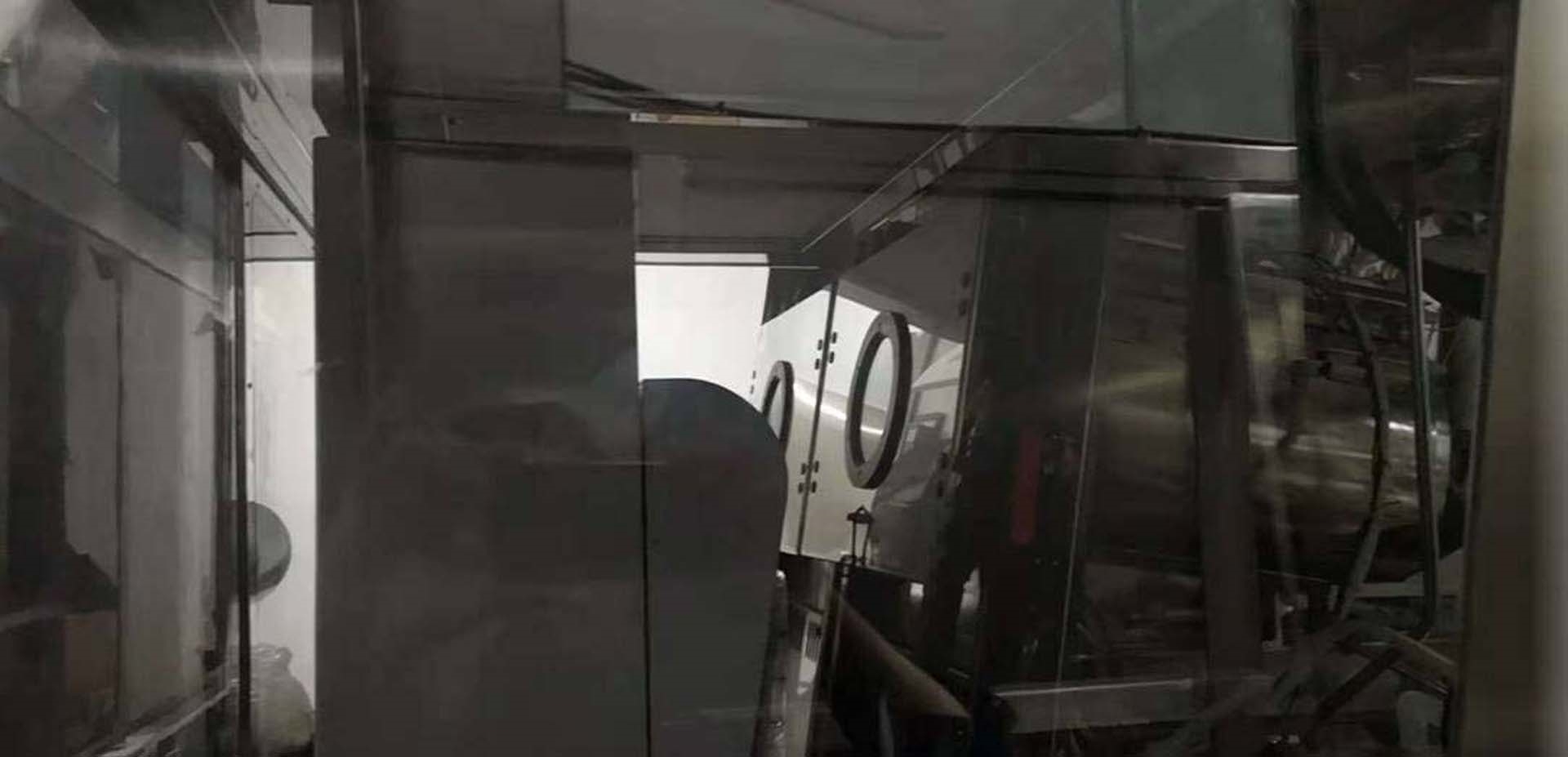

Used SEMITOOL Spectrum #9232917 for sale

URL successfully copied!

Tap to zoom

SEMITOOL Spectrum is a photoresist equipment that enables users to quickly and accurately pattern various photoresist materials. It consists of a host of components, each with distinct functions, that allow the efficient batch processing of wafers. Spectrum boasts a full suite of features, including a larger process chamber for increased throughput and gas dispersion, an improved low temperature photoresist compatibility for higher quality patterning, and enhanced control of both development and deposit uniformity. The process starts with a pretreatment module; this is where the wafers are cleaned and pre-treated. Then they are coated with photoresist. Next, they travel to the exposure module. Here, the wafers are exposed to a programmed, patterned light source. Following exposure, the wafers are transferred to the developer module. This is where the exposed photoresist is chemically developed, allowing light reactive chemicals to harden or dissolve depending on their type. After developing the photoresist, the wafers are transferred to the plasma etching module. Using a plasma, the etching module evaporates away material from the wafer surface. This results in a patterned photoresist layer. Finally, the module contains a dry-etch module, which uses a combination of gas, ionized particles, and electric voltage to remove any unwanted photoresist residue. SEMITOOL Spectrum is capable of accommodating various types and dimensions of substrates and photomask materials. The system is equipped with the ultra-precise Leica™ technology for mask alignment and accurate exposure of multiple images across a wafer. Furthermore, the unit offers uniform substrate and photoresist handling, quick wafer-to- substrate loading, as well as low substrate handling angle and vacuum clamping technology. This photoresist machine is also highly programmable and customizable. Users can choose the sequence of steps performed, the rate of speed, the temperature range and pressure levels, as well as other details. All of these features make Spectrum an excellent choice for high-volume, precision photoresist processing.

There are no reviews yet