Used SEMITOOL WST-306MI #81412 for sale

URL successfully copied!

Tap to zoom

ID: 81412

Wafer Size: 6"

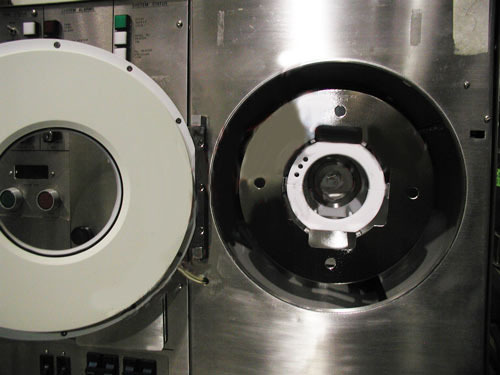

Spray solvent strip tool, 6"

Power: 208vac, 60 Hz, 30 amps

Dimensions: 36" wide x 33" tall x 59" tall

System has a 4" clam shell and rotor (810R0014-01)

2 tanks (bulkhead in between)

One side has 2 tank (fresh and reclaim)

Heater controller are Omeron

SEMITOOL ITS controller

270 matted bowl (max size 6" wafers)

Bulk fill option

Dimensions: 36" wide x 33" tall x 59" tall.

SEMITOOL WST-306MI Photoresist Equipment is a system designed for high precision patterning of photoresist materials onto substrates. This unit is perfectly suited for applications in the semiconductor and microelectronics industries, where precision and accuracy are paramount. WST-306MI is a single-chamber tool that features a Projection Aligner (PA), which supports wafer and mask exchange and can perform accurately aligned shadow imaging on up to 300mm wafers. The machine also has an integrated Contamination Monitoring Tool (CMS), which allows for particle monitoring and cleaning sensors in the process chamber for enhanced cleanliness and sanitation. In addition, the asset supports deep UV, i-line and deep-UV/i-line photoresist processes. The process chamber of SEMITOOL WST-306MI is equipped with a uniformed low-pressure chemical-free (ULPCF) bulk lamp and a quartz ceramic photoresist coater. The uniformed low-pressure chemical-free (ULPCF) bulk lamp is designed to provide homogenous UV and deep-UV patterning on the substrate, as well as precise and accurate control of the location and intensity of light. The quartz ceramic photoresist coater utilizes an integrated heater, micro-pump and fan to ensure evenly distributed resist coating, which is essential for precise results. The integrated temperature and flow sensors enable accurate control of the temperature and viscosity of the photoresist material. WST-306MI also supports various specialty photoresist processes including positive ultra-violet, negative ultra-violet, two-layer photoresist, and single-layer photoresist. It is also pre-configured with a special thermal control package, which ensures uniform resist patterning at all temperatures. The model is compatible with most types of photosensitive materials and has an intuitive software interface to easily setup, monitor and control the process. SEMITOOL WST-306MI provides a reliable, efficient and precise photoresist patterning process, which is especially beneficial in industrial applications. The accuracy and uniformity of the process are second to none, while the easy setup and intuitive operation make it suitable for high-throughput applications. This equipment is an ideal choice for the most demanding photoresist patterning applications.

There are no reviews yet