Used SEMITOOL SST-C-321-280 #9238397 for sale

URL successfully copied!

Tap to zoom

ID: 9238397

Wafer Size: 8"

Vintage: 2000

Spray solvent system, 8"

Part number: SST-C-221-280

Cabinet: Stainless steel, class 1

Gen-2 build

Front local interface (Standard)

Tool side touch screen

EMO (Front and rear)

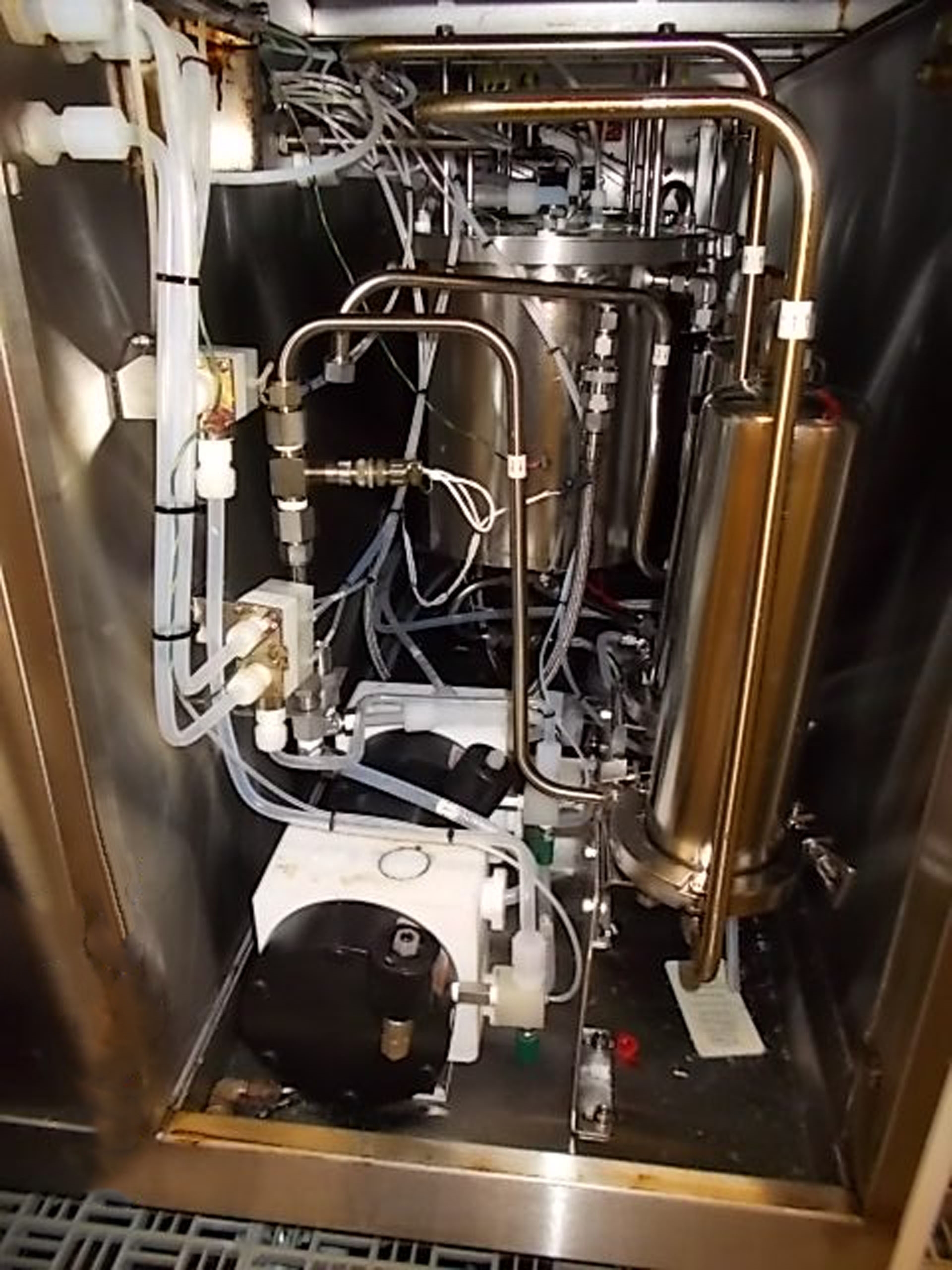

Bottom fed facilities

Top fed exhaust

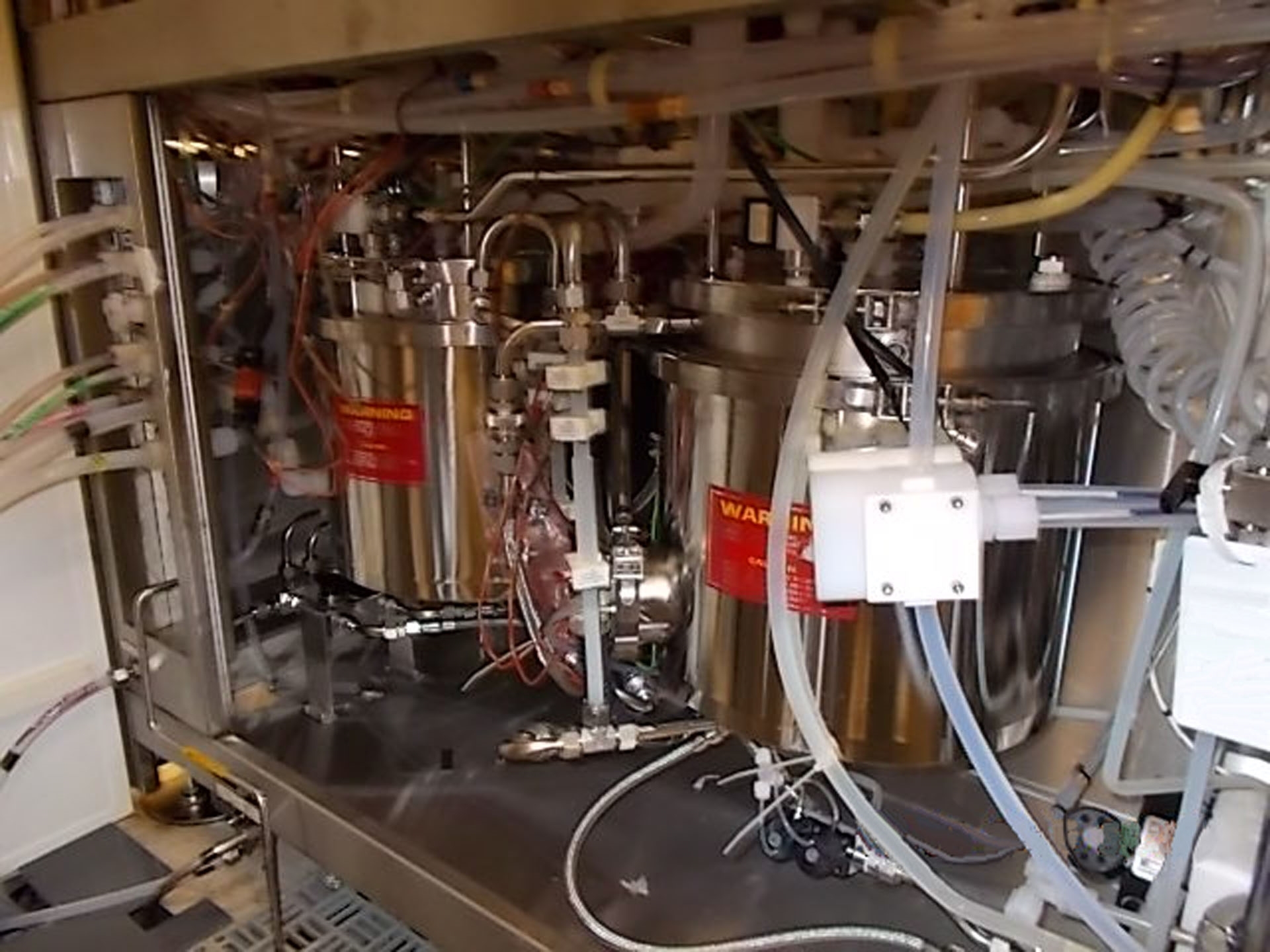

(2) Heated tanks for NMP based processing (Standard)

(2) IPA Tanks (Non heated)

(280) Bowls (Accommodates, 8" substrate-low profile)

Encapsulated Ferro fluidic drive seal

KALREZ Bowl seal

N2 Purged dedicated chemical

DI Water spray manifolds

TFE N2 Dry manifold

Graphic color controller

Process variable control of RPM

Heated chemical temperature

Power supply: 208 VAC, 30 A, 5 wire, 50/50 Hz, 3 Phase

2000 vintage.

SEMITOOL SST-C-321-280 is a semiautomatic photoresist equipment designed to be used in medium to high-volume production applications. It is suitable for single- or double-sided processing of substrates up to 12" in diameter. The system is composed of several distinct components: exposure head, spray-developer stage, spin rinse stage, conveyor and spin-coater. The exposure head consists of a stepper motor, control electronics, and a two-stage shutter unit to ensure correct exposure times for both positive and negative photoresist. The head is equipped with a manually adjustable focus and intensity dials and is capable of handling up to 12" substrates. It is attached to the machine by a 175cm long robotic arm for easy access and automated substrate handling. The spray-developer stage is a multi-port nozzle tool that uses isopropyl alcohol (IPA) to remove unexposed photoresist from the substrate surface. It is equipped with a PLC for accurately controlling the amount of developer used and has a built-in waste recirculating asset. It is also fitted with an evacuation port to facilitate safe and easy maintenance of the developer panel. The spin rinse stage is used to rinse the substrate before the spin-coater process. It has a dedicated control panel and PLC to ensure precise rinse times and temperatures relevant to the type of resist being used on the substrate. The stage is equipped with a solvent recovery tray and uses IPA to carry out the rinse cycle. The conveyor facilitates movement of substrates between various stages of the model and features a dedicated ceramic heating board to ensure consistent temperatures throughout the photoresist cycle. The spin-coater is used to apply the photoresist to the substrate surface as a very thin film. It features a digital programmable timer and provides a number of pre-programmed application cycles for various resist types. The stage is capable of spinning substrates up to 12" in diameter at speeds between 200-2500 RPM. In conclusion, SEMITOOL SSTC321280 is an ideal equipment for photoresist processing in medium to high volume production applications. It features a variety of specialized components, including an exposure head, spray-developer, spin rinse and coater stages, and a conveyor. The system is not only easy to access and maintain, but is also able to accommodate a range of substrate sizes up to 12" in diameter.

There are no reviews yet