Used SEMITOOL ECP LT210 CU #9038305 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9038305

Wafer Size: 8"

Vintage: 1999

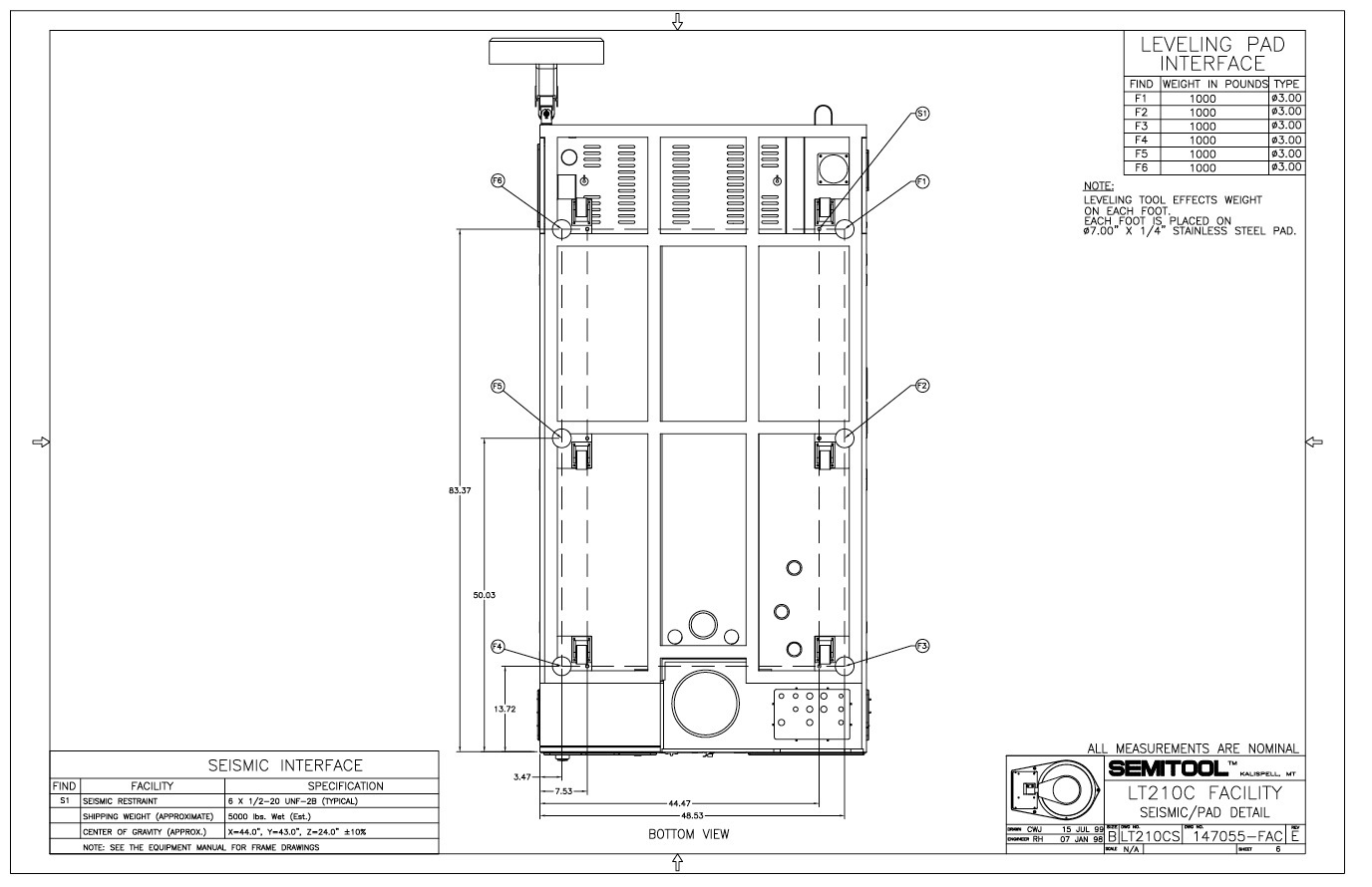

CMP - Cu plating system, 8"

(10) Chambers

Module: CMP/CU

SMIF interface: (2) Asyst indexers

Process application: copper plating

Copper process: yes

Batch/single wafer: single wafer

Electrochemical copper deposition in diluted CuSO4/H2SO4 solution with organic additives

Backside cleaning and bevel etching with diluted PIR-Solution

(6) Plating chambers

(4) Bevel etch capsules

External chemical Conc. Control by support tool

Capable of Pulse-Reverse-Plating and DC-Plating and Hot-Entry

ECD Chamber Retrofit: Wet contact rings and finger clean for ext. ring lifetime

Photometric insitu analysis: Cu and H2SO4

Robot Beam

Capsule Retrofit: fingerless rotors

Capsule Retrofit: one piece delivery manifold

Modified bowl return-flow for bubble suppression

M&W Systems chiller

Dynatronix Power Supply Upgrade

Capsules: adjustable flowmeters for chemical supply

UPS-Retrofit: Data Saving in case of power loss)

Plating rotors with extended wafer supporting posts

Currently crated

CE marked

1999 vintage.

SEMITOOL ECP LT210 CU is a next-generation photoresist equipment designed for wafer fabrication and photochemical processing. This device features a state-of-the-art design that enables efficient etching and photoresist coating processes. It is equipped with an LT210 CU etch chamber, which is a down-stream exposure tool, allowing the user to uniformly apply photoresist over the entire wafer with varying thicknesses. The LT210 CU etch chamber utilises a low-pressure, sealed chamber with a rotating disc, which maximises exposure and accelerates processing times. The system is equipped with an advanced exposure unit with indigo lamps that produces a high amount of radiant energy, ensuring a uniform exposure across the wafer surface. The exposure machine also includes dynamic focus capabilities, allowing for greater control over the exposure parameters, resulting in superior process control. Additionally, the exposure tool features a digital power supply with adjustable frequency, enabling precise control over the exposure process. The asset also features Smart Track Software, which allows the user to control and monitor process parameters, such as photosettings and radiation dosage, from a centralised computerized model. This software is also capable of monitoring and adjusting the power supply on-the-fly as well as providing detailed data on the process statistics. Furthermore, the equipment is equipped with two sets of programs for corresponding to both positive and negative photoresist processes. This enables users to not only coat the wafer with negative and positive photoresists, but also removes them with equal accuracy. The LT210 CU etch chamber also includes a high-precision temperature control system to ensure optimal processing temperatures. In conclusion, ECP LT210 CU photoresist unit is an advanced, versatile and user-friendly photoresist machine, which provides superior process control and excellent exposure results. It is suitable for a variety of photochemical processes, such as high cleaning and resists etching, providing a high-yield and cost-efficiency fabrication solution to its users.

There are no reviews yet