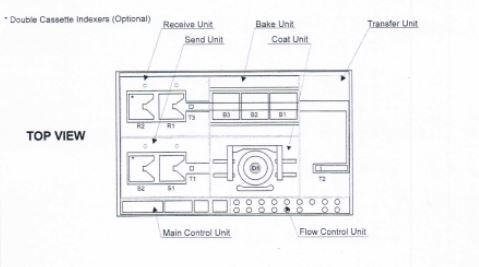

Used SEMIX / TAZMO TR 6133UD #293598589 for sale

URL successfully copied!

Tap to zoom

ID: 293598589

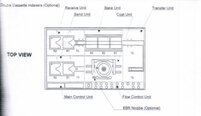

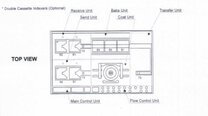

Wafer Size: 4"-6"

Coater systems, 4"-6"

(3) Zone hotplate

Single / double cassette

Fluoroware type with pitch of 3/16" for (25) Wafers

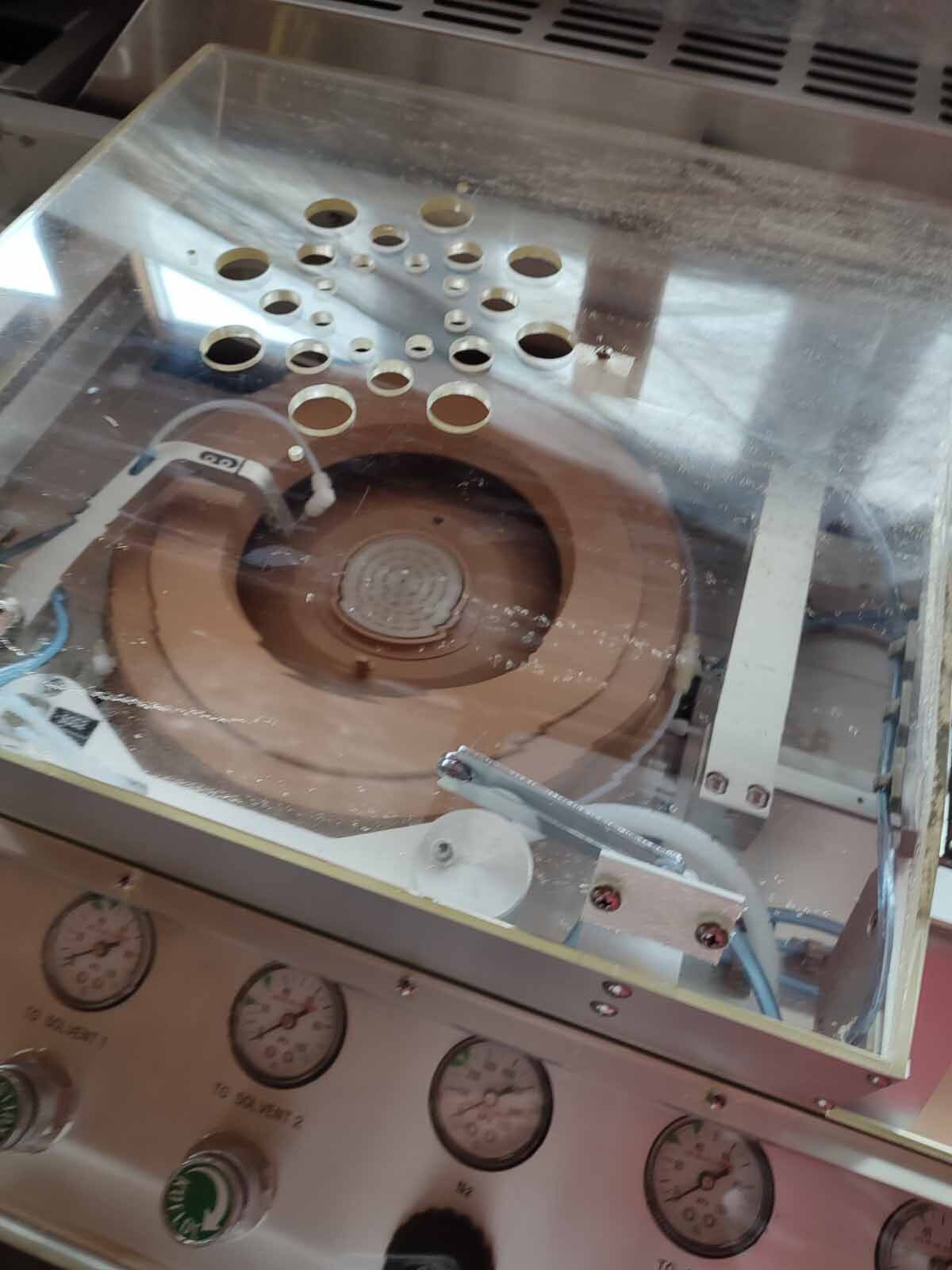

SOG Nozzles: 0.85mm, 1/16" tubing

Nozzle capping mechanism

Nozzle cleaning with solvent

Splash back cup cleaning with solvent

Adjustable suck back valve

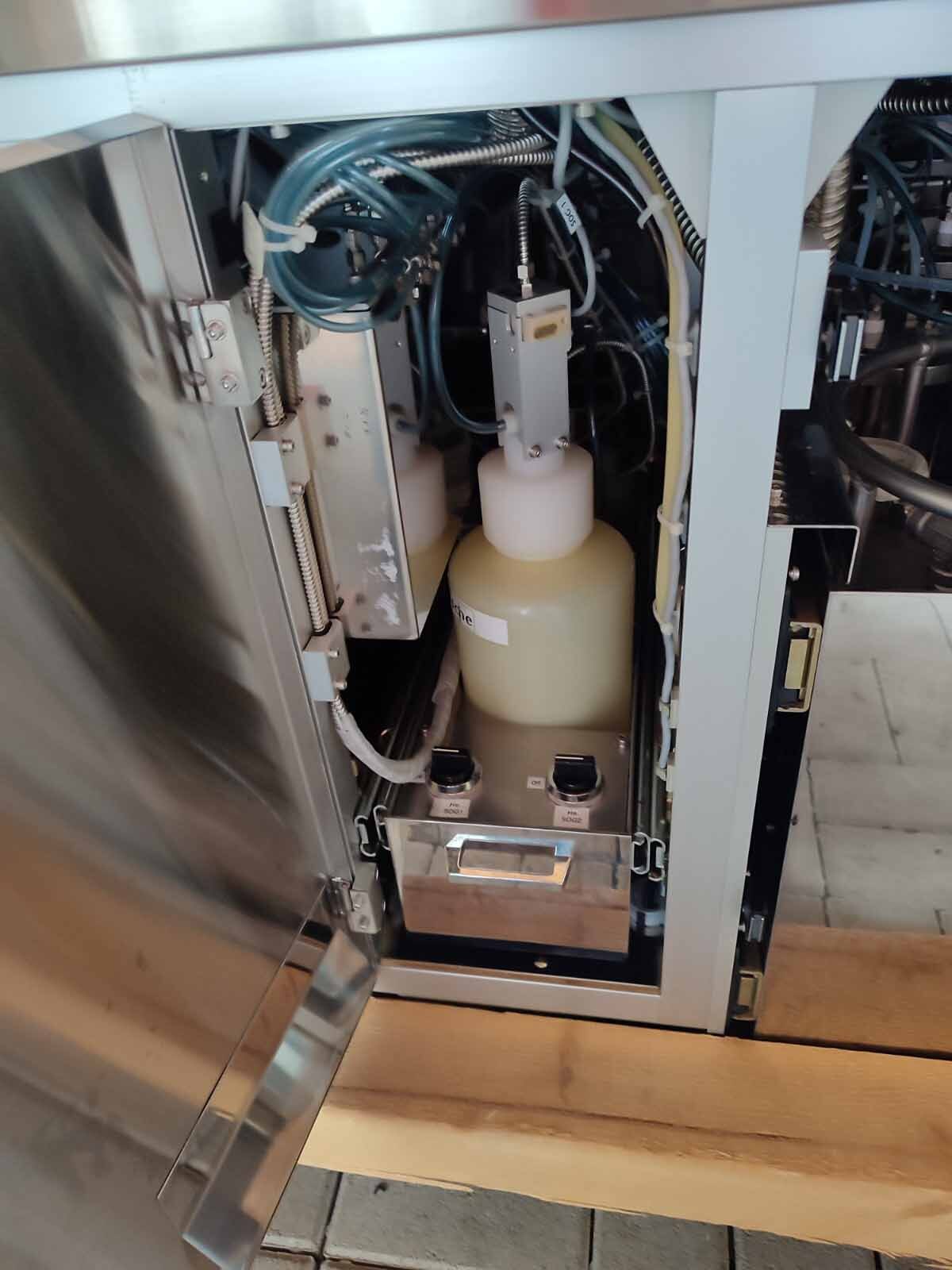

Polypropylene tank: 1 gallon

PVC, 11"

Teflon solvent tubing and suck back valve

(3) Vacuum chuck hot plates

Heater capacity: 3.8 Kw (total) at 250°C

Baking time: 0-999.9 secs with increments of 0.1 sec

Normal indicator setting: ±3°C

SOG Filter: .22 µm Fluoropore fitter

Chemical cabinet: 5 Gallon capacity

(2) Nozzles back side rinses (edge bead removal)

Solvent filter: MILLIPORE CWFG00403 Fluorex / WGFG04HP6 Wafergard

Gas line filter: MILLIPORE GTL WGFG01D Wafergard 0.22 µm filter

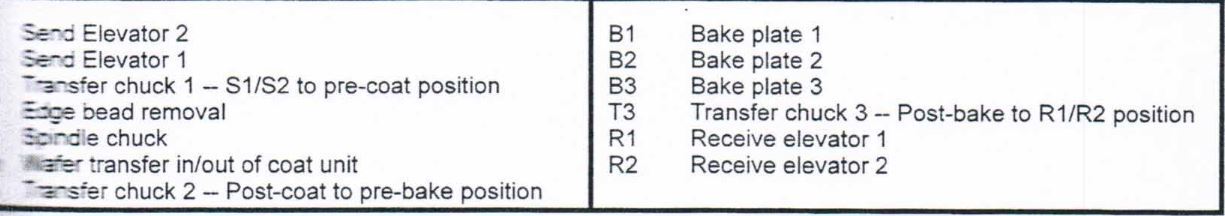

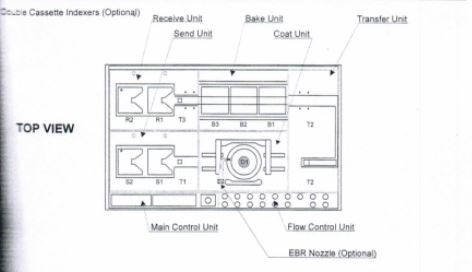

Wafer transport system:

Indexing elevator

Vacuum chuck

Shuttle mechanism

Walking beam

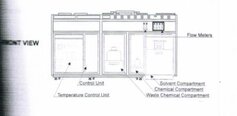

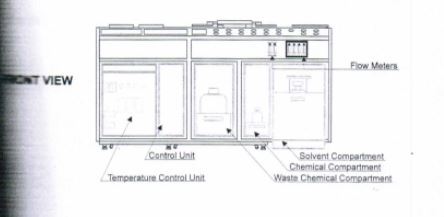

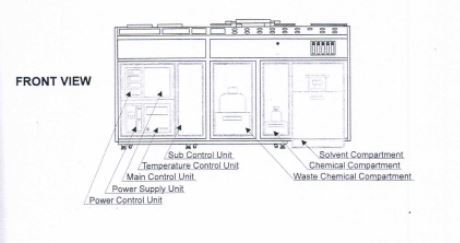

Control unit:

Microprocessor: INTEL 8065 (main and (2) sub CPUs)

Speed: 100-9000 RPM (4") / 8000 RPM (6") ± .15% (50-1990 RPM) and ±.1% (2000-6000 RPM) Alarm for speed ±3% of RPM (speed higher than 300 RPM)

Acceleration: Maximum rate 1 sec for 0 to 5000 RPM (programmable in increments of 1 sec)

Process: 20-Steps, 8 / 16 recipes

Temperature control: ±1°C Uniformity with alarm setting of ±3°C

Spinning, dispensing time: 0-99 Sec programmable

Baking time: 0-999 Sec programmable

Process display: Back-lit LCD.

SEMIX / TAZMO TR 6133UD is a fully automated and versatile photoresist equipment that can be used for a broad range of industrial applications. It is designed with photolithography techniques in mind and is capable of producing deep etch, planarization and high resolution patterning down to resolutions of 0.5 microns. The main unit consists of a digital control console and a vacuum table. The control console operates the micrometer scale X,Y,and Z axes of the vacuum table for accurate alignment and positioning of photoresist patterns. The vacuum table also contains a programmable exposure chamber and a dispense system for automated loading and unloading of the photoresist. SEMIX TR 6133UD offers a range of features, including a digital image recorder, dispense and drive control, wafer hand-off unit, and a vacuum machine. The image recorder records the desired green light exposure pattern, which is then used to drive the motion control of the X, Y and Z axes. The dispense and drive control is used to precisely control the flow of photoresist and the operation of the micrometer scale stages during patterning. The wafer hand-off tool helps with the transfer of photoresist coated wafers between the unit and the processing chamber. The vacuum asset helps to ensure a uniform and clean surface for high resolution patterning. TAZMO TR 6133UD provides excellent performance, with a repeatability of 10 microns and a high resolution of 0.5 microns. In addition, the model has a broad range of support equipment to aid in the development of photoresist-based devices and products. This includes automated dispensing tools, high-speed scanning tools, photoresist sputtering systems, and an array of photoresist-based depositing systems. TR 6133UD is an advanced photoresist equipment that provides high-resolution patterning capabilities, excellent repeatability and a broad range of support tools. It is designed to meet the needs of industrial applications requiring photolithographic procedures and can deliver high-precision results in a fraction of the time.

There are no reviews yet