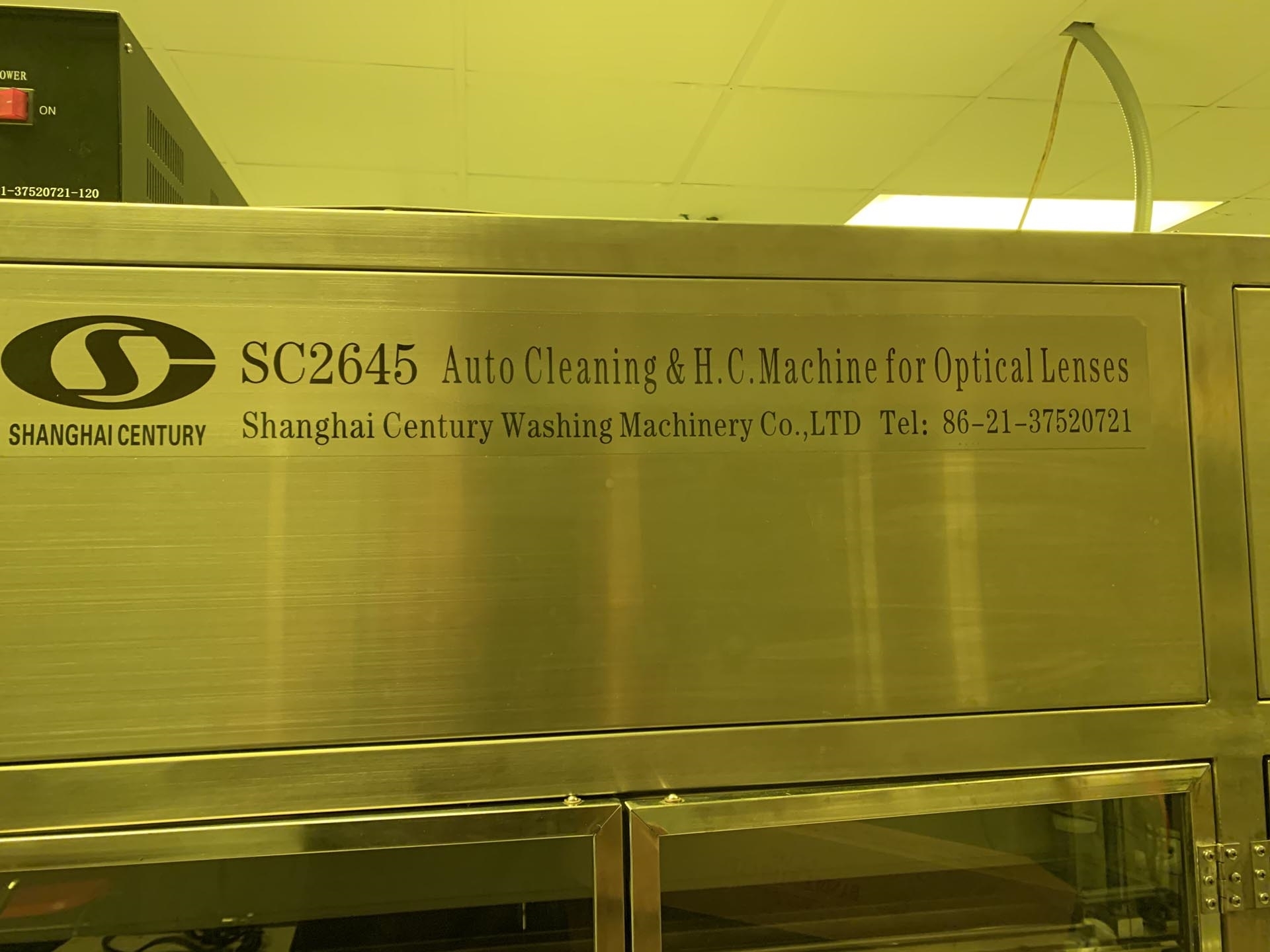

Used SHANGHAI CENTURY SC2645 #9269006 for sale

URL successfully copied!

Tap to zoom

SHANGHAI CENTURY SC2645 is a state-of-the-art photoresist coating and exposure equipment designed for advanced photolithography-based processes in semiconductor fabrication. It is suitable for both wet-etching and dry-etching based processes and can handle wafers up to 8-inch diameter. SC2645 photoresist system is comprised of several different components. The core of the unit is made up of a wet spray coater and a capillary. The coater is made up of a stainless steel housing, a spray gun, and a wafer stage tilt mechanism. The spray gun has an adjustable nozzle that can be adjusted for angled and targeted sprayed particle deposition. The capillary provides a consistent, controlled flow of photoresist material to the spray gun. The machine also includes two lithography exposure units, which can handle both contact and proximity exposure. These exposure units are outfitted with laser-beam scanners that can generate patterns with excellent precision and accuracy. The scanners can adjust light intensity, focus, alignment angle, exposure time, and beam length to generate optimized exposure. The drying station of SHANGHAI CENTURY SC2645 tool is a high-speed hotplate oven equipped with infrared thermometers and a high capacity fan. The oven can be set to temperature ranges from 90 to 330 degrees Celsius, with the duration of the drying controlled by an adjustable timer. This ensures that wafers are uniformly exposed and dried and provides consistent outcomes. To finish the photoresist coating process, SC2645 asset has a chemical development chamber equipped with an attached filtration pump model. The chamber is pressurized and can be heated up to 200 degrees Celsius to accelerate development. The filtration pump helps ensure that low-quality works don't enter into the process, thus improving quality control. The overall equipment also includes a filter unit, a vacuum pump, and a cooling system. All of these components are designed to provide a consistent and cost-effective photolithography process that can consistently produce high-quality results for advanced semiconductor fabrication.

There are no reviews yet