Used SEMITOOL WST-406MG #35587 for sale

URL successfully copied!

Tap to zoom

ID: 35587

Wafer Size: 4"

Vintage: 2000

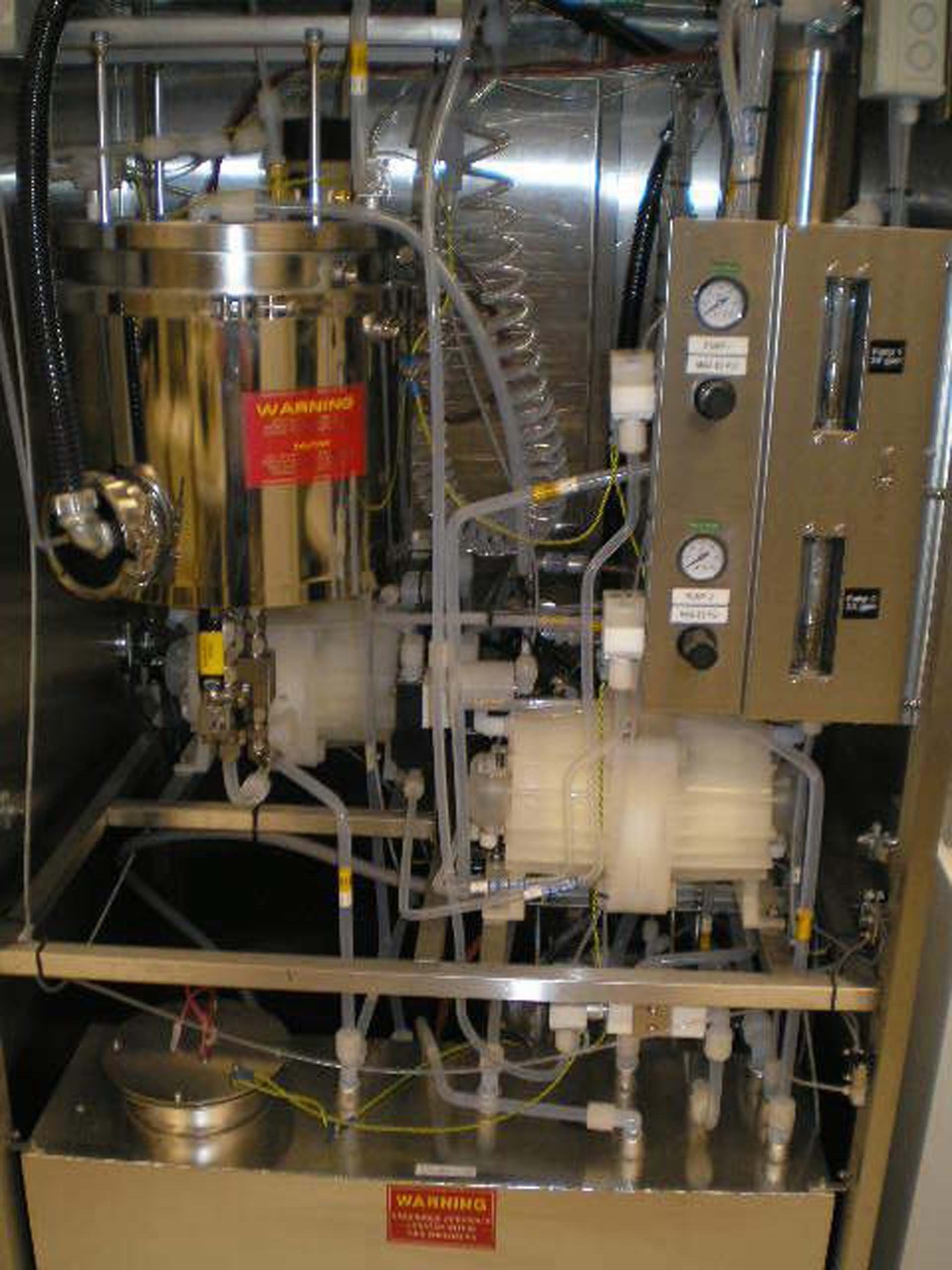

Wet solvent stripper, 4"

Strip photoresist with water soluble based (NMP) strippers

(270) Electropolished bowls: Maximum 6" wafers product

Brushless motor

Fire suppression

No tanks

Remote chemical cabinet

(2) Tanks:

Fresh PRS1000

Reclaim PRS1000

Power: 208VAC, 60 Hz, 30 Amps, 5 Wire

BAKER PRS 1000 Positive photoresist tripper

Accessories:

Chemical delivery module

Dual heated chemical tanks, 6 Gal

Dual chemical pumps

Chemical waste tank with pump

Dual chemical filters

Features:

Front loading with on-axis spin

Self-contained fluid dispensing and recirculation

Surfaces: Stainless steel or Teflon coating

Spray and atomizing manifolds for fluid deliver

Microprocessor controlled process

Rotor installed for 150mm, P/N: A194-60MB-0215

Sub-system: Chemical cabinet

SEMITOOL Graphic controller display screens

Power supply: 208 VAC, 50/60 Hz, 30 Amps, 3-Phase.

SEMITOOL WST-406MG is a state-of-the-art photoresist equipment designed for wet processing, such as cleaning, etching and plating of wafers in a cleanroom environment. The system controls the temperature, concentration and duration of the wet processes with an automated feedback loop, enabling users to achieve repeatable, high-quality results. WST-406MG is a modular unit that can be easily configured to match the needs of a variety of processes. It features temperature control through an advanced digital heating and cooling machine maintaining a precise and consistent temperature range between 20°C and 80°C. The tool is also capable of precise control of the concentration of the photoresist solution with a pH meter and titration regulators. SEMITOOL WST-406MG also features a wide range of automated process controls, allowing users to program precisely timed processes that are easily adjustable. This flexibility enables users to easily adapt the asset to their specific requirements. The model also has integrated safety features such as automatic shut-off and fluid leak detection to prevent accidents and ensure the cleanroom environment provides safe operation. WST-406MG has a high-capacity, precise automated wafer handling equipment that can perform up to 16 wafers in a single processing cycle, with a maximum wafer diameter of 200mm. The automated handling system ensures repeatable results and minimal downtime. SEMITOOL WST-406MG also offers process monitoring with a data logging function, allowing users to record and analyze the performance of their processes in real-time. This capability is essential for troubleshooting and improving the quality of the end results. Overall, WST-406MG is an advanced, flexible wet processing unit capable of producing exceptionally high-quality photoresist wafers. Its automated operation and integrated safety features guarantee consistent results with minimal operator intervention, making it an ideal choice for use in demanding, cleanroom environments.

There are no reviews yet