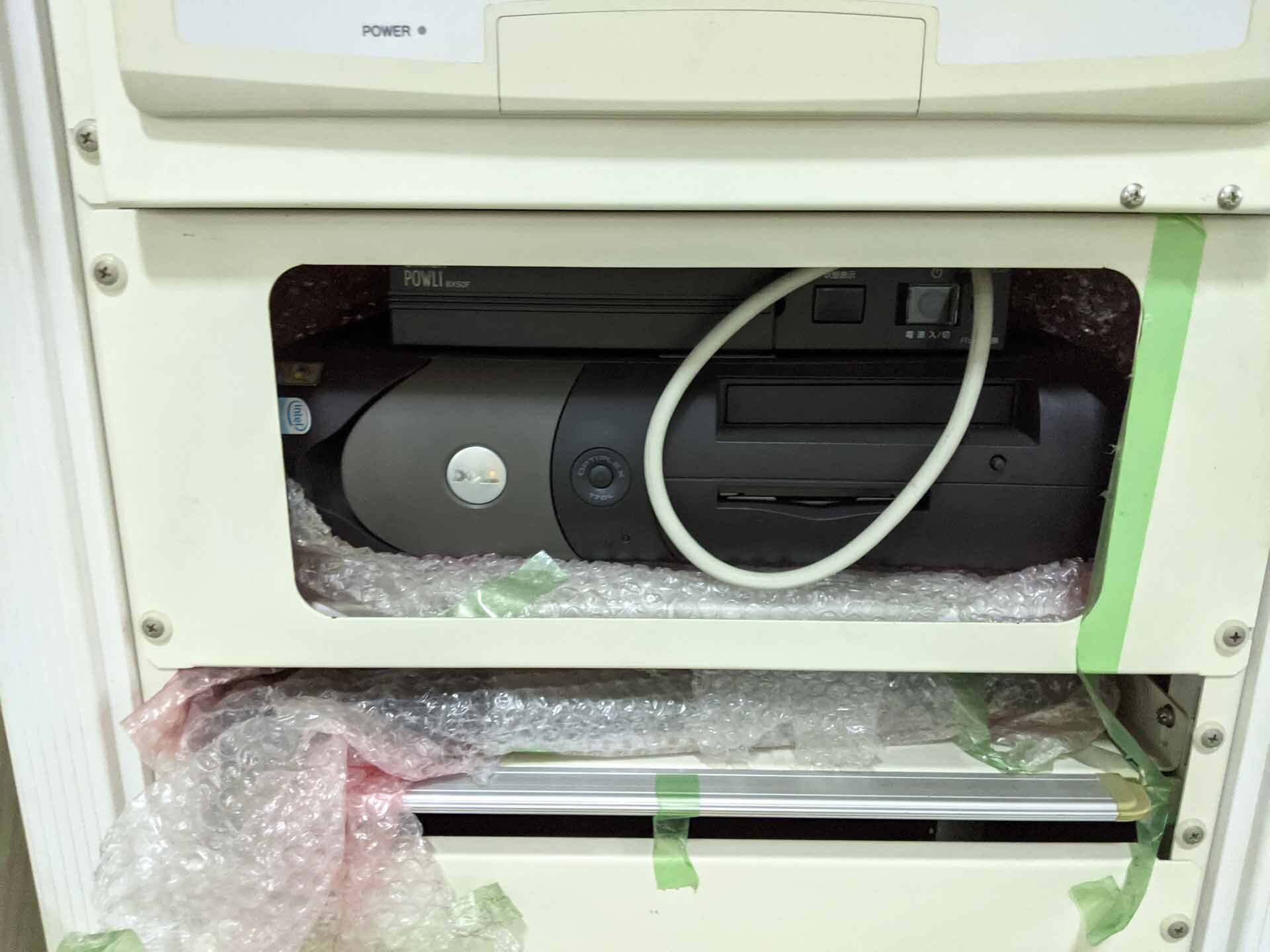

Used SSC BPE-2708-SP #9080483 for sale

URL successfully copied!

Tap to zoom

ID: 9080483

Wafer Size: 8"

Vintage: 2006

Gold plating machines, 8"

Plating mechanism: Fountain, face-down

Manual wafer load and unload

Solution: Non-cyanide, Au solution

Solution capacity: (14) Cups

Temperature control: Direct heating

Mechanism: PID Control

Temperature control range: Room temperature to ~70°C

Flow rate: Auto control by flow sensor, cup / Pump control mechanism

Plating tank: Laminate

Upper lid: PVC

Cup holder: HT-PVC and PPS, 8"

Upper lid arms: SUS Coated with PTFE

Upper lid open / Close: Air cylinder

Fountain pump: Polypropylene

Valve: PTFE AV valve, HT-PVC, PVC and PFA

Piping of Au solution: HT-PVC, Polypropylene and PFA

Piping of DIW and drain: HT-PVC, PVC, and PFA

Piping of exhaust: PVC

Plating unit: PVC

Cup location: (7) Lines x (2) cups

Fountain pumps: (14) MD-100FYK with inverter control: 8~50 L/min

With cup / Pump flow rate

Circulation pumps: (2) MD-100FYK with inverter control

With (2) circulation piping lines

Fountain filtration: (14) Sets of PP (Housing and cartridge)

Circulation filtration: (2) sets of PP (Housing and cartridge)

Solution level control: N2 level sensor for each solution tank

With (2) upper, lower, fixed, additive

Sensors: Temperature, leakage, flow rate, area

(4) Heaters, 3 kW

Power supply: Cabinet (Caster and adjuster)

Fixed electrical current

2-Channel switch: (2) 8~3000 mA (8 ~300 mA)

Precision: ±0.5 % by 300 mA

Control: Sequence control

Touch panel and PLC

Data recorded PC

(30) Programmable numbers

(90) Recipes per programmed number

Count current mod (mA / Hour)

Bump height uniformity: ≤ 5 % (10-15) points / Wafer

Bump height uniformity: ≤ 2 um - ≤3 um, 8" (80-120 points)

Flow rate: 35 L/min

Edge contact area / Cathode

No plating cup

2006 vintage.

SSC BPE-2708-SP is a photoresist equipment designed for use in the electronic industry. This system enables the deposition of sensitive patterns and other components on circuit boards and other substrates. It provides a high degree of accuracy, repeatability, and reproducibility. This unit is designed to work with different types of media, from printed circuits boards to epoxy boards. The machine works by using light-sensitive materials to deposit a pattern onto the substrate. These materials are then developed in a process called photoetching, which exposes them to light. BPE-2708-SP tool is equipped with several features that help ensure accurate and reliable results. First, it has a calibrated light sources that are adjustable in order to provide the best quality results possible. Secondly, it is equipped with an automated film pressure chamber, which maximizes contact between the photoresist and the substrate and helps ensure consistent results. Lastly, it comes with a variety of photoresist products, including dry films, liquid masks, and wet etch solutions. The asset is designed for both one-time use applications and for use in a permanent application over multiple boards. For permanent applications, the user can adjust the light source intensity, the film pressure thickness, the film temperature, and even the developing time in order to achieve the desired results. The model is also designed to be used with various common circuit board materials, from Plastic to Ceramic. SSC BPE-2708-SP is a versatile, reliable and efficient photoresist equipment for optimal patterning. This system has the ability to produce high quality images both in single-pass applications and permanent applications across numerous substrates. It is a unique and capable tool for producing fine details on every material.

There are no reviews yet