Used SEMITOOL WSST-805A #9270149 for sale

URL successfully copied!

Tap to zoom

ID: 9270149

Wafer Size: 8"

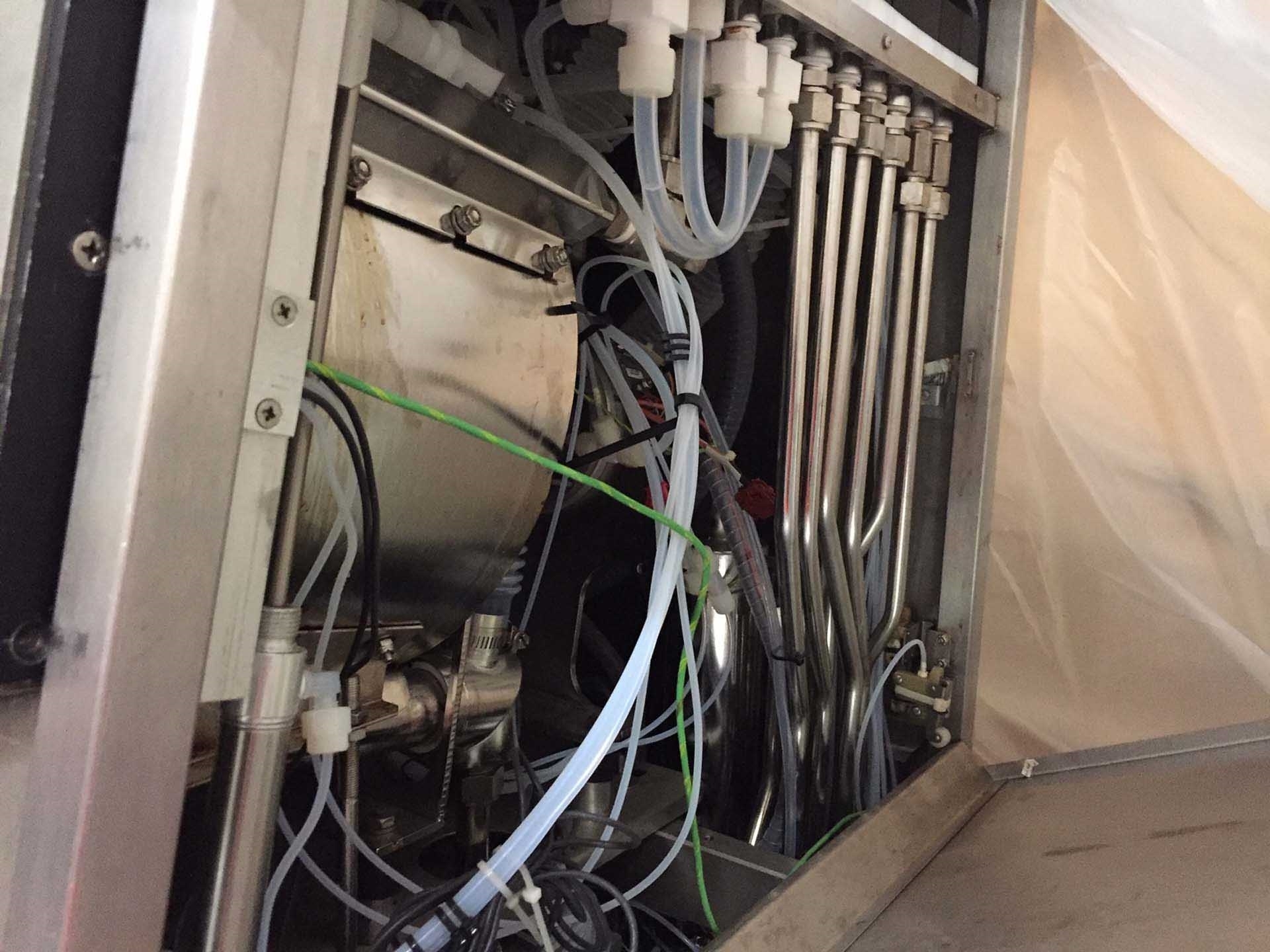

Water soluble strip system, 8"

Designed to strip photoresist

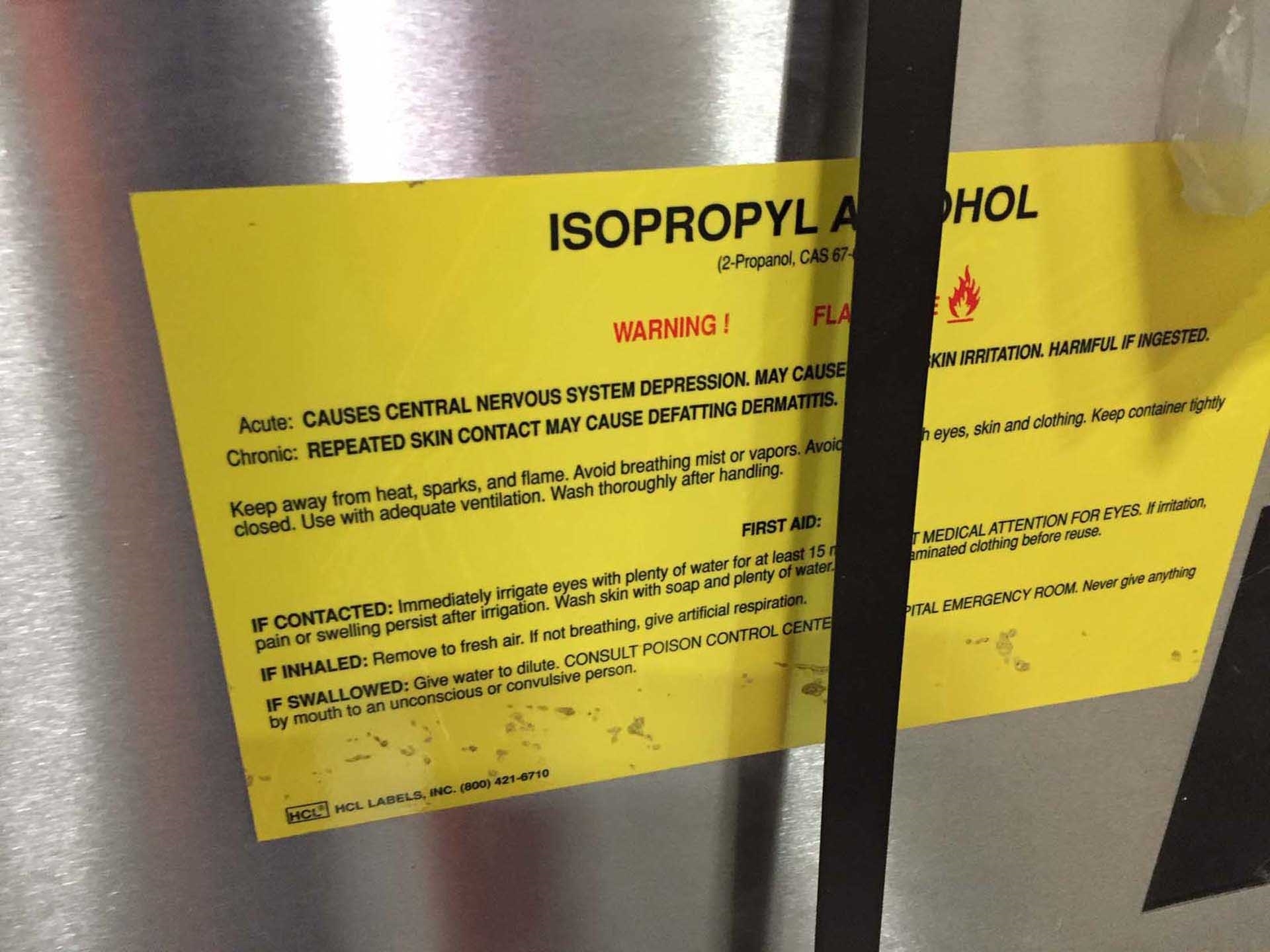

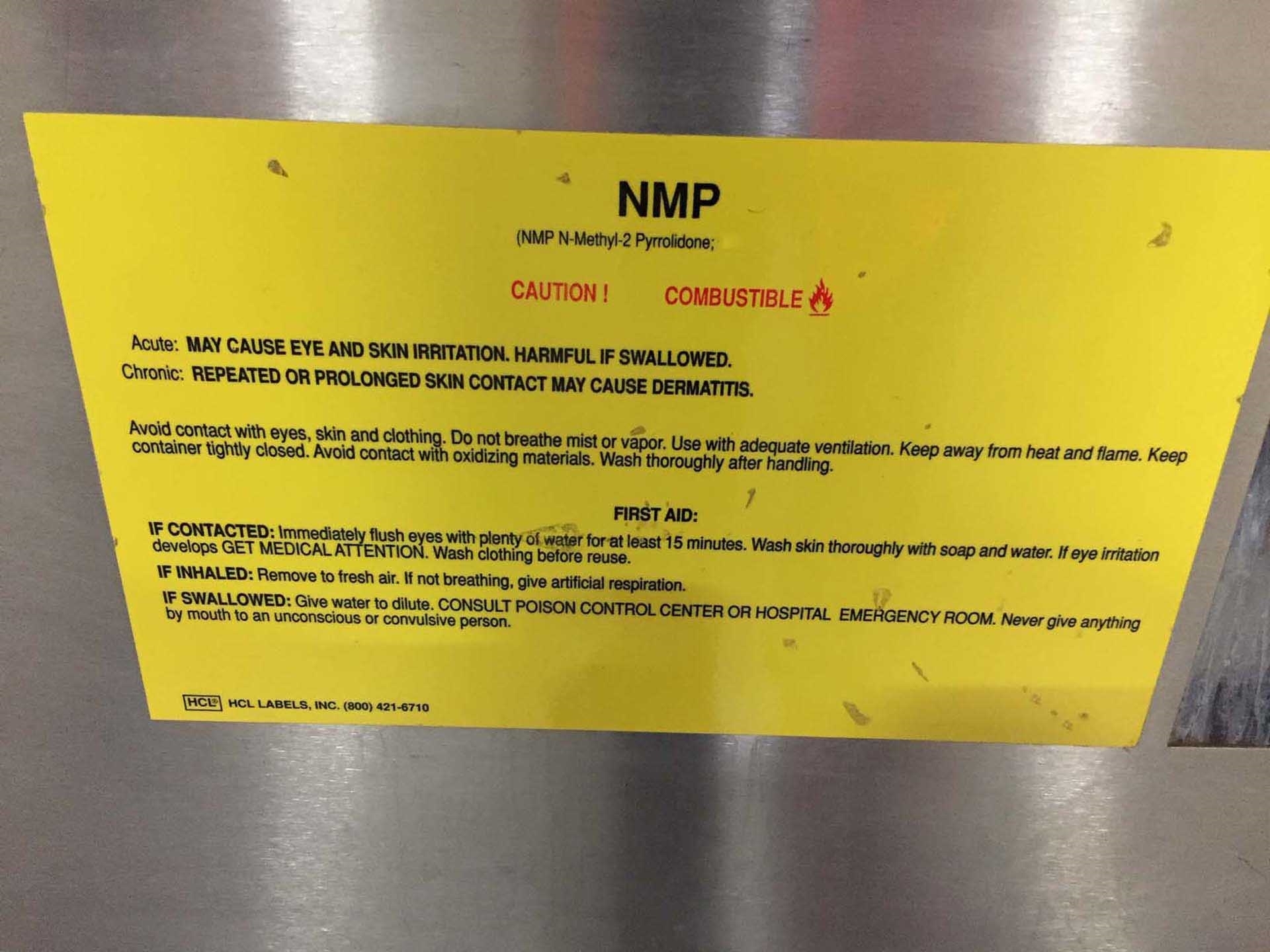

With water soluble based (NMP) strippers then do Isopropal rinse and dry

280 Matted bowl (Max size 8" wafers)

(2) Heated NMP tanks

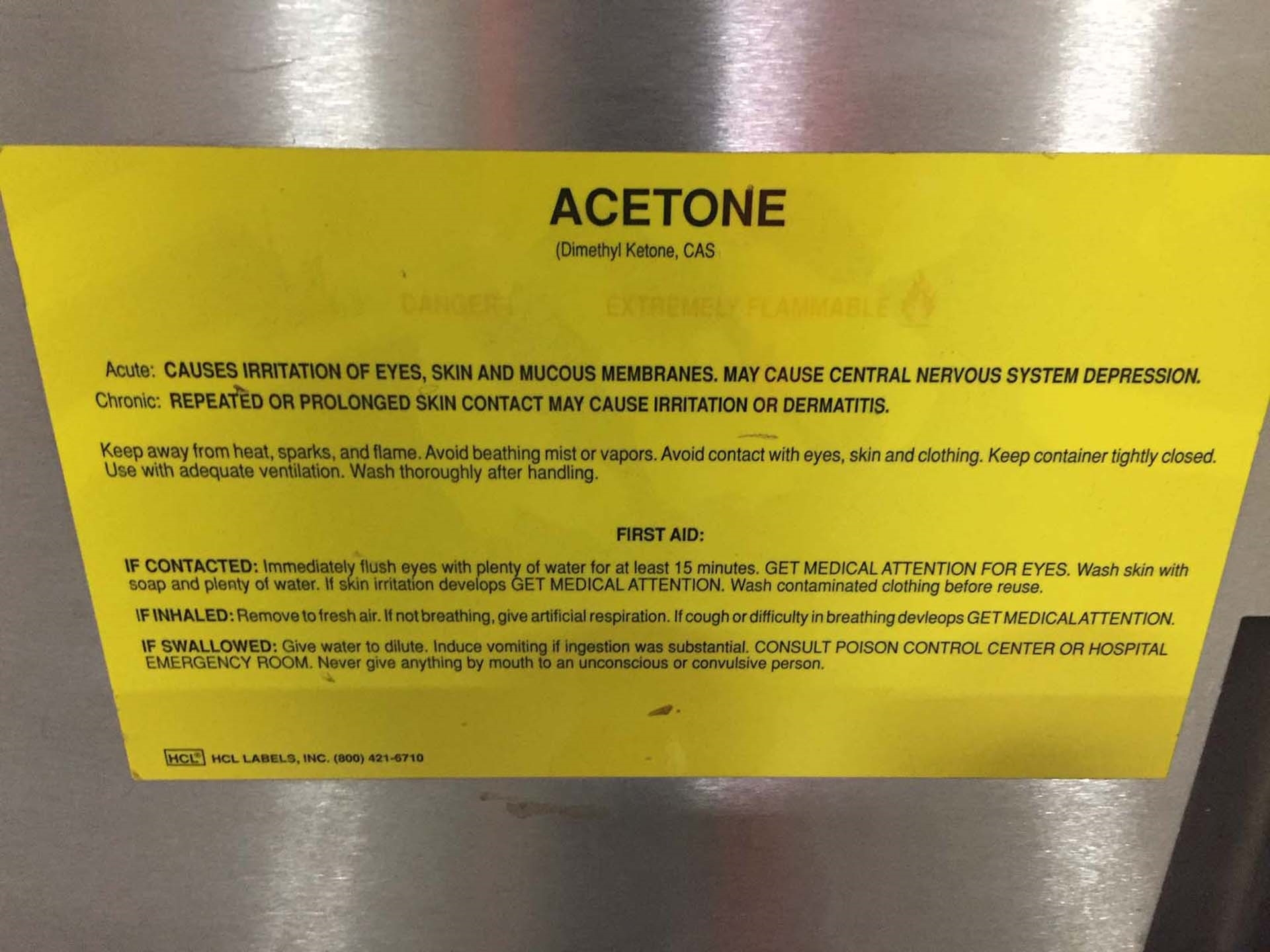

(2) Non-heated Acetone tanks

(2) Non-heated IPA tanks.

SEMITOOL WSST-805A Photoresist Equipment is an advanced wafer spin-coat and develop technology that offers reliable deposition and processing of high-quality thin film dielectric layers. The system utilizes wafer technology that is compatible with many common substrates such as aluminum, copper, ceramic, silicon, quartz, and more. It is specifically designed for processing wafers up to 8" in diameter and achieving uniform coverage across the entire surface of the wafer. The unit features a pneumatically operated chuck, which can accommodate wafers up to 8" in diameter and operates at a maximum of 450 rpm spin speed. It also includes a wafer motor with 0-50 hertz speed range. For uniform wafer coverage, the machine has automatically adjustable spin ramp rates that can be set to achieve an optimal coat thickness for each substrate. The tool is also equipped with a colling asset that helps to ensure the uniformity of the film deposition. The model uses a resist tank for the delivery of photoresist and developer. The resist tank is heated to optimal temperatures for maximum uniformity in processing. Heating is done with a thermocouple and controlled by a temperature controlled heater. The temperature control is adjustable for a varied range of processing temperatures dependent on the type of resist. A timing device allows operators to set the equipment to deliver the desired amount of photoresist at pre-programmed intervals. The device also has the ability to monitor the concentration of photoresist and adjust the level accordingly. The system is designed to ensure accurate and repeatable thin film uniformity with each processing step. The unit also includes a closed-loop feedback loop that can detect changes in process conditions and adjusts the machine to maintain consistent processing. WSST-805A photoresist tool is designed for modern semiconductor fabrication and offers high level of reliability and precision in thin film dielectric layer depositions. It is compatible with a variety of common substrates and can be used for processing wafers up to 8" in diameter. It is also equipped with a heating asset and a timing device that ensures the desired photoresist concentration and uniformity of the film deposition. The model is also equipped with a closed-loop feedback loop which is designed to monitor and adjust process conditions to ensure consistent performance from batch to batch.

There are no reviews yet