Used SEMITOOL SST-C-321-280 #9238796 for sale

URL successfully copied!

Tap to zoom

ID: 9238796

Wafer Size: 8"

Vintage: 2000

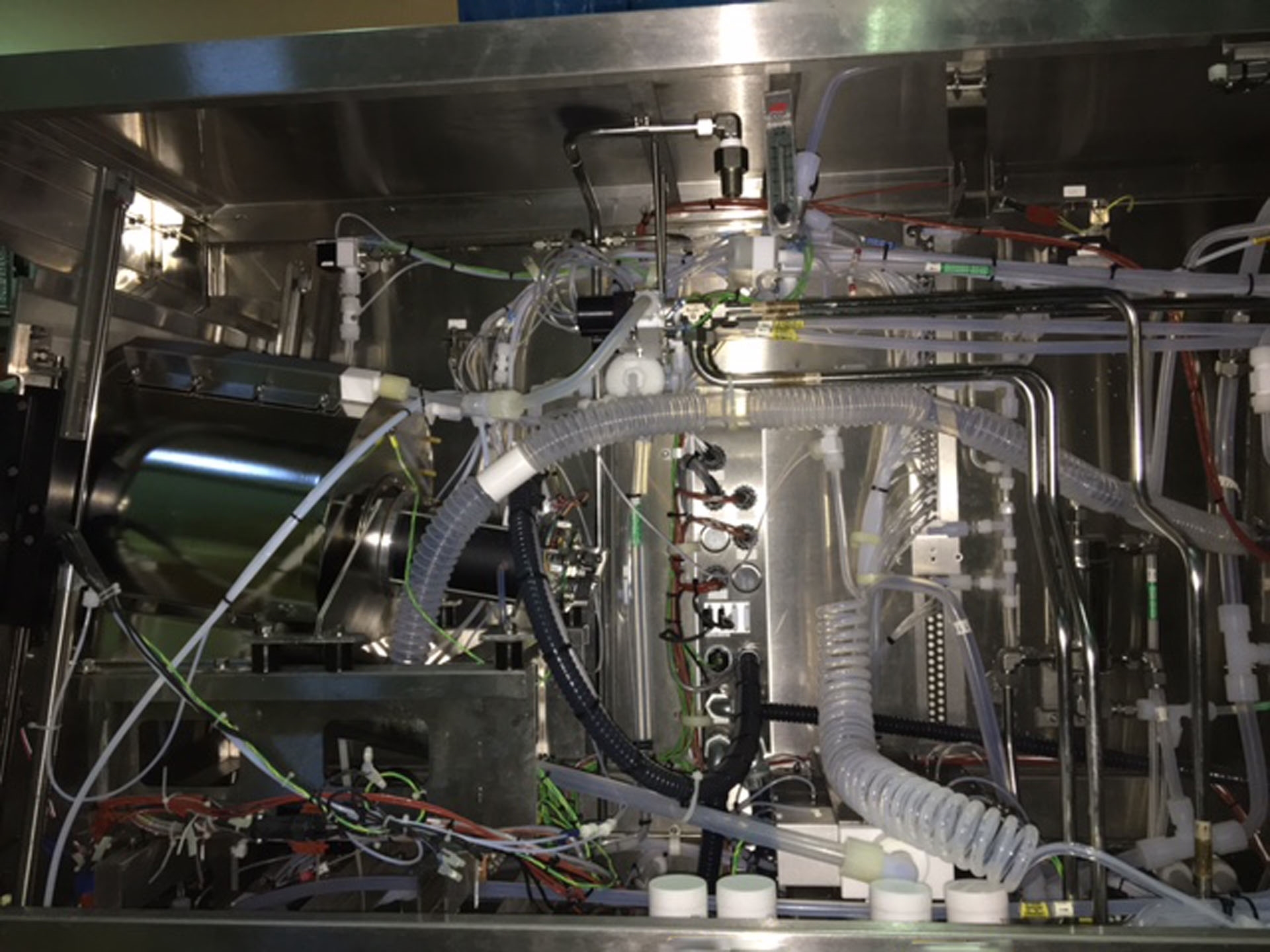

Spray solvent system, 8"

Part number: SST-C-221-280

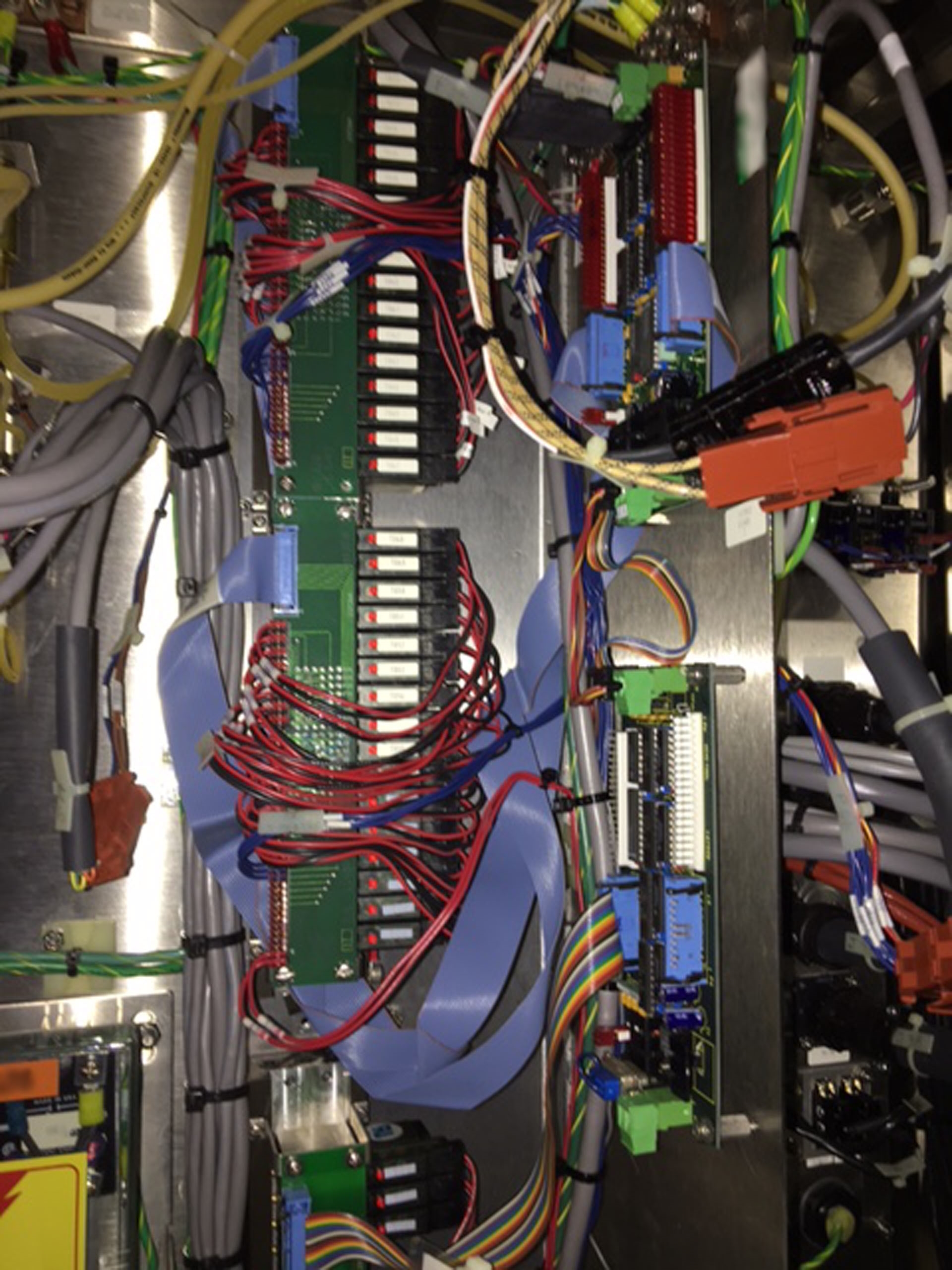

Cabinet: Stainless steel, class 1

Gen-2 build

Front local interface (Standard)

Tool side touch screen

EMO (Front and rear)

Bottom fed facilities

Top fed exhaust

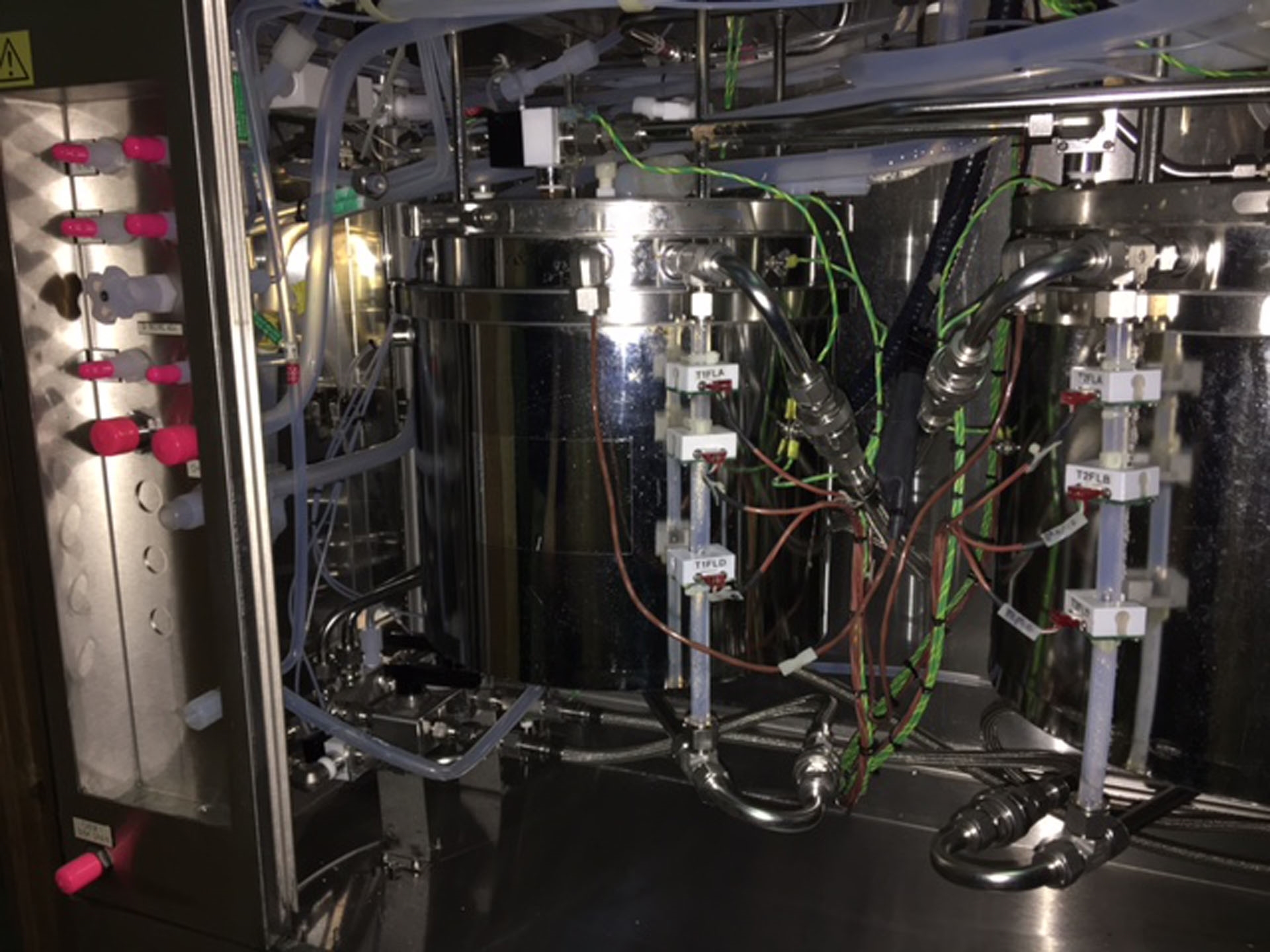

(2) Heated tanks for NMP based processing (Standard)

(2) IPA Tanks (Non heated)

(280) Bowls (Accommodates, 8" substrate-low profile)

Encapsulated ferrofluidic drive seal

KALREZ Bowl seal

N2 Purged dedicated chemical

DI Water spray manifolds

TFE N2 Dry manifold

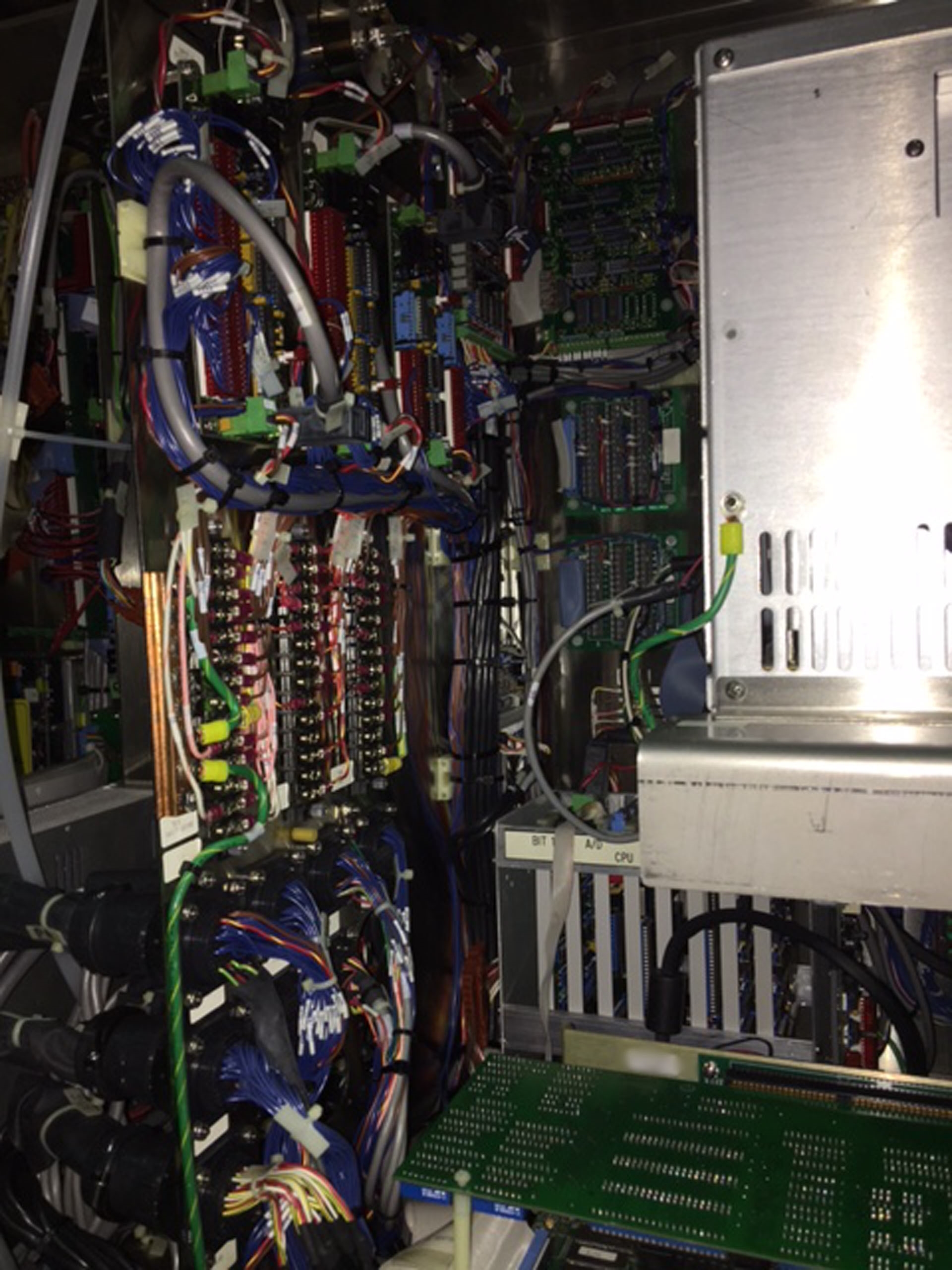

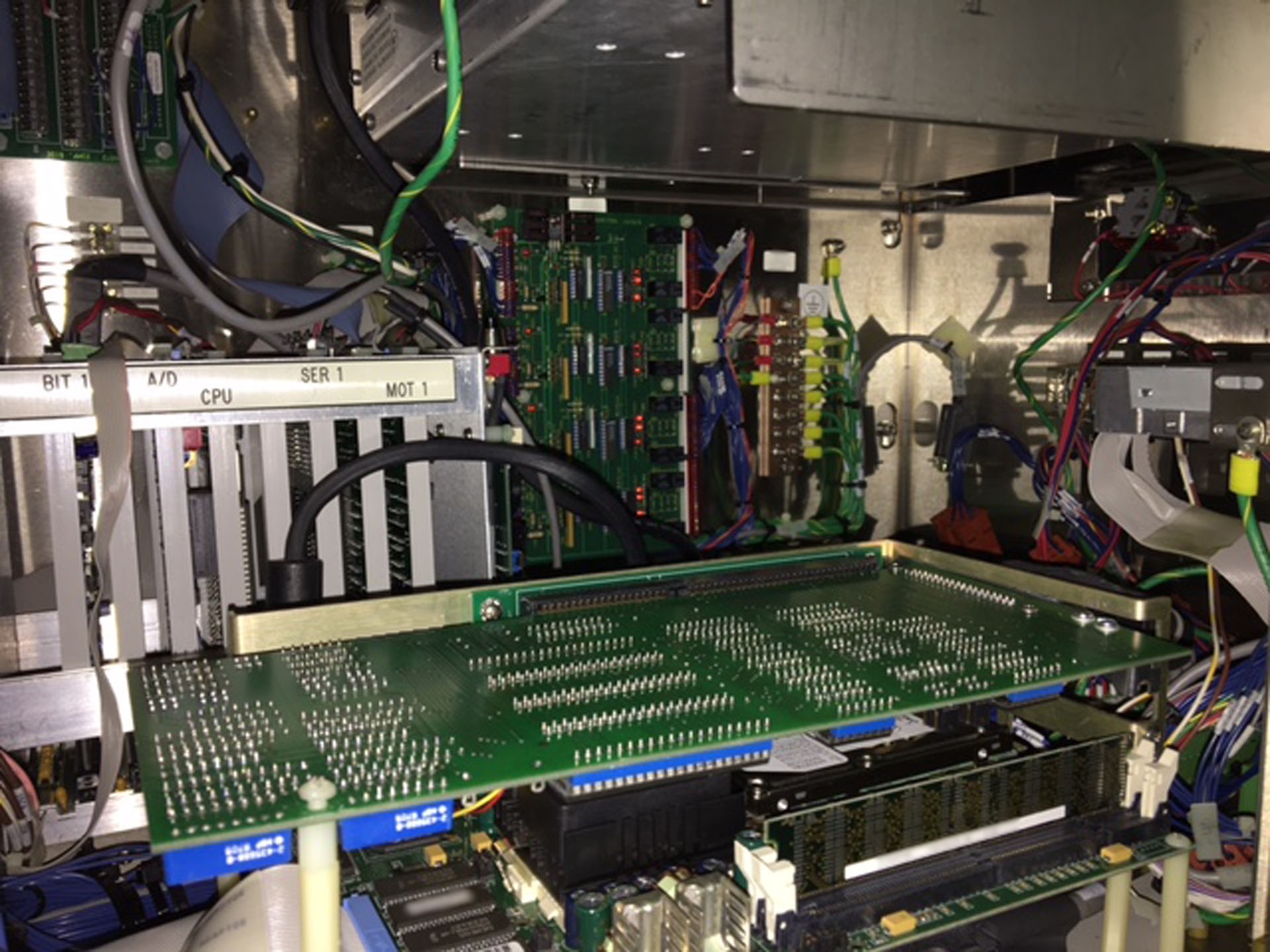

Graphic color controller

Process variable control of RPM

Heated chemical temperature

Power supply: 208 VAC, 30 A, 5 wire. 50/50 Hz, 3 Phase

2000 vintage.

SEMITOOL SST-C-321-280 is designed for use in a variety of photoresist applications. It is an automated batch processing equipment that can handle large loads of resists quickly and efficiently. The system is designed to provide an accurate, repeatable coating layer on a variety of substrates in a robust environment. The unit features a base composed of stainless steel giving it the strength and corrosion resistance required to withstand the harsh environment of a photoresist process. The base also features an array of well-positioned mechanical components that increase reliability in various demanding production environments. The machine is fully automated, supporting programmable motion of the showerhead, allowing for multiple processing steps and recipes. The core of the tool is a 280-liter chamber cooled by a single stage compressor that creates vacuum in the chamber. The chamber is outfitted with showerhead and wafer chuck for substrate support. This combination ensures uniform and controlled resist dispersion over the substrate surface, providing a consistent thickness. The digital controls on the front panel allow for easy set-up and operation. The wafer transport asset on the chamber supports up to eight wafers of varying diameters. It is designed for production throughput and features a wafer-to-wafer time within a five-second range. This faster wafer transfer allows for higher throughput as well as faster start-up during production runs. The wafer transfer model is also designed with a self-cleaning mechanism to prevent contamination build-up. For maximum accuracy during production runs, the equipment's vision systems are provided with integrated vision and light source systems to ensure clear visibility of the back side of the substrates. The integrated systems provide the best possible results at all times. The system also has a state-of-the-art signal input/output control unit allowing for remote monitoring of the machine's status. SEMITOOL SSTC321280 tool is an efficient and reliable tool ideal for photoresist processing operations. It is designed to provide robust and reliable operation for large scale production runs with high-quality results.

There are no reviews yet