Used SEMITOOL WSST-806A #9269858 for sale

URL successfully copied!

Tap to zoom

ID: 9269858

Wafer Size: 8"

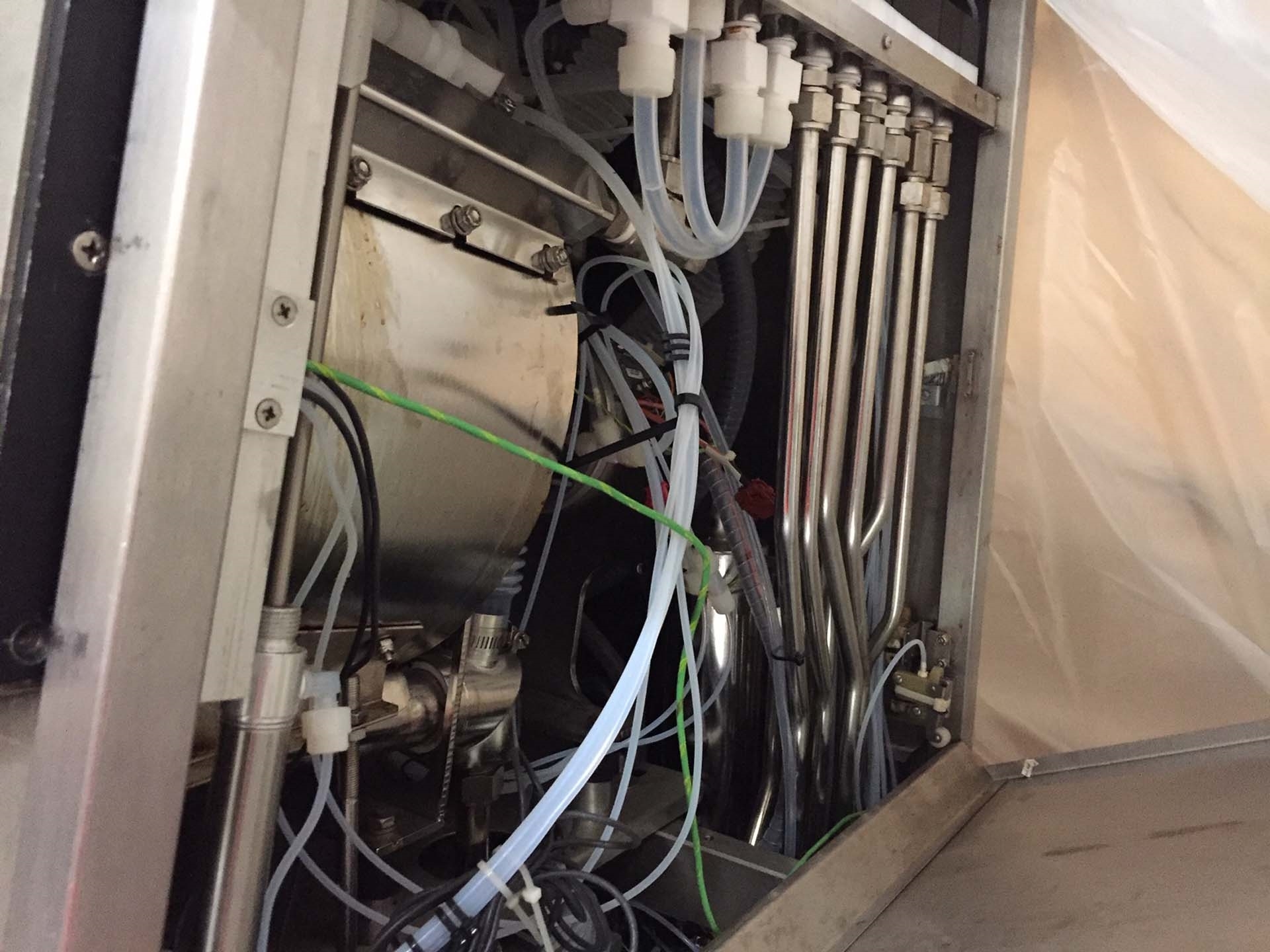

Water soluble strip system, 8"

Designed to strip photoresist

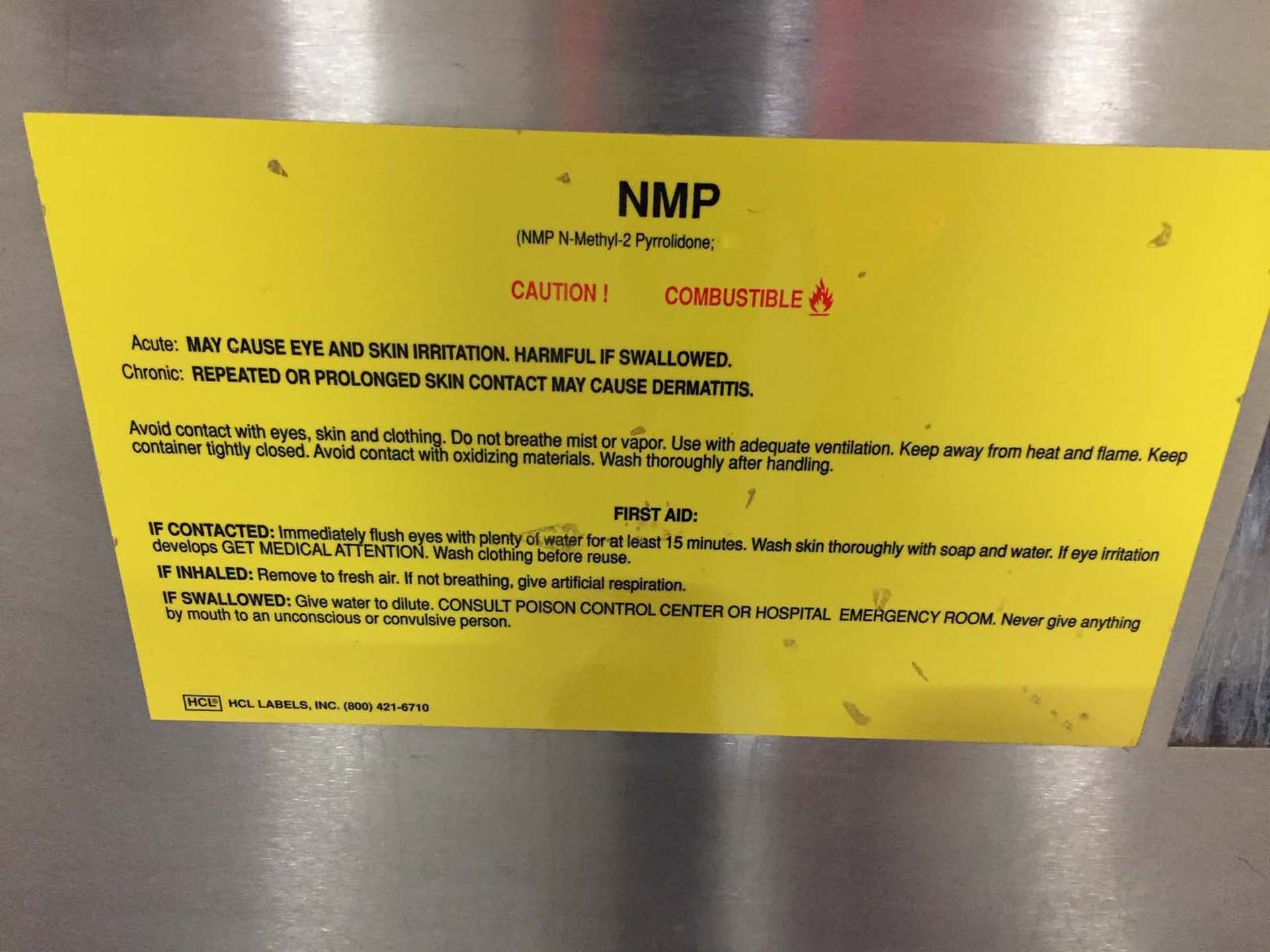

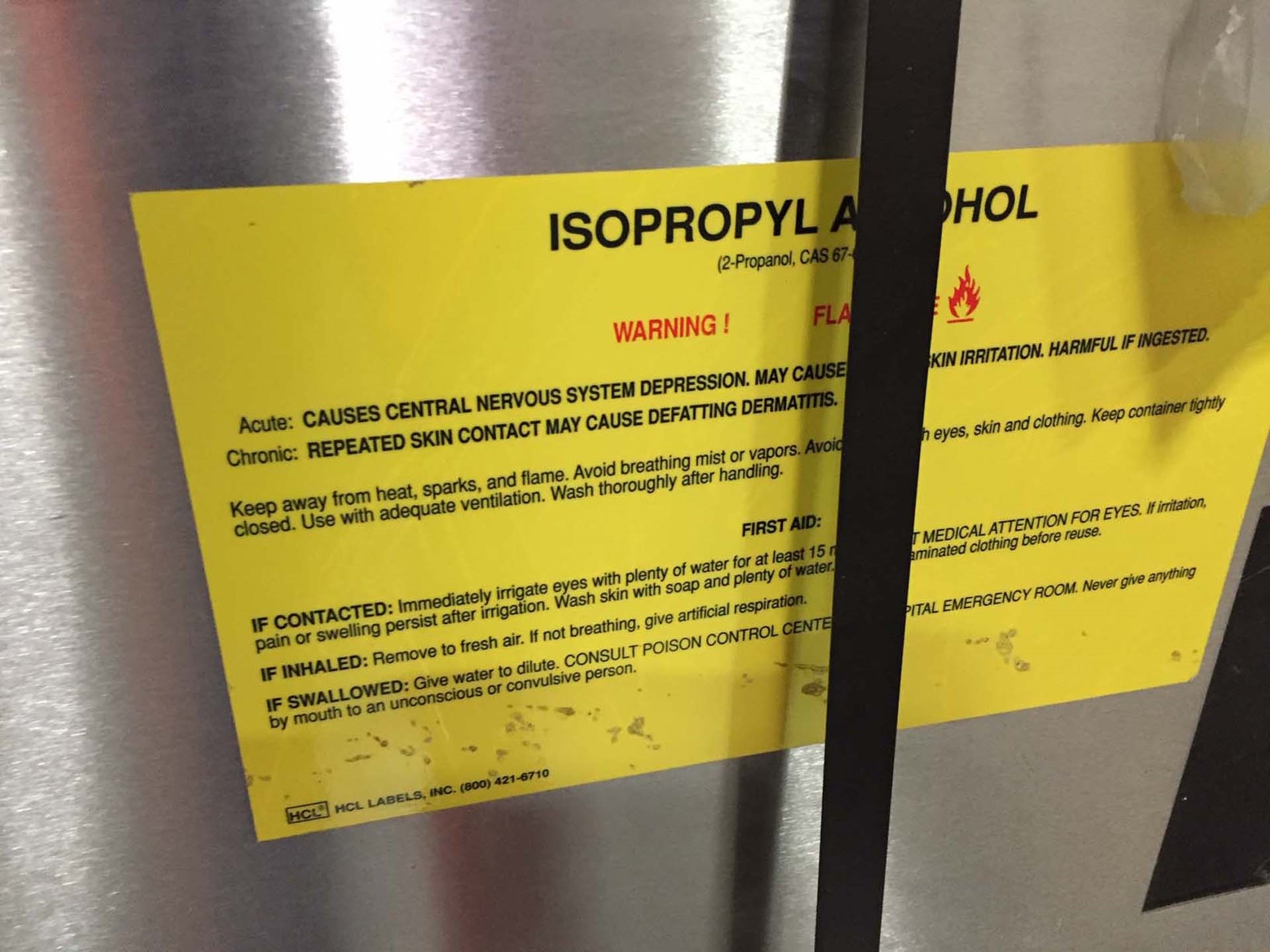

With water soluble based (NMP) strippers then do Isopropal rinse and dry

280 Matted bowl (Max size 8" wafers)

(2) Heated NMP tanks

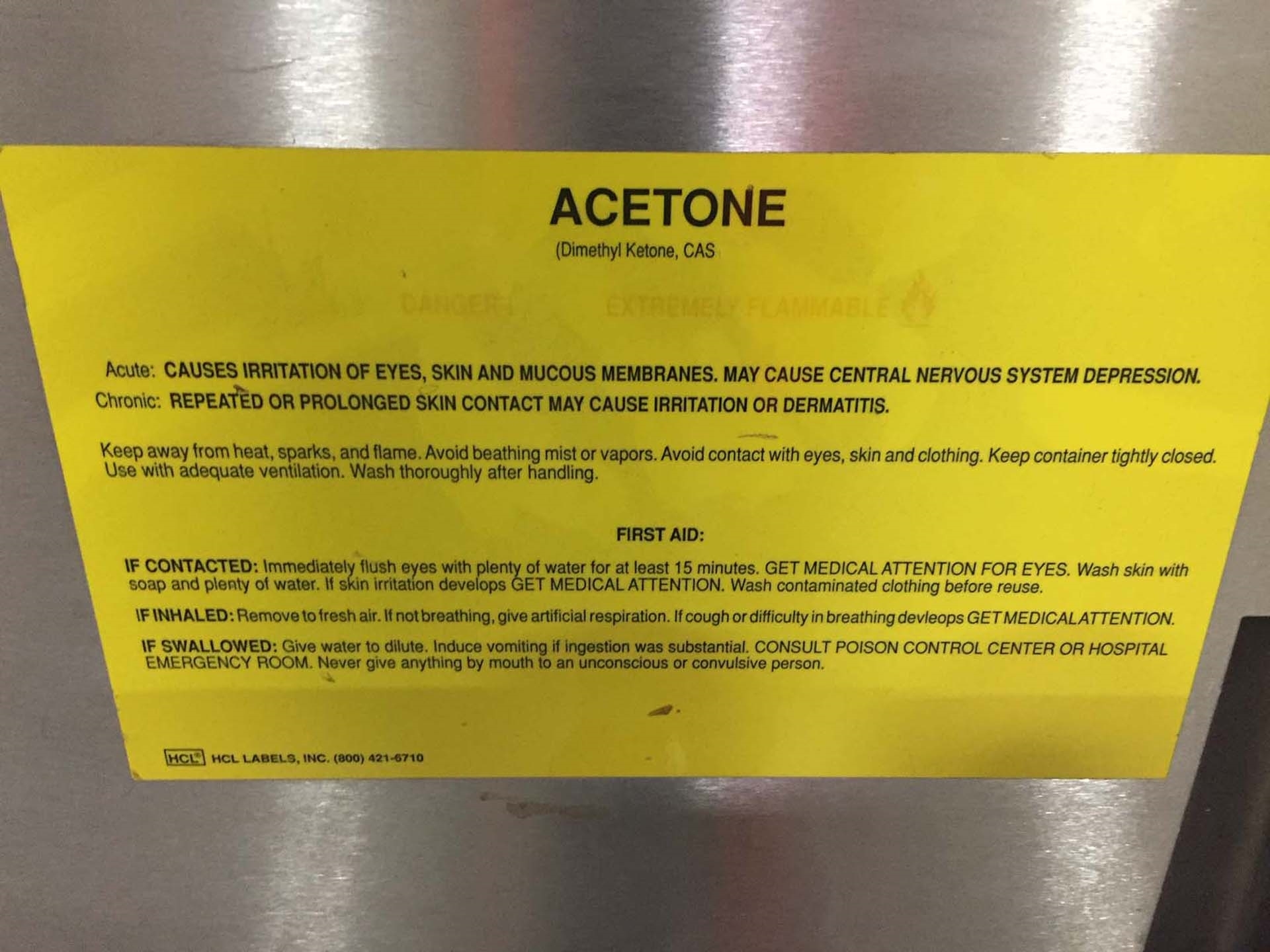

(2) Non-heated Acetone tanks

(2) Non-heated IPA tanks.

SEMITOOL WSST-806A is a photoresist equipment, designed to handle both single and multi wafer applications for the manufacture of semiconductor components. It features a motorized immersion chuck with a temperature control range of -20°C to +75°C and an adjustable centerline height. The system is equipped with a high resolution motion unit as well as a stepper motor controller to allow for accurate positioning of the wafer at the desired height and angles. The machine also has a high speed spin motor and temperature sensor for precise time and temperature control. The photoresist process uses a masking pattern to create a device from a given material through chemical and etching processes. In this particular tool, the photoresist is applied to the wafer. The applied photoresist can be exposed to ultraviolet radiation or laser light, which etches into the exposed areas of the photoresist. The exposed areas are then removed, leaving behind the defined pattern. In order to produce reliable and repeatable results, the time and temperature of the photoresist must be accurately controlled throughout the process. SEMITOOL WSST806A asset is designed to provide a precision, consistently repeatable environment for photoresist processing. It has a spin speed of up to 2885 RPM, allowing for an optimized time and temperature of photoresist exposure. The model also features a high-resolution, motorized immersion chuck with temperature regulation of -20°C to +75°C for repeatable results. Additionally, the equipment is equipped with encoder interfaces, which allow for precise control of the centerline height of the wafer. WSST-806A system is an effective tool for semiconductor manufacturers to create sophisticated semiconductor components with repeatable processes. Its motorized immersion chuck and automated unit parameters provide accurate and consistent imaging results. The high-speed spin motor and temperature regulation provide reliable photoresist exposure, ensuring a reliable and repeatable processing environment of one or multiple wafers.

There are no reviews yet