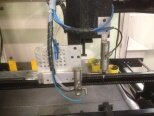

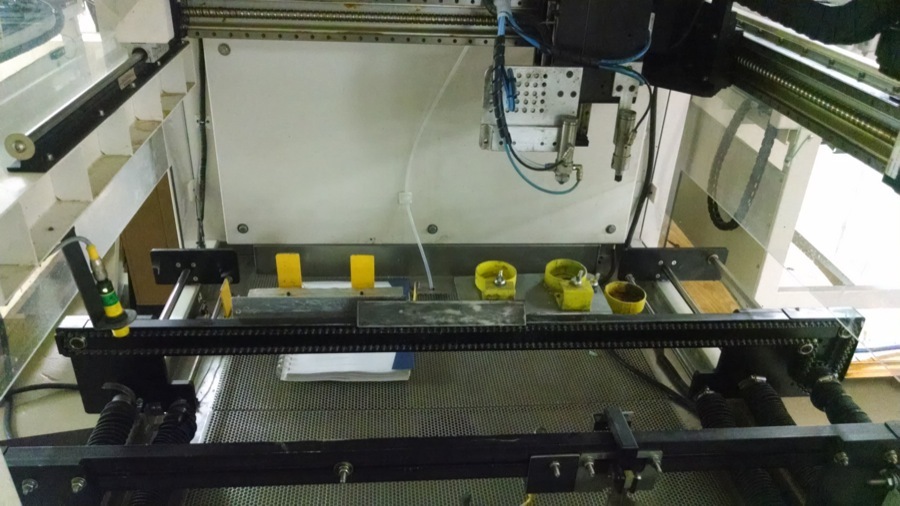

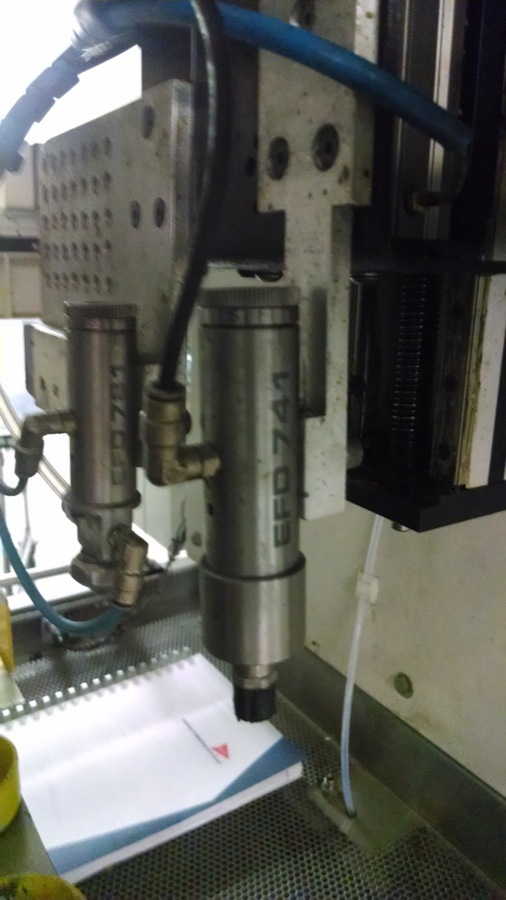

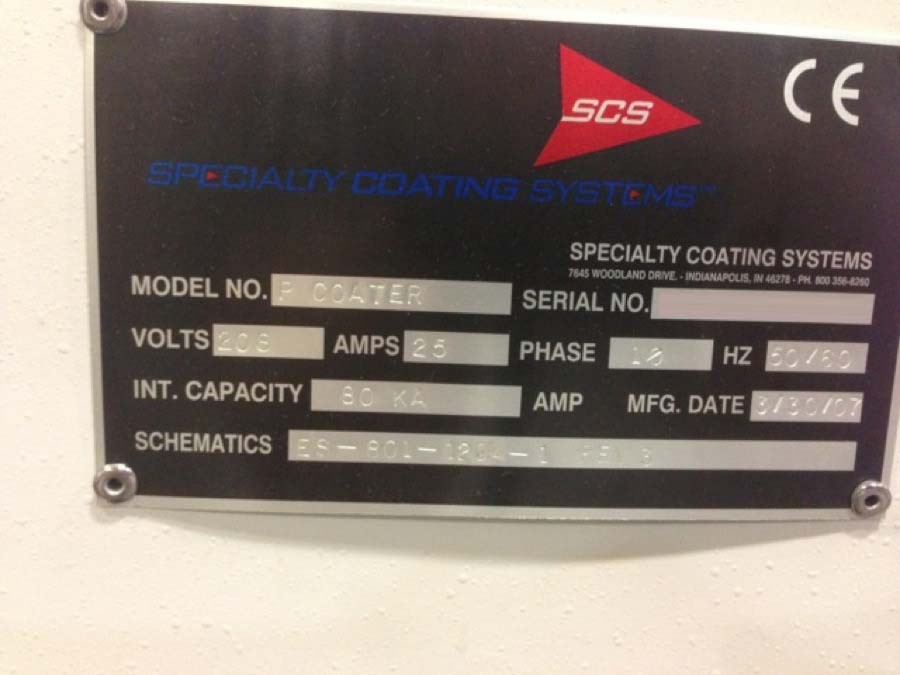

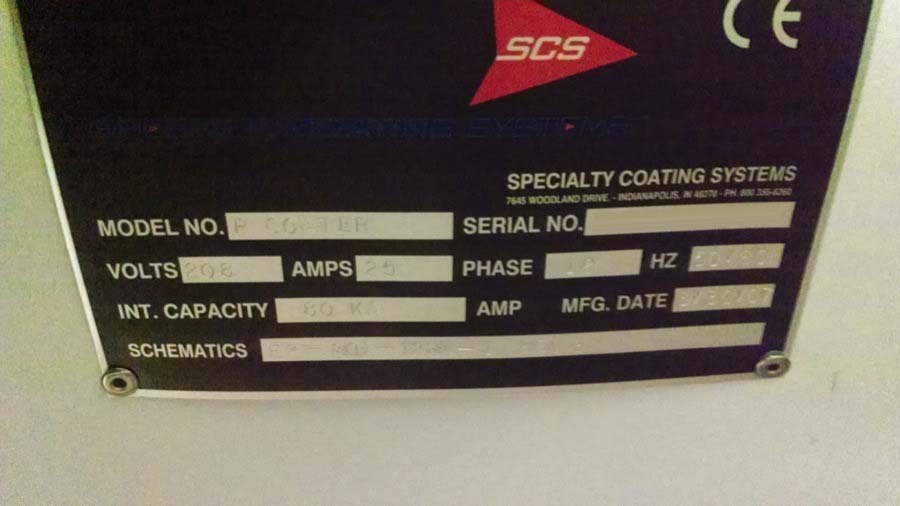

Used SPECIALTY COATING SYSTEMS / SCS P Coater #9093851 for sale

URL successfully copied!

Tap to zoom

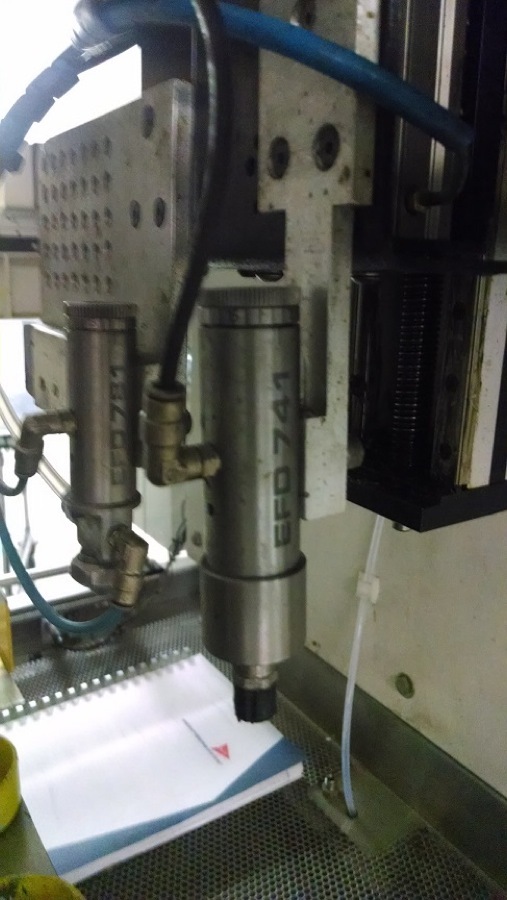

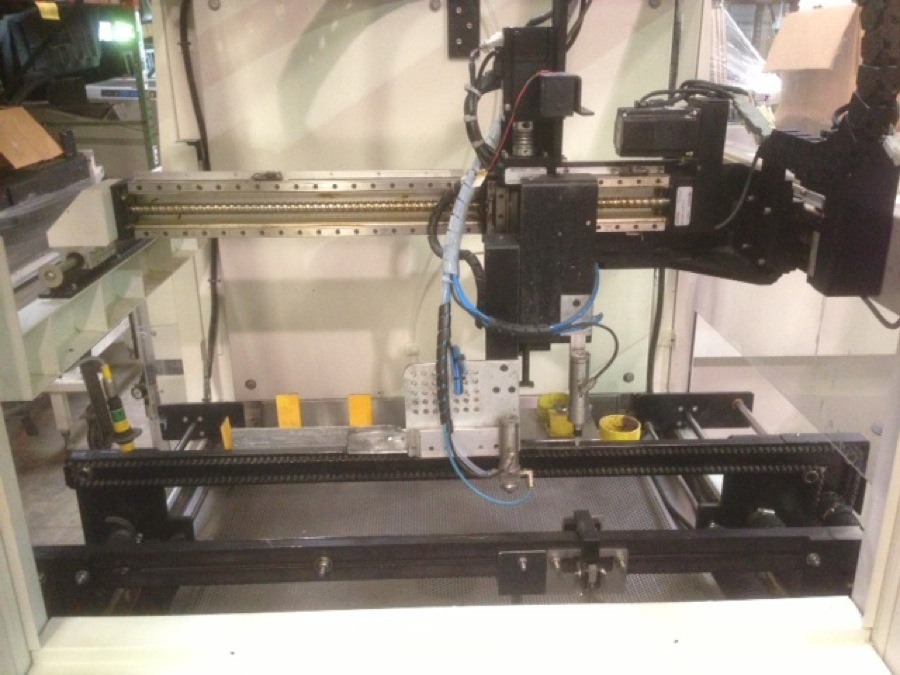

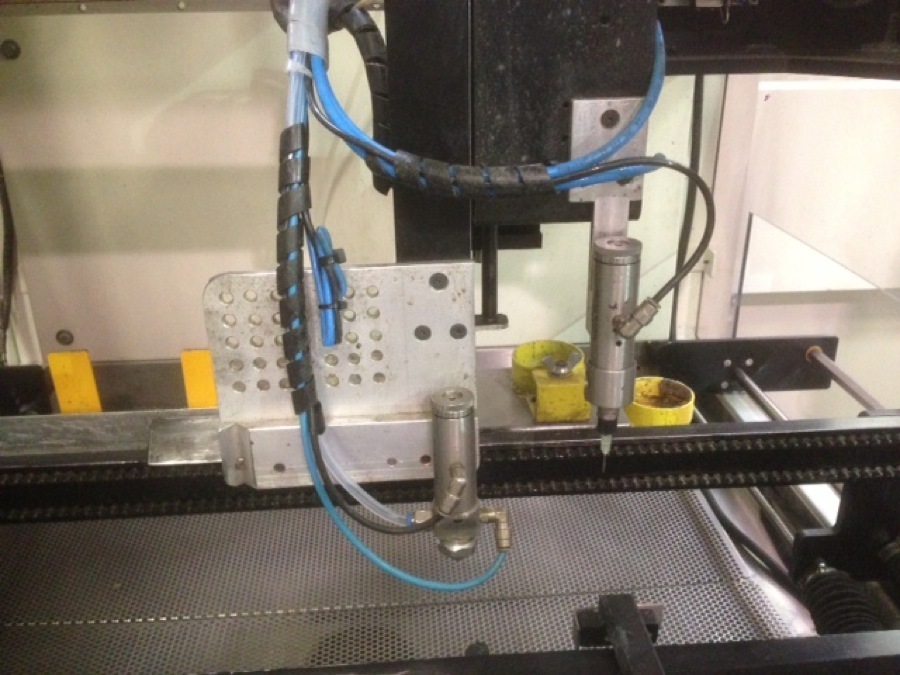

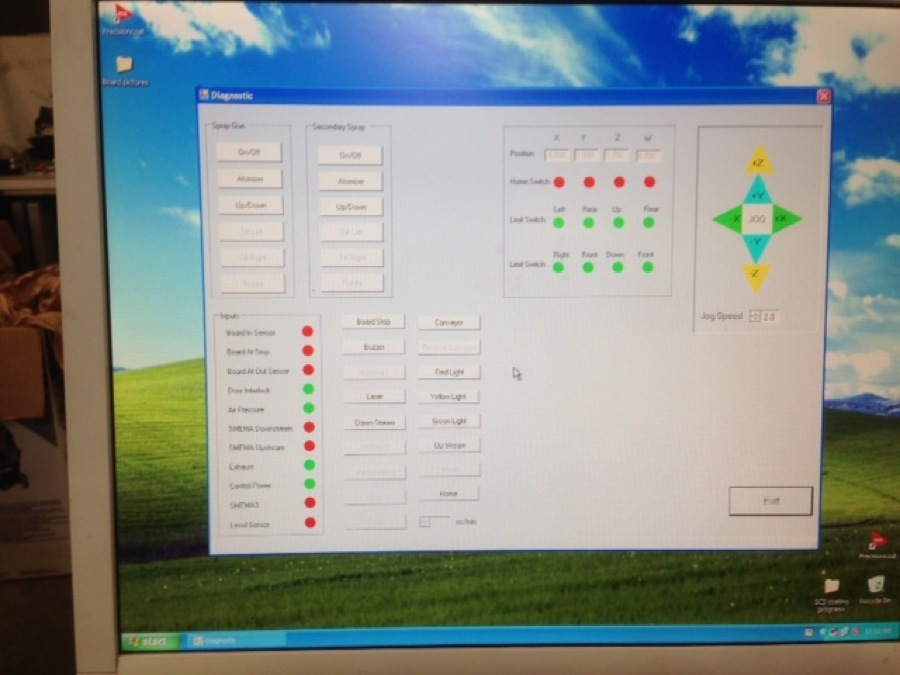

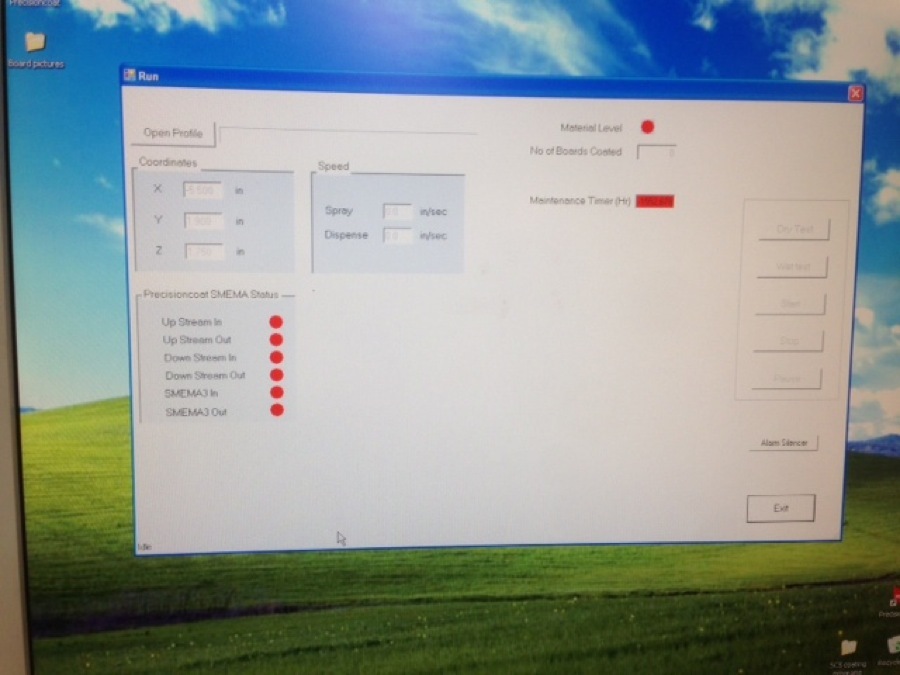

SPECIALTY COATING SYSTEMS / SCS P Coater is a photoresist equipment developed for the deposition of light-sensitive coatings onto glass and and other optically transparent substrates. The system consists of a light source, a controller, a sample stage, and an interchangeable filter wheel. The unit is capable of producing high-resolution, single-photon light exposure patterns with thicknesses ranging from 1 to 50 nm. The use of a beam shaping lens decreases the required beam energy, while the filter wheel creates a spectral control to select an appropriate light spectrum. SCS P Coater utilizes an advanced 6-axis robotic stage that allows for large amounts of sample movement while keeping the sample in the desired focal plane. The light source provides a high-intensity, coherent light source with random access patterns to create varying light exposures. The controller enables the user to set up exposure patterns, select exposure times, scan areas, and repeat exposures over desired sample areas. SPECIALTY COATING SYSTEMS P Coater is designed to coat photoresist onto any compatible substrate surface. The coated material is exposed with incident light, which triggers a chemical process that causes the photoresist material to harden at the exposed areas. In addition, the machine has the ability to vary the exposure levels, allowing for the creation of highly optimized surface patterns. P Coater also provides users with flexibility through a number of useful accessories. These include a sample heating source, a choice of sample holders, and a range of filters for selecting appropriate wavelengths for sputtering. The tool also includes an automated wafer cleaning station for removing dispersed particles from the surface in between sample coating processes. Overall, SPECIALTY COATING SYSTEMS / SCS P Coater is an efficient, high-precision asset for the deposition of light-sensitive coatings. Its advanced technology simplifies coating process setup and provides flexibility in coating parameters such as exposure level and spectrum. The model is suitable for a wide range of applications in the photolithography industry, enabling accurate deposition of functional layers onto substrates of varying type and size.

There are no reviews yet