Used SEMITOOL SST-C-221-280-PB #9408953 for sale

URL successfully copied!

Tap to zoom

ID: 9408953

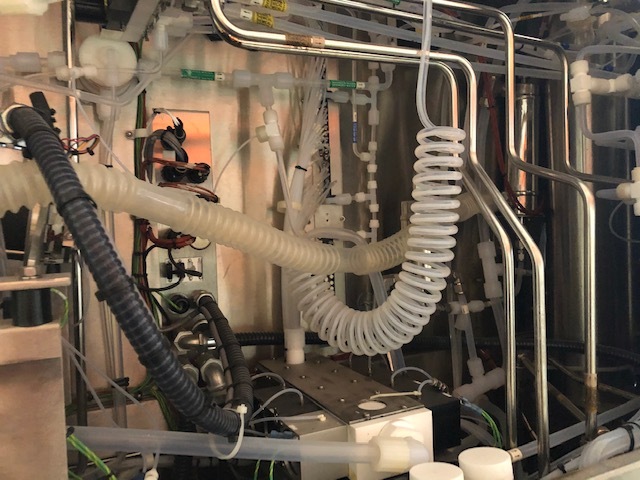

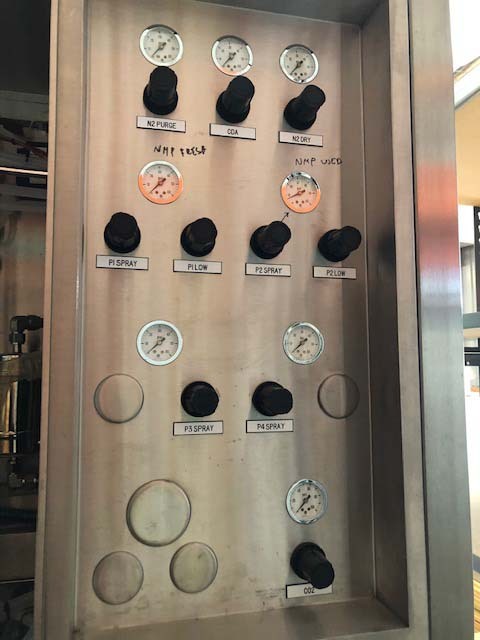

Spray solvent system

Stainless steel cabinet

Process:

Metal lift off

Resist strip

Polymer removal or wafer cleaning

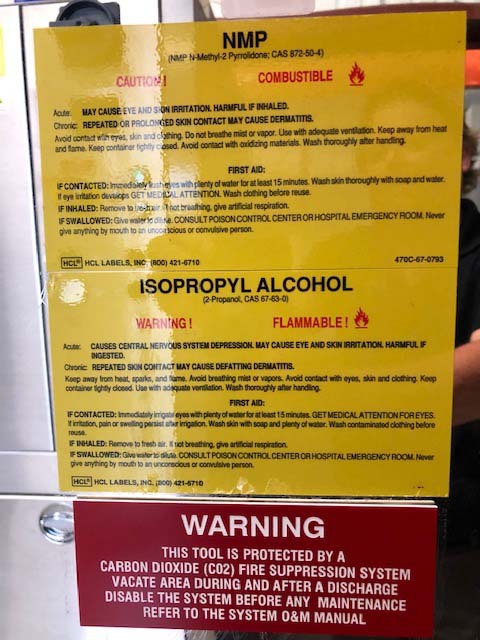

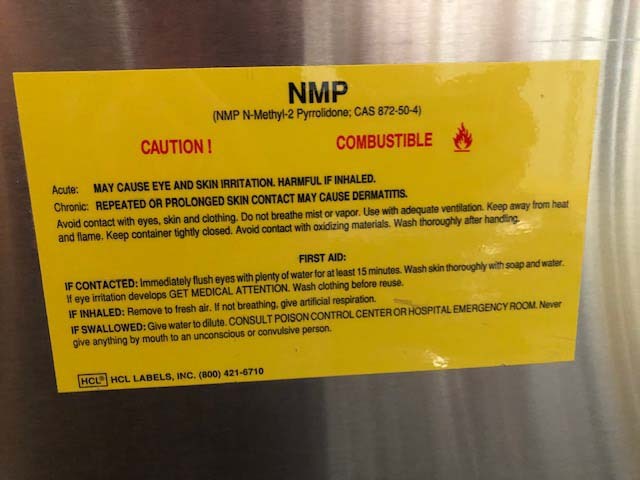

(2) Heated tanks (NMP)

(2) Ambient heated tanks (IPA)

Front touch screen

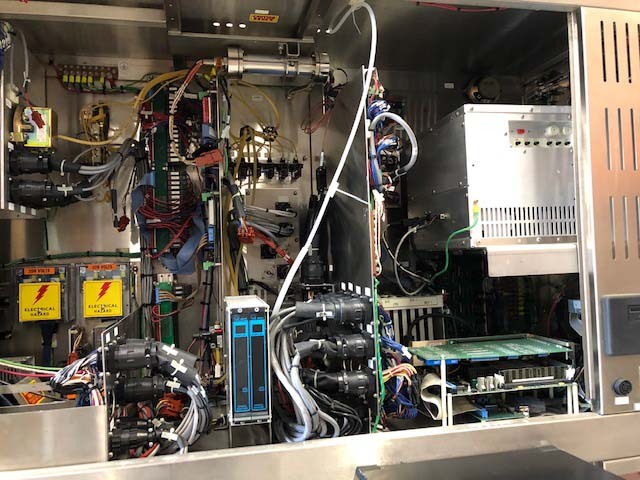

SEMITOOL 302 Controller

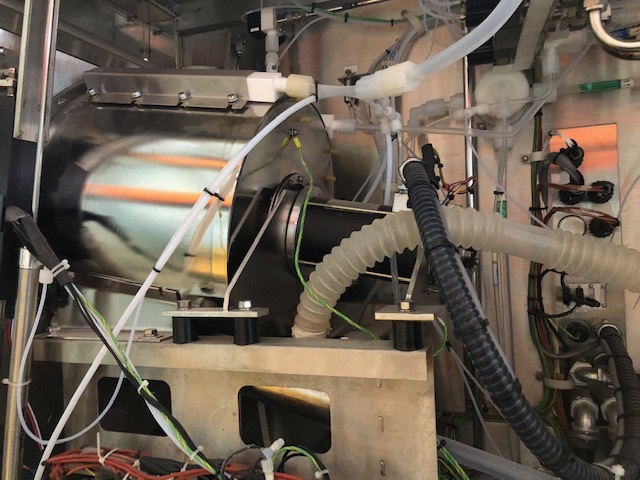

280 Bowl (Accommodates 8" substrate-low profile)

Encapsulated ferro fluidic drive seal

KALREZ Bowl seal

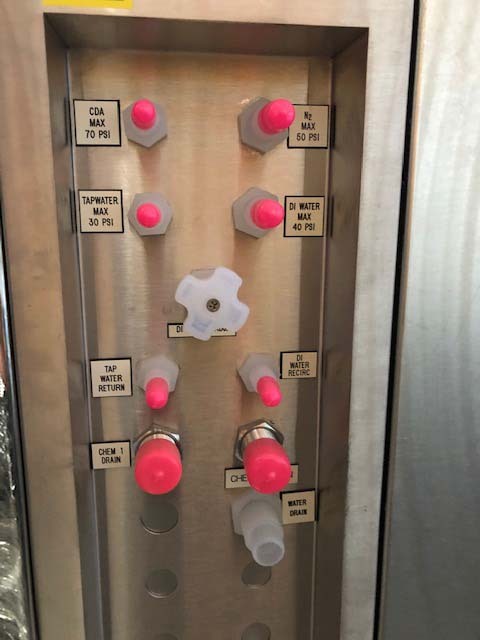

N2 Purged dedicated chemical

DI Water spray manifolds

Dedicated TFE N2 dry manifold

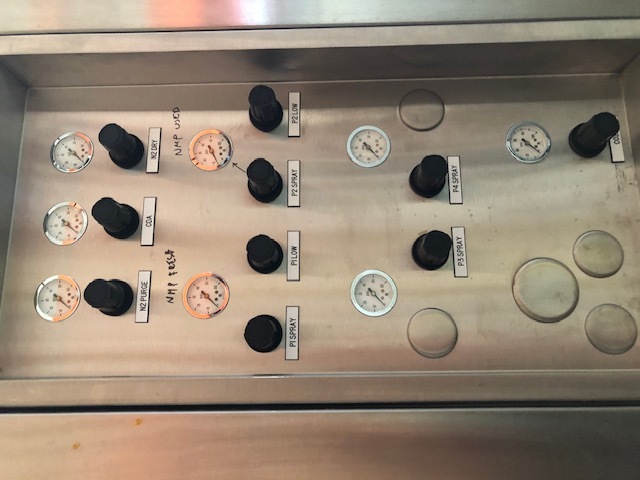

Graphic color controller

Process variable control of RPM

Heated chemical temperature

Vertical Auto Door (VAD)

Power: 208V, 5 wires, 3 Phase.

SEMITOOL SST-C-221-280-PB is a photoresist equipment designed to provide superior performance and superior process reliability when processing in advanced lithography processes. The system is a fully automated, full-featured photoresist processing solution, capable of running single-step and multi-step processes with multiple substrate configurations. The unit utilizes a fully automated substrate loading machine, and is capable of storing up to five recipe sets for different processes. The tool features the highest quality materials, components and engineering practices to ensure superior performance, repeatability, and process reliability. The asset uses patented gas delivery technology to uniformly distribute the photoresist to the substrate surface and to eliminate the need for manual spreading. A unique dual-pump model is used to ensure a uniform distribution of photoresist over the substrate while also providing a consistent and repeatable process. The equipment is capable of processing wafers sizes up to 6 inches in diameter and with a maximum thickness of 200 um. The system utilizes a fully integrated quartz crystal monitor unit to measure the wafer-level photoresist thickness and to monitor the uniformity of the photoresist layer. The machine also features a real-time, in-process inspection tool which allows the user to monitor the photoresist layer while the process is running. SST-C-221-280-PB is also equipped with a high-density, low-temperature bake capability that ensures repeatable process conditions, and ensures consistent resist patterning and baking. The asset is also equipped with two heating stages and two cooling stages, allowing for precise process control. Overall, SEMITOOL SST-C-221-280-PB is an advanced photoresist model designed to provide superior performance, process reliability, and repeatability. The equipment is designed for advanced lithography processes, and allows for a range of process parameters that can be customized for the specific application. The system utilizes the highest quality materials, components and engineering practices to ensure superior performance, repeatability and process reliability. The unit is capable of processing wafers up to 6 inches in diameter and 200 um in thickness. The machine also features integrated quartz crystal monitor and in-process inspection systems to ensure superior performance and process reliability.

There are no reviews yet