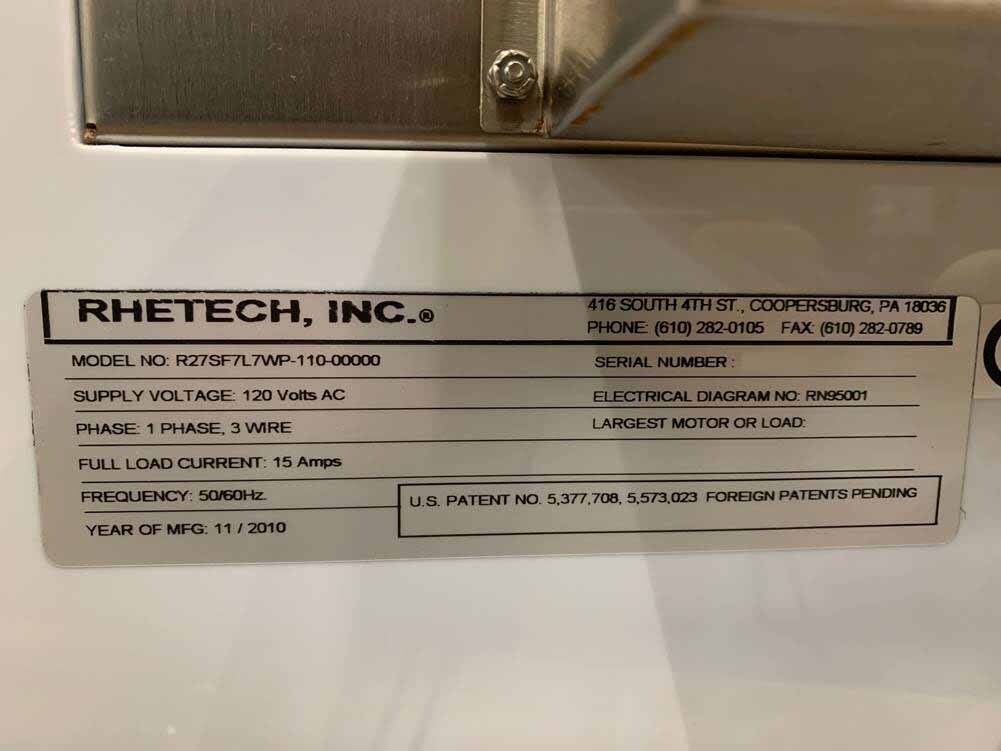

Used SEMITOOL / RHETECH ST 270 #293594925 for sale

URL successfully copied!

Tap to zoom

ID: 293594925

Vintage: 2010

Spin Rinse Dryer (SRD)

Wafer cassette, 6"

A182-60MB-0215 Teflon carrier, 6" (25-Slots)

PSC-107 Controller

Table included

2010 vintage.

SEMITOOL / RHETECH ST 270 is a vital tool for the substrate processing industry. It is a photoresist equipment that is used to create patterned layers on semiconductor wafers and other substrates for applications like microelectronic components and the production of microfluidic devices. It has three basic components: A pellicle, a chrome or light sensitive film, and a controller unit. The pellicle serves as a window for irradiating the substrate with light and contains an aperture that is used to limit the light intensity. The chrome or light sensitive film is a photosensitive material that is spun-on to the substrate. When exposed to light, the photosensitive material reacts and changes its chemical formation to form a desired pattern. The controller allows for the fine-tuning of the irradiation parameters. RHETECH ST 270 photoresist system has several features designed to enhance process control. It can be operated in a non-destructive mode, allowing multiple exposures and the testing of the substrate while it continues to be processed. In addition, a wafer stage recognition unit is included to maximize process accuracy. The machine allows for accurate alignment of the irradiated area to the substrate for achieving complex patterns that are necessary for device production. Its high resolution dynamic scanning capability allows for smaller feature sizes and finer patterning accuracy. Additionally, the high speed scanning capability of the tool allows for shorter process cycle times. SEMITOOL ST 270 also offers optional optical filters and pattern recognition software as part of its remote control interface. This allows users to refine the asset's exposure parameters and adjust its parameters to optimize the process. It also features an in-situ cleaning option that is performed before the re-exposure of the substrate. The in-situ cleaning process significantly reduces defectivity on the substrate. Overall, ST 270 photoresist model is the ideal solution for creating intricate patterns with fast throughput and high reproducibility. It has a variety of advanced features that allows users to optimize the process for their specific application. Its optical filters, remote control interface, and in-situ cleaning option provide users with the process flexibility and robustness needed for high-precision applications.

There are no reviews yet