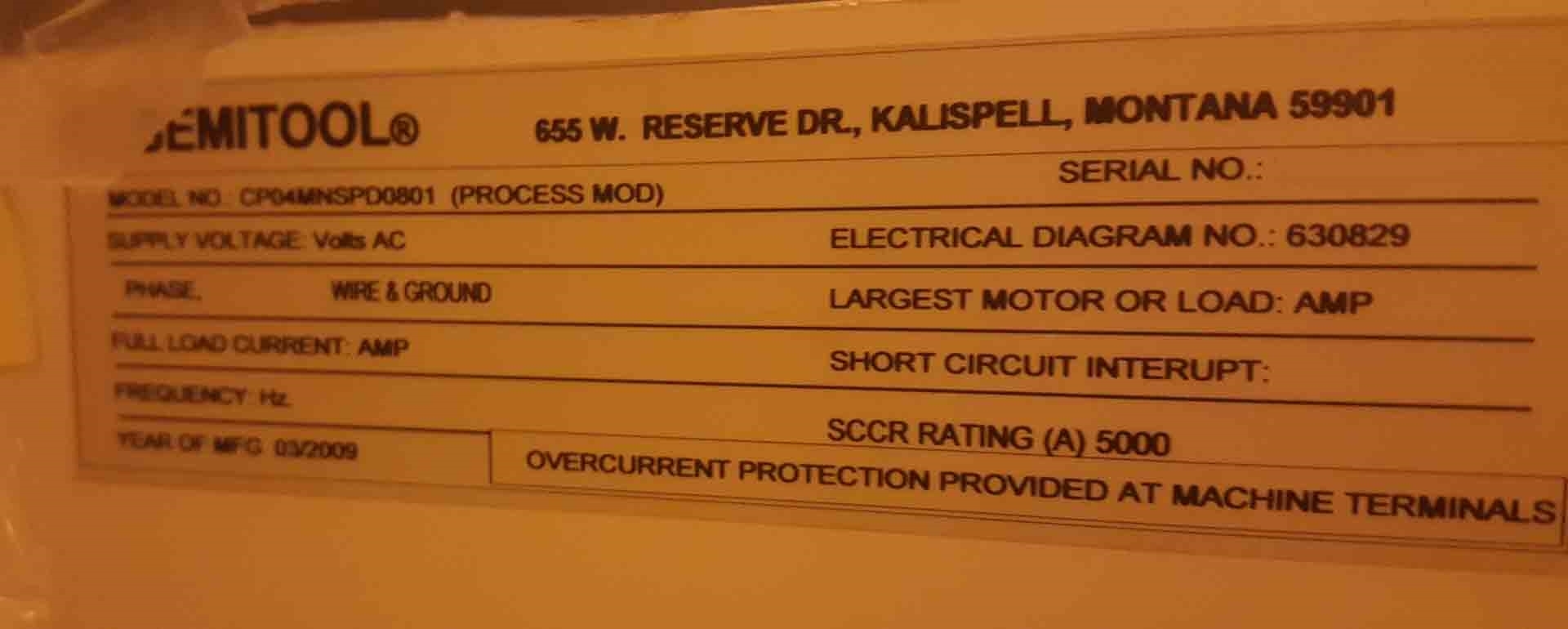

Used SEMITOOL Alpha Raider #9160953 for sale

URL successfully copied!

Tap to zoom

ID: 9160953

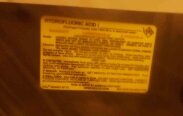

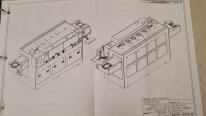

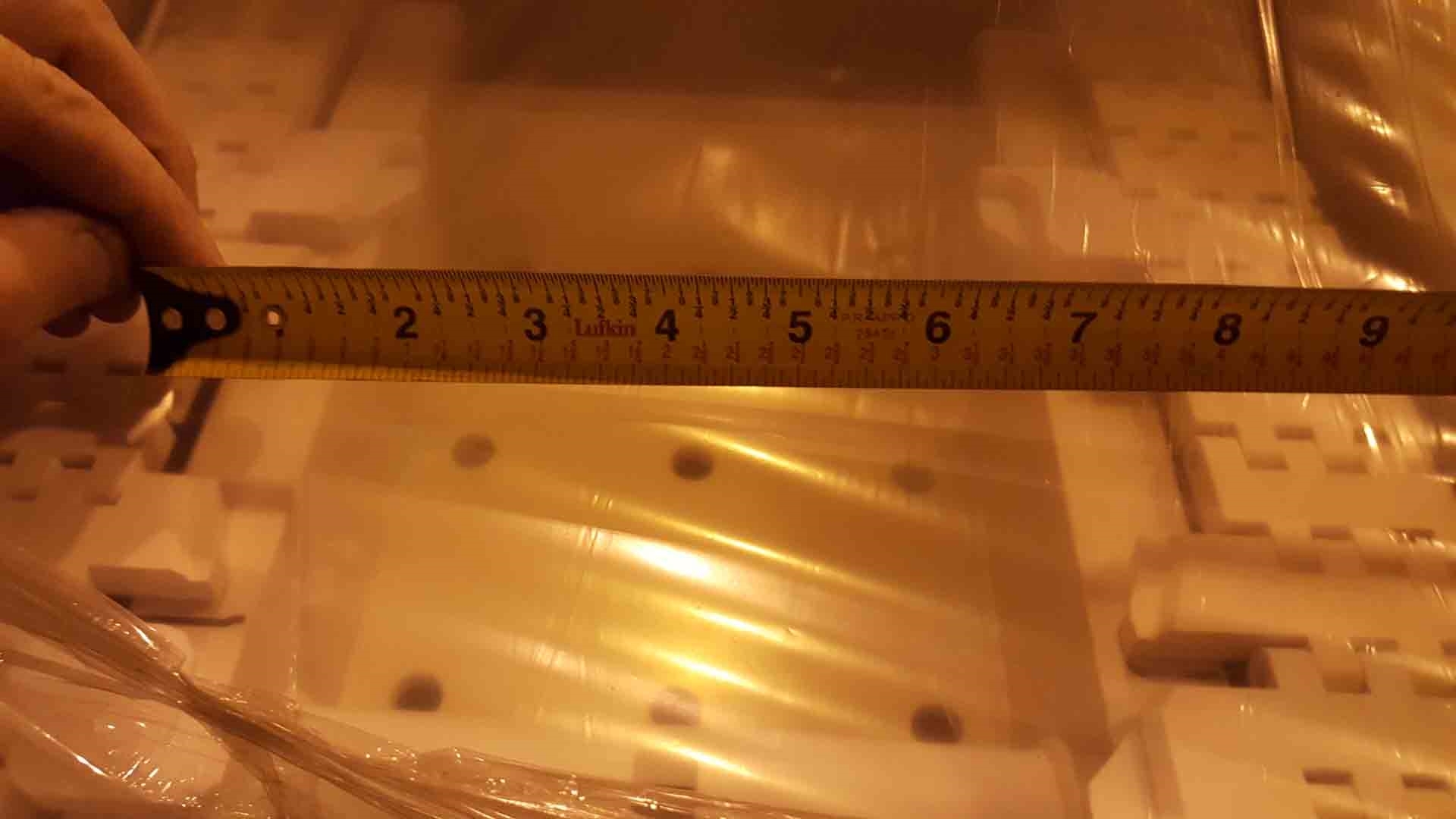

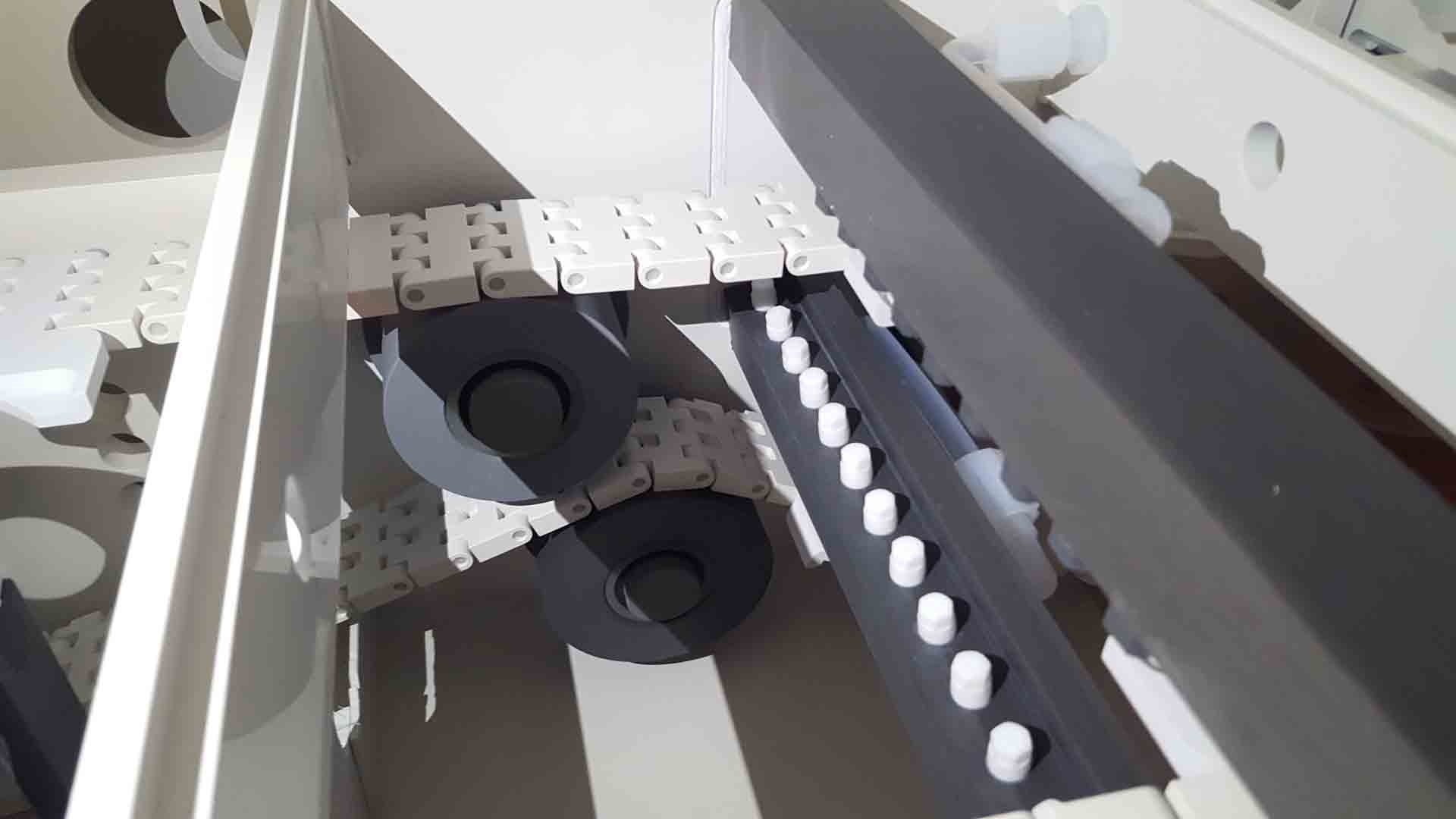

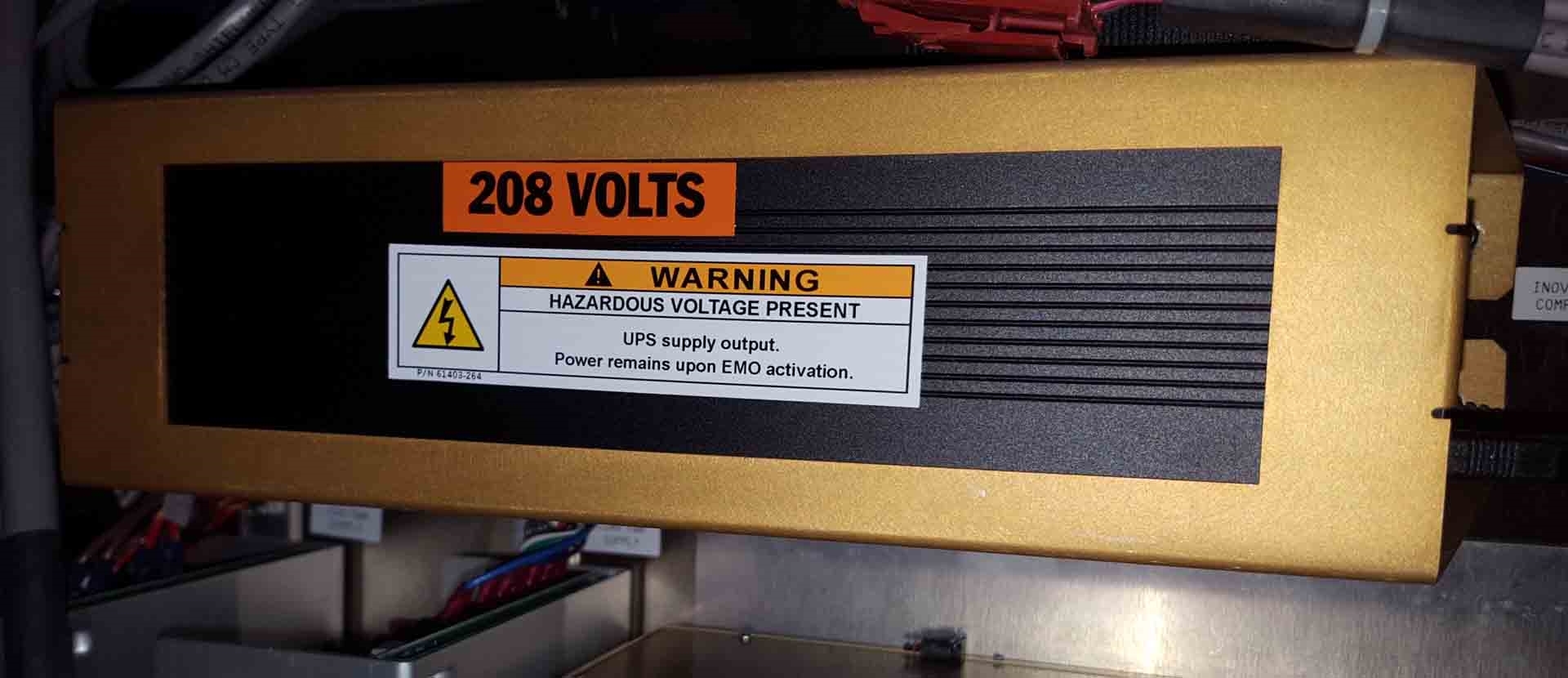

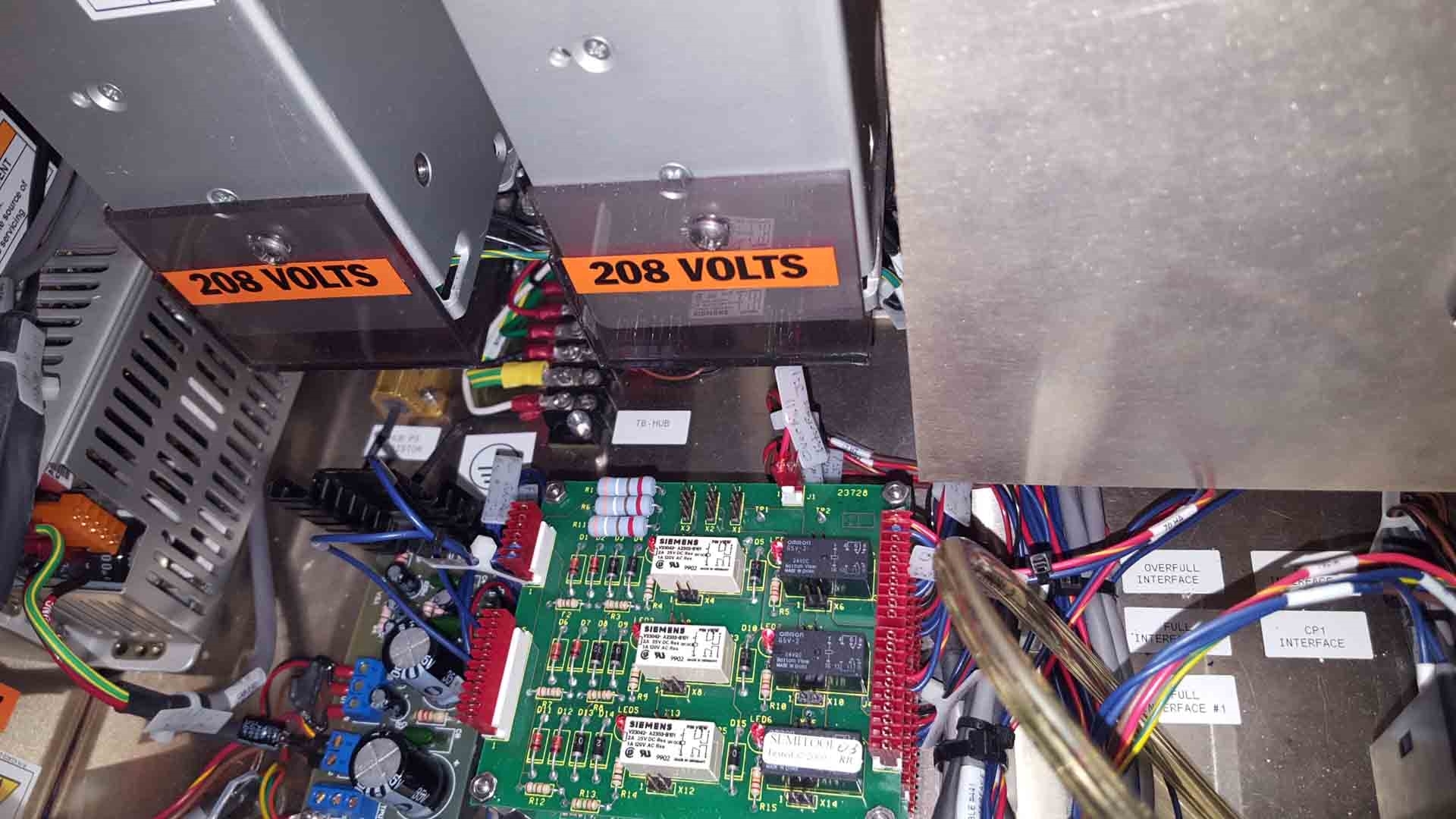

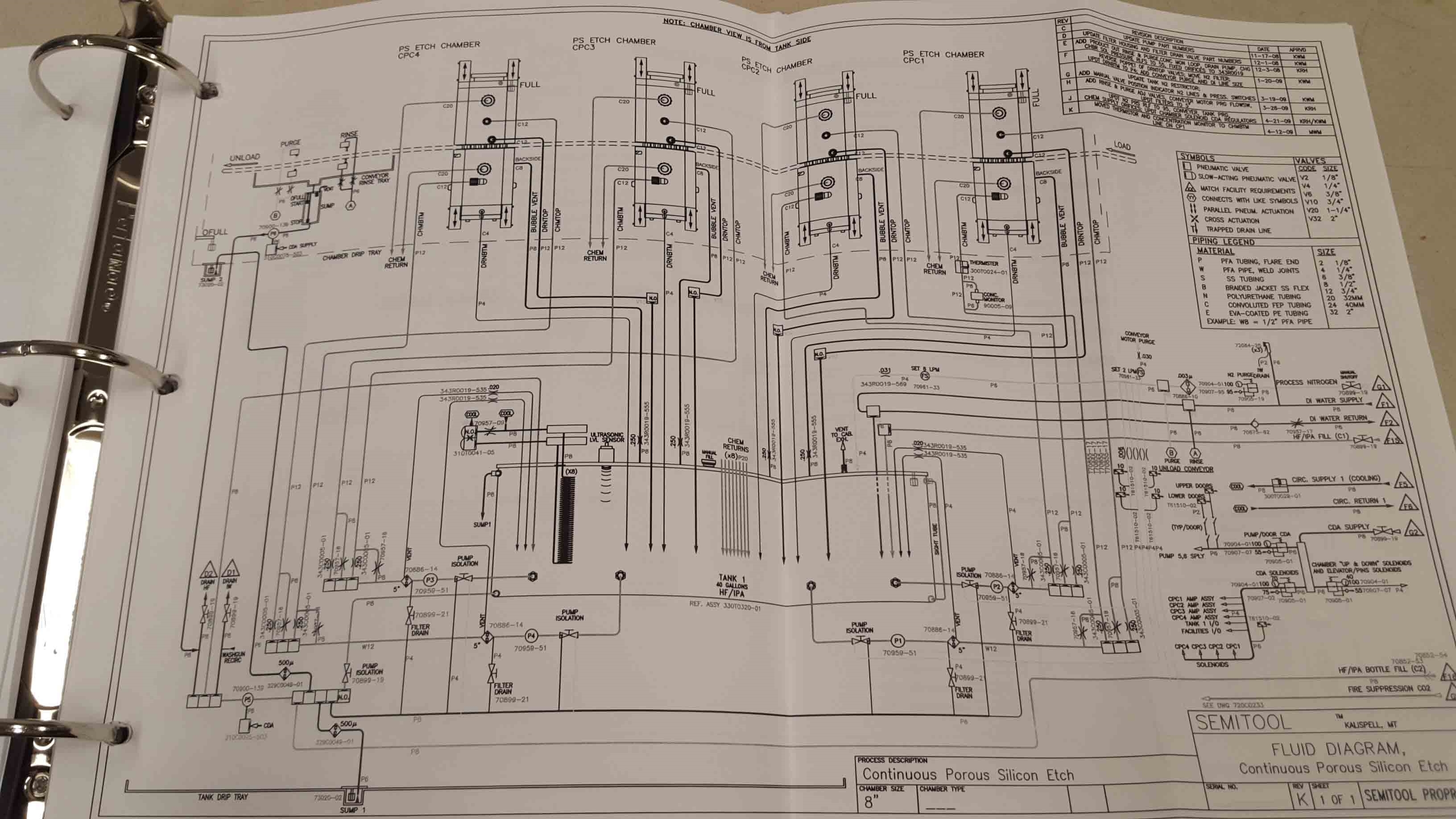

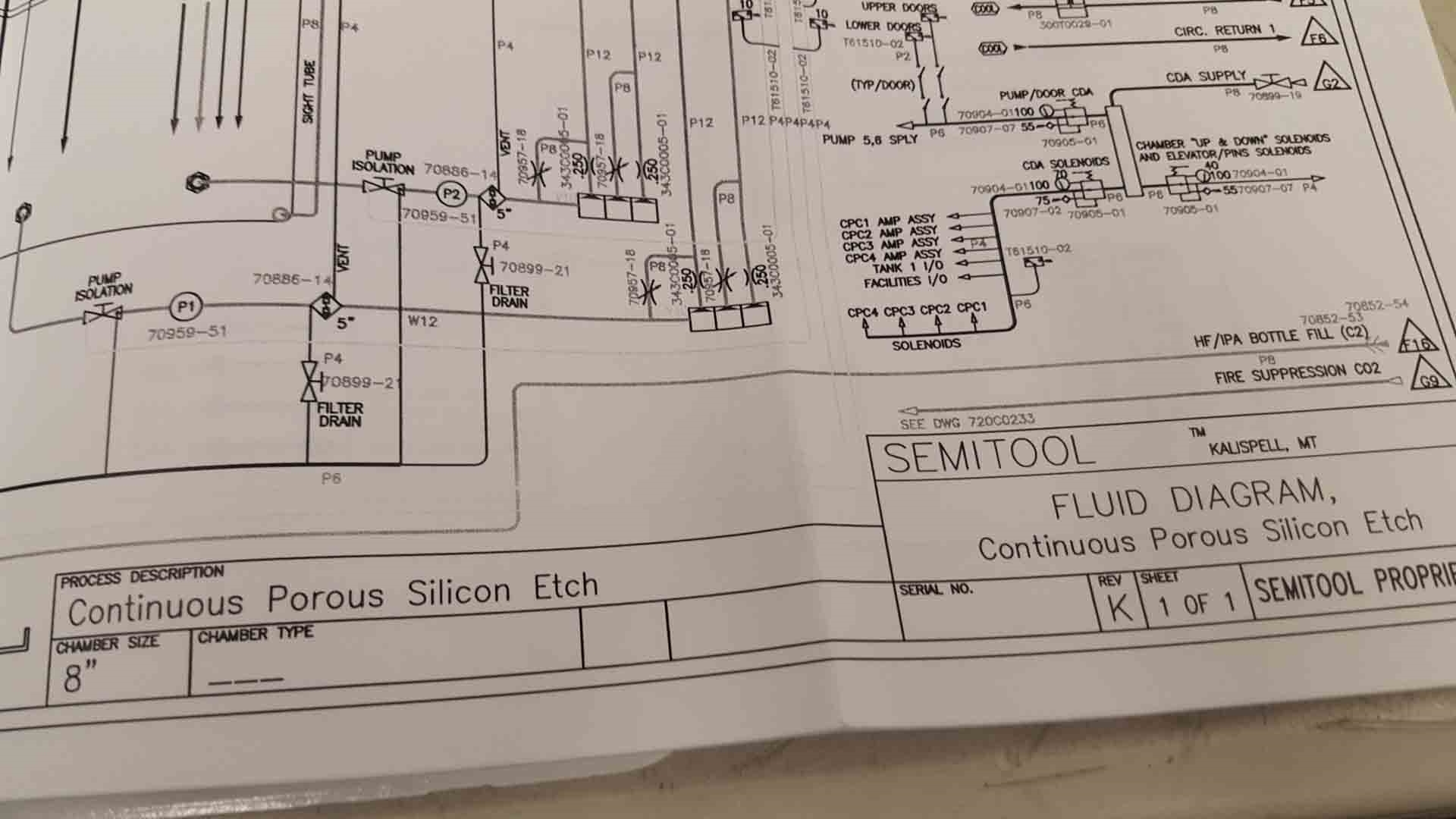

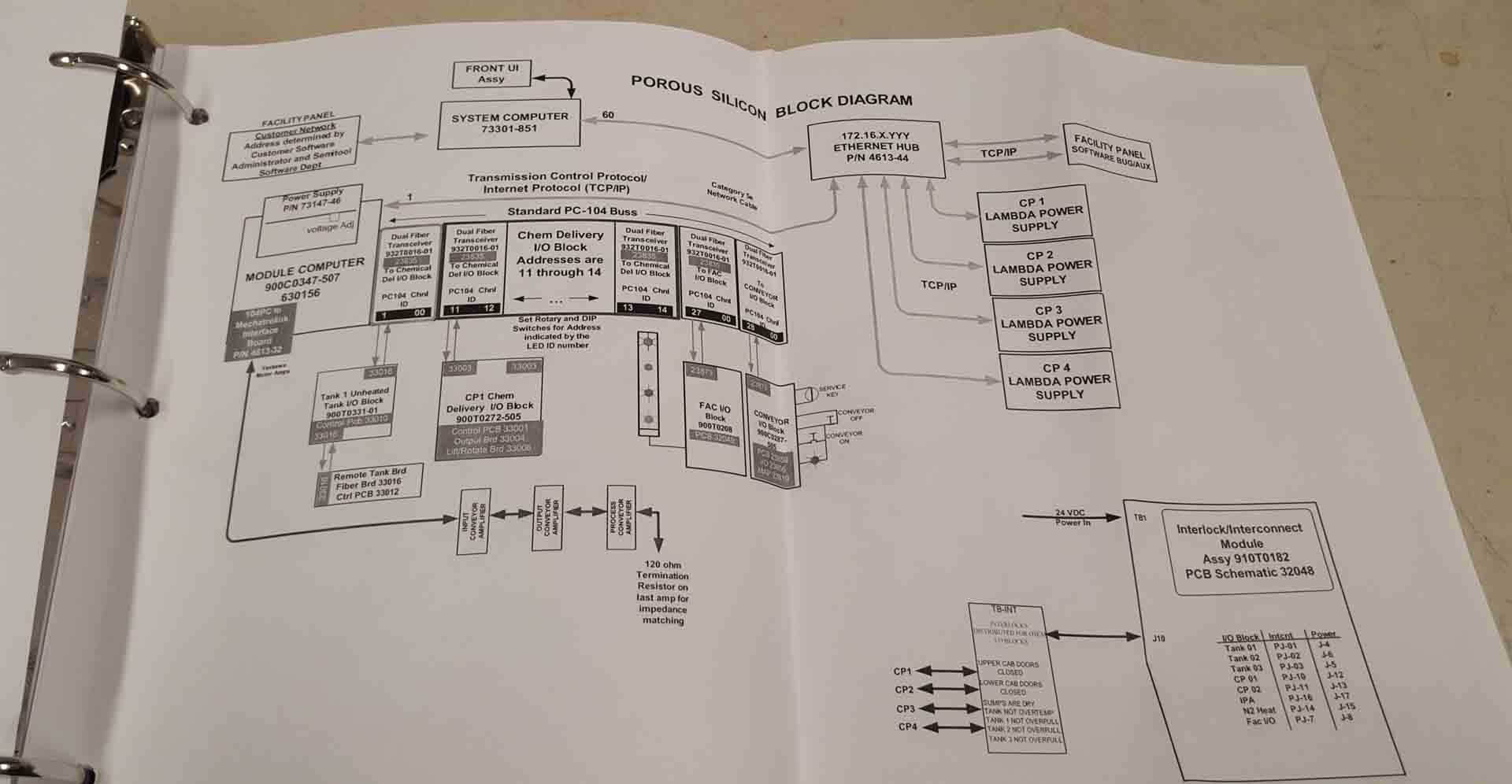

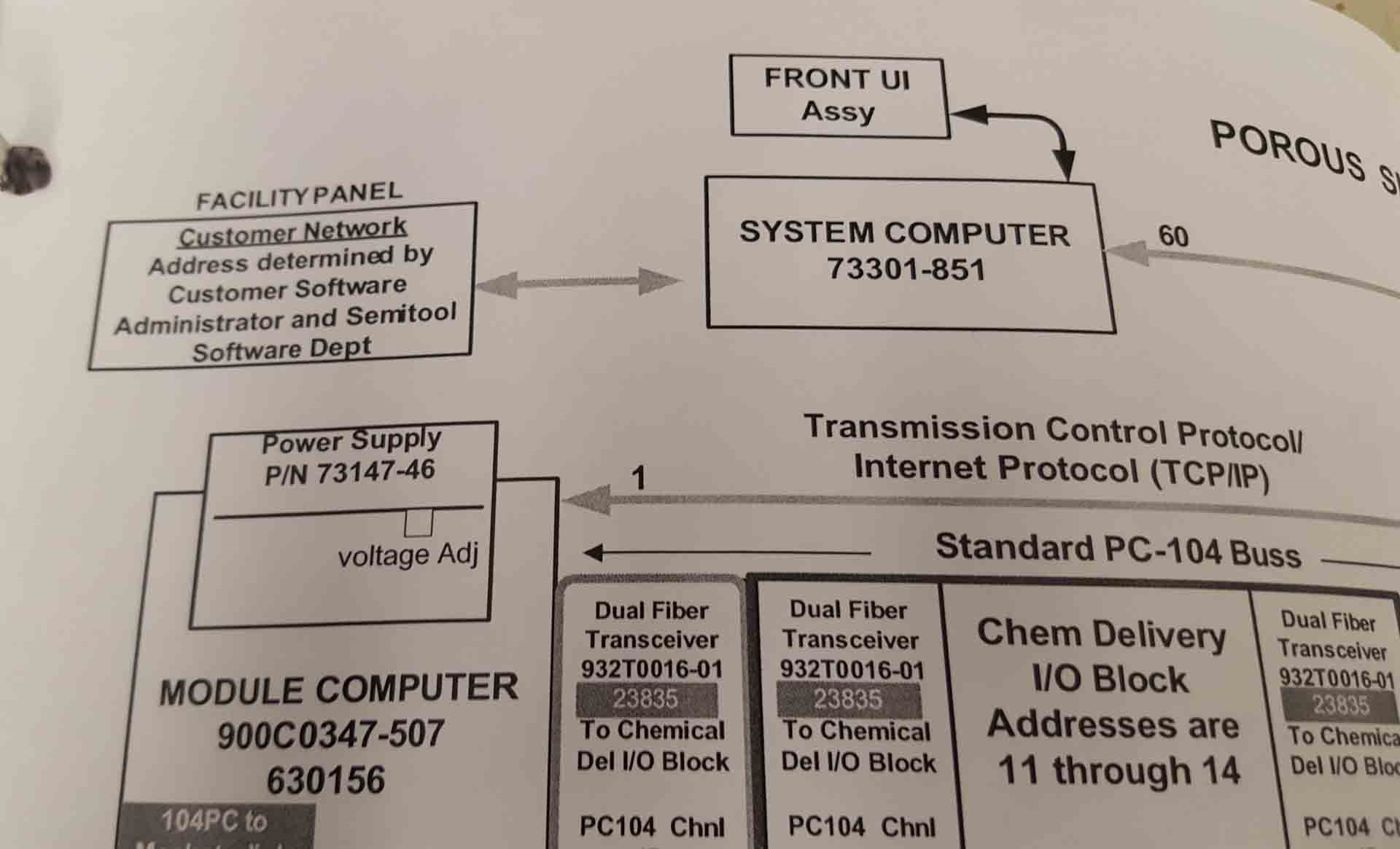

Wet processing system, 8"

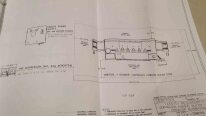

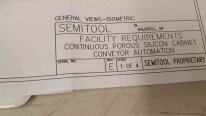

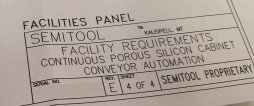

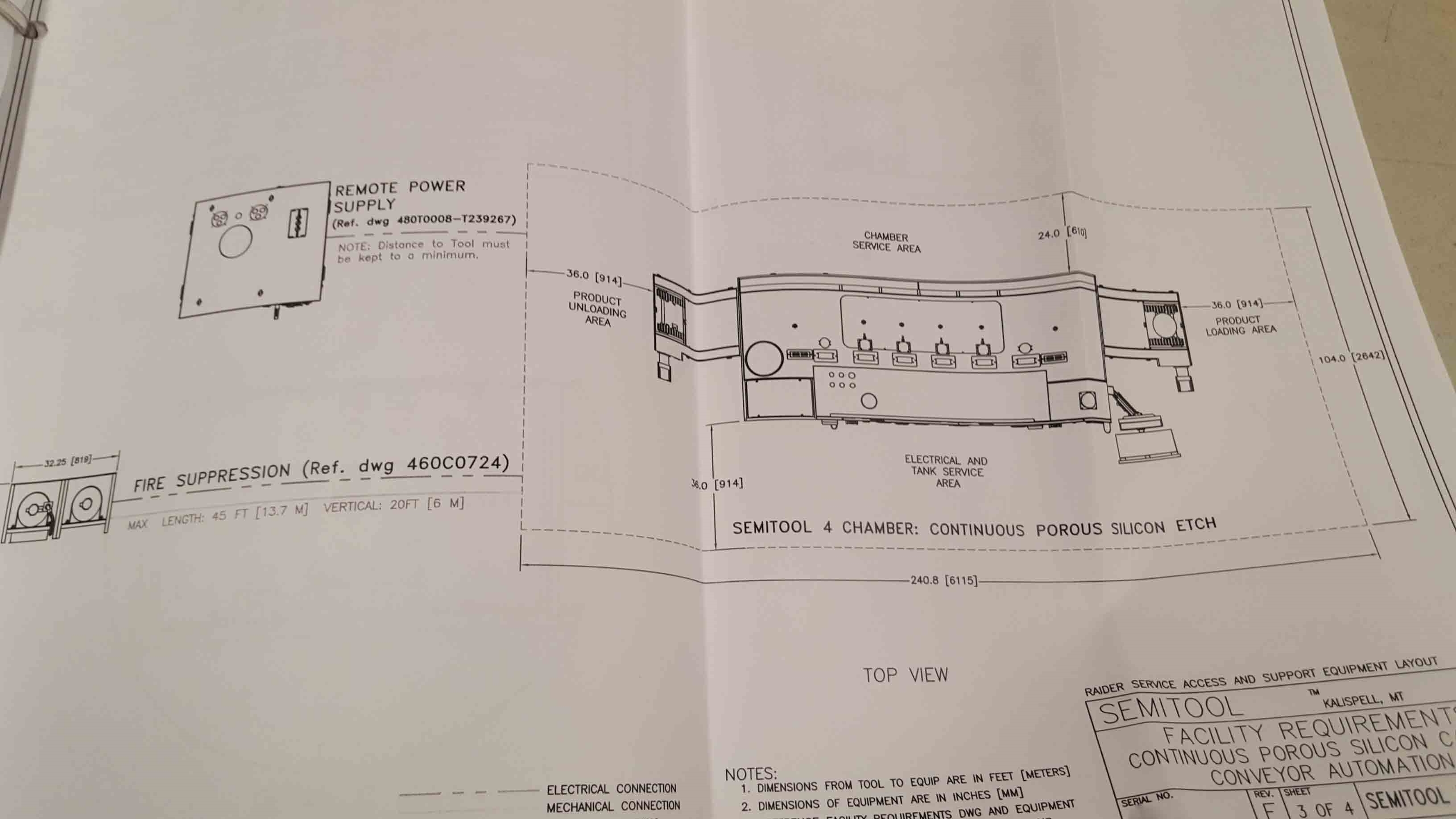

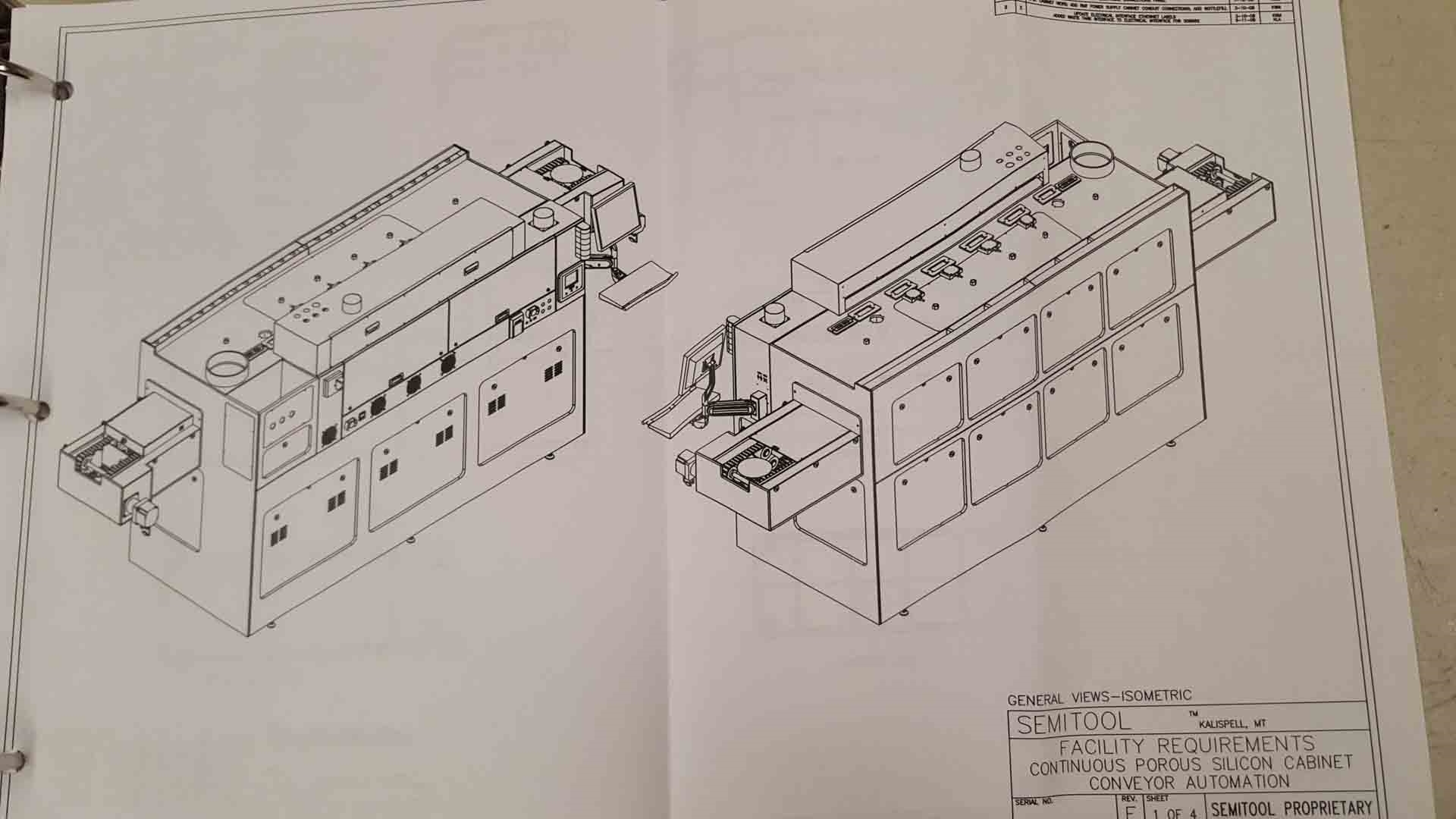

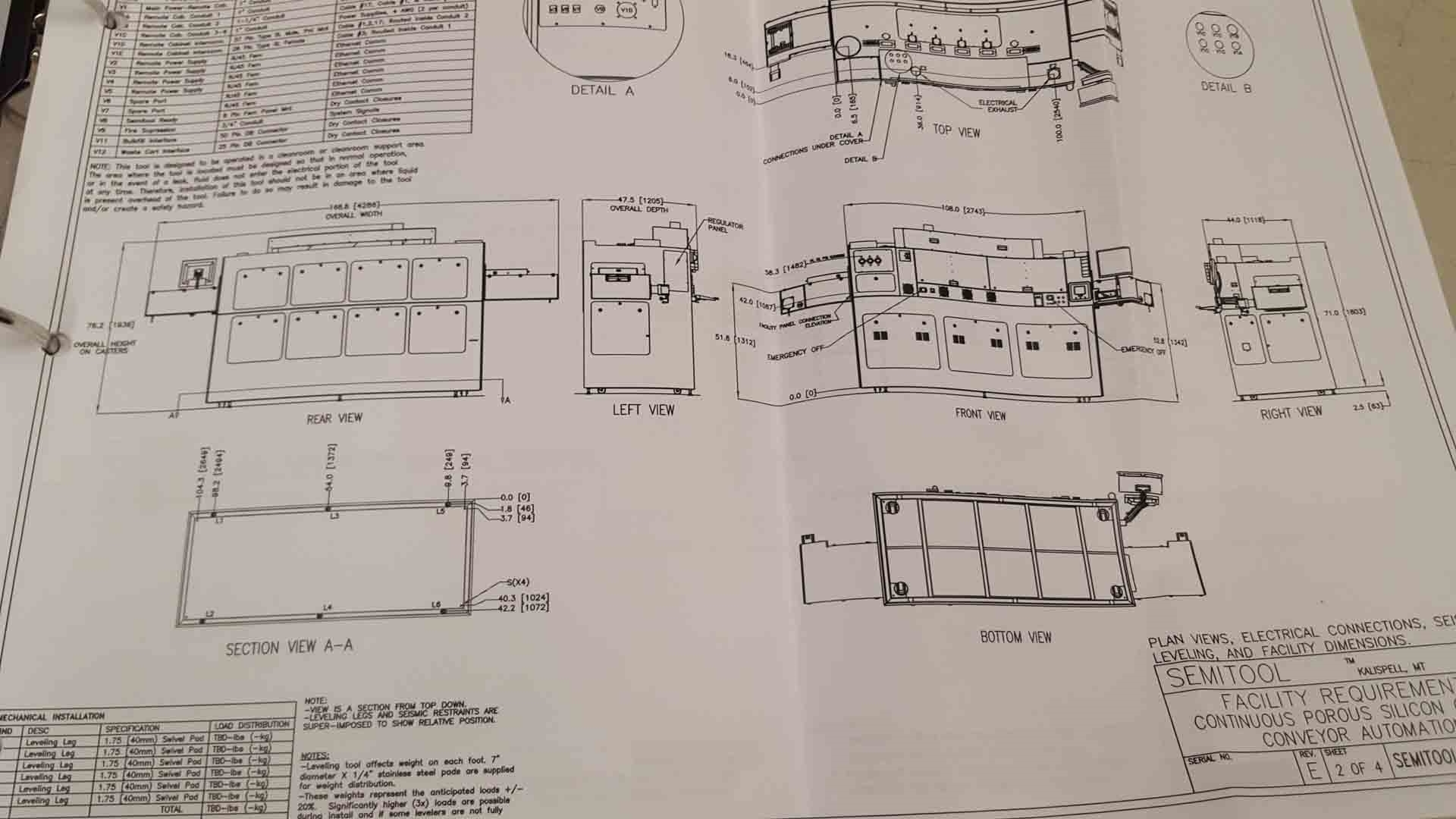

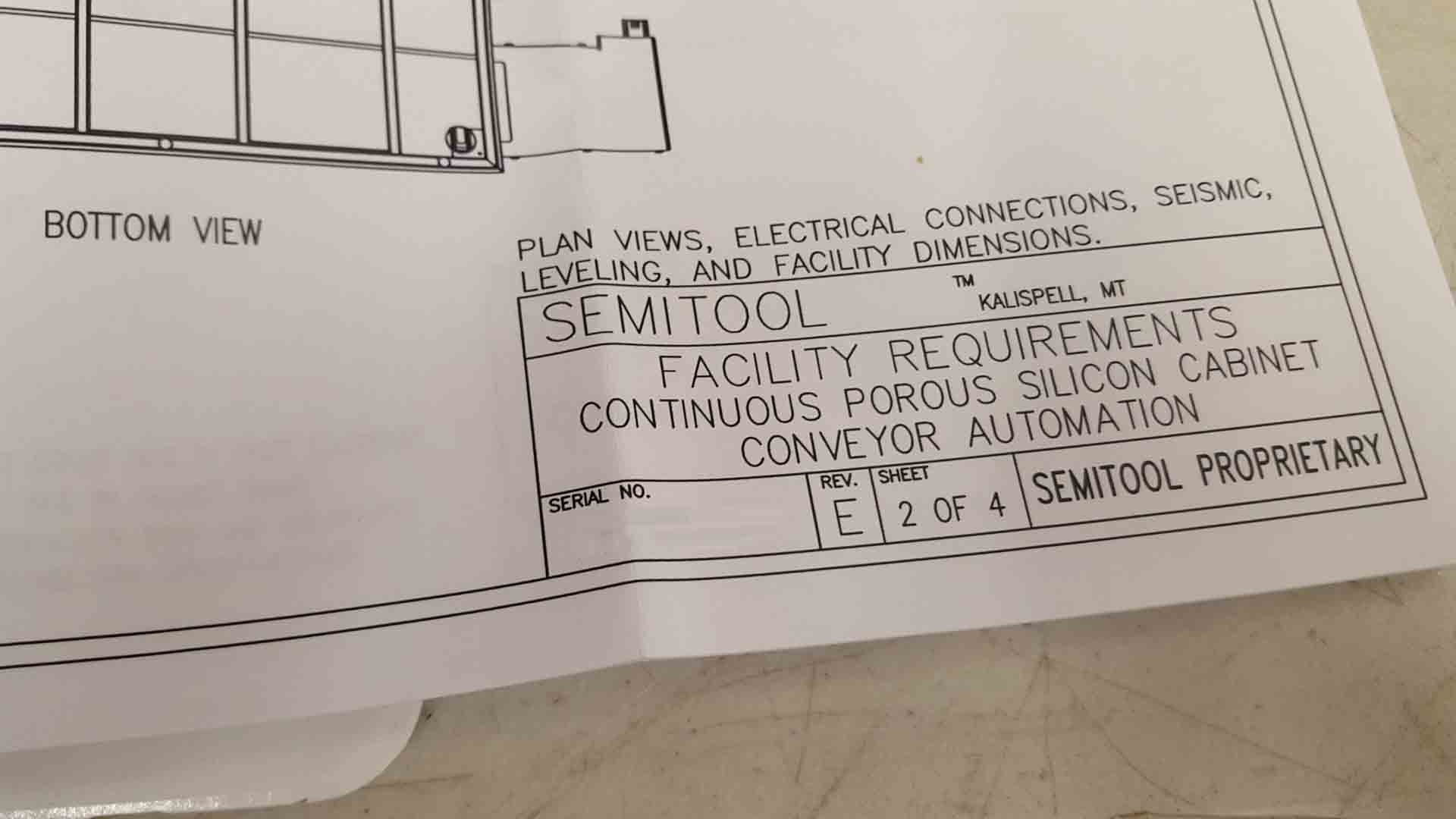

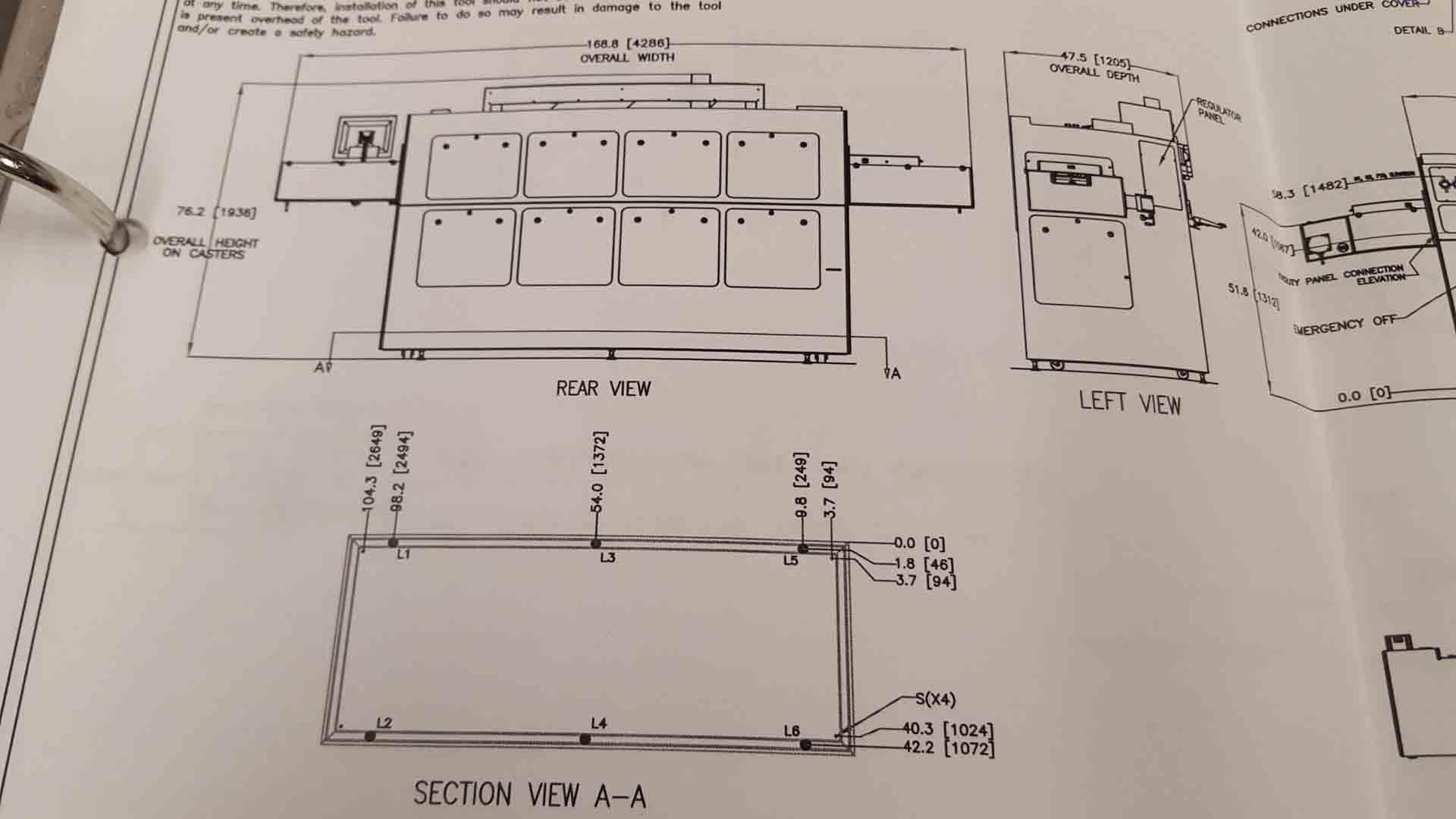

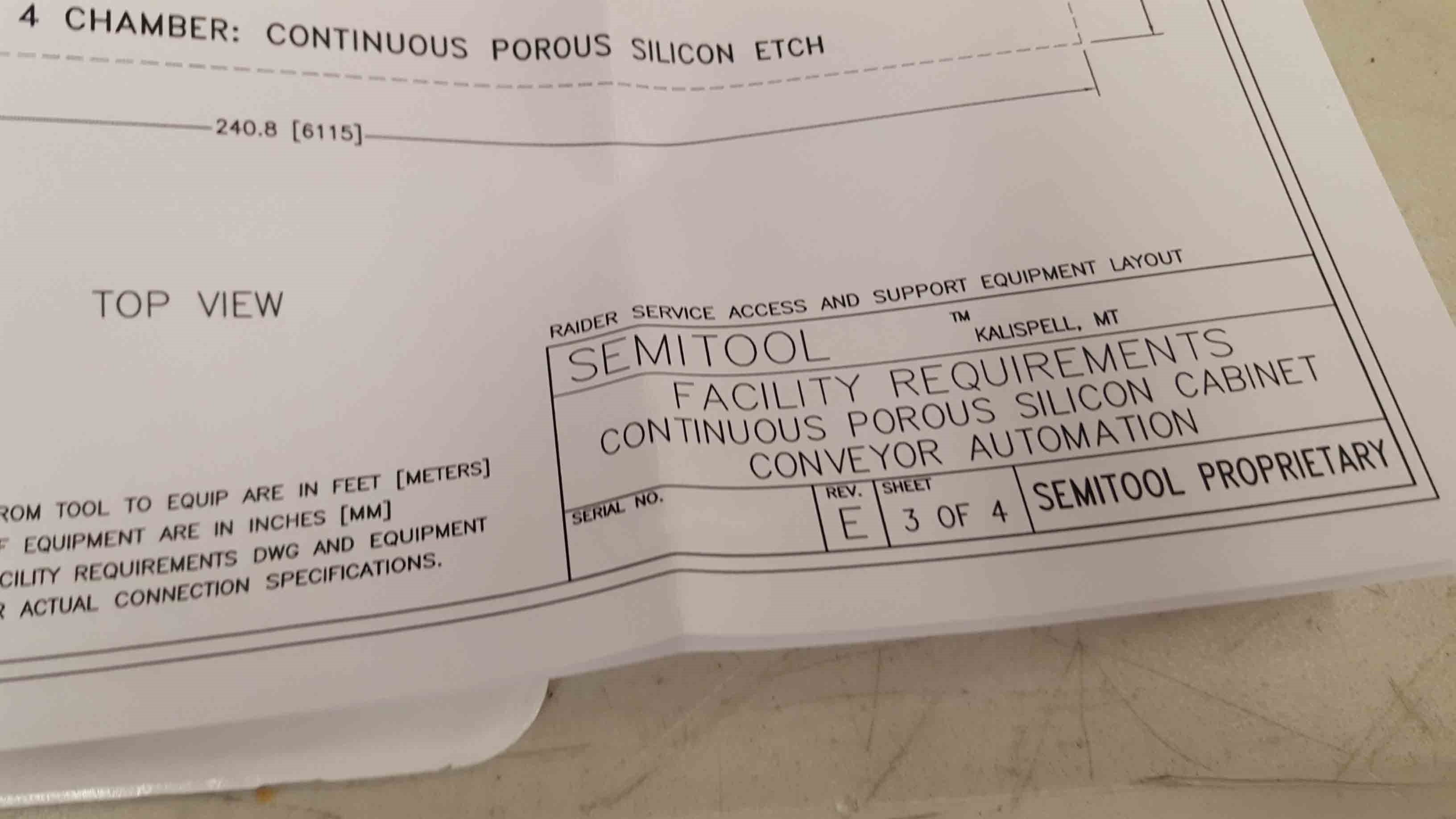

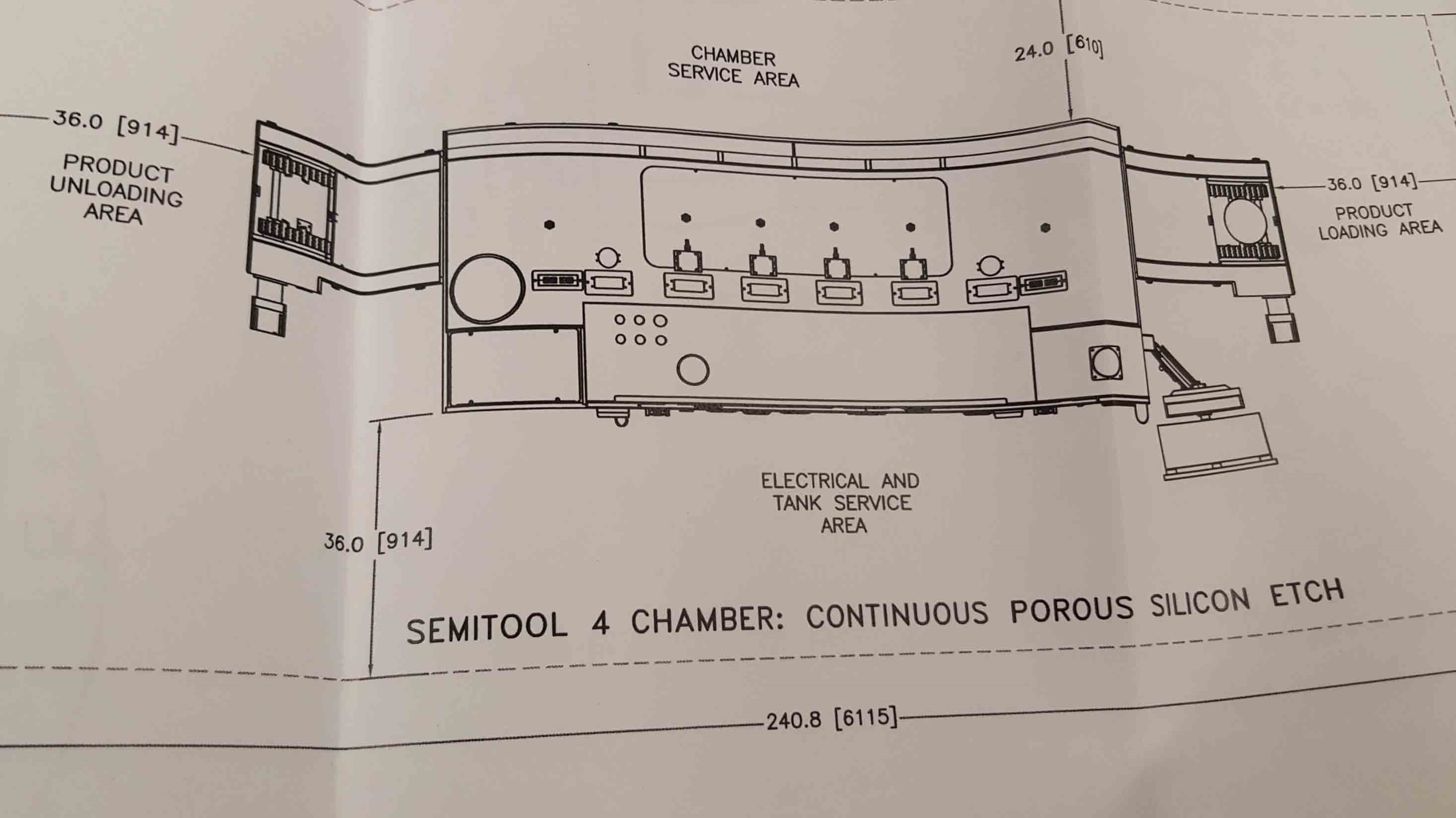

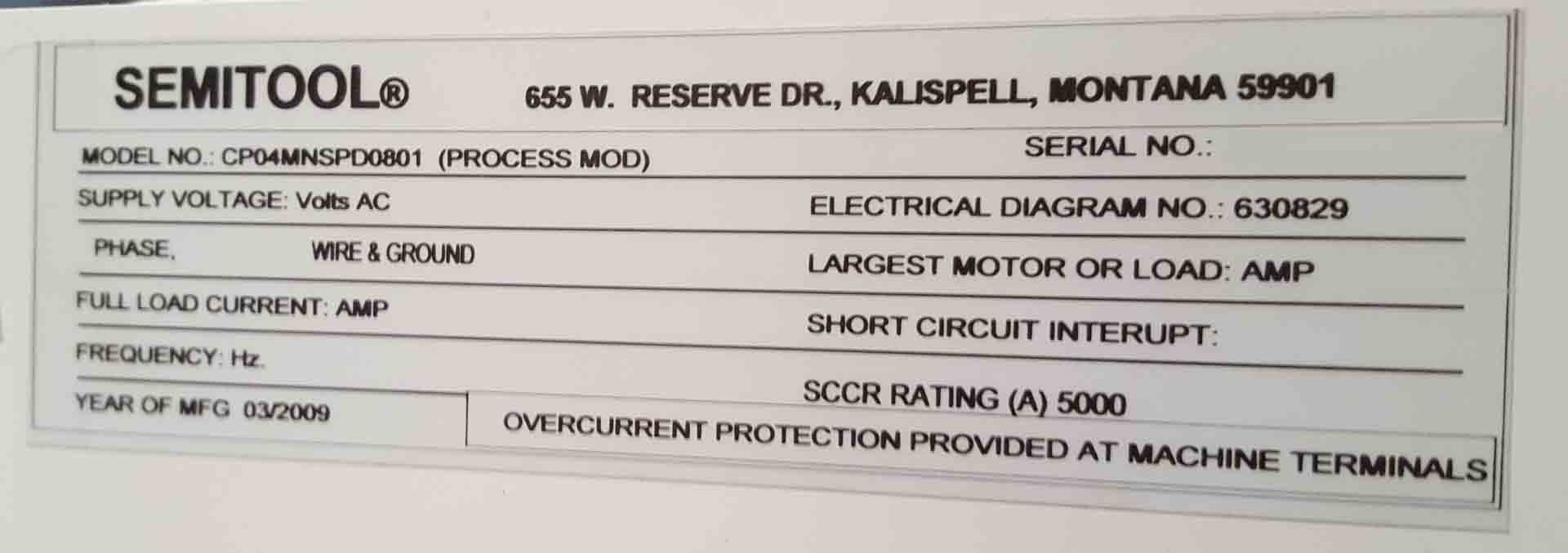

Model: CP04MNSPD0801

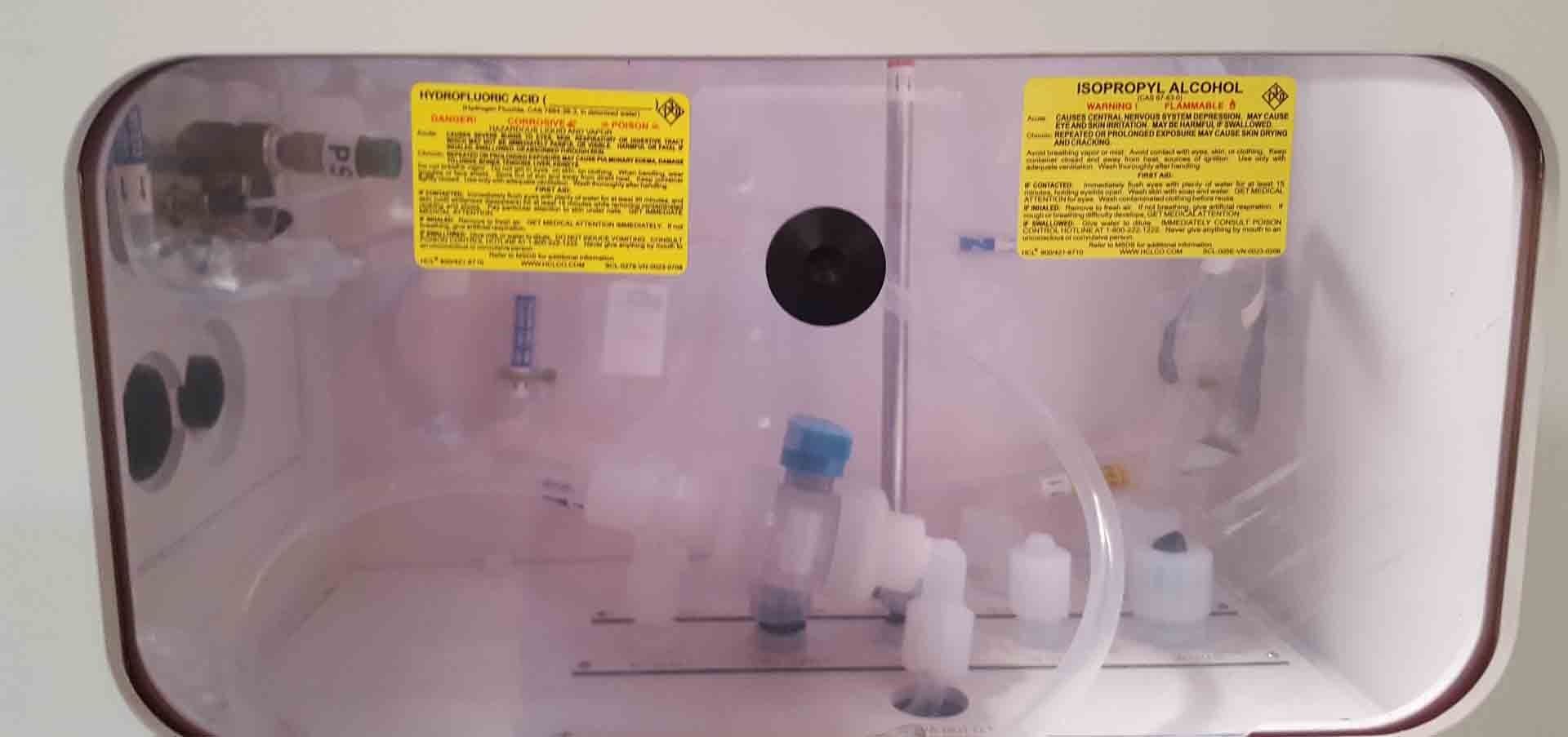

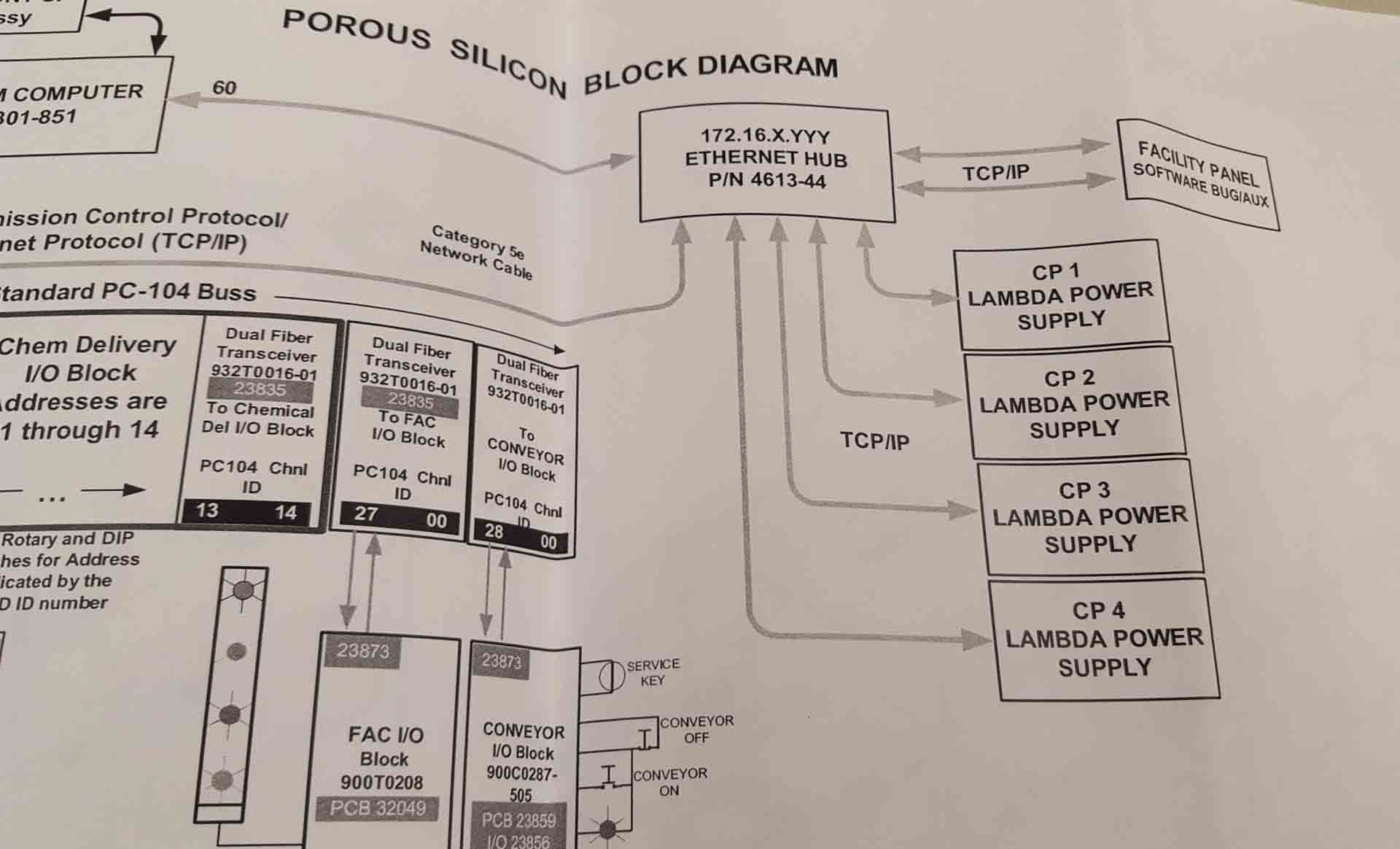

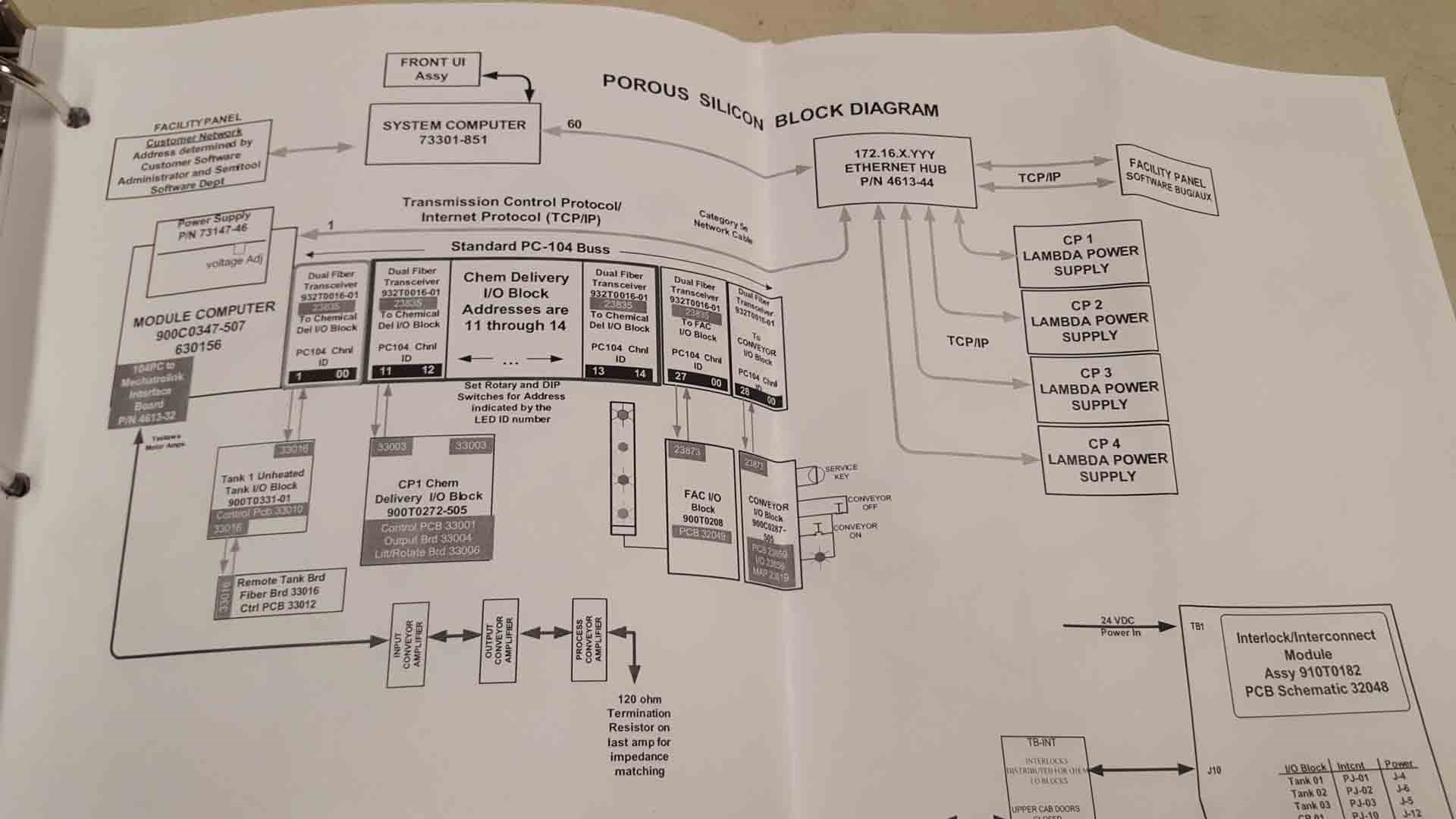

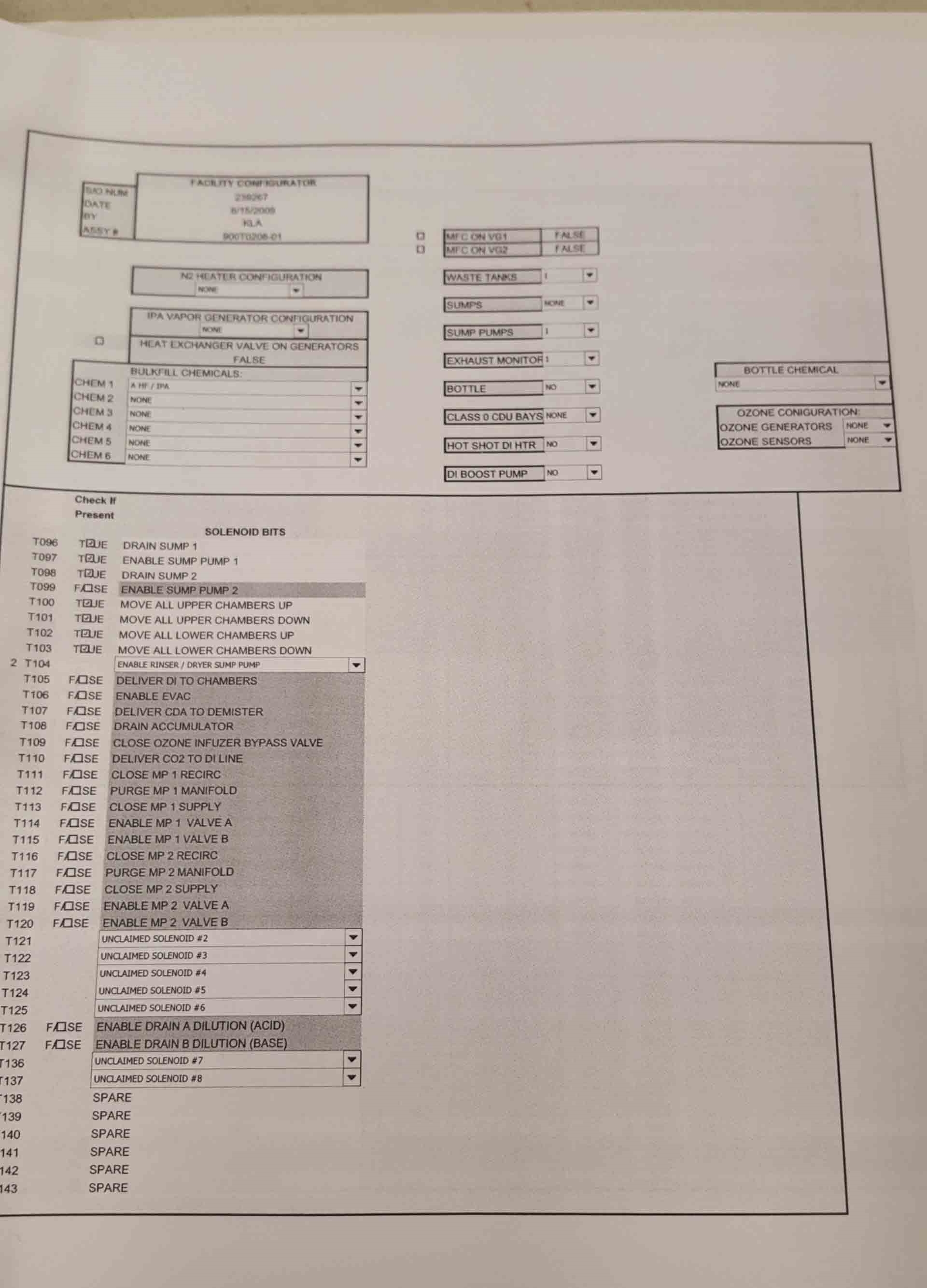

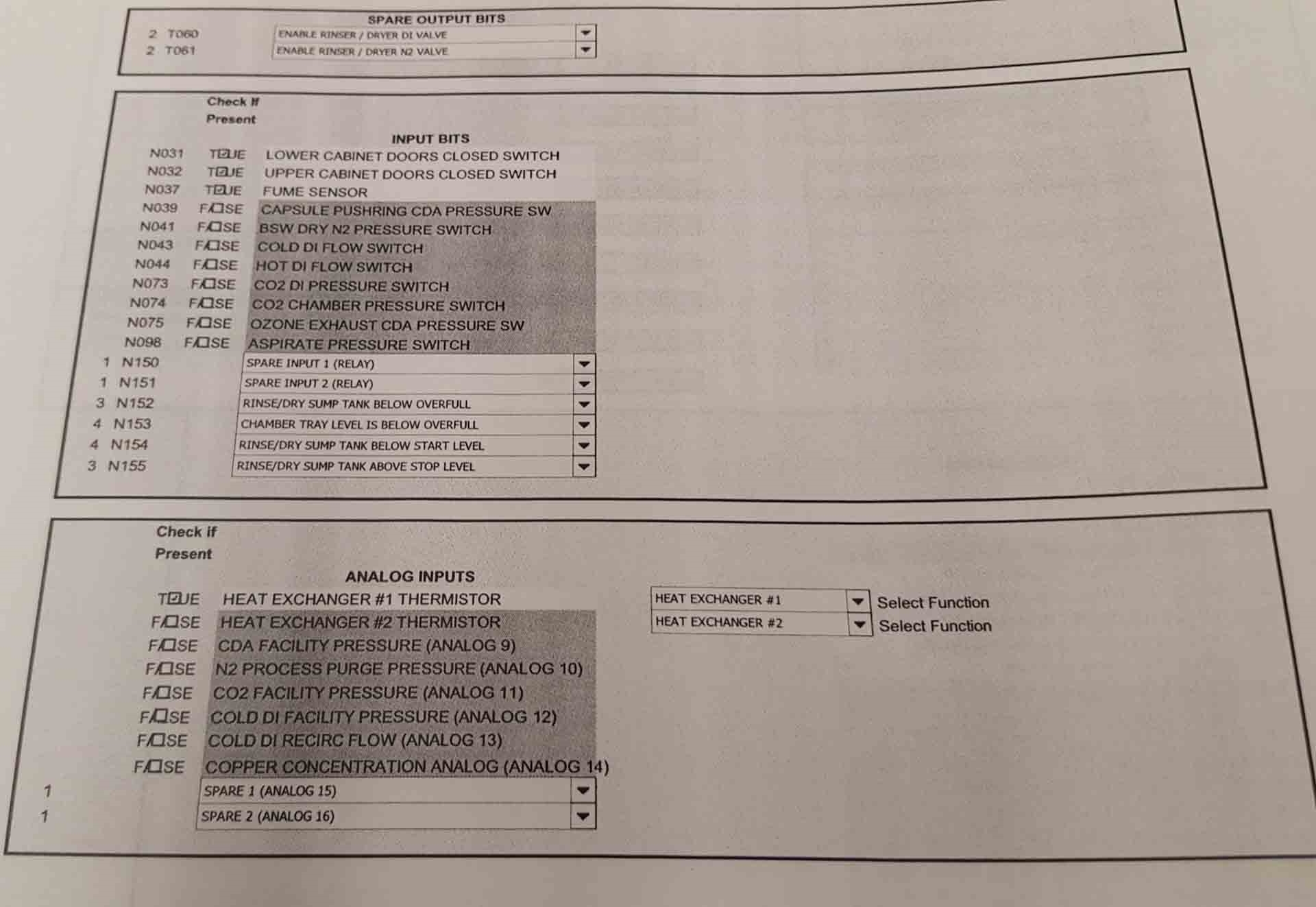

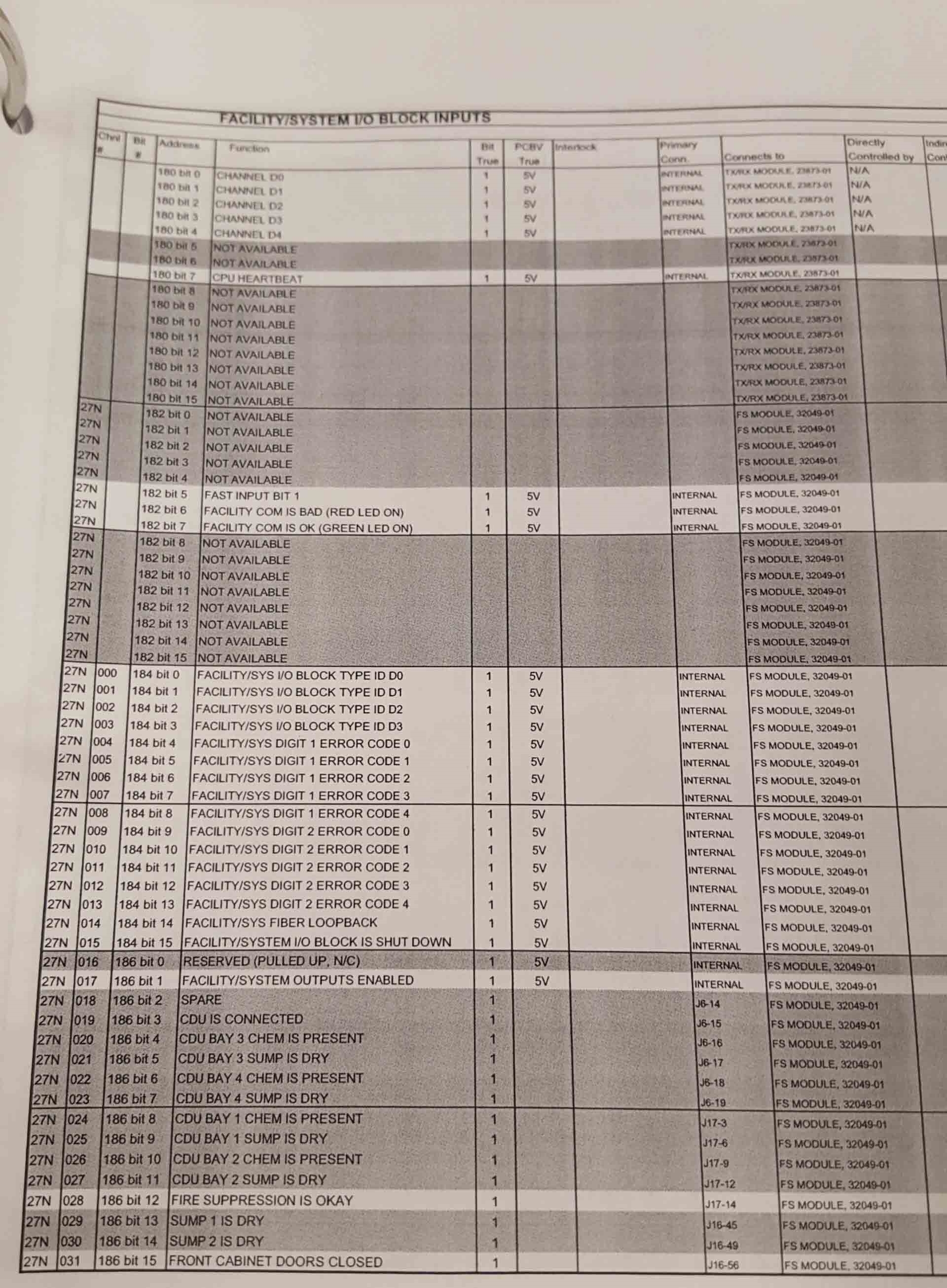

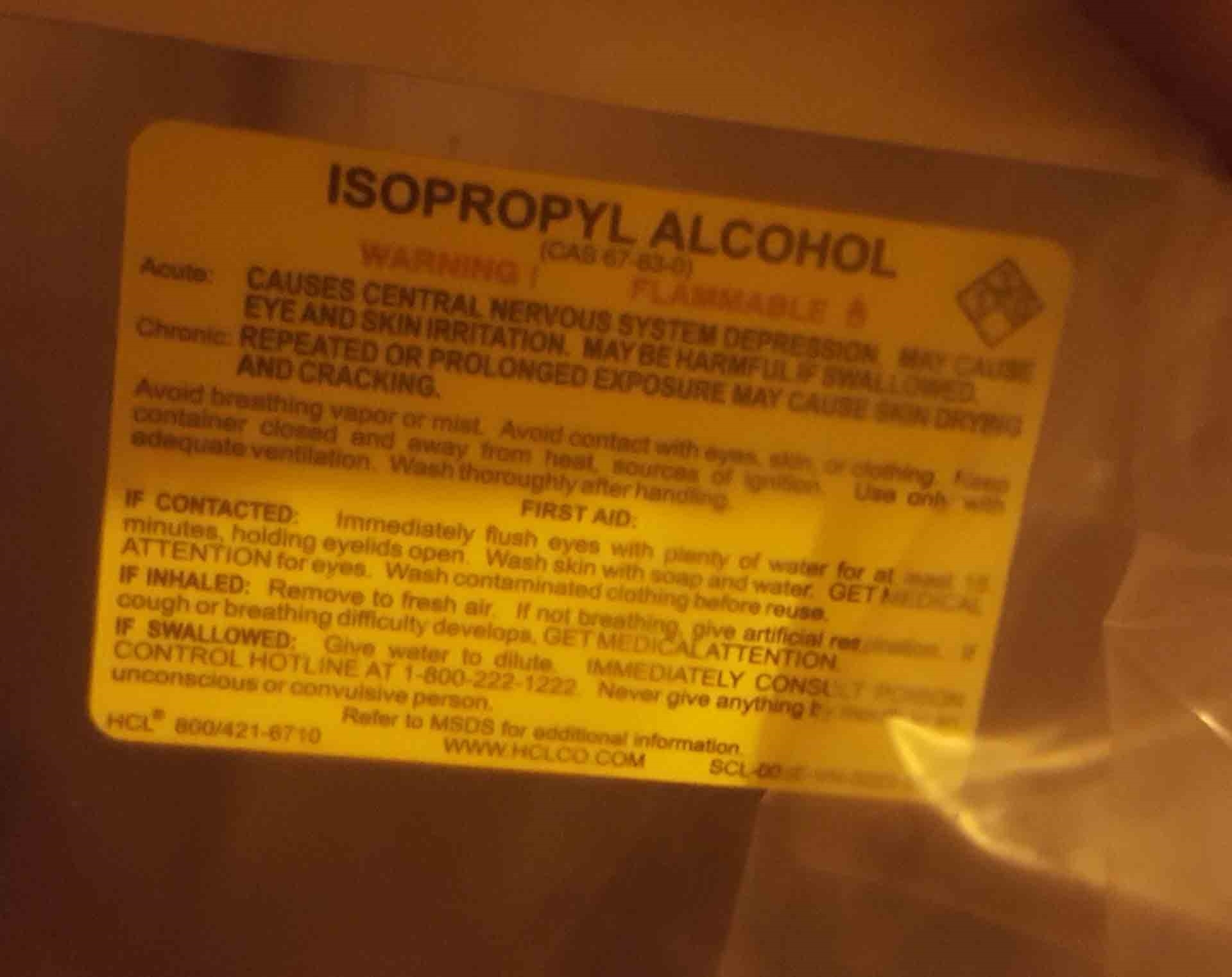

Porous silicon

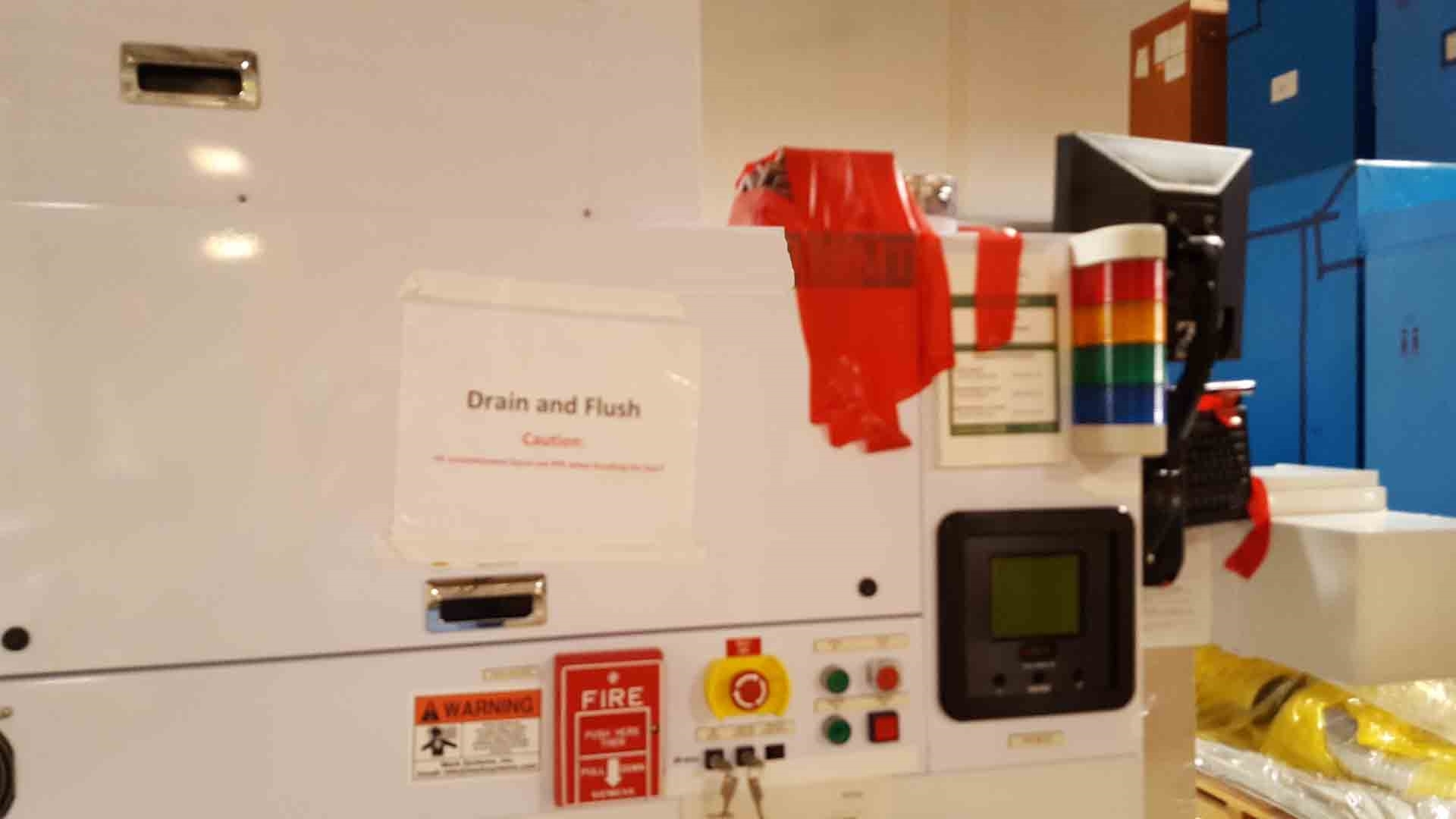

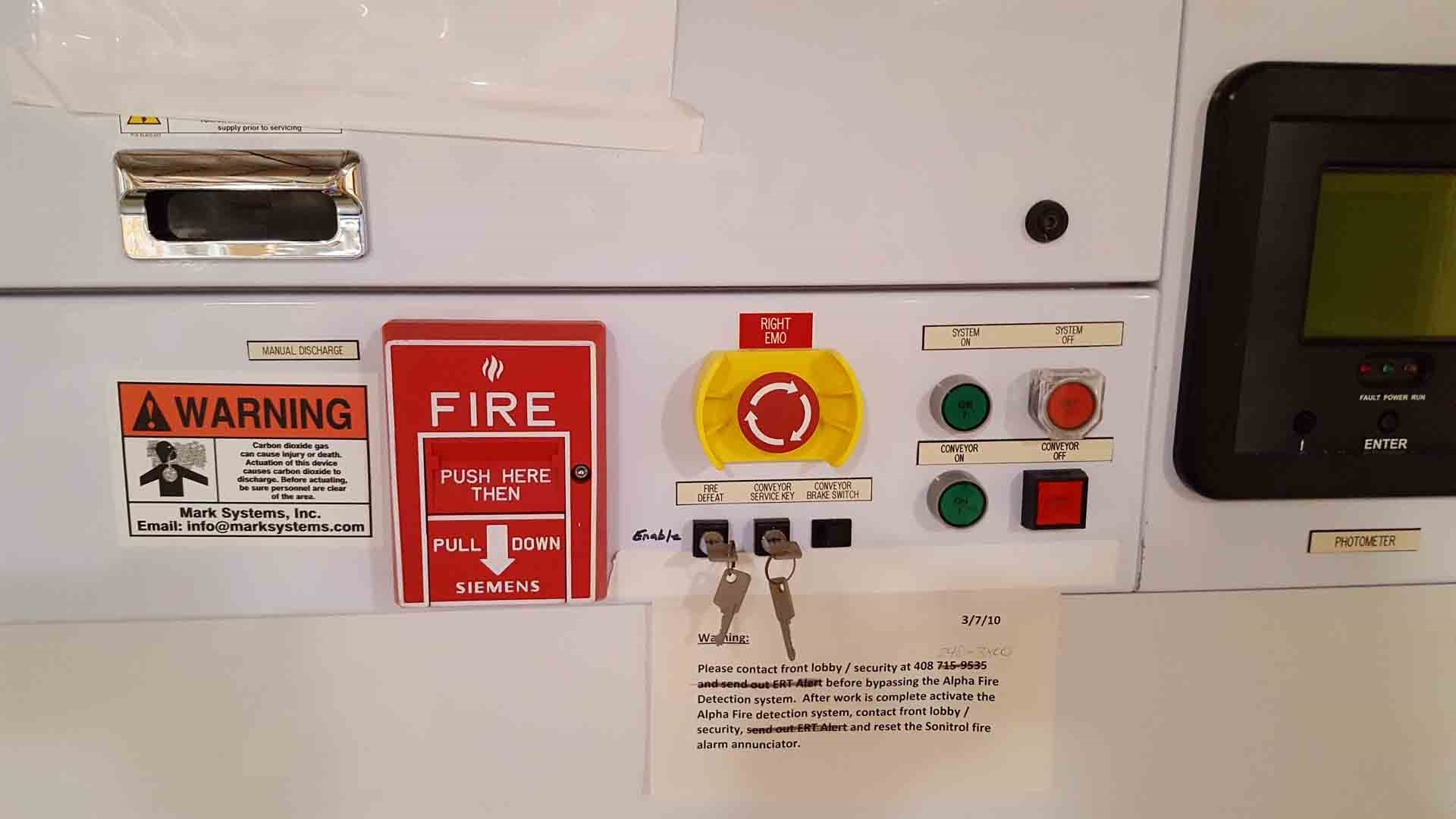

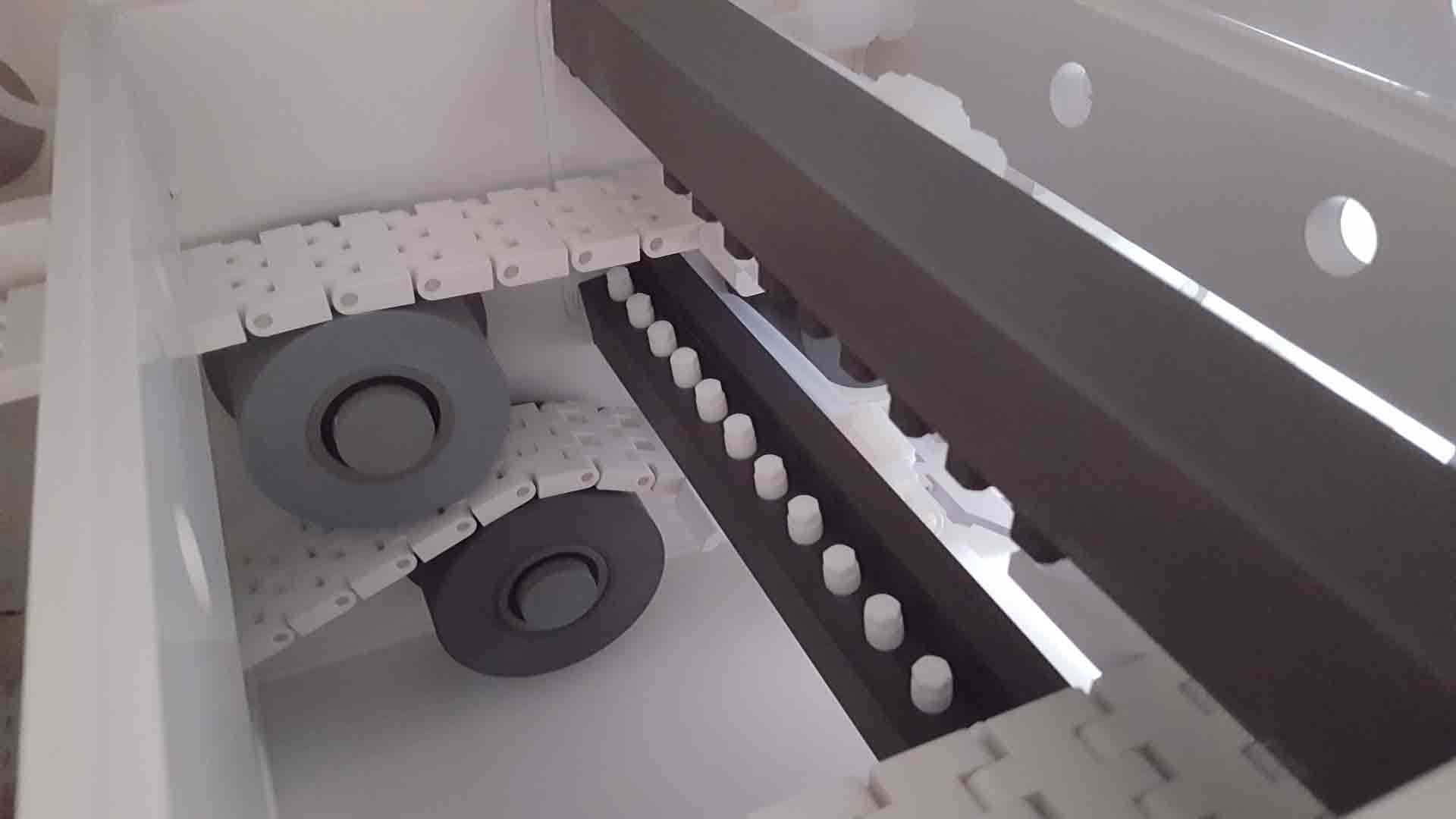

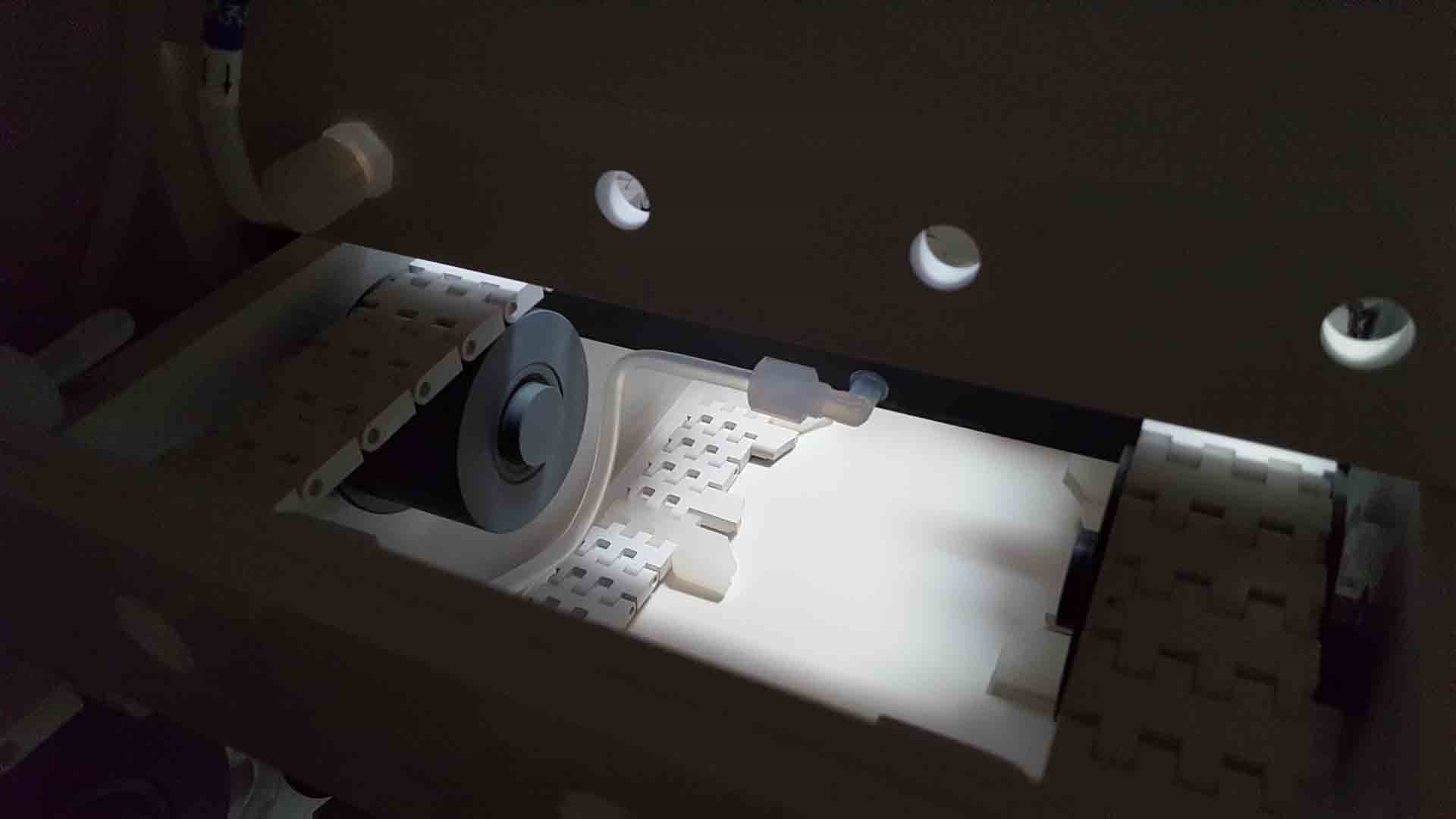

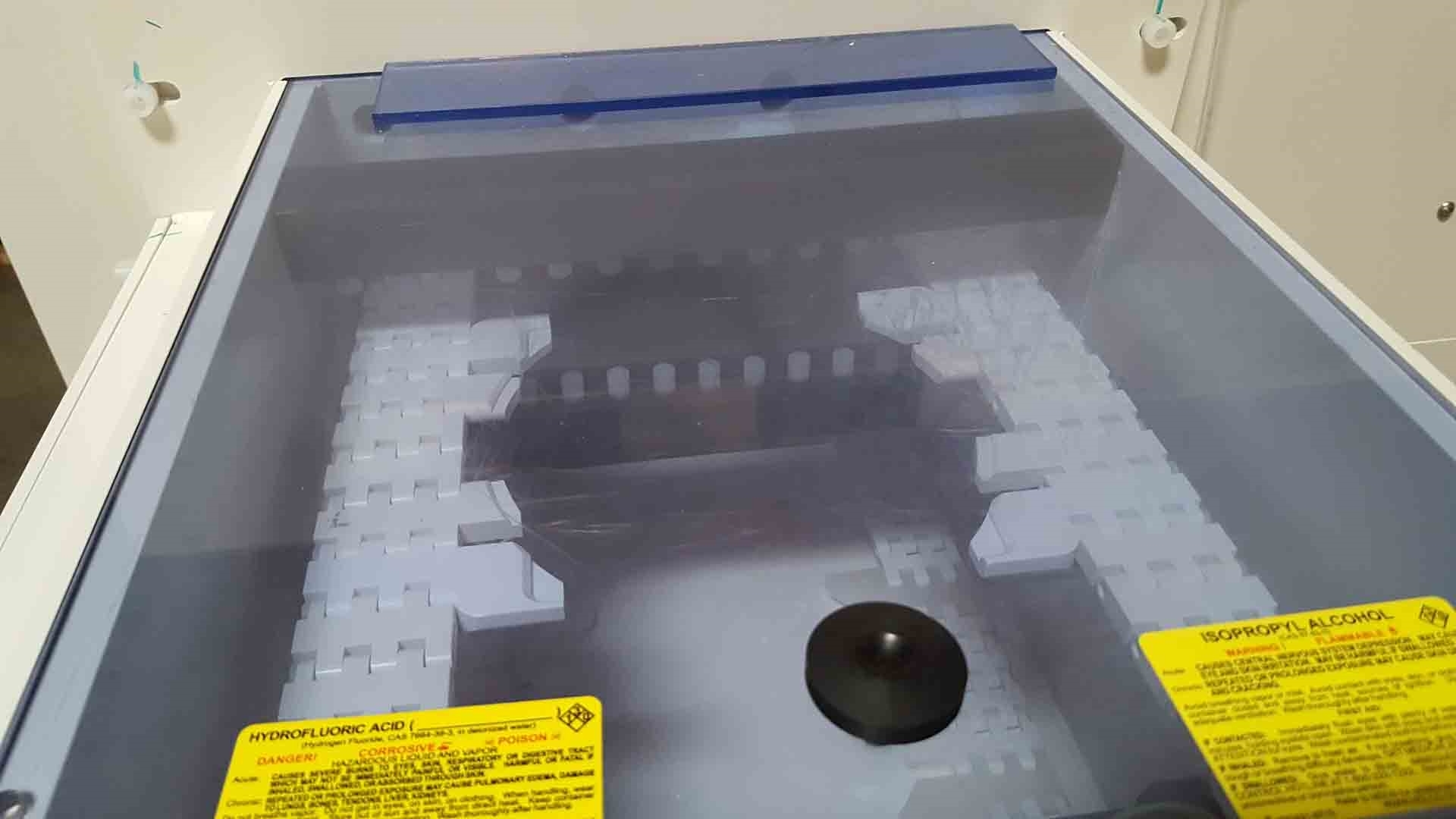

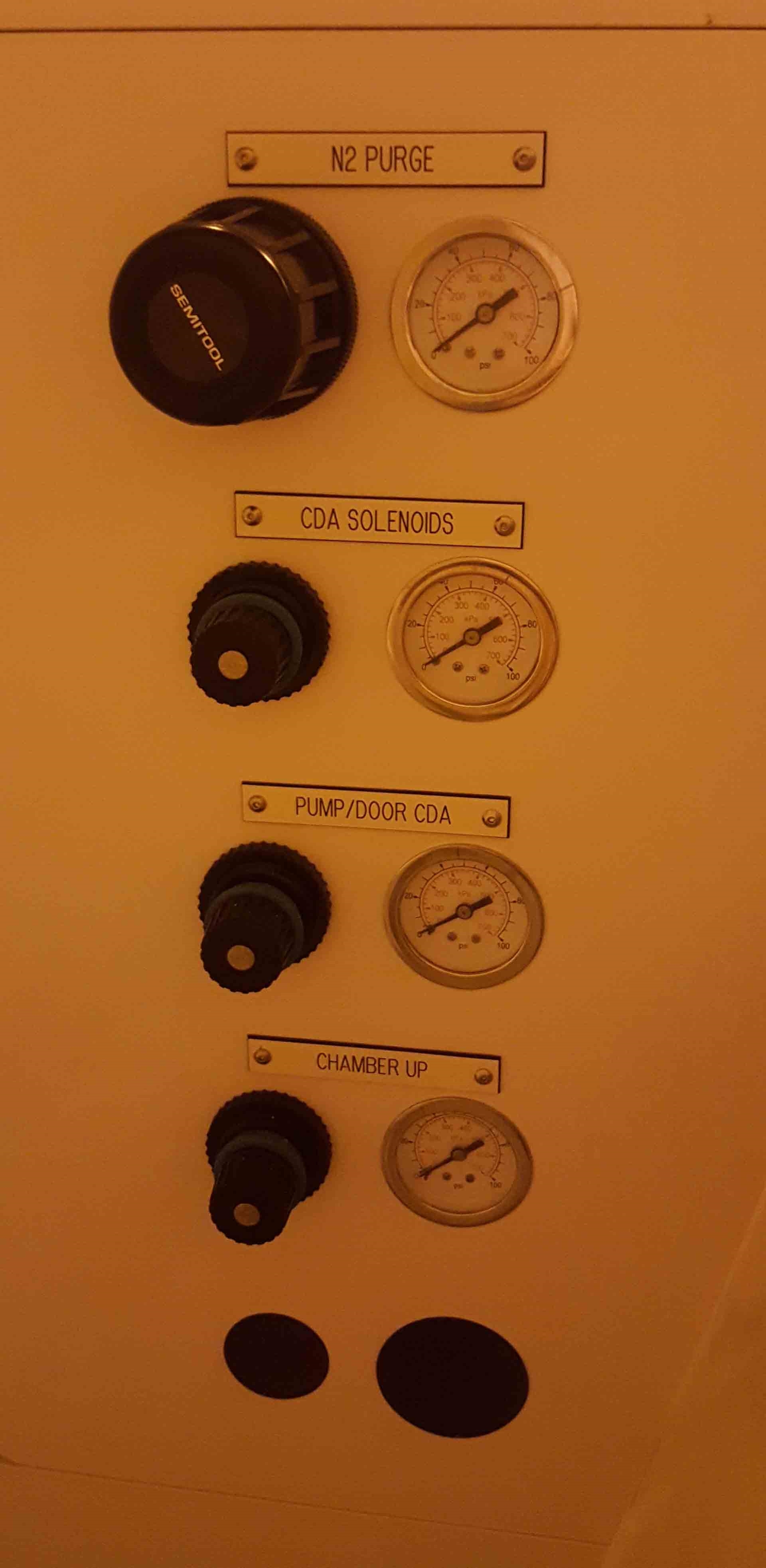

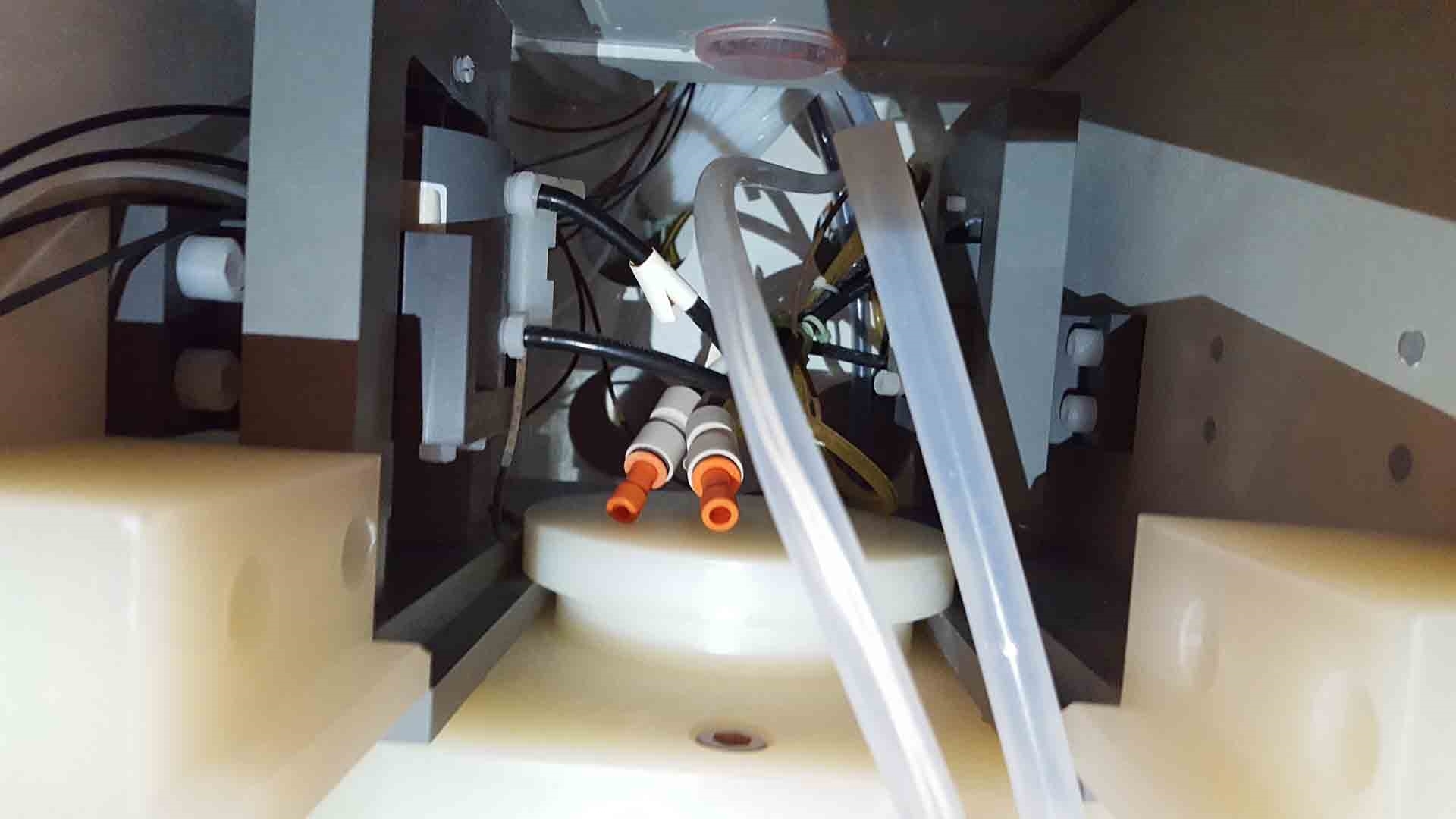

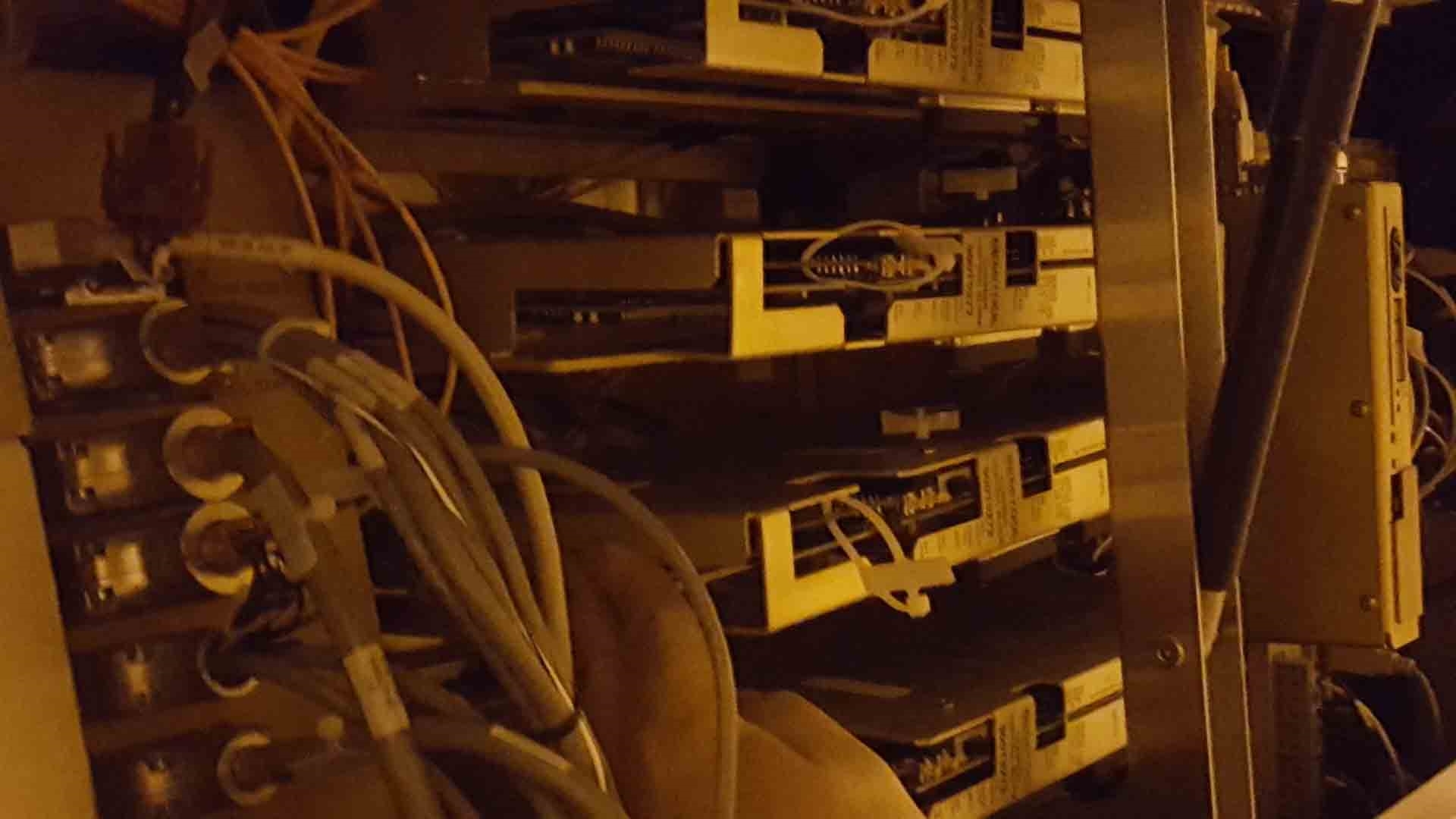

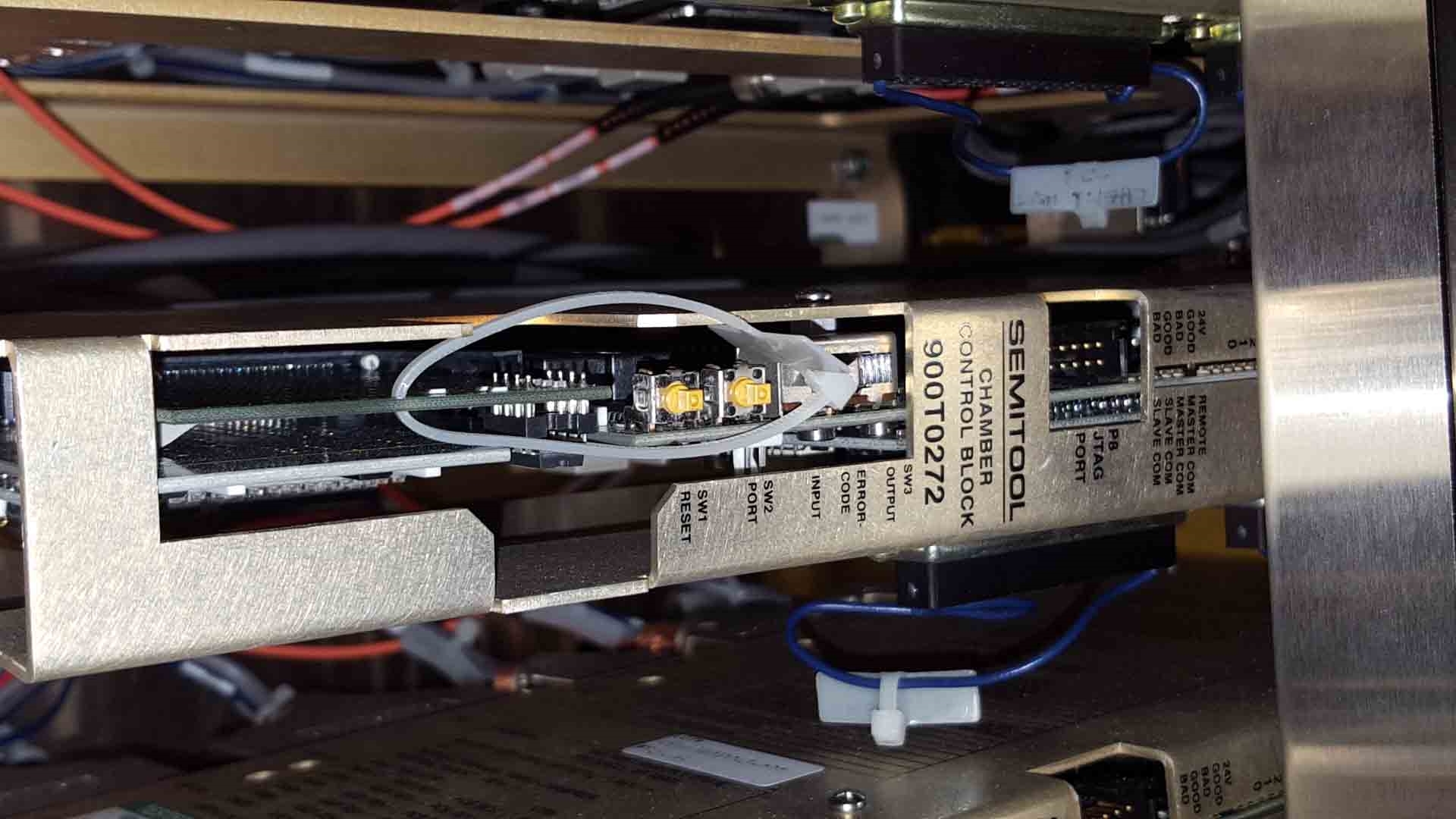

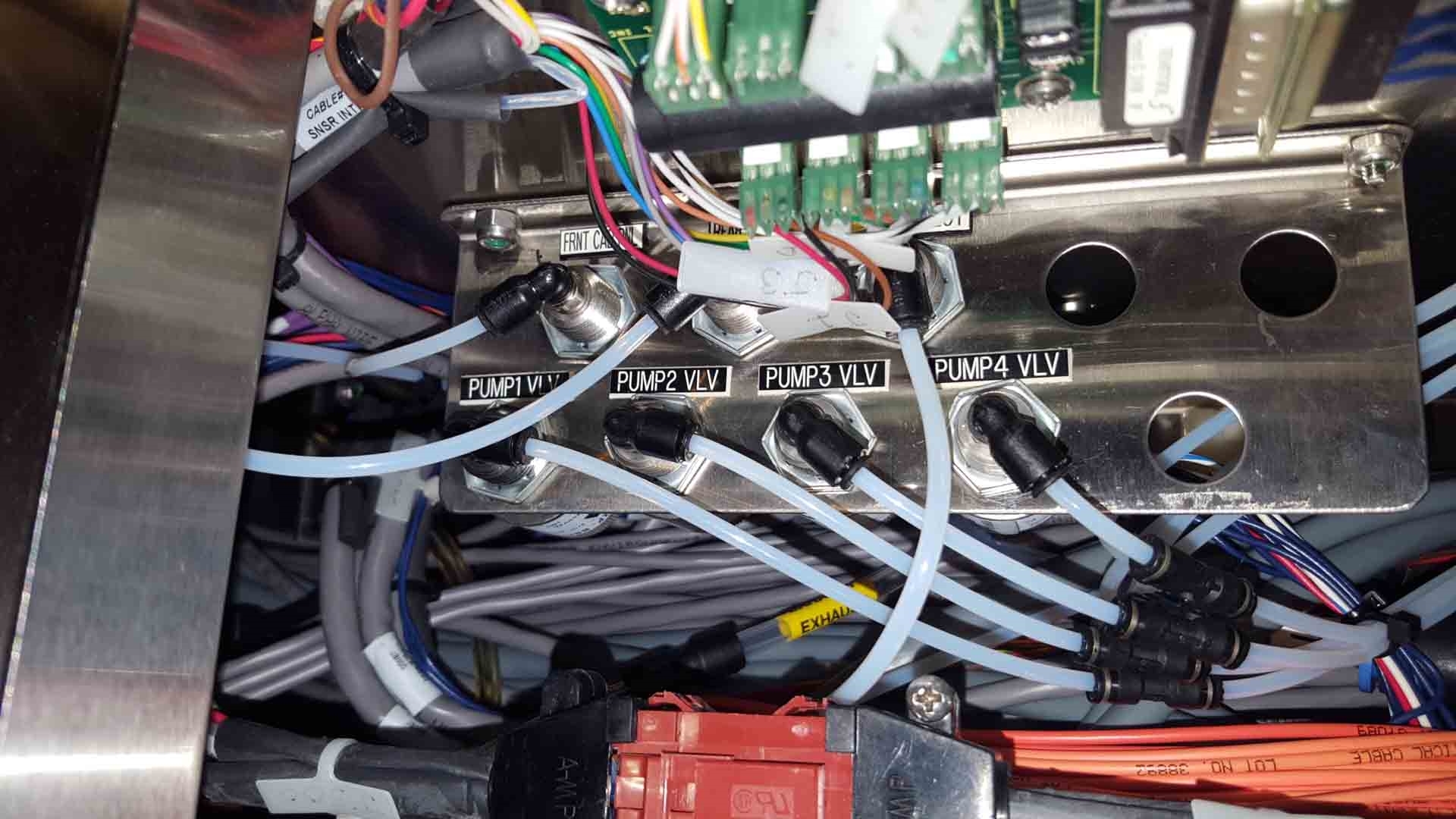

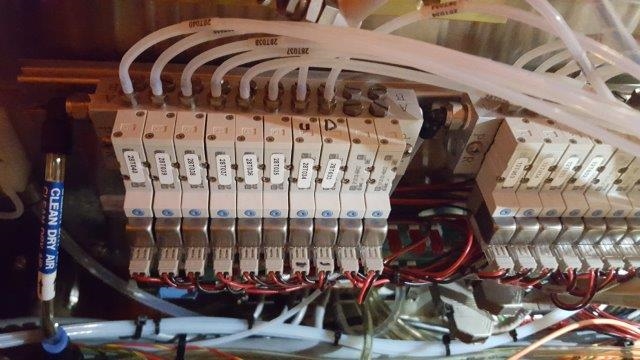

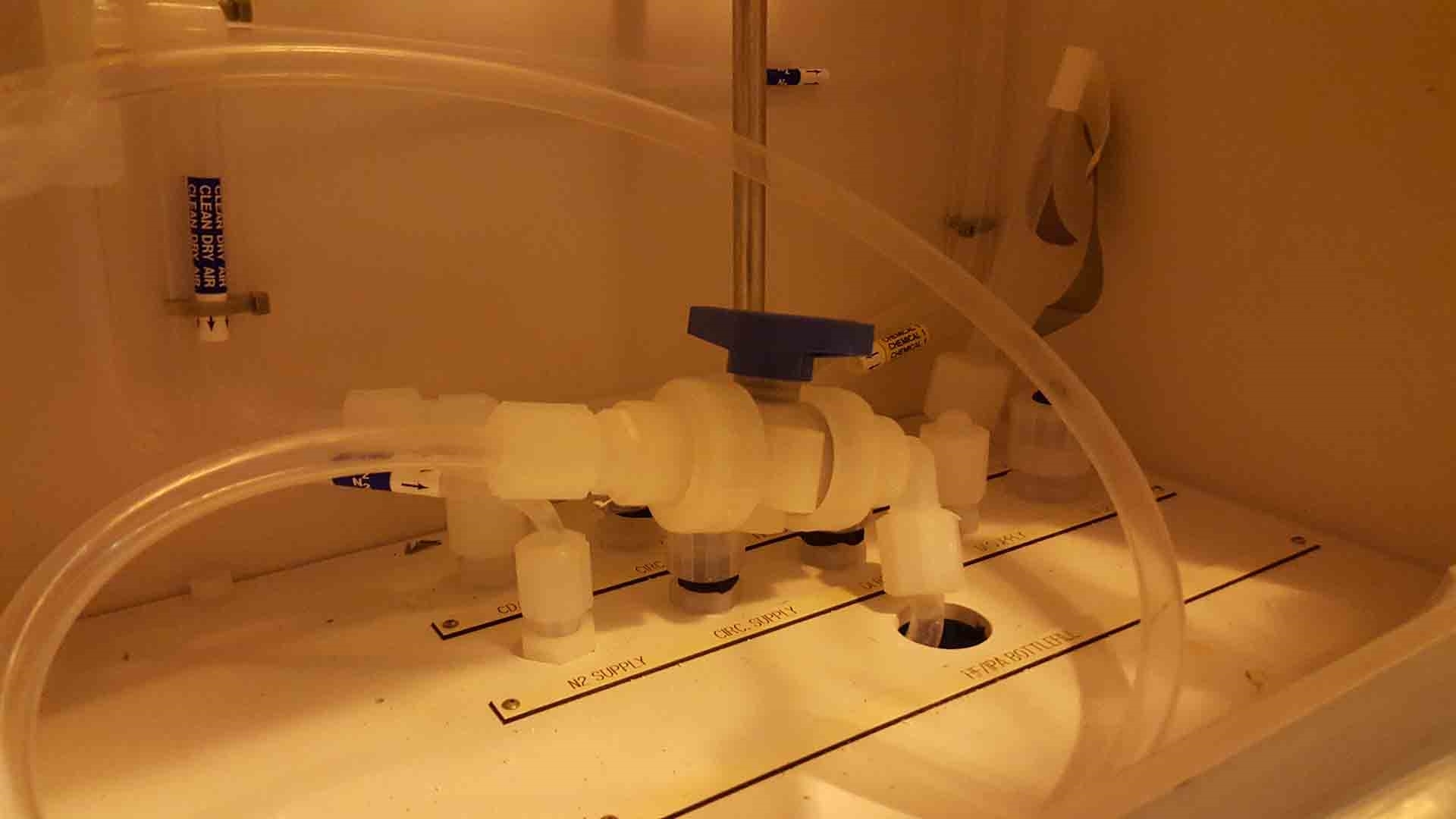

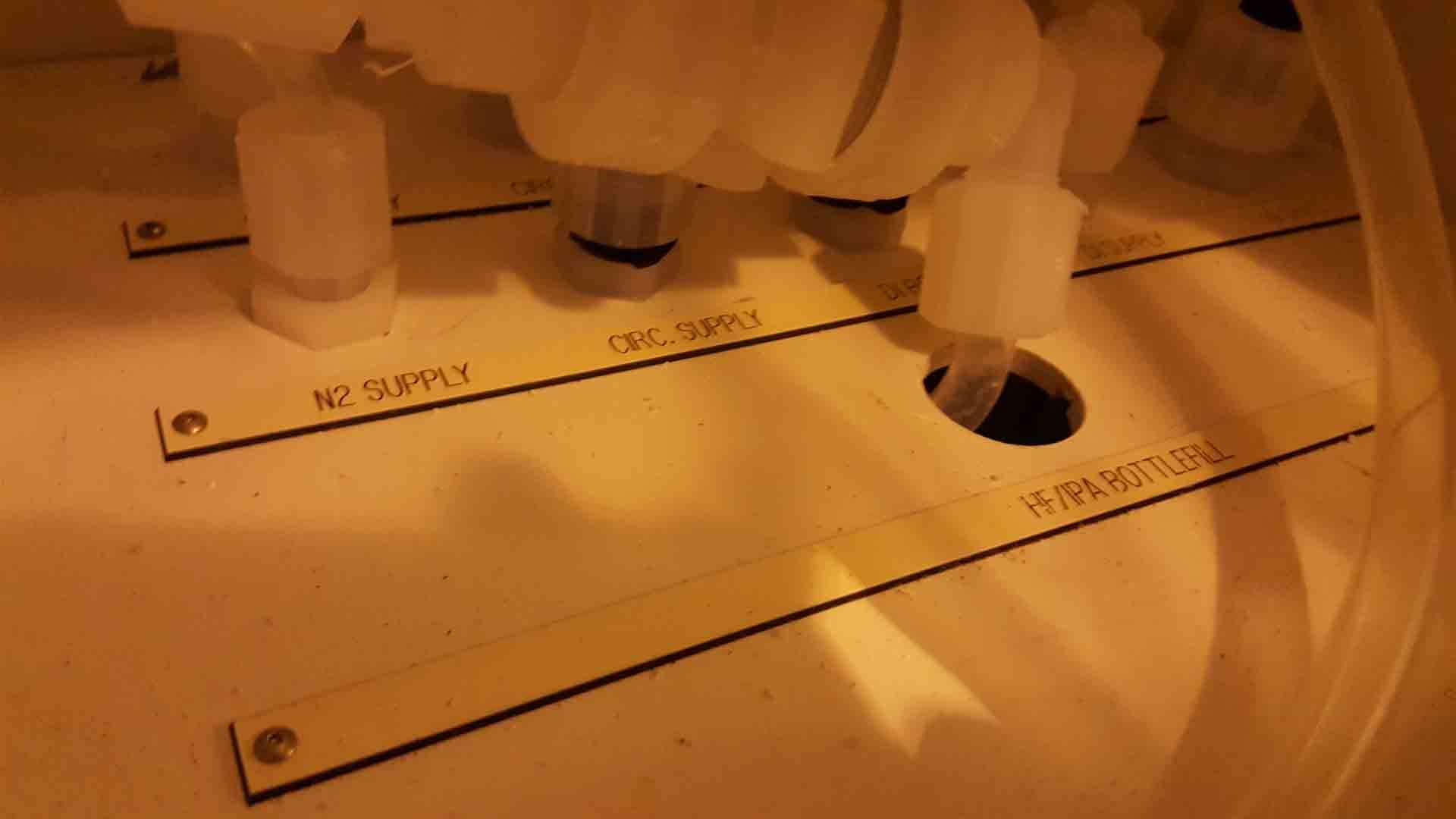

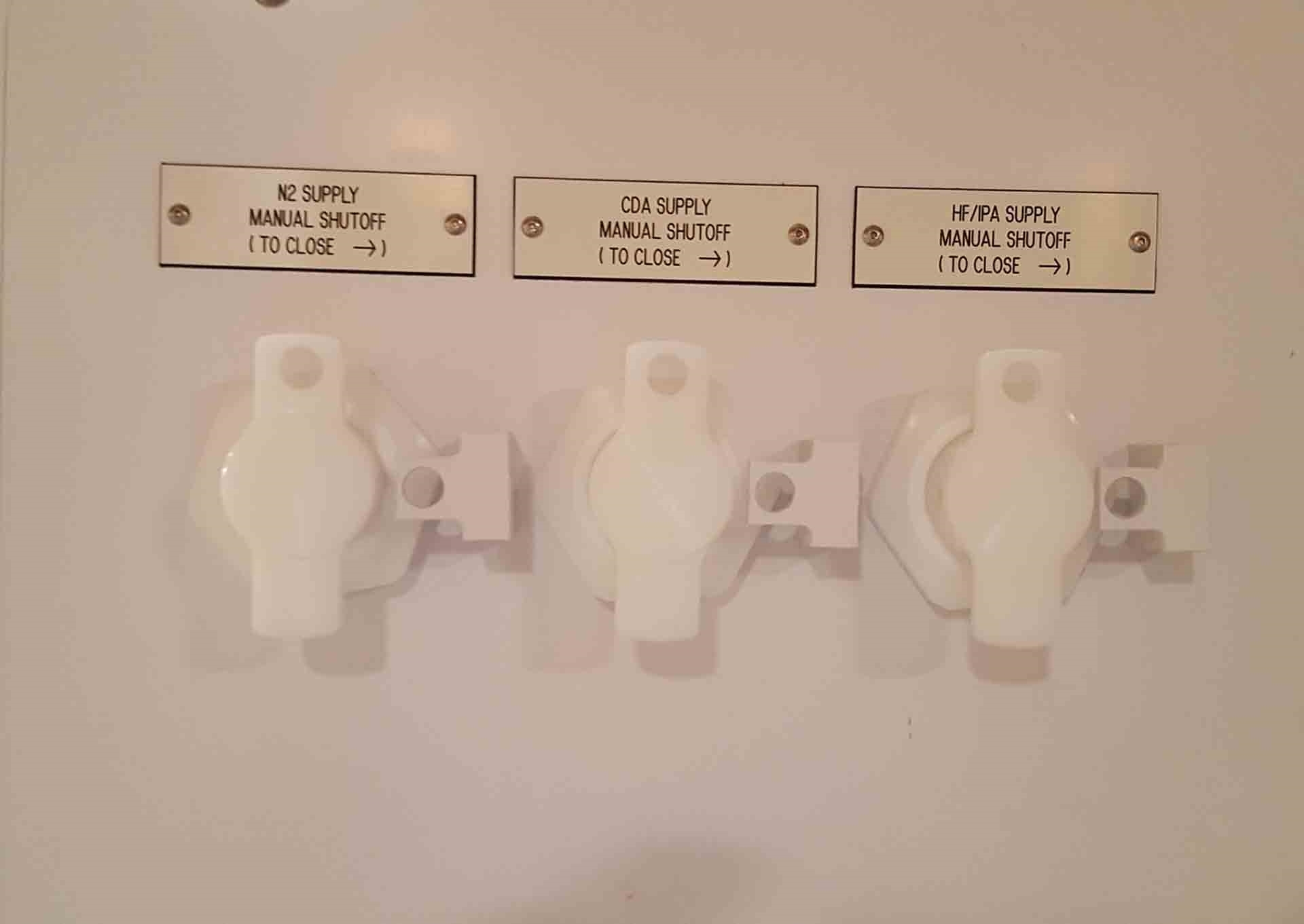

Process chambers:

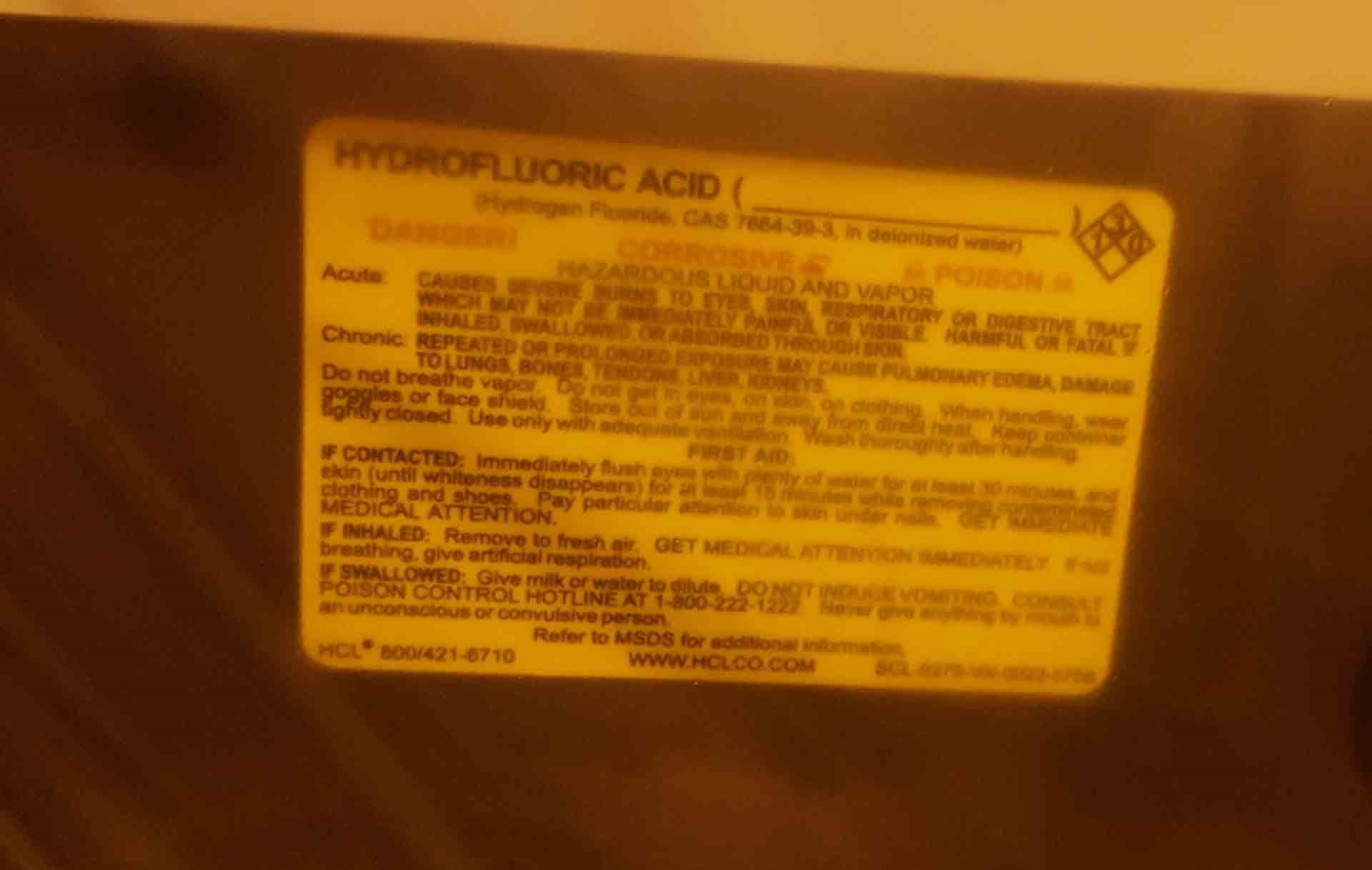

Spray

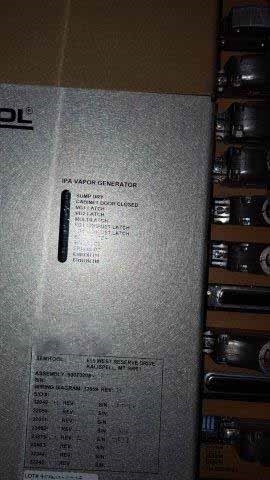

Vapor

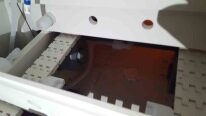

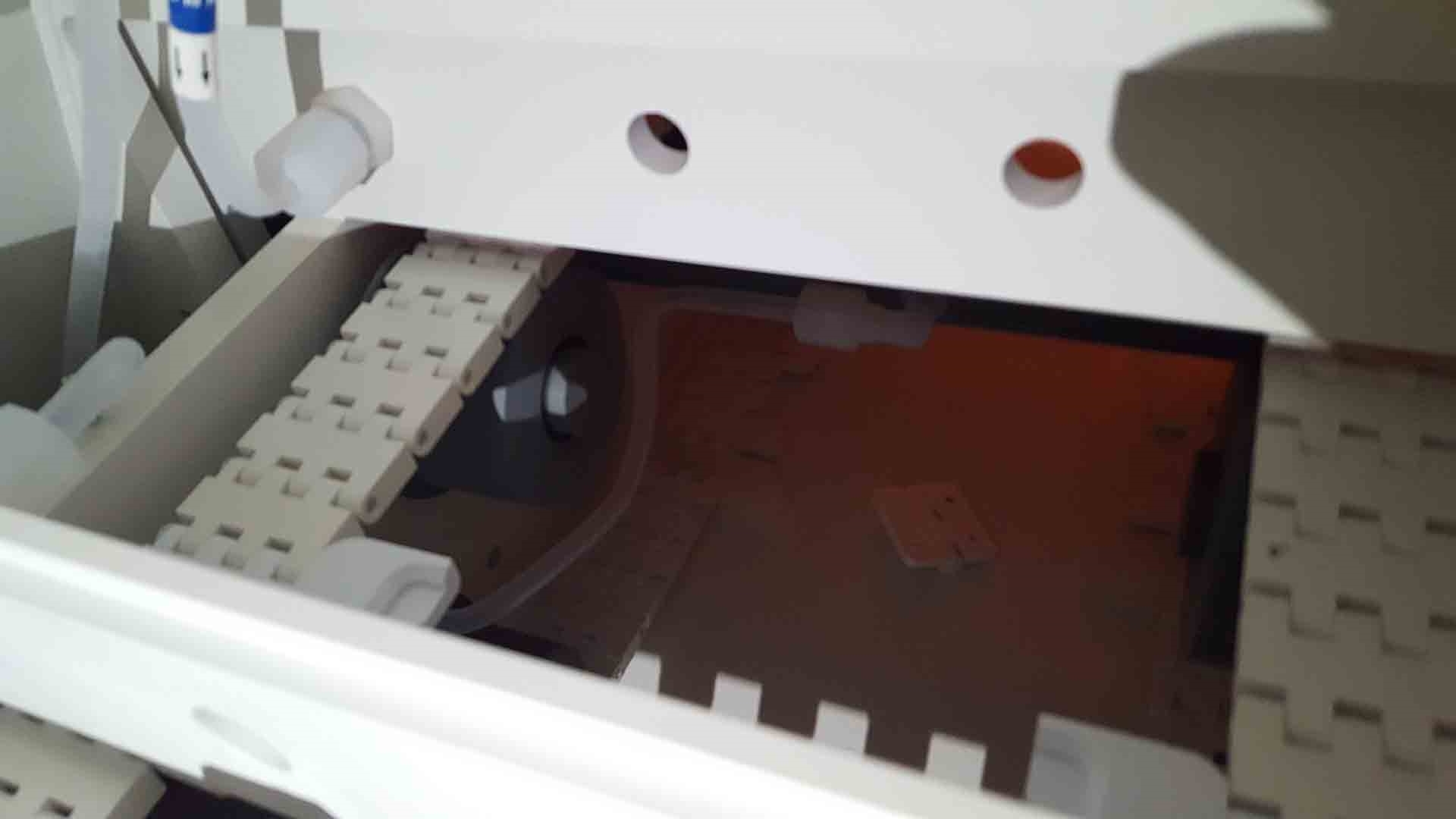

Immersion

Electroplating applications

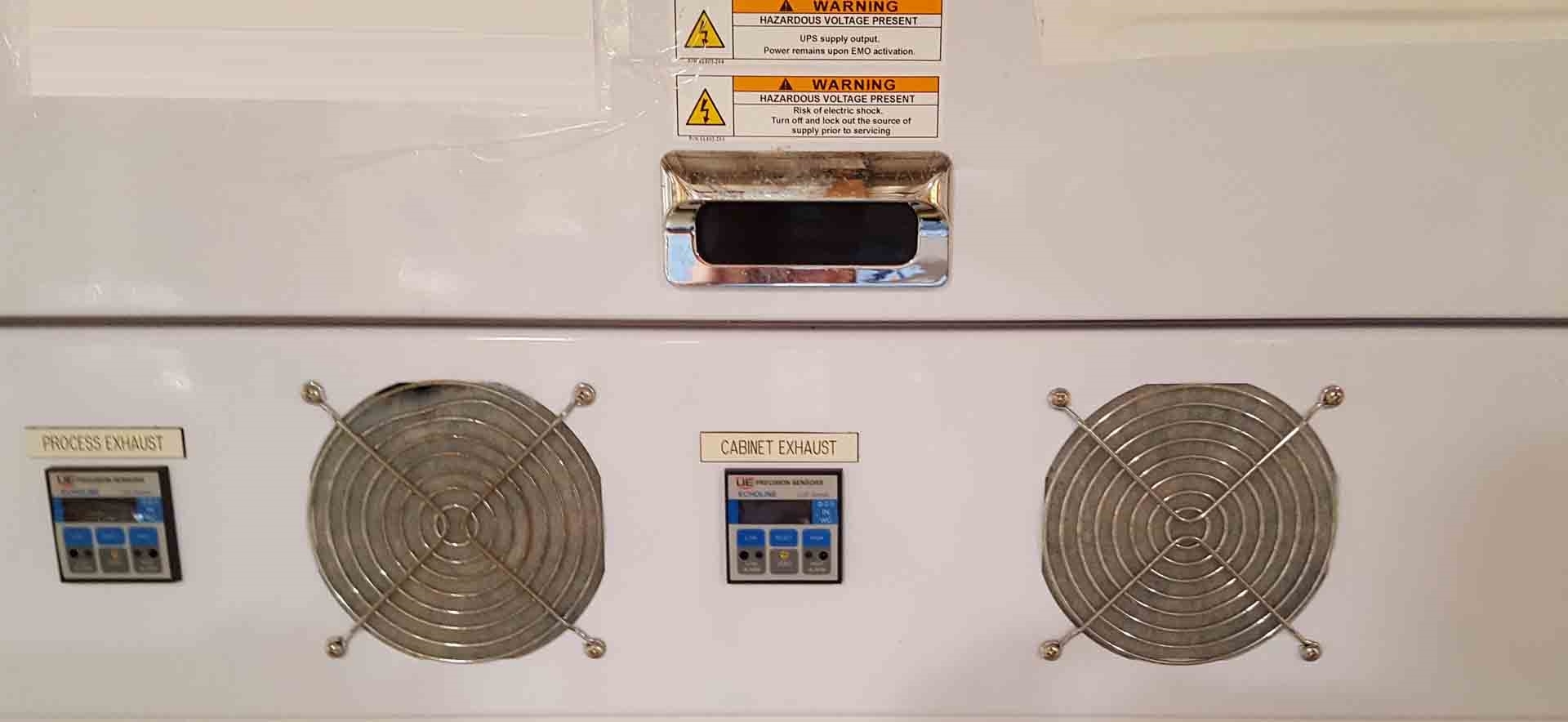

Integrated into single cluster tool

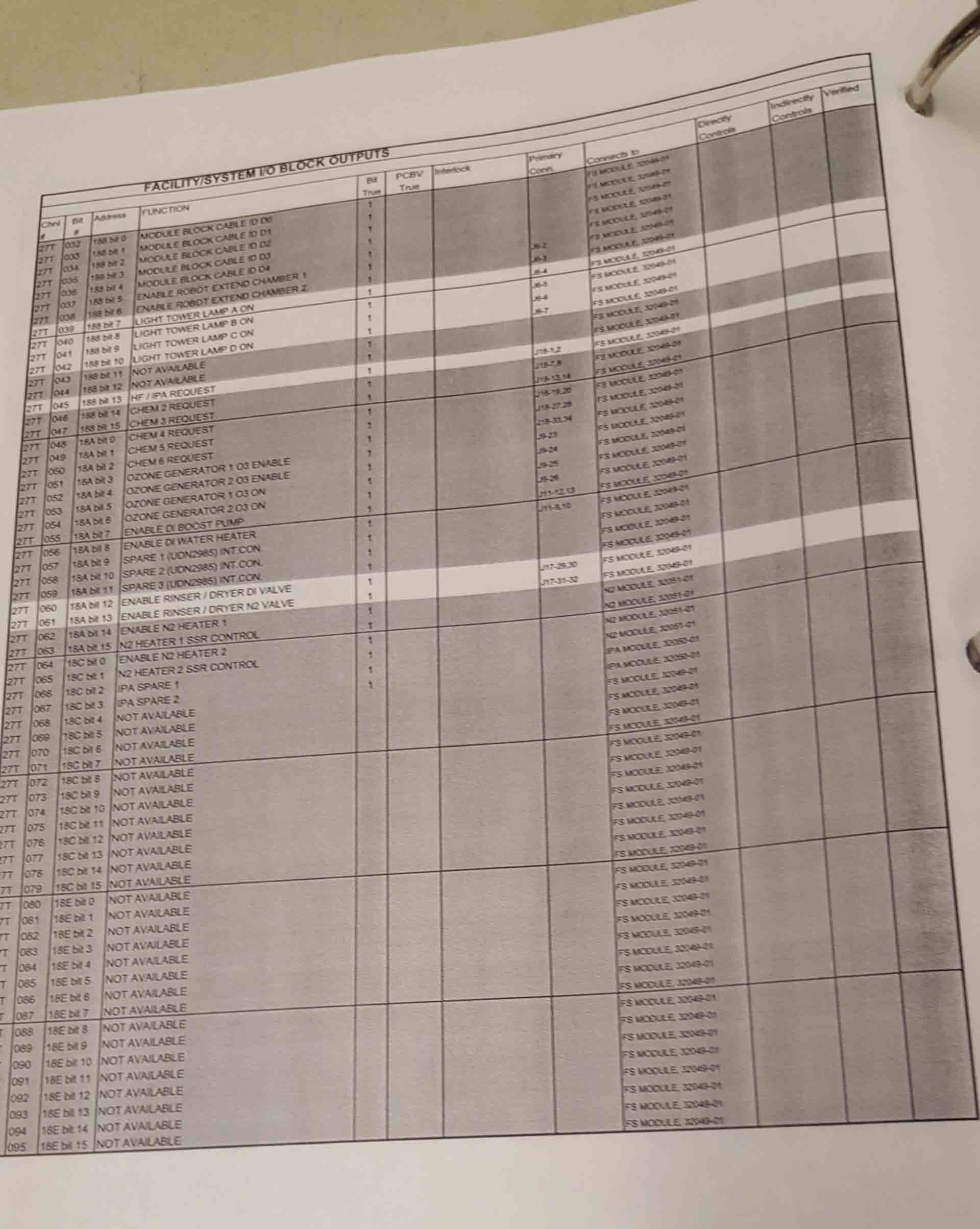

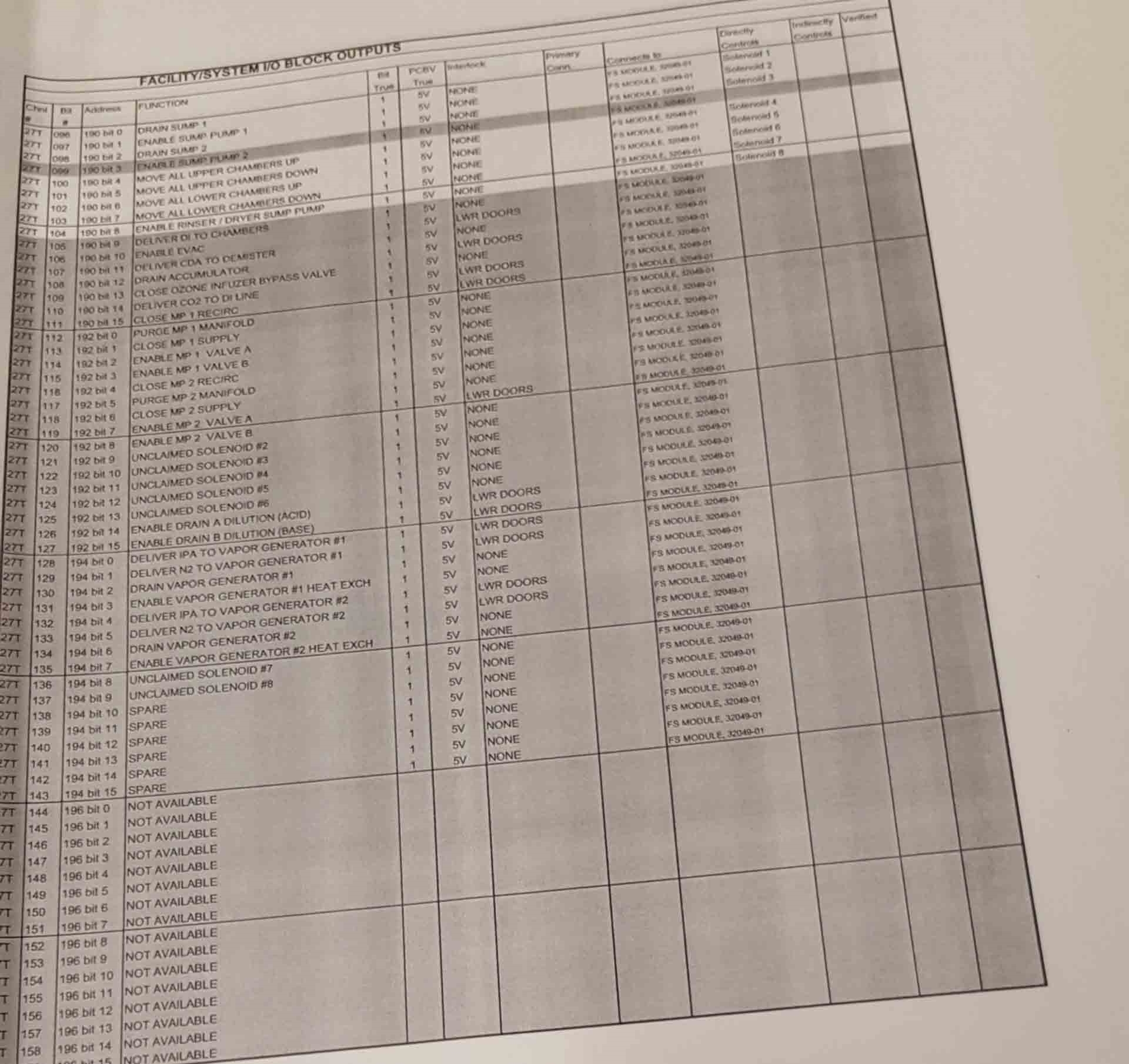

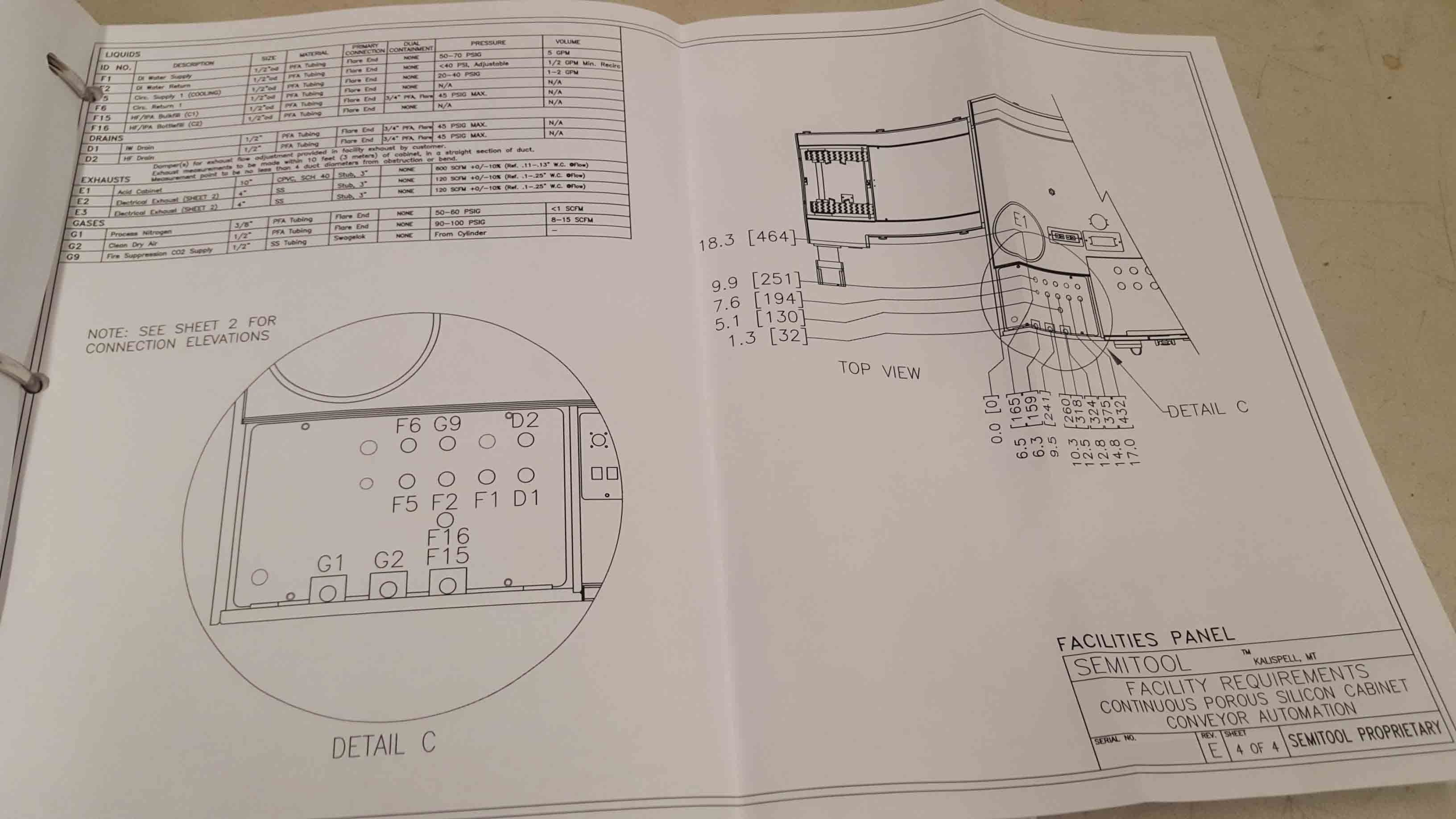

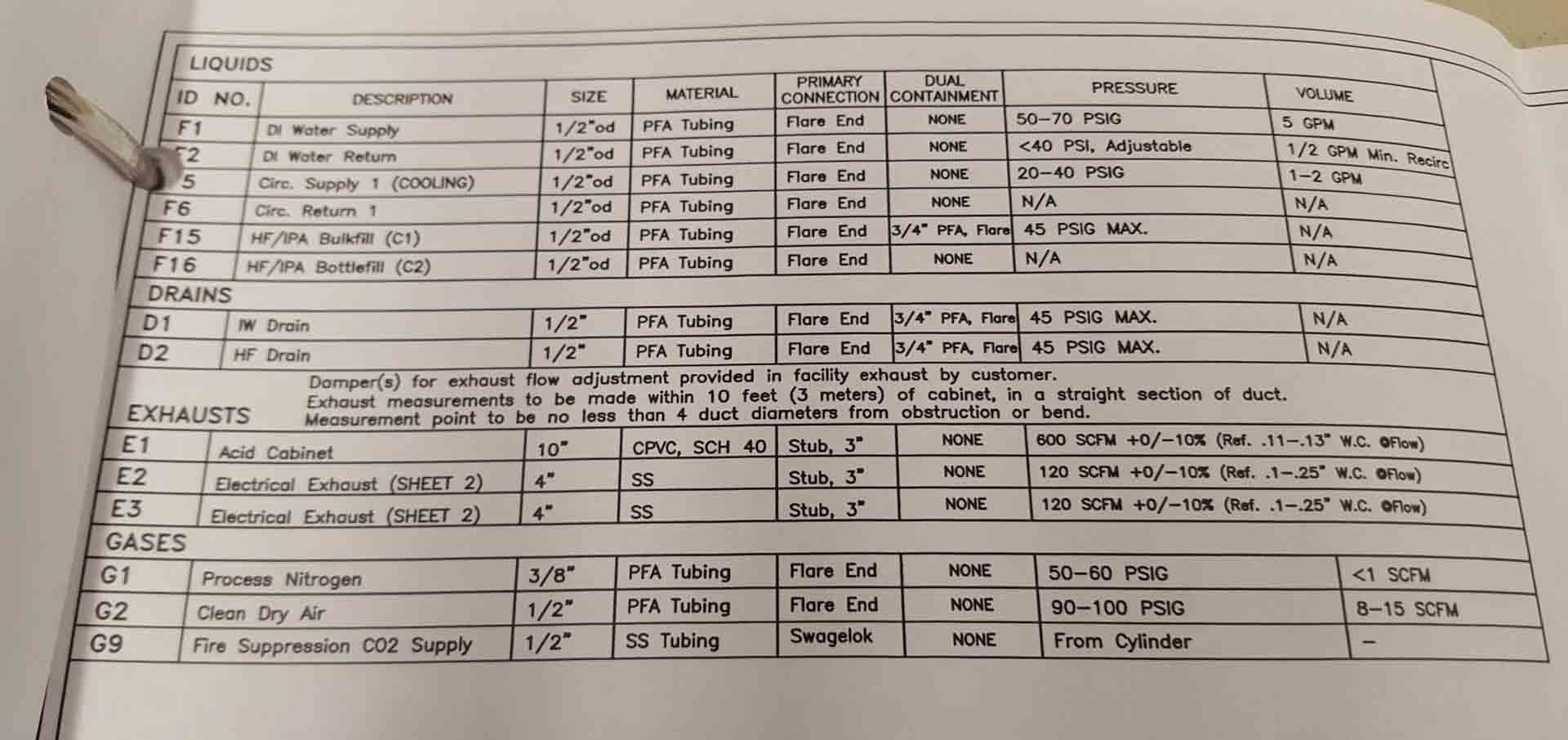

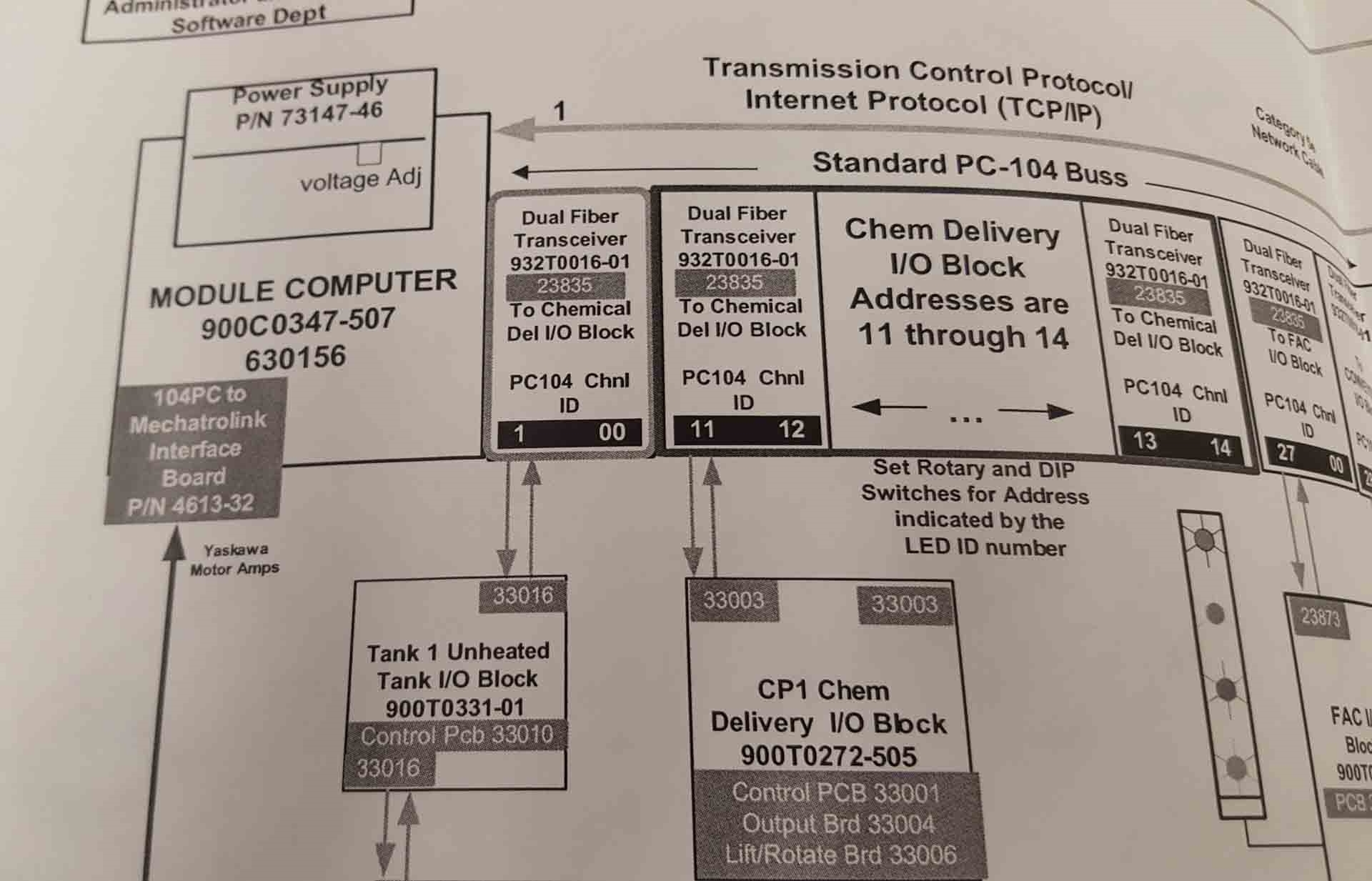

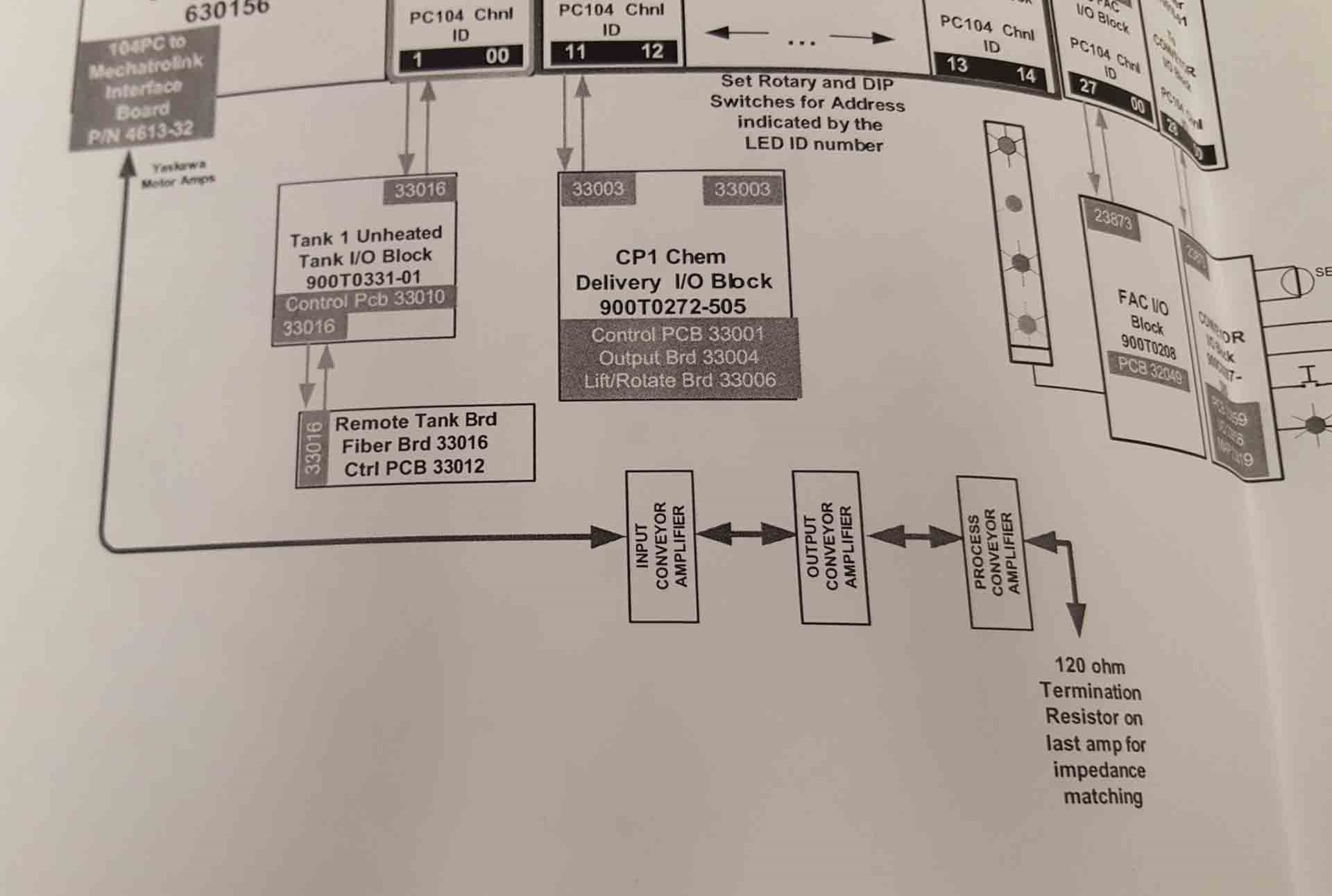

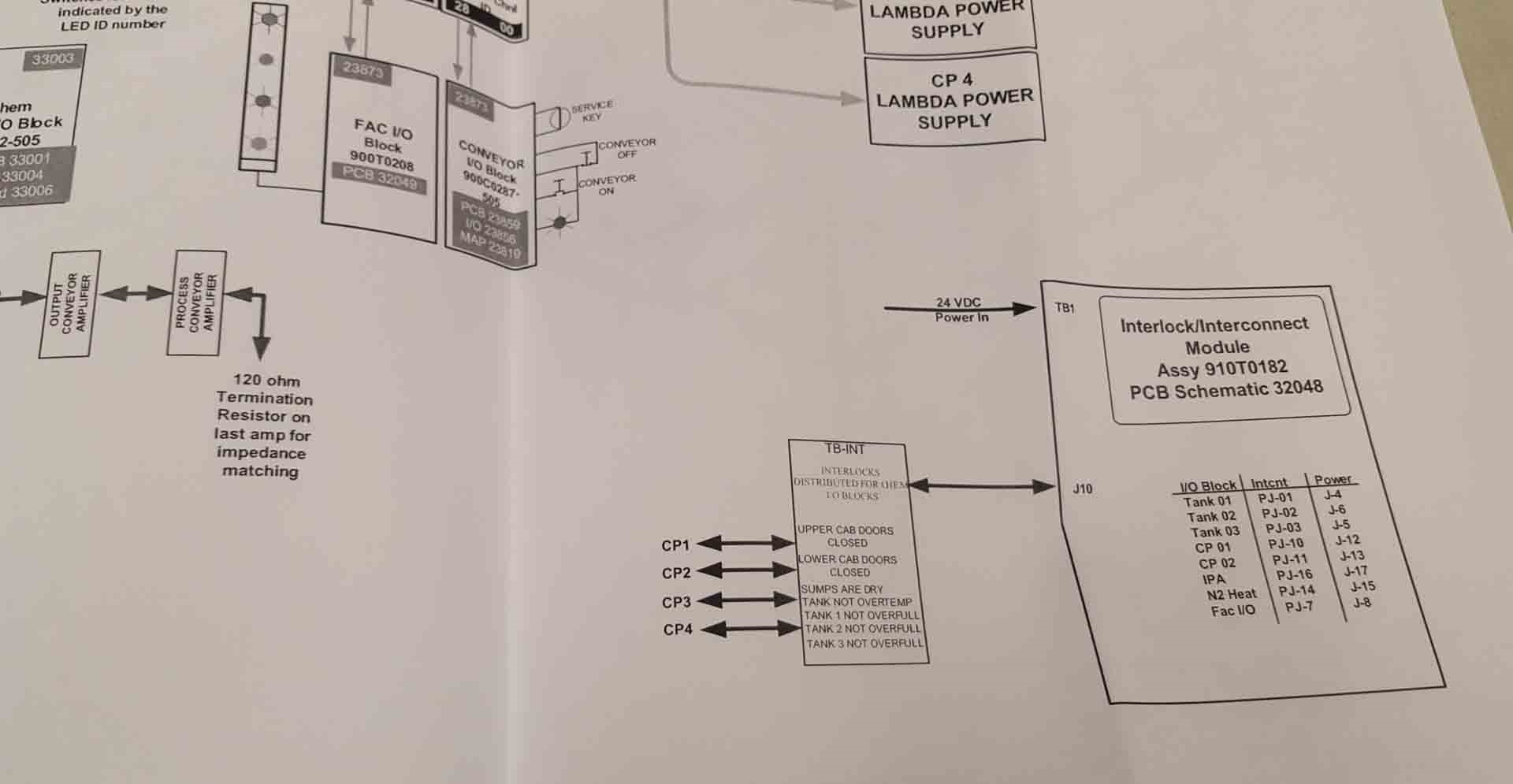

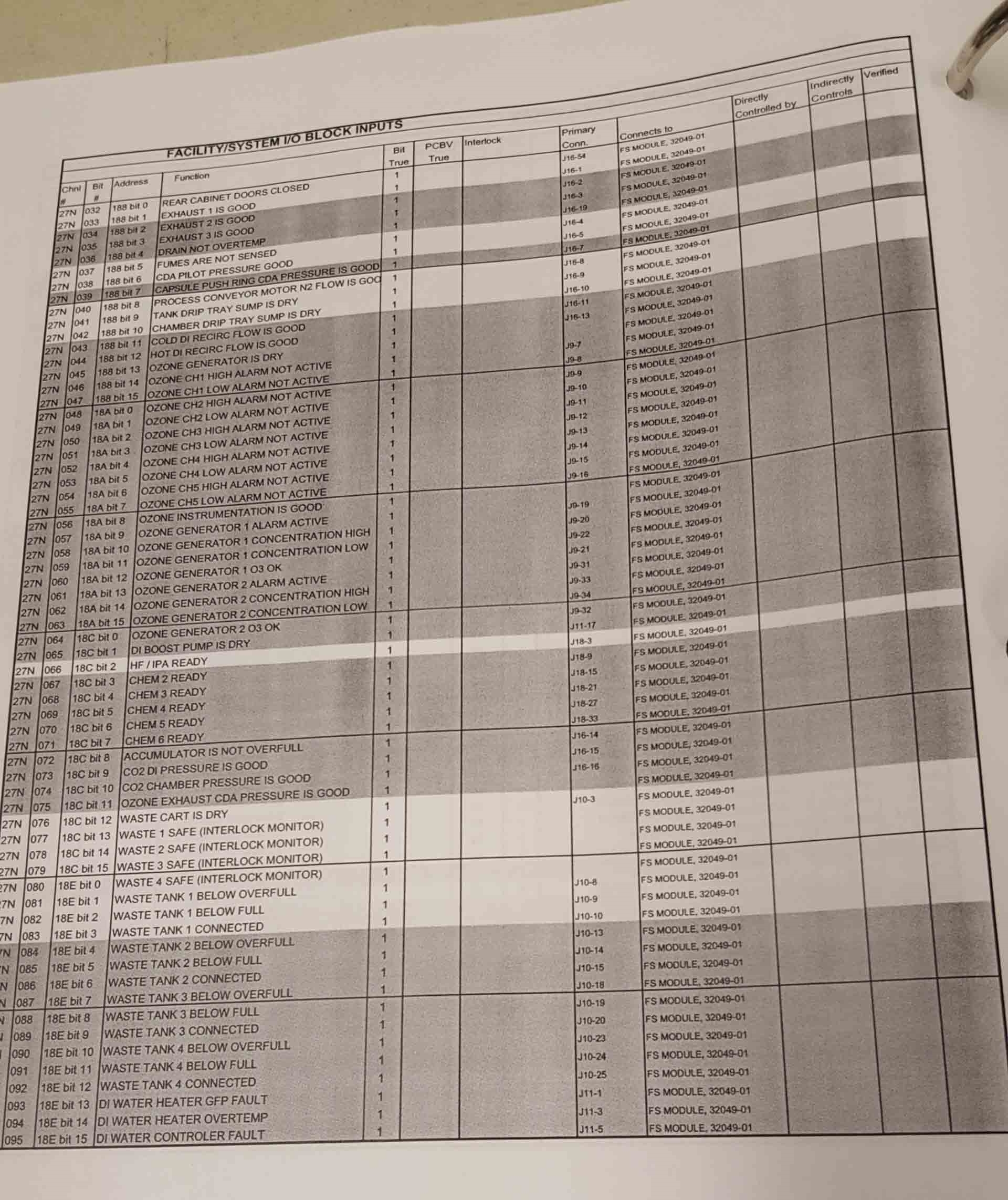

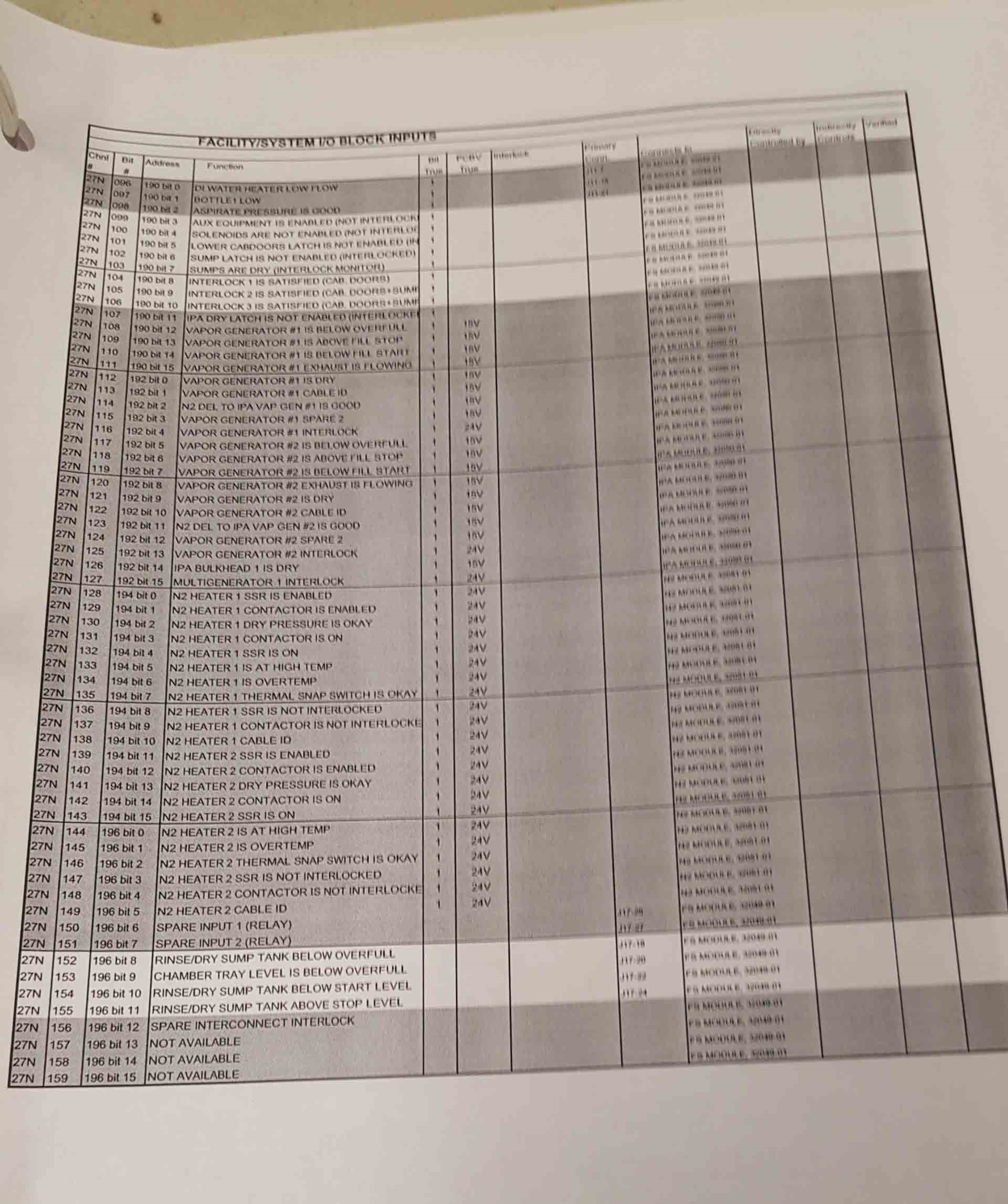

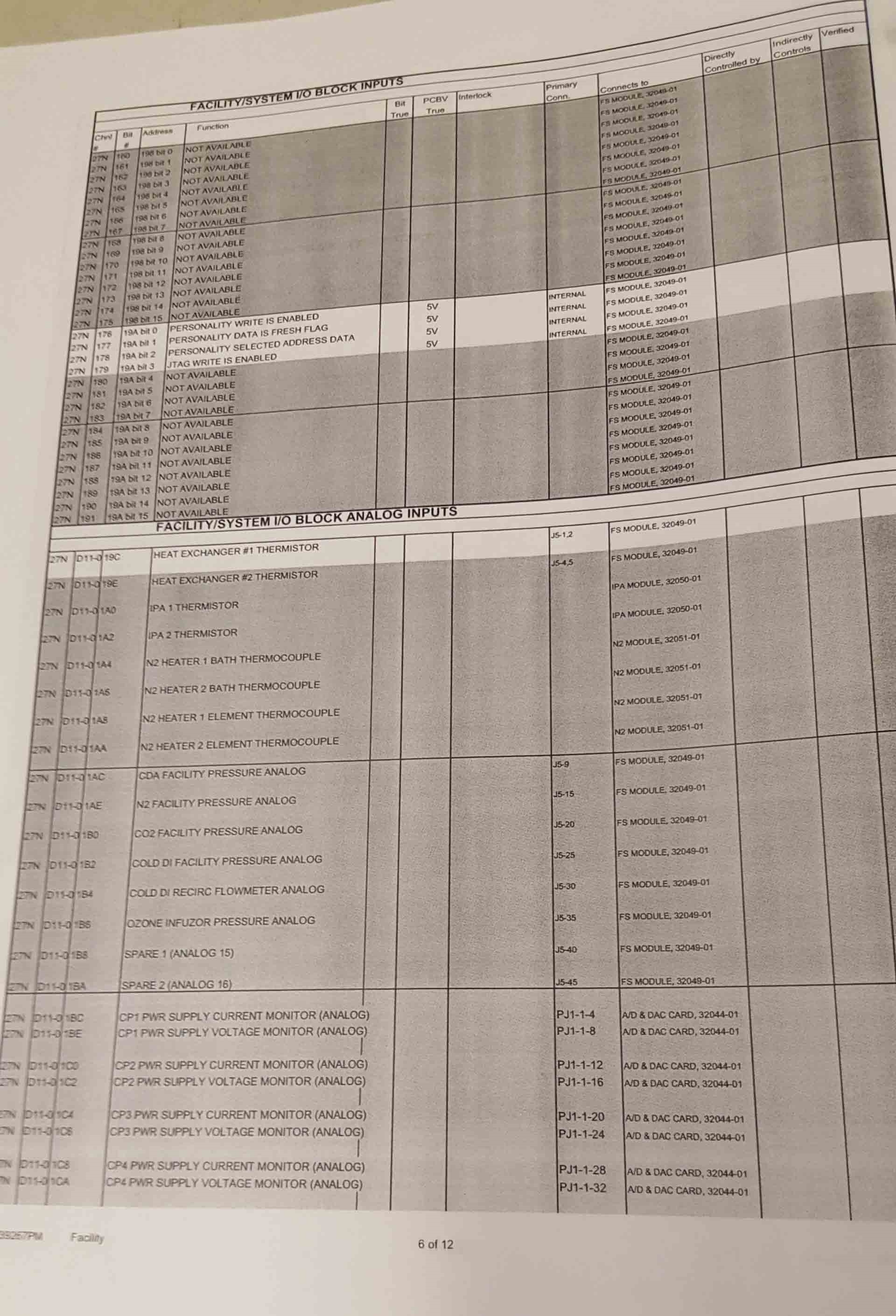

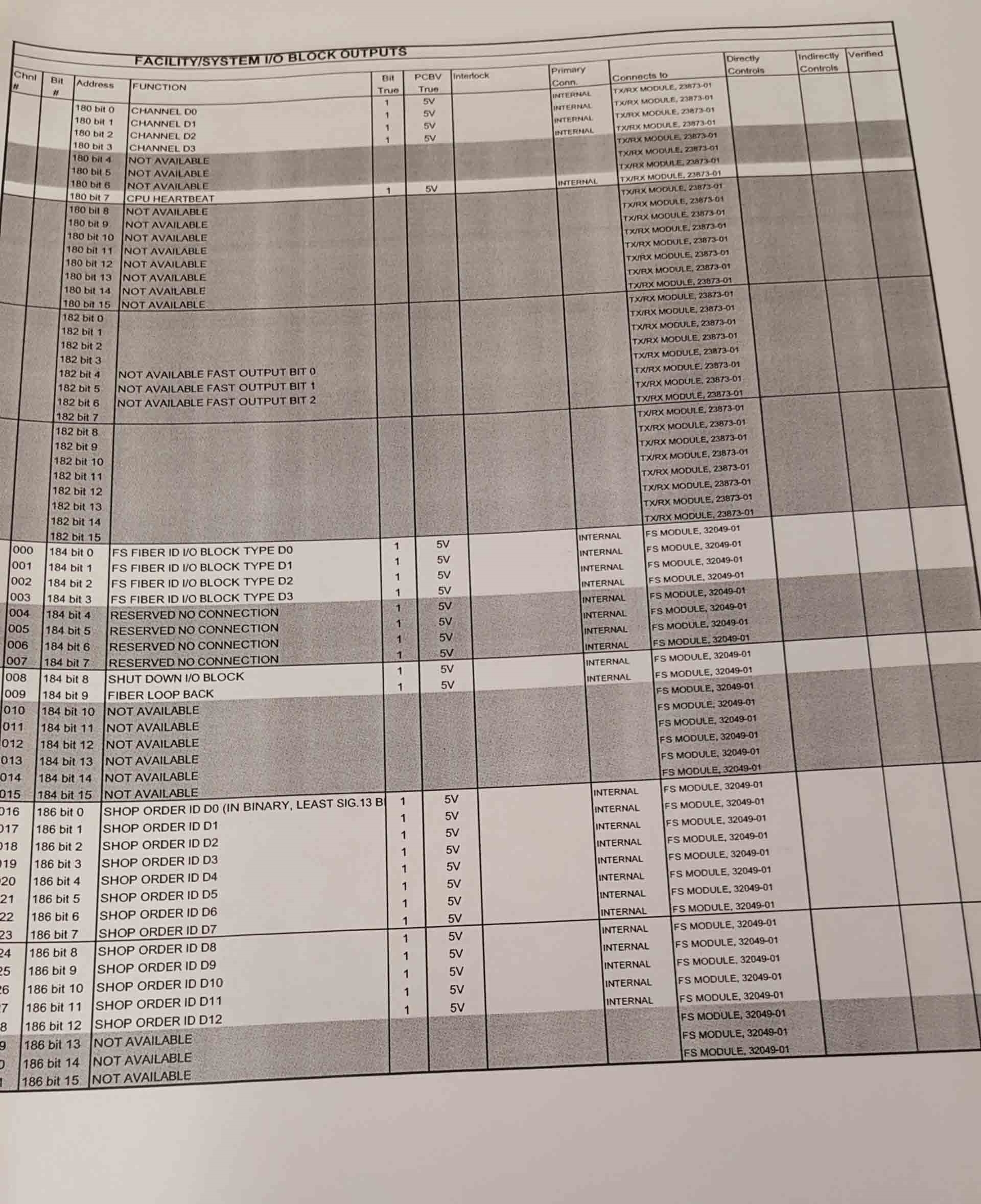

Manuals and schematics

2009 vintage.

SEMITOOL Alpha Raider is a photoresist processing equipment designed to meet the stringent requirements of the semiconductor industry. It is an advanced system designed for improved compatibility with new substrates, cleaning chemistries and resists. The unit is based on proprietary doping technology and is capable of working with a variety of photoresists. Alpha Raider utilizes an ambitious multi-step design, which includes various parameters such as film thickness, uniformity, surface quality and resist distribution that can be tuned to specific applications. It features a spin-coat machine for resist application which is coupled with a high-tech aspect scanner, allowing for the resist to be applied in a manner that achieves an even, uniform coating over the entire wafer surface. Substrate heating is quickly achieved with a fast delivery of hot, inert gas. The temperature can be tuned to match the application requirements. SEMITOOL Alpha Raider is also equipped with a unique dual spray nozzle for resist processing, which is capable of quickly producing a uniform exposure on the surface of the wafer. Alpha Raider also features an advanced rinse cycle which ensures the removal of any residual resist. The tool also features a unique combination of a high-speed electron beam and UV laser that is specifically designed for in situ patterning. This allows for the rapid diode patterning of individual substrates. Finally, SEMITOOL Alpha Raider features a sophisticated O2-plasma ashing asset which is used for precise pattern definition, allowing for superior device-to-device repeatability and superior yield. In conclusion, Alpha Raider is an advanced photoresist model that offers great control over a variety of parameters, allowing for precise patterning and device repeatability. Its advanced nozzle design, precise temperature control and high-speed processing allow for uniformity and improved yields, making it an ideal choice for semiconductor production.

There are no reviews yet