Used SEMITOOL WST-306MI #137518 for sale

URL successfully copied!

Tap to zoom

ID: 137518

Wafer Size: 6"

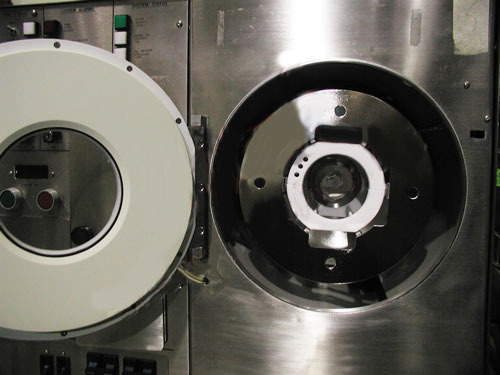

Spray solvent strip tool, 6"

System designed to strip photoresist with water soluble based (NMP) strippers

270 bright EP bowl, up to 6" wafers

System has a 4" clam shell and rotor (810R0014-01)

2 tanks: fresh and reclaim

OMERON heater controller

SEMITOOL ITS controller

Bulk fill option

Power: 208VAC, 60 Hz, 30 amps.

SEMITOOL WST-306MI is an advanced photoresist equipment designed for use in high volume photolithography production. Featuring an advanced robust design, WST-306MI is capable of propping up to 300mm wafers with a temperature accuracy and repeatability of 0.1°C. This system consists of a wet bench and Aseptically Transport Processor (ATP) for processing of photoresists and other liquids. SEMITOOL WST-306MI features an integrated conveyor that allows for efficient ingress and egress of work pieces, including substrate carriers and edgebead removal fixtures. Additionally, the unit is designed with multiple options for venting to maximize chemistry life, such as carbon based filters, photochemical treatment systems and inline degasser filtration. WST-306MI supports applications such as positive and negative photoresist, stripping, developing, templating and masking with both wet chemicals and developer gases. It has intelligent user interface that allows an operator to run sequence using predefined programs or user-defined recipes. SEMITOOL WST-306MI also offers standard cleanroom interfaces and can be remotely monitored with its integrated monitoring unit. WST-306MI provides a 5-step photoresist process module, which includes prebake, postbake, post-exposure bake, post-strip bake, and post-removal bake processes. It also includes temperature sensor monitoring within the substrate transport flume and internal sensor monitoring of the process cabinet. Overall, SEMITOOL WST-306MI is an advanced photoresist machine with efficient workflow that can reliably process different photoresists, chemicals and developer gases. Its automated processing sequence, user-friendly interface and integrated monitoring allow for excellent results and efficient operation. The tool is suitable for high-volume applications in the semiconductor and optoelectronic industries.

There are no reviews yet