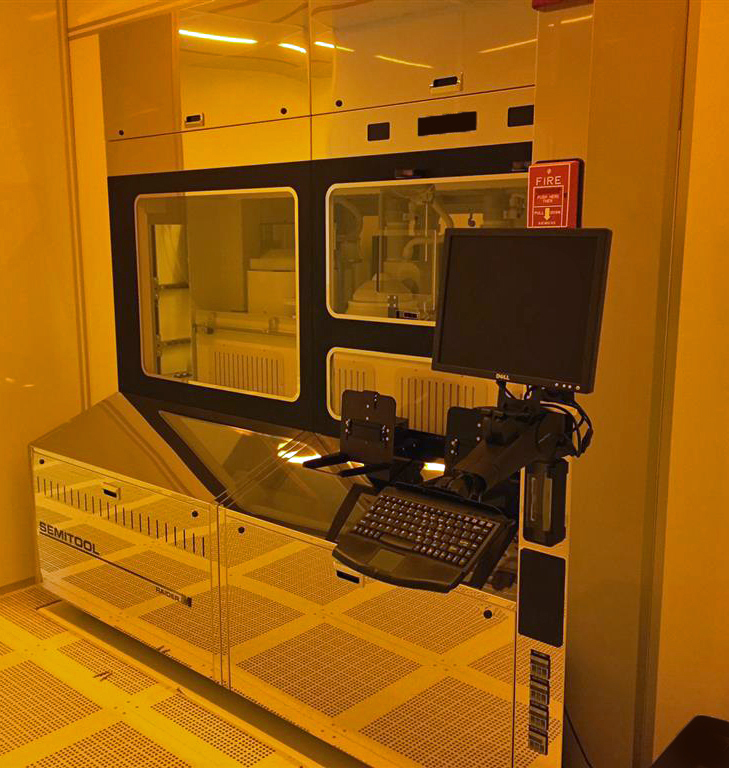

Used SEMITOOL Raider #9029095 for sale

URL successfully copied!

Tap to zoom

ID: 9029095

Wafer Size: 8"

Vintage: 2006

Plating system, 8"

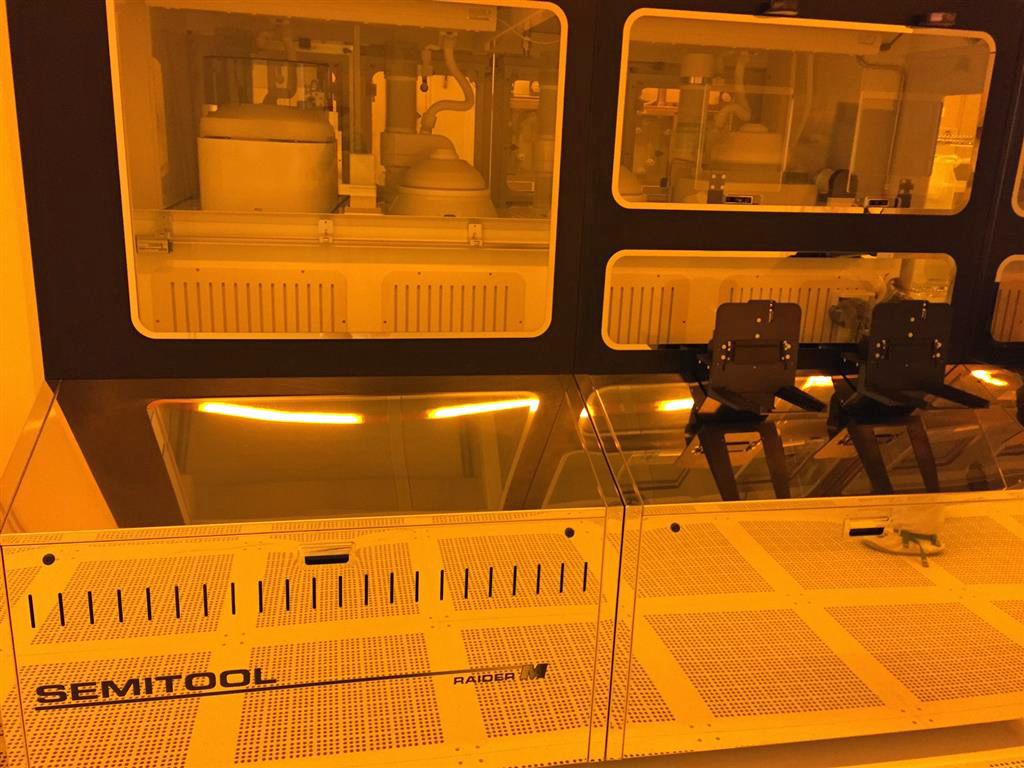

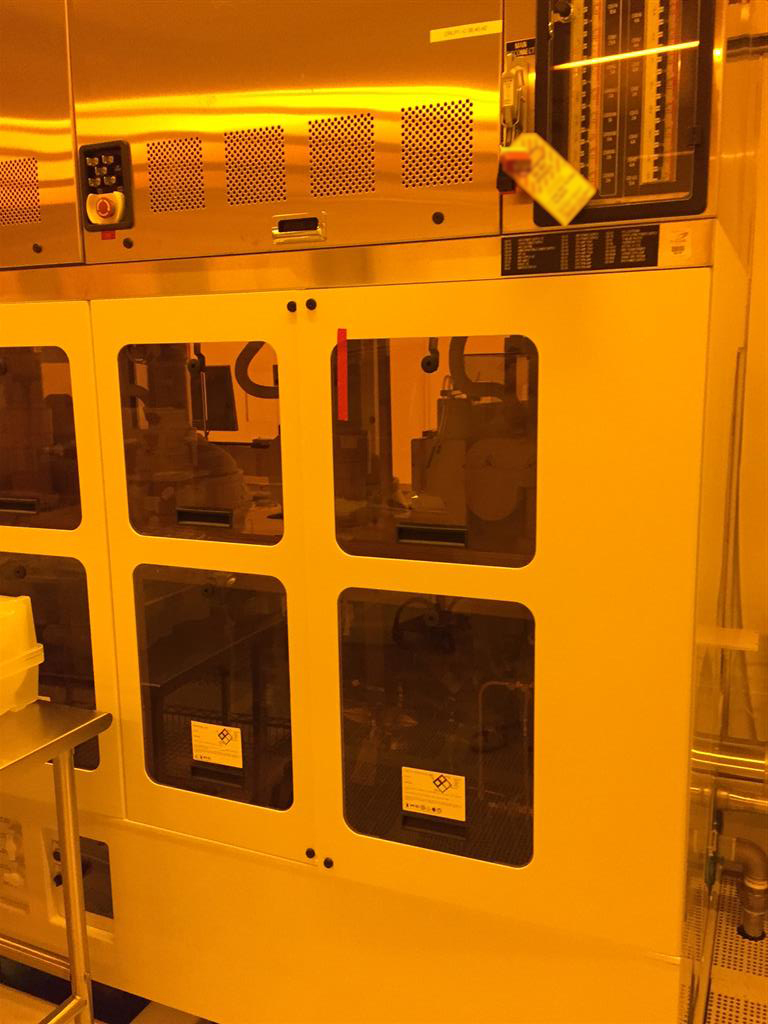

(4) Chambers

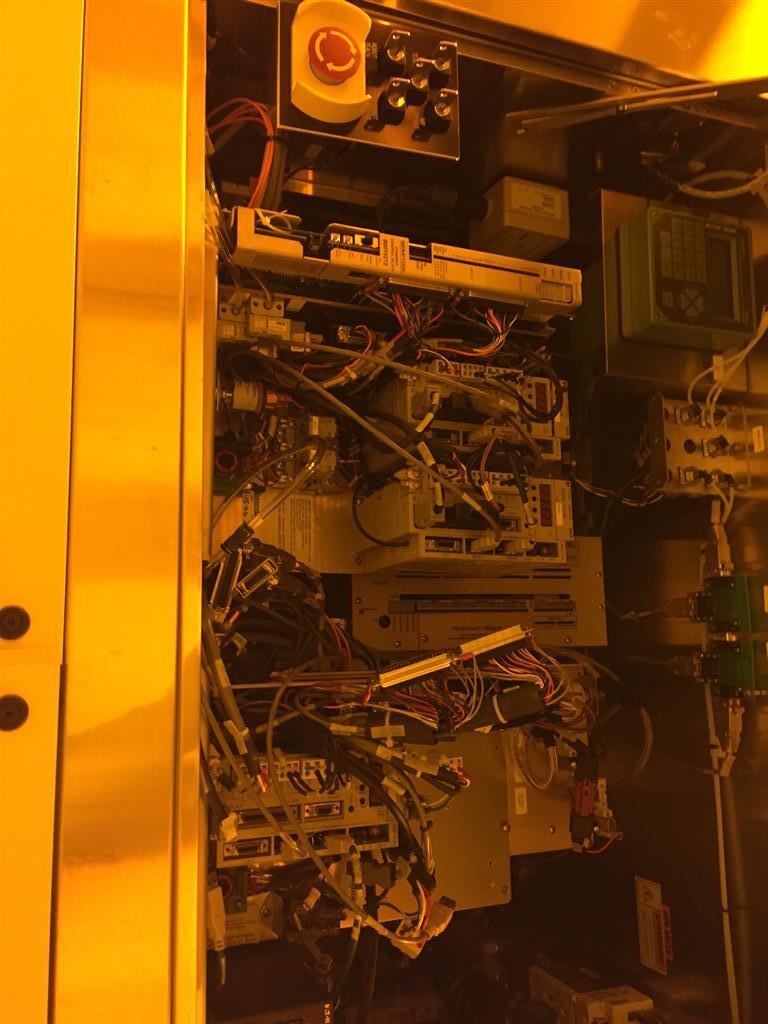

Missing parts

Currently installed in a cleanroom

2006 vintage.

SEMITOOL Raider is a photoresist equipment that is used in the semiconductor industry for processing wafers. The system is used for coating, stripping, and ashing photoresist from semiconductor wafers. The unit is designed to provide consistent and repeatable processing times, uniformity across wafers, and improved yields. Raider offers a range of features to accommodate the needs of different applications. The machine can be configured for manual or fully automated operations, and can be tailored to meet specific applications. It also provides a range of safety features, including double-sealed doors, a built-in emergency stop button, a PLC-based safety tool, splash guards to protect operators, and an electro-statically compliant enclosure. The asset includes multiple processing chambers, including a pre-cleaning chamber, an exposure chamber, a conveying chamber, and a post-exposure chamber. The model's pre-cleaning chamber is used to clean the substrate, while the exposure chamber is used to expose the substrate to product-specific UV radiation. The conveying chamber is where wafers are moved from one chamber to another. Lastly, the post-exposure chamber is used to remove any residual photoresist after exposure. The equipment features an integrated robotic arm that allows for simplified wafer handling and improved wafer throughput. The arm can be programmed to move wafers automatically from the begin chamber to the end chamber, as well as to rotate wafers before and after processing. The robot arm is capable of being programmed to move up to three wafers at a time at speeds up to 10 cm/s. SEMITOOL Raider is designed to handle a variety of photoresist materials, including standard aqueous and non-aqueous solutions. The system can also be configured to handle multiple materials simultaneously, which allows for increased efficiency. Additionally, the unit can be programmed to process different types of wafers at different times. The machine is also designed with an advanced control tool that allows users to monitor and adjust the processing parameters, as well as set calibration curves and timing parameters. This ensures the asset is producing wafers to the highest level of performance. The model is also designed with multiple safety features to ensure the safety of operators. This includes safety shutoff valves that can quickly stop the material delivery when a problem arises, as well as an emergency stop switch that can be used to immediately stop the equipment if an operator needs to exit the room. Overall, Raider is a reliable and efficient system designed to satisfy the needs of the semiconductor industry. The unit offers quick and precise processing times, improved yields, and user-friendly operation. It is a great option for companies looking to improve their photoresist processing capabilities.

There are no reviews yet