Used SSC BPE-2708-SP #9220820 for sale

URL successfully copied!

Tap to zoom

ID: 9220820

Wafer Size: 8"

Vintage: 2006

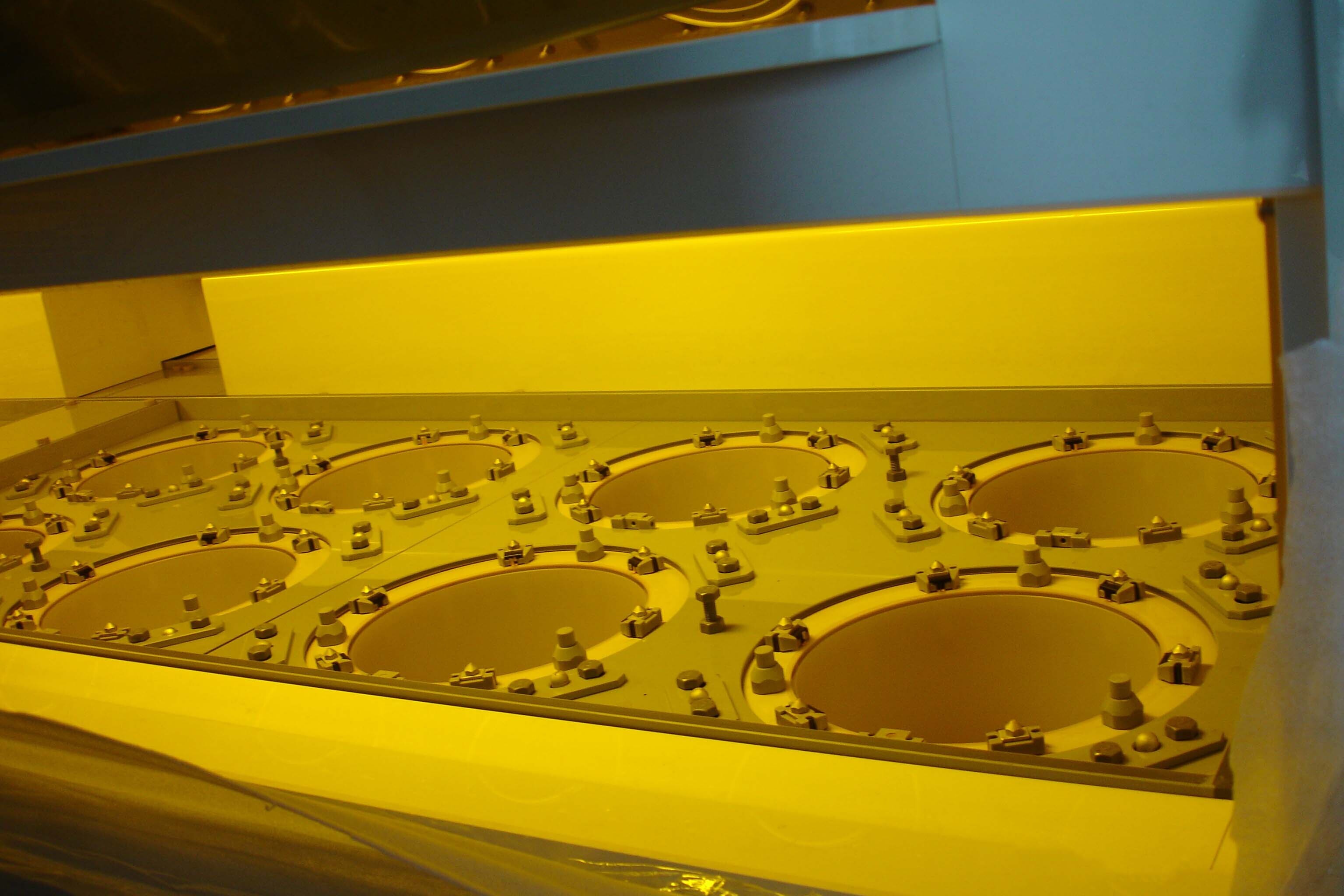

Gold plating machines, 8"

Plating mechanism: Fountain, face-down

Manual wafer load and unload

Solution: Non-cyanide, Au solution

Solution capacity: (14) Cups, 8"

Temperature control: Direct heating

Mechanism: PID Control

Temperature control range: Room temperature to ~70°C

Flow rate: Auto control by flow sensor, cup / Pump control mechanism

Plating tank: Laminate

Upper lid: PVC

Cup holder: HT-PVC and PPS, 8"

Upper lid arms: SUS Coated with PTFE

Upper lid open / Close: Air cylinder

Fountain pump: Polypropylene

Valve: PTFE AV valve, HT-PVC, PVC and PFA

Piping of Au solution: HT-PVC, Polypropylene and PFA

Piping of DIW and drain: HT-PVC, PVC, and PFA

Piping of exhaust: PVC

Plating unit: PVC

Cup location: (7) Lines x (2) cups

Fountain pumps: (14) MD-100FYK With inverter control: 8~50 L/min

With cup / Pump flow rate

Circulation pumps: (2) MD-100FYK With inverter control

With (2) circulation piping lines

Fountain filtration: (14) Sets of PP (housing and cartridge)

Circulation filtration: (2) sets of PP (housing and cartridge)

Solution level control: N2 level sensor for each solution tank

With (2) upper, lower, fixed, additive

Sensors: Temperature, leakage, flow rate, area

(4) Heaters, 3 kW

Power supply: Cabinet (Caster and adjuster)

Fixed electrical current

2-Channel switch: (2) 8~3000 mA (8 ~300 mA)

Precision: ±0.5 % by 300 mA

Control: Sequence control

Touch panel and PLC

Data recorded PC

(30) Programmable numbers

(90) Recipes per programmed number

Count current mod (mA / Hour)

Bump height uniformity: ≤ 5 % (10-15) points / Wafer

Bump height uniformity: ≤ 2 um - ≤3 um, 8" (80-120 points)

Flow rate: 35 L/min, no leakage from backside

Edge contact area / Cathode

No plating cup

2006 vintage.

SSC BPE-2708-SP Photoresist equipment is an advanced automated, precision laser exposure system designed to meet the needs of rapidly evolving fabrication technologies. It is ideally suited for advanced photolithography applications that require high precision and high detail resolution. At its heart, the unit is equipped with SSC proprietary solid-state laser machine. This laser tool produces high-powered pulses at a variety of adjustable frequency, duration, and energy levels that can precisely and accurately exposure photoresist material without causing damage. The asset further includes a pair of high-resolution camera systems, designed to monitor and control the laser exposure process. This ensures that each pass of the laser precisely follows the pre-determined pattern, resulting in a uniform photoresist exposure. In addition, the model includes an automated material handling equipment factors. This enables the operator to quickly and easily load two standard masks per photolithography job, maximizing throughput. The material handling system ensures that the masks can be precisely positioned before the laser is fired, resulting in high precision and repeatability. The unit also includes a high-powered and capable archiving machine. This enables the operator to store photolithography settings and parameters for easy recall, further maximizing throughput. The tool is controlled via an intuitive, easy-to-use interface. This display includes real-time feedback on photolithography progress, providing a visual summary of the results of each laser exposure step. Overall, BPE-2708-SP Photoresist Asset is an ideal solution for advanced photolithography applications that demand high precision and high detail resolution. Its robust feature set and automated material handling enables high throughput and ensures repeatable and consistent results with every job.

There are no reviews yet