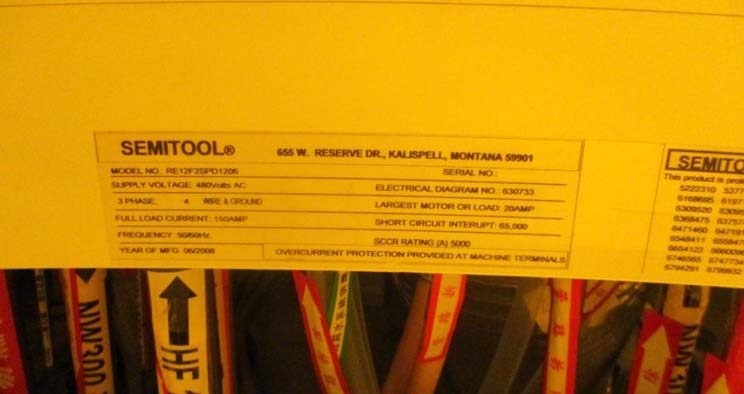

Used SEMITOOL Raider #293600285 for sale

URL successfully copied!

Tap to zoom

ID: 293600285

Wafer Size: 12"

Vintage: 2008

Systems, 12"

(8) Chambers

Substrate: Si, 12"

Chiller

DHF Mix tank

CO2 Bottle

S2 Computer

502SE Controller

Remote PPS

MARATHON Standard

Automation:

Type: (2) FOUP WIP (PGV compatible)

COAXIAL HT Robot

STI Robot controller

End effect controller:

Edge grip

Wet transfer edge grip

FOUP ID: ASYST, P/N: 9750-2000-000

HERMOS RF Tag reader

Vacuum source

Wafer protrusion sensor

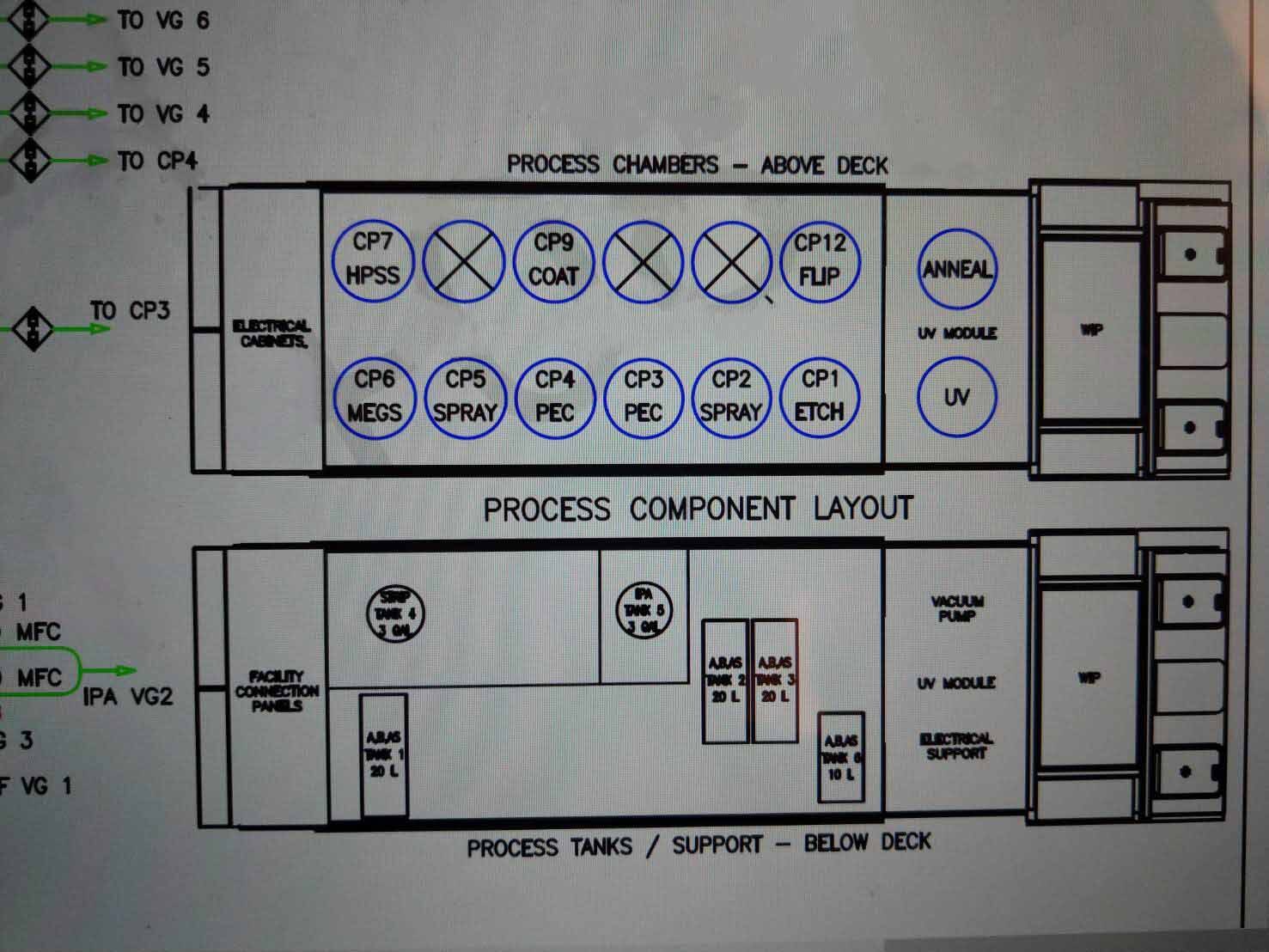

Process module:

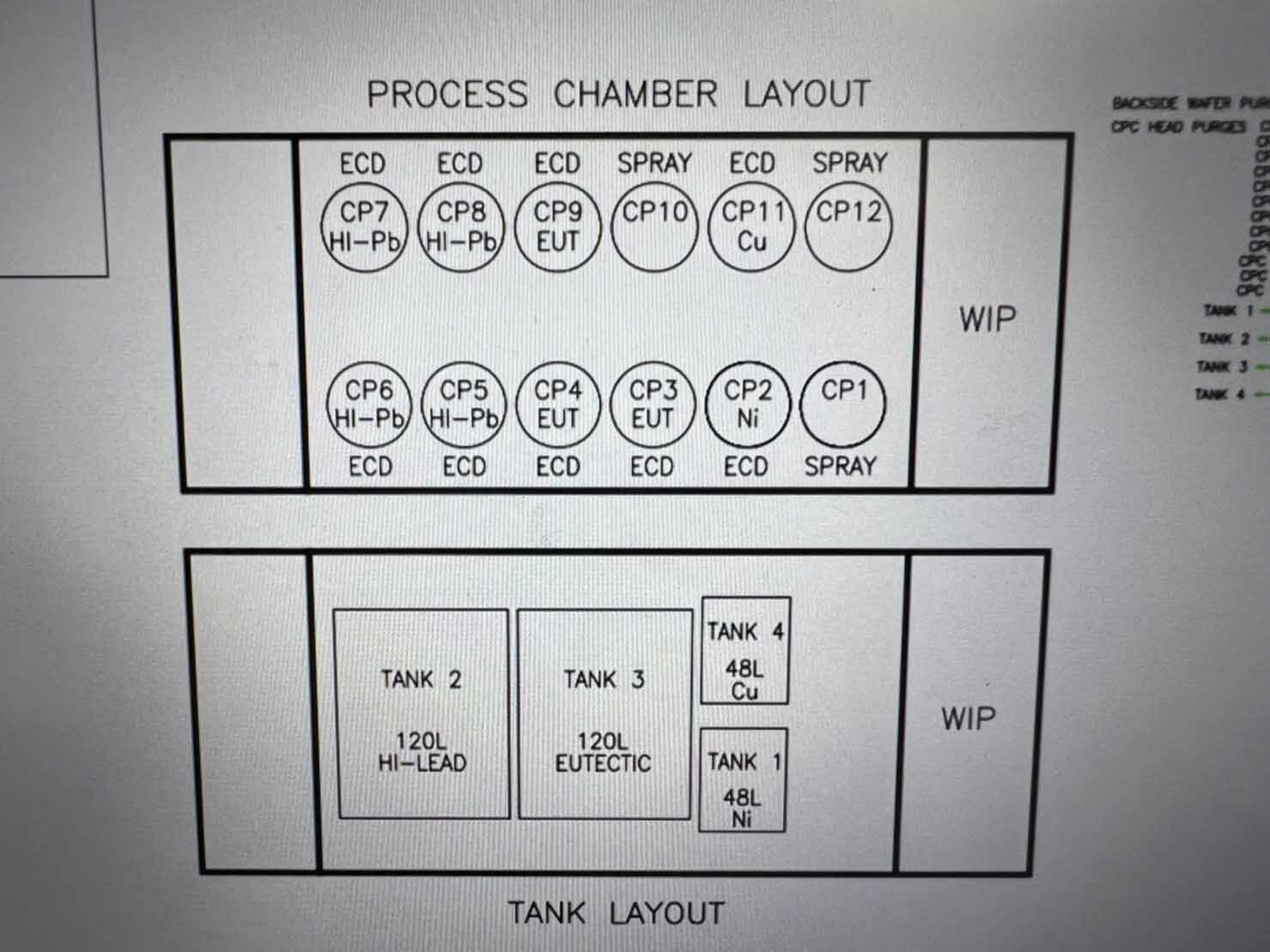

CPC 1, 10, 12

Process: SRD / Prewet

PTFE Spray chamber P/N: 271T0020-03

Rotor: Cantilever, N2 Wafer purge

Bulk fill supply with filter, 5"

IW Drain

Spray bar nozzel, P/N: 341 T0011-05

CPC 2

Process: Ni plating

Chamber, P/N: 271T0130-01 CFD III

Ring, P/N: 213T1055-501

Anode, P/N: 110T0198-01, 111T0000-10

Plating PS, P/N: T16852-118

Wafer present sensor

Mercury contact

Wafer extraction (mechanical)

Flow meter on chemical line

Shield / Weir, P/N: 111T1204-511

CPC 3, 4, 9

Process: Solder plating (eutectic)

Chamber, P/N: 271T0130-01 CFD III

Ring, P/N: 213T1055-501

Plating PS, P/N: T16852-118

Wafer present sensor

Mercury contact

CPC 5, 6, 7, 8

Process: Solder plating (high lead)

Chamber, P/N: 271T0130-01 CFD III

Ring, P/N: 213T1055-501

Plating PS, P/N: T16852-118

Wafer present sensor

Mercury contact

Wafer extraction

Flow meter on chemical line

Shield / Weir, P/N: 111T1204-511

CPC 11

Process: Cu Plating

Chamber, P/N: 271T0130-01 CFD III

Ring, P/N: 213T1055-501

Anode, P/N: 111T1197-01

Plating PS, P/N: T16852-118

Wafer present sensor

Mercury contact

Wafer extraction

Flow meter on chemical line

Shield / Weir, P/N: 111T1204-511

Capacity: 48 L

Style: Unsealed NPP

Heat exchange coils

Temperature: 50-55°C

Filter, 10"

Sensor: (5) Floats

LEVITRONIX BPS 3 Pump

WK AP50 Pump

Supply: ARU / CDU / Bulk fill / Manual fill tube

Sample Port

CPC 2

Ni Plating solution

Carbon polishing filter

Conditioning electrodes

pH Monitor

Sight tube

Power supply

Tank 2: High lead solder

Capacity: 120 L

Style: Unsealed NPP

Heat exchange coils

Temperature: 25-35°C

Filter, 10"

Sensor: (5) Floats

LEVITRONIX BPS 3 Pump

WK AP50 Pump

Supply: Bulk fill / CDU / Manual fill tube

Sample Port

CPC 5, 6, 7, 8

Chemical: High lead plating Solution

Sight tube

Tank 3: Eutectic solder

Capacity: 120 L

Style: Unsealed NPP

Heat exchange coils

Temperature: 25-35°C

Filter, 10"

Sensor: (5) Floats

LEVITRONIX BPS 3 Pump

WK AP50 Pump

Supply: Bulk fill / CDU / Manual fill tube

Sample port

CPC 3, 4, 9

Chemical: Eutectic plating solution

Sight tube

Tank 4: Cu

Capacity: 48 L

Style: Unsealed NPP

Heat exchange coils

Temperature: 25°C

Filter, 10"

Sensor: (5) Floats

LEVITRONIX BPS 3 Pump

WK AP50 Pump

Supply: ARU / CDU / Bulk fill / Manual fill tube

Sample port

CPC 11

Cu Plating solution

Sight tube

Drains:

IW

Eutectic

Hi lead

Ni

Cu

Process:

Cu

Ni

Eutectic

High lead plating

Options:

(3) Heater chillers

AARU

Dl Booster pump cabinet and Interface

Power supply: 480 V, 4 Wire, 3 Phase

2008 vintage.

SEMITOOL Raider is a photoresist equipment launched in 2001 by semiconductor equipment manufacturer SEMITOOL. The system uses a spray-on coating to deposit a layer of photoresist on semiconductor wafers for subsequent patterning processes. Raider features features several computer-controlled components, including a load lock transporters, a spray arm and a particle control unit. SEMITOOL Raider processes up to 50 wafers per hour and produces uniform resist profiles across the entire wafer surface. It unloads wafers from a cassette, transports them to the spray arm, deposits the resist layer and transports them to an external conveyor. The spray arm is capable of applying thin (100-200nm) layers of SU-8 resist. The particle control unit ensures that the particles don't contaminate the photoresist and ensures uniform coating of the resist. It monitors the oxygen concentration, humidity, temperature and pressure in the spray chamber, as well as monitors the concentration of particles in the environment. Raider also has an autofocus unit which allows it to maintain constant focus on the entire wafer surface. SEMITOOL Raider has numerous safety features which protect against external factors such as static electricity build up and exhaust gas. Each of its systems can be individually calibrated for maximum precision and the spray arm is fully motorized for maximum control and accuracy. Raider is a modular machine, capable of upgrading its electronics and components with time. It has been designed in a manner that enables it to process wafers with diameters ranging from 1 to 12 inches. SEMITOOL Raider is a dependable tool of choice for photoresist applications in the semiconductor industry. It is low maintenance and can process large batches of wafers routinely without requiring an inordinate amount of supervision. It produces thin, uniform resist layers and ensures that the environment remains clean and particle free. Raider has been built with user safety in mind and its various safety features ensure that operators remain safe at all times.

There are no reviews yet