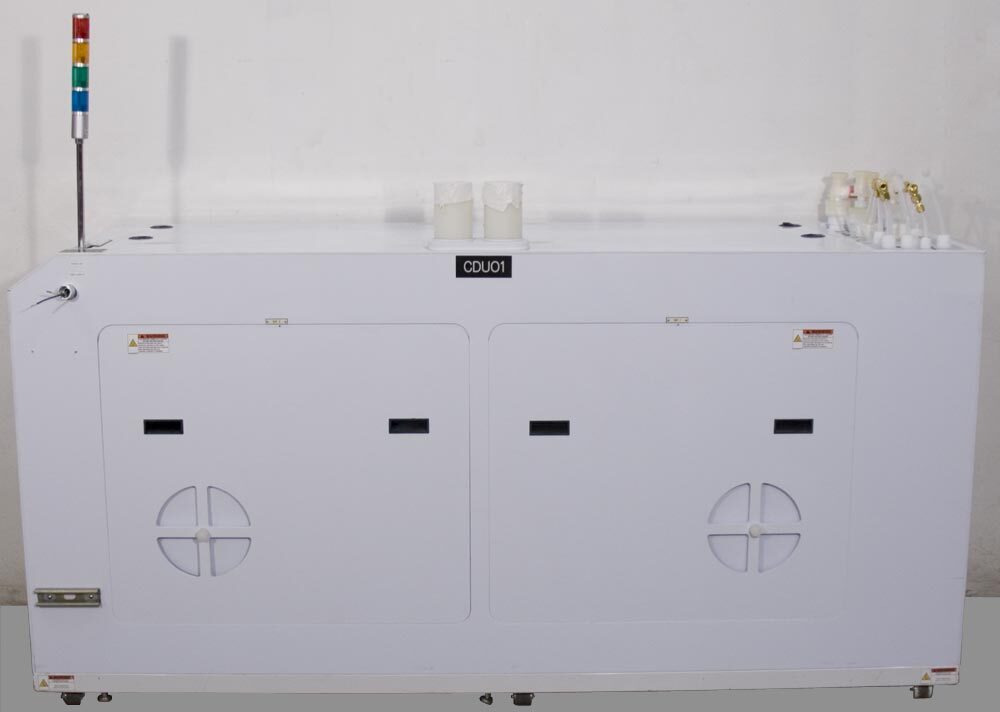

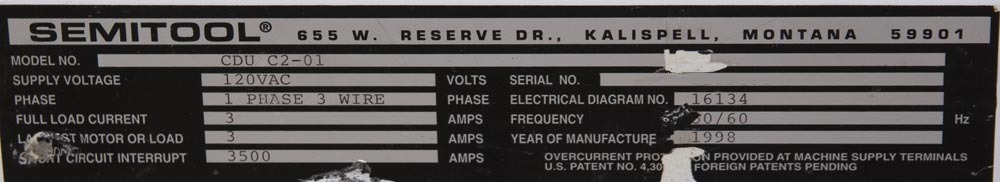

Used SEMITOOL CDU-C2-01 #9093501 for sale

URL successfully copied!

Tap to zoom

ID: 9093501

Vintage: 1998

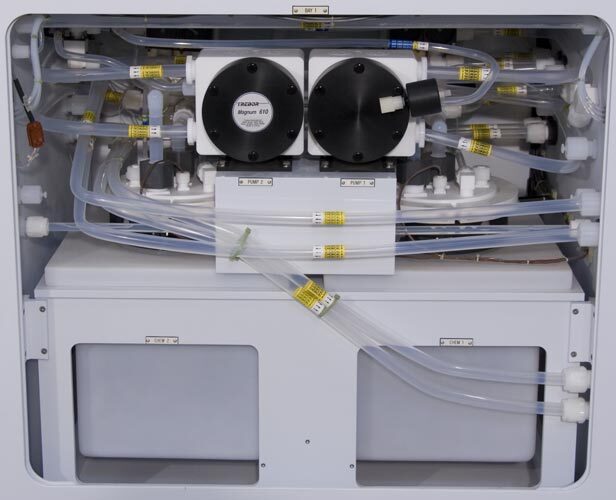

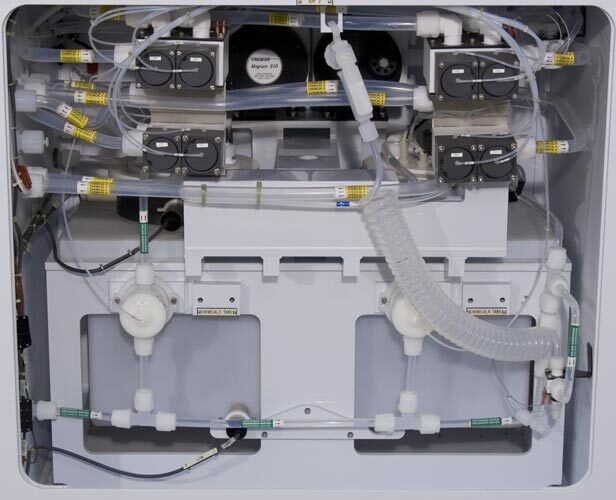

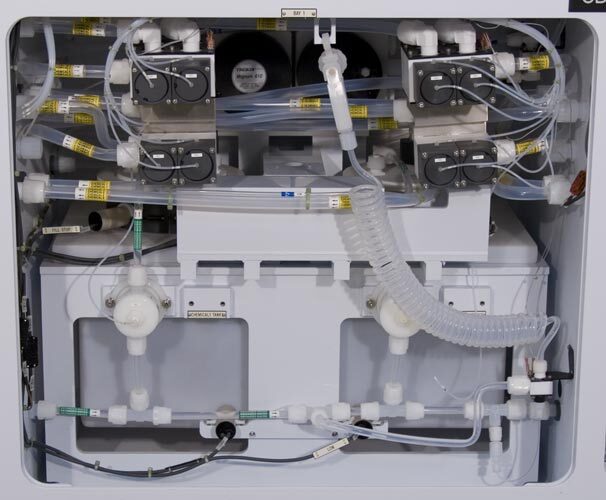

Chemical delivery unit

For spray acid tools (SAT Series)

Spray solvent tools (SST Series)

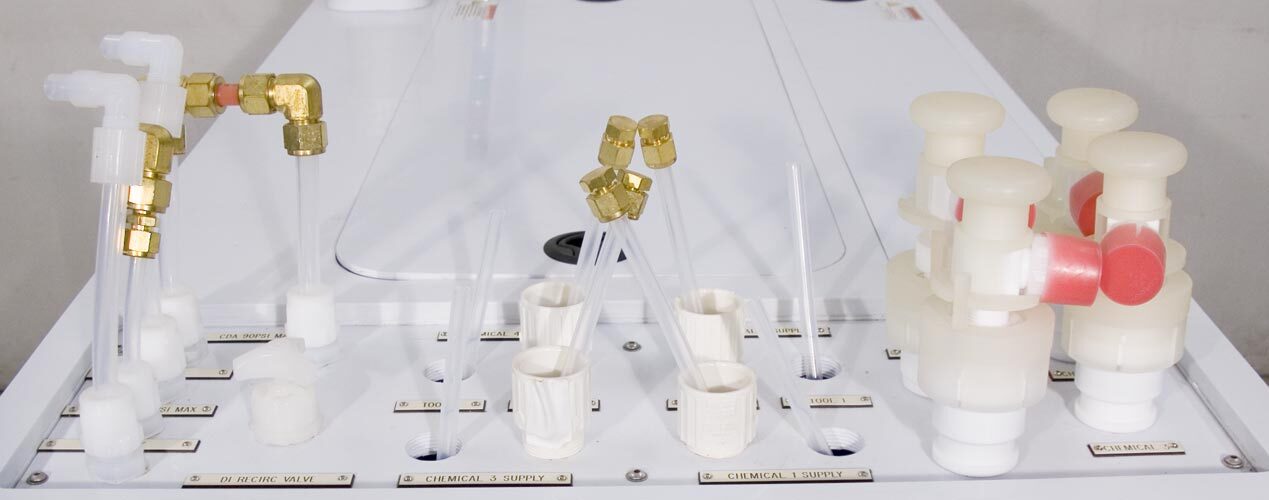

(4) Chemical tanks

(4) Separate chemicals

DI Water return

Supply connections

CDA (clean dry air)

Supply facility requirement: 90 PSI Max

N2 Supply facility requirement: 80 PSI Max

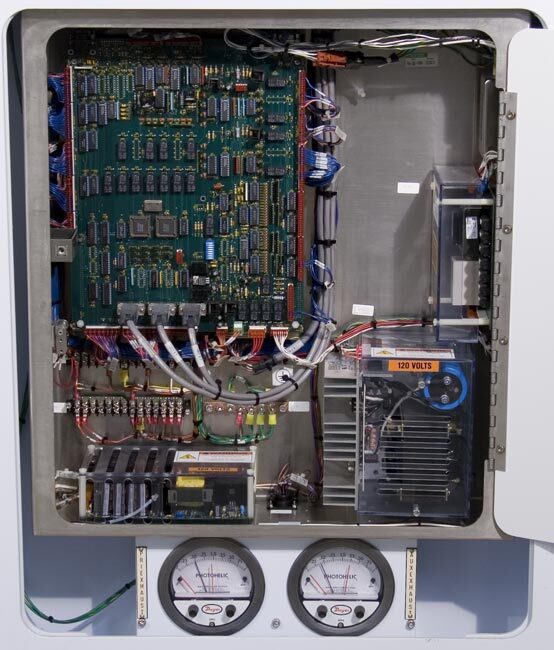

(6) Trebor magnum 610 diaphragm pumps installed:

Software version: CDU-402, 1.03

Full load current: 3A

Largest motor or load: 3 A

Short circuit interrupt: 3500 A

120 VAC, Single phase, 3-wire, 50 / 60 Hz

1998 vintage.

SEMITOOL CDU-C2-01 is a photoresist equipment designed to equip semiconductor manufacturing facilities with efficient and reliable photoresist processing. It utilizes a state-of-the-art combination of advanced mechanical and control engineering for superior photoresist processing. The system integrates a high-performance, large-capacity, vacuu-ised loadlock chamber with advanced scanning robot unit that provides full mobility from wafer loading/unloading to movement within the process modules. The automation combined with the chamber-cleaning capability, results in a gross to net throughput of up to 20 wafers per hour. The machine includes features such as a 21-inch wafer handling capability and a spin-rinse-dry process for fast and reliable processing. An additional feature is the optimized wetting of wafers through a reverse spin-auto-center cycle, achieved for the first time for photoresist processing. Additionally, an advanced self-diagnose tool is integrated to keep operations at peak performance. Furthermore, the self-contained nature of CDU-C2-01 also allows for a small asset footprint. This reduces the space occupied by the model compared to other production systems. In terms of safety and reliability, the equipment offers a safe and secure environment for multiple robots operating in parallel. This reduces risk and ensures system stability. All of these features combine to give SEMITOOL CDU-C2-01 unparalleled performance. It is ideal for reliable and cost-effective photoresist processing and can easily be integrated into any existing production line.

There are no reviews yet