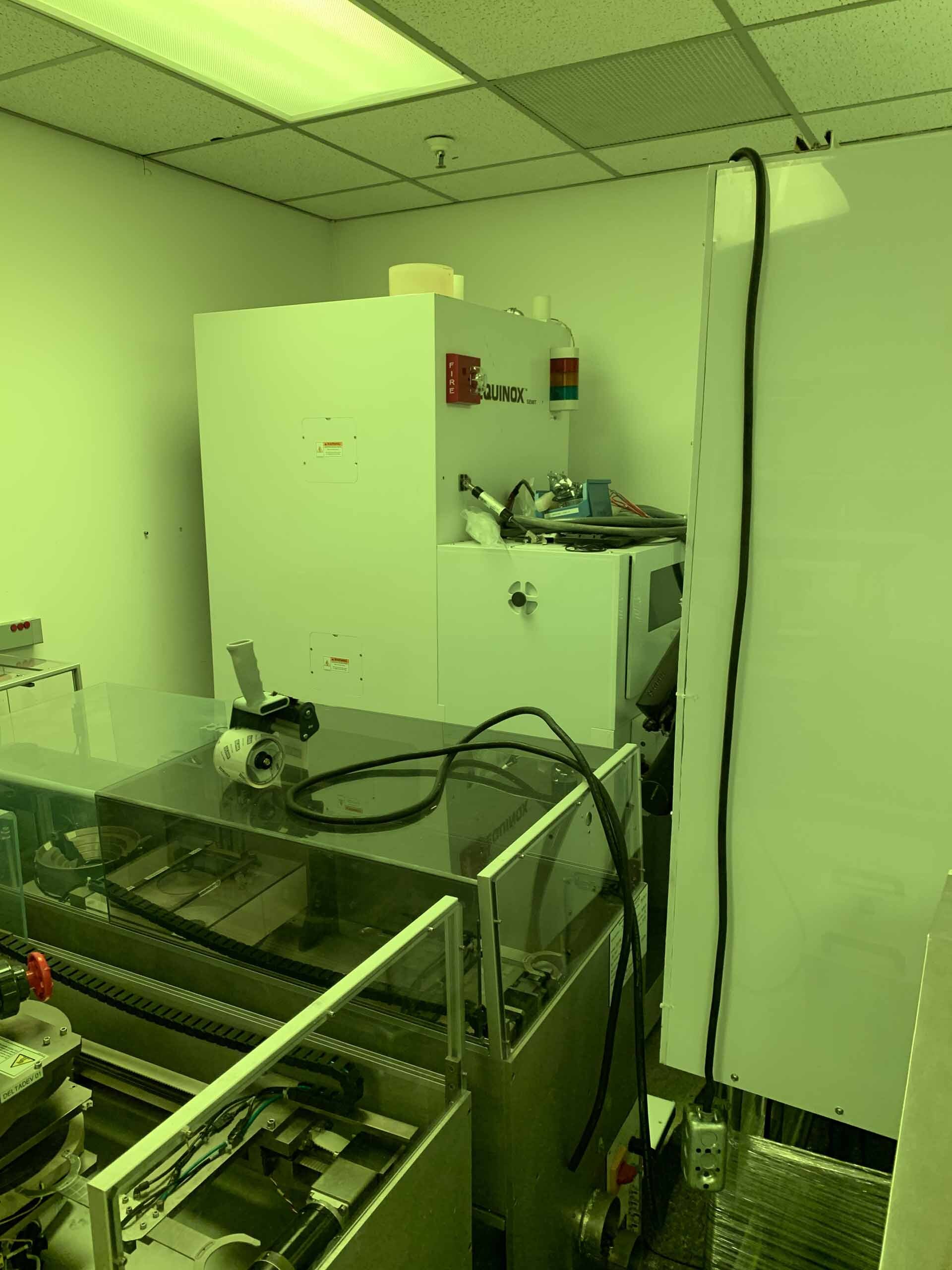

Used SEMITOOL Equinox #293648582 for sale

URL successfully copied!

Tap to zoom

ID: 293648582

Wafer Size: 6"

Vintage: 2010

Electroplating system, 6"

Non-functional

Single wafer process head design

Material: Ni sulfamate plating (tank 1) and gold sulfite (tank 2)

Gold sulfite is a non-cyanide solution

Fountain plater with (2) Separate plating bath tanks and (2) SRD Heads

(4) Heads

Input cassette on left nest

Output cassette on right nest

Robot connection, non-functional

Plating cell power supply

CP2 Head, non-functional

(2) SRD Chambers

(2) Plating chambers

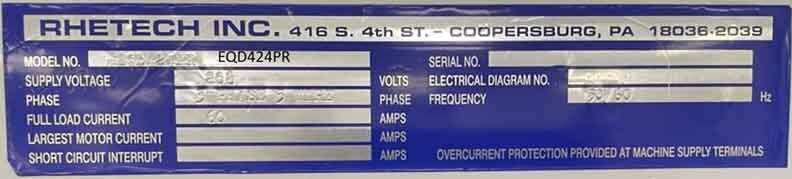

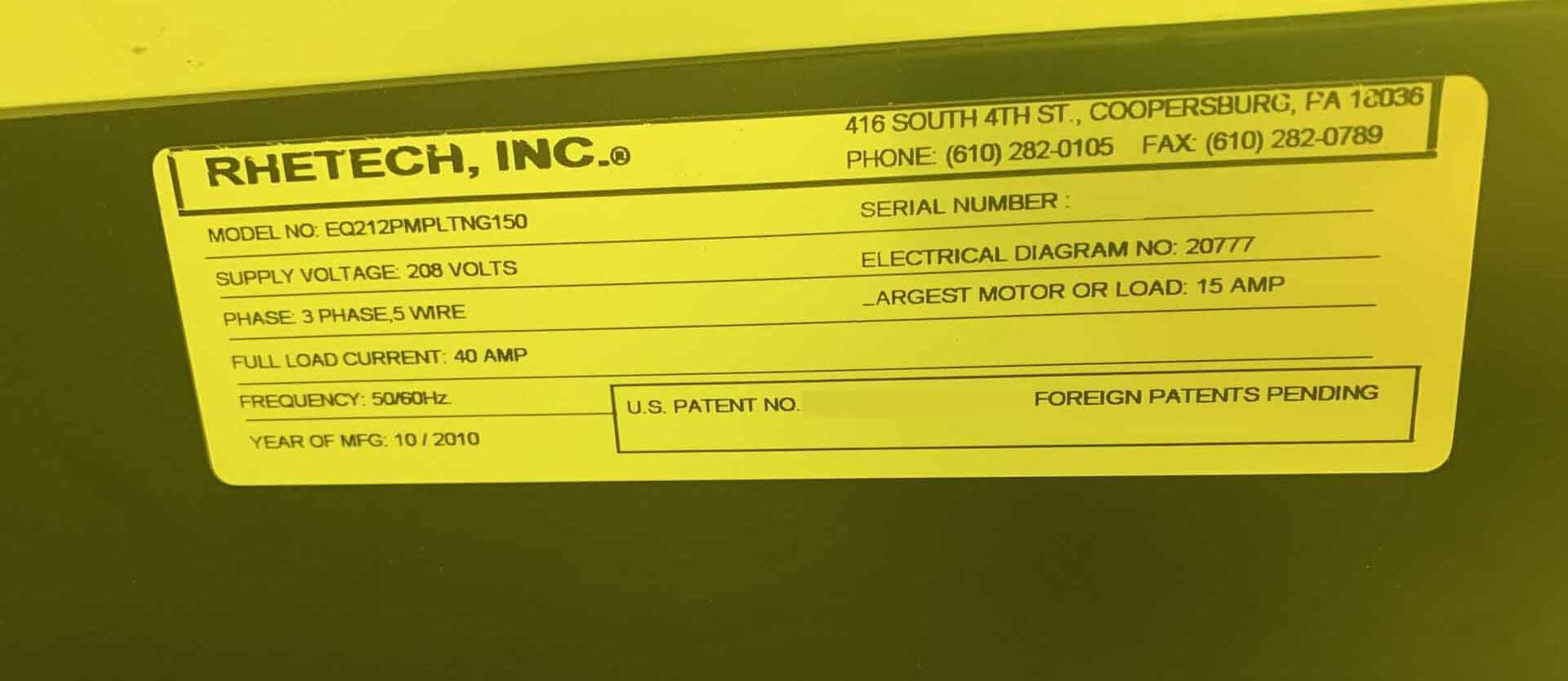

DYNATRONIX PMC 102/1PR-20-30XR Power supply (P/N: 990-0296-212)

Power supply: 208 V, 50/60 Hz, 40 A, 3 Phase

2010 vintage.

SEMITOOL Equinox is a photoresist equipment designed for semiconductor fabrication. Photoresist systems are used in semiconductor manufacturing to create layers of semiconductor materials on silicon wafers. Equinox system features automated processes that help speed up production and reduce the amount of human labor required. SEMITOOL Equinox is capable of processing four-inch or six-inch wafers at up to 300mm per hour. It features an open platform design, allowing users to quickly and easily integrate custom software algorithms into their processing control schemes. Its software options support advanced photolithographic tools and techniques such as step and repeat, image blurring, and advanced alignment. Equinox features a robust, two-lock wafer transfer unit. This provides precision alignment between the wafer and its associated mask. It also has a dual-stage spin chuck with integral centering capability for better wafer handling. SEMITOOL Equinox is also designed for reliability and robustness, with its frame constructed from heavy-duty aluminum and corrosion resistant components. The machine's software is designed to ensure accuracy and repeatability. It runs on a stable solid state operating platform, offering real-time process monitoring and analysis. The software also provides for up to five user based control schemes and also offers macro file generation and execution. Equinox's heater stages offer precision temperature control, ensuring quick and accurate pattern imaging. The tool also features an adjustable slit, allowing users to adjust their patterning. SEMITOOL Equinox supports standard pattern algorithms as well as custom scripts and provides the option of tailoring exposures to the customer's needs. The asset is also designed to provide maximum process control and uniformity. It offers a separate controller for each element of the process, allowing users to easily monitor and adjust all process parameters. Equinox also features an advanced caching model to minimize development times and improve tool utilization. In conclusion, SEMITOOL Equinox equipment is a reliable and compact photoresist system ideal for high-throughput semiconductor fabrication. Its automated processes, precision temperature control, robust wafer transfer unit and advanced patterning options make it an excellent choice for any chip fabrication needs.

There are no reviews yet