Used SEMITOOL SRD-880S #9287266 for sale

URL successfully copied!

Tap to zoom

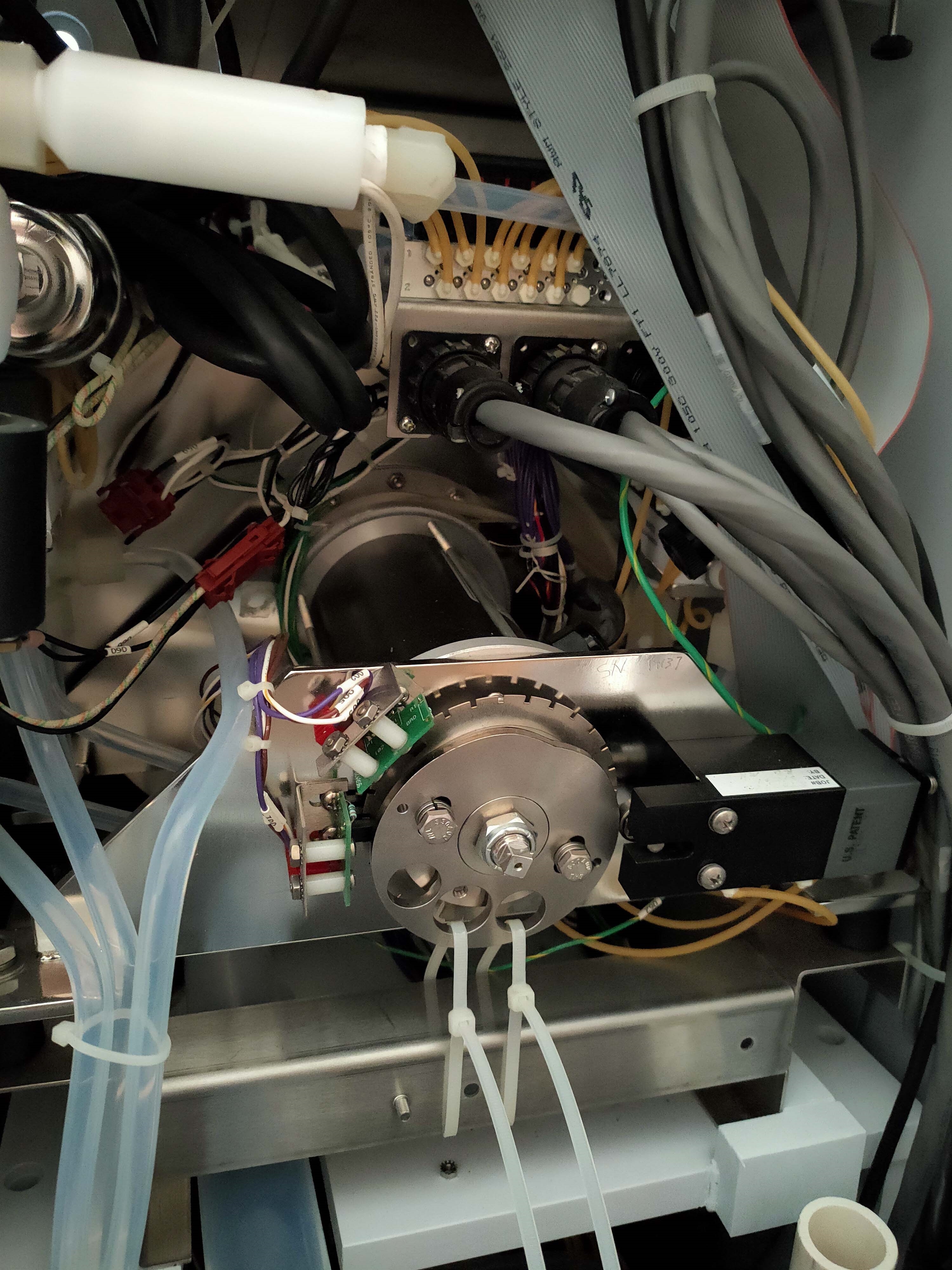

SEMITOOL SRD-880S is an advanced photoresist equipment designed for wafer processing applications. The system includes a high-precision stepper, a wet station, two spinners, a laser alignment unit, and a UV hotplate. The stepper features a 6.5-inch working stage with the ability to change to a 8-inch working stage. This allows for wafer sizes up to 300mm and enables high precision alignment of wafers for low-current and high-current applications. The wet station has two elevated tanks which can be filled with DI water, deionized (DI) water, or purified water. Additionally, there is a drain which allows for easy cleanup and disposal of hazardous liquids. The two spinners on the machine are configured to provide quick and efficient photoresist processing. The horizontal spinners are equipped with a corrosion-resistant chamber for photoresist and dry process chemistries, and they use up to 600psi of spin speed for faster throughput. The vertical spinners have two vacuum chambers that can be used for photoresist and dry process applications. The two spinners also have adjustable back edge alignment for greater accuracy. The laser alignment tool on SRD-880S is used for precision alignment prior to coating and etching. The unit has high accuracy alignment lasers, a field stop turret for different size wafers, and a range of laser wavelengths that can be adjusted to better match the specific photoresist used. Finally, the asset includes a UV hotplate which provides high intensity far-UV radiation for quick curing of photoresists. This UV hotplate is adjustable from 0.37 to 1.2 watts/cm2 to accommodate a wide variety of photoresist formulations. Additionally, the UV hotplate is designed to maintain temperature uniformity during operation. Overall, SEMITOOL SRD-880S is a comprehensive photoresist model that provides high precision alignment, quick spin rates, and uniform UV curing. The equipment is ideal for wafer processing applications in low-current and high-current fabrication operations.

There are no reviews yet