Used SEMITOOL SPS-2000 #9284262 for sale

URL successfully copied!

Tap to zoom

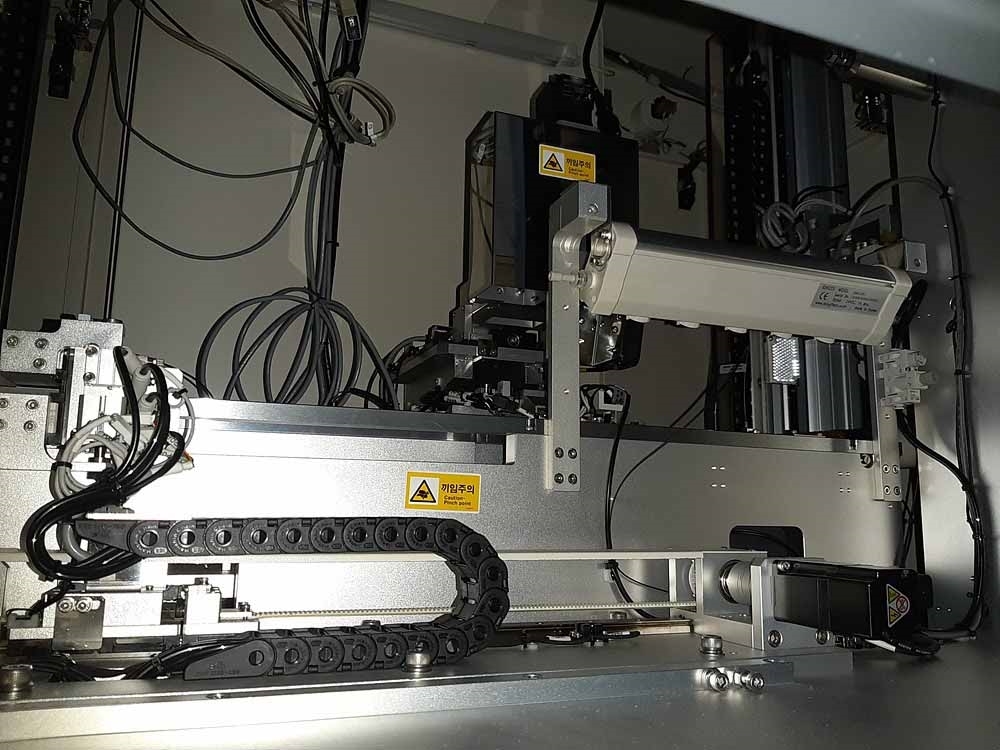

SEMITOOL SPS-2000 is an advanced photoresist equipment designed for wafer conditioning, dry strip, spin and spray coating operations. The system is designed to meet today's high-precision requirements for chemical-mechanical processing of semiconductor wafers. The unit is able to handle wafers up to six-inch diameter, and is equipped with a programmable substrate process controller. This controller is capable of executing up to 16 programs, each program with up to 32 segments. It also offers custom program segment and parameters adjustment, allowing users to process substrates with minimal human intervention. Additionally, SPS-2000 has the ability to detect wafer stoppage during spray operations. The precision spray head is an important feature of SEMITOOL SPS-2000. The spray head is designed with a nozzle of varying size, created using a 5-axis machining process. This helps create the desired spray pattern to achieve uniform films. The spray head is further adjustable according to height and angle with a manual or motor-driven process. For dry strip applications, SPS-2000 features a wet-bench with a two-channel version bubbler to precisely control the temperature and flow rate of the deionized water. This helps ensure precision etching behavior upon contact with the wafer, achieving the desired thin-film profile without contact-scuba patch or hotplate damage to the wafer. The machine also has an automatic hotplate detection feature which prevents contact of the hotplate to the wafer, eliminating potential damage. Furthermore, SEMITOOL SPS-2000 includes an integrated, high-speed spin tool that offers the speed accuracy of 2200 rpm. It features a durable motorhousing with dual-bearing design, and a balanced external wheel for enhanced precision performance. An optional noise filter can be added to the asset to reduce environmental noise and improve the accuracy of coating operations. In summary, SPS-2000 is a versatile and advanced photoresist model that enables users to perform precise wafer conditioning, dry strip, spin and spray coatings. It offers customizable programs and parameters, along with an adjustable and precise spray head, bubbler equipment, spinhead, and hotplate prevention. For these reasons, this system is an excellent choice for manufacturers that need a reliable and accurate photoresist unit.

There are no reviews yet