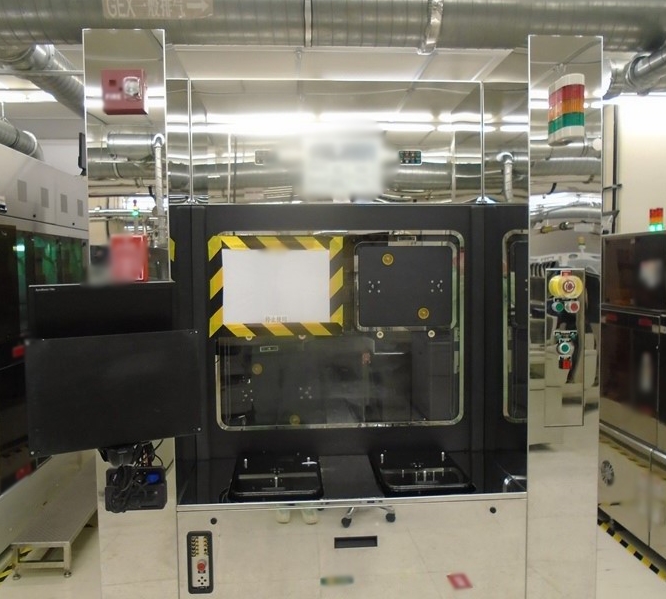

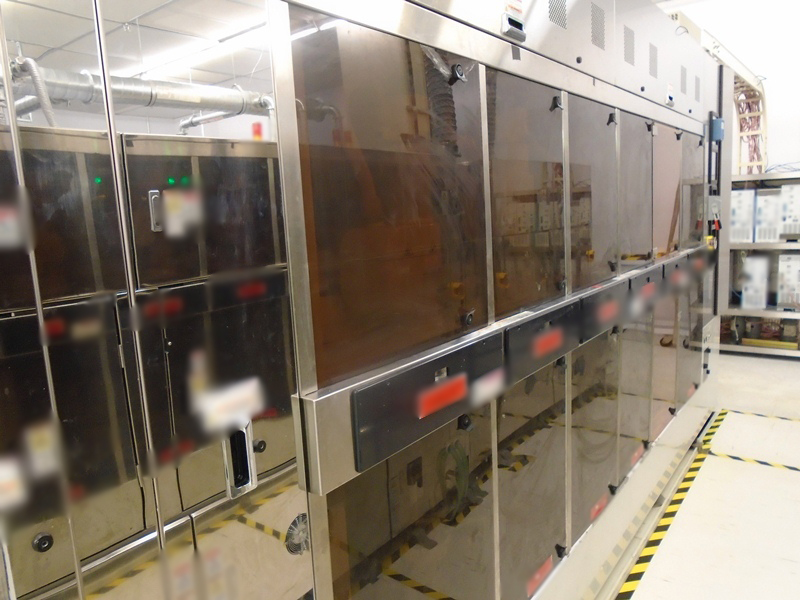

Used SEMITOOL Raider ECD 312 #9143778 for sale

URL successfully copied!

Tap to zoom

ID: 9143778

Wafer Size: 12"

Etcher, 12"

Configuration:

Ni

(3) SRD

(3) Lead free

(4) Cu

Missing parts:

CP1: Pressure sensor 310C0143-70, Pressure sensor 310C0142-70, 310T0045-01

CP2: Level sensor

CP3: Pump 70959-31P, anode set

CP5: Pump 70959-31P

CP6: Pump 70959-31P

CP8: Lift assy

CP9: Anode bowl, anode set, Pump 70959-31P

CP10: Pressure sensor 310C0143-70, valve 310T0045-01

CP12: Lift assy

Tank 3: Valve

Tank 4: Valve

(2) Drain connectors

(2) Pump connectors 206044-1 / 206039-1.

SEMITOOL Raider ECD 312 is a sophisticated, multi-functional photoresist processing equipment. This system mixes, disperses, and transports photoresist to a variety of substrates in a controlled environment. It provides advanced precision in aligning the photosensitive medium onto the substrate, ensuring that the optimal levels of resolution and uniformity are achieved during the resist lithography process. SEMITOOL RAIDER ECD-312 works in three basic stages. First, the photoresist material is received into the unit where it is electronically dispensed into the reservoir that stores and supplies the photoresist to the substrate. Second, this medium is precisely aligned and situated onto the substrate in an even and uniform layer. This is accomplished by adjustable conveyor, a wafer-leveling machine, and other automated controls. Lastly, the photoresist is simultaneously exposed to ultra-high-intensity light and extremely precise patterns that are obtained through a multi-axis scanner. This process enables even the smallest features of a component to be accurately imprinted onto the resist film. Raider ECD 312 also features a variety of user-friendly features, allowing complete control of the lithography process. This tool can be calibrated to adapt to a variety of different substrates, including glass, quartz, quartz-silicon substrates, thinned semiconductor wafers, and more. The LCD monitor displays real-time information during resist lithography, providing the operator with a comprehensive view of the photoresist pattern and results. This helps the operator easily identify any issues during the process and make the necessary adjustments if needed. The Eagle Point Software Suite, which is available with RAIDER ECD-312, makes process optimization a breeze. This package includes software for controlling and monitoring the resist coating homogeneity, creating customized photoresist patterns, manual loading and dispense calibration, and substrate inspection. As expected from such a technologically advanced asset, SEMITOOL Raider ECD 312 is entirely compatible with several standard computer languages, allowing it to be easily integrated into an existing automated manufacturing process. In conclusion, SEMITOOL RAIDER ECD-312 is a truly remarkable photoresist processing model. It offers unprecedented photoresist patterning accuracy and control, along with an array of user-friendly features that simplify resist lithography optimization. This equipment is an invaluable asset for any technician, engineer, or scientist seeking to produce the highest-quality components for their projects.

There are no reviews yet