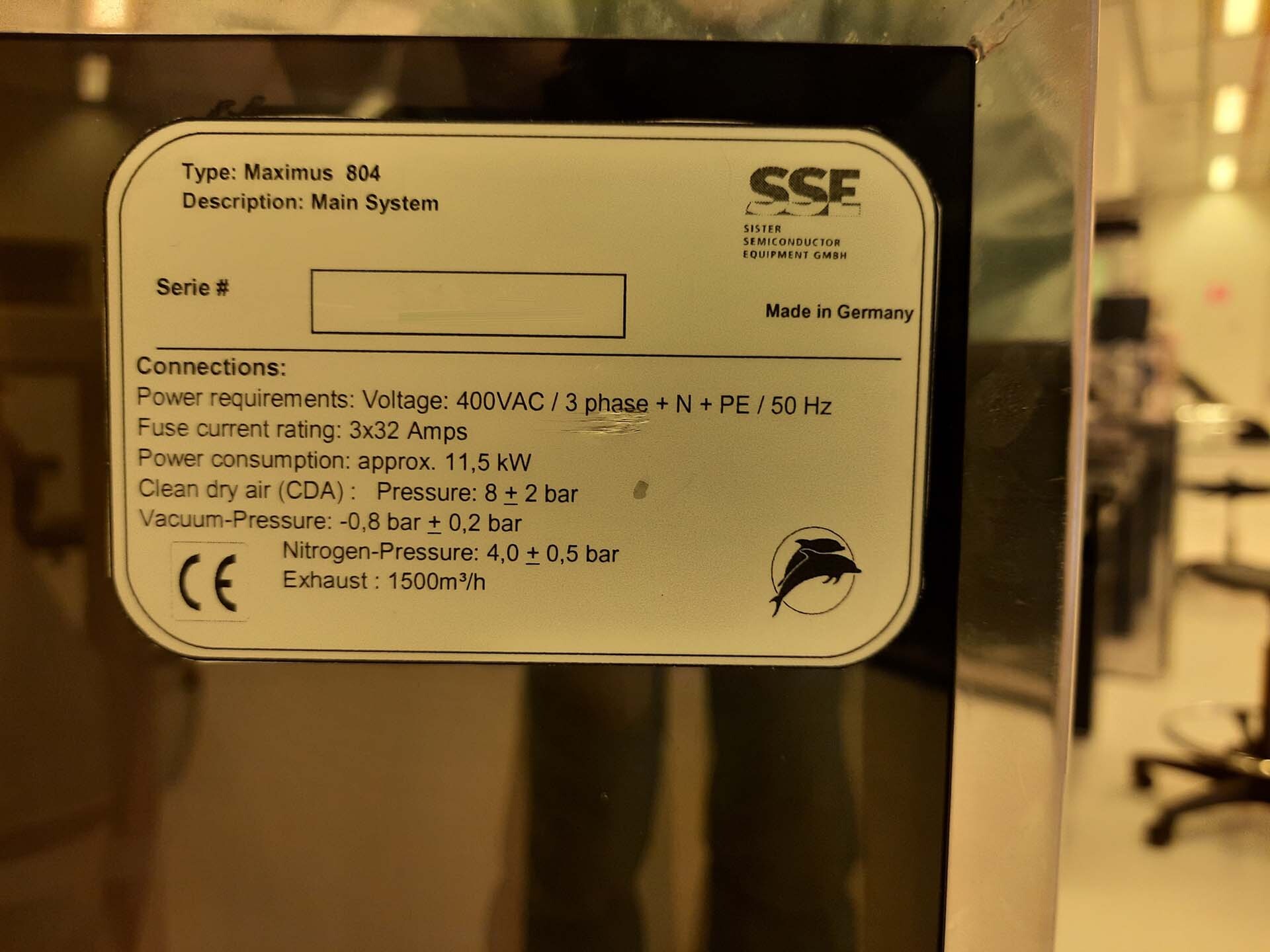

Used SSE Maximus 804 #293651477 for sale

URL successfully copied!

Tap to zoom

ID: 293651477

Coater / Developer system

Hot plates, 8"

Substrates: 6" x 6"

Cabinet

3-Axis robot

End effector vacuum standard, 4" -6"

Flat touch screen monitor

Computer

Ethernet interface

Cassette loading plate, 6"

Touchless video pre-alignment, 6"

Light tower: Red, yellow and green

Remote controller

Open bowl: 10,000 RPM

Acceleration ramp: 50,000 RPM

Spinning time: 0.1-999 Sec

Standard drain with 5I waste tank

High level sensor

Clean dry air pressure: 8 ±.2 bar

Vacuum: -0.8 ± 0.2 bar

Coater and developer module:

Bowl, 8"

Waste tank with high level sensor: 5 Litres

Chuck, 4"-6"

BSR Nozzle

Media valve

Tubing

Nozzle

(3) Dispense pumps: 15 ml

EBR Nozzle

Hot / Coolplate stacker module:

8-Slots

Nitrogen purge

Vacuum

Exhaust

Coolplate, 8"

(2) Hotplates, 8"

Temperature uniformity and control: +0.5°C at 100°C

Maximum temperature: 250°C

HMDS Vapor prime hotplate, 8"

Temperature uniformity and control: +0.5°C at 100°C

Maximum temperature: 200°C

CE Marked

Power supply:

3 x 208 VAC, 60 Hz, 32 A

3 x 400 VAC, 50 Hz, 32 A.

SSE Maximus 804 is a photoresist equipment designed to provide a comprehensive solution for a variety of photolithography and mask making applications. This system is used to transfer circuit patterns onto a substrate or wafer in the fabrication of semiconductor devices, printed circuits, and other microelectronic components. Maximus 804 utilizes a "traditional" ultraviolet (UV) photoresist unit, meaning it uses a chemical coating that is sensitive to UV light, resulting in a pattern being formed upon exposure to UV light. The machine features a variety of components to ensure efficient and accurate pattern transfer. It features a master tool controller, which is responsible for the operation of all components, an alignment asset for the accurate placement of the substrate for processing, and a range of photoresist options for various applications. In order to obtain the desired pattern result, an accurate alignment of the mask and the substrate must be achieved. The model utilizes the Alignment Equipment to accurately position the substrate. The Alignment System is capable of auto-align with a sub-micron accuracy using a combination of a digital camera unit and a 4-axis robotic arm. The machine is also equipped with the Photoresist Spray Tool, which utilizes a specially designed nozzle to apply a thin and uniform layer of photoresist to the substrate. The asset boasts a photoresist delivery range of up to 24 inches, and can be used in a variety of substrates such as quartz, glass, silicon, and various metals. Finally, a pattern is formed by the UV Exposure Model, which utilizes a laser source that is used to expose the photoresist material to ultraviolet (UV) light, resulting in the formation of a defined pattern on the substrate. The UV Exposure Equipment is capable of producing patterns up to 36 inches in size and offers a wide range of exposure intensities for various resist processing conditions. In conclusion, SSE Maximus 804 offers a comprehensive photoresist solution for a variety of photolithography and mask-making applications. It features a modern set of components such as an Alignment System, Photoresist Spray Unit and a UV Exposure Machine, all integrated into one tool, making it an ideal tool for photolithography processes.

There are no reviews yet