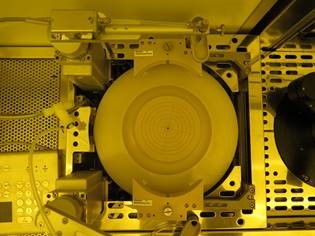

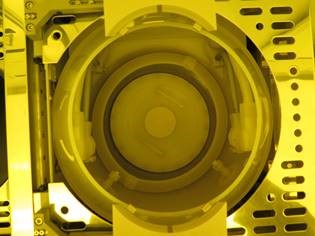

Used STEAG Cluster 421 #9136000 for sale

URL successfully copied!

Tap to zoom

ID: 9136000

Vintage: 1995

Microtech coater / developer

Coater-module with wafertec-pump, EBR

I/O-Station with separate input and output

(1) Cool plate mounted on Stack

(2) Hotplates

Robot for wafer transfer

Chiller to support cool plate

(1) Box of spare parts

1995 vintage.

STEAG Cluster 421 is a photoresist equipment that is designed for large-volume, high-precision production of planar and cylindrical lenses, as well as optoelectronic components. It uses an exposure resource to simulate various types of optical instrument characteristics and a lithographic process to create different structures on a substrate. Cluster 421 offers superior precision, with a spot size of 50 mm (1.97 in). The photoresist system is designed to accommodate a variety of substrates, including amorphous and crystalline materials, as well as all types of quartz, glass, and plastic surfaces. STEAG Cluster 421 also supports a wide range of substrates with different surface shapes, making it ideal for complex optical fabrication. The photoresist unit includes a print head, which can be used to apply the photoresist material to the substrate, as well as a developer machine, which can be used to develop the photoresist material. The developer tool is configured to provide high-resolution results at a high development speed, making it suitable for high-volume production. Cluster 421 also includes tools for controlling the exposure and developing processes, which allow users to tailor the photoresist asset to fit their specific needs. For example, users can select the right exposure resource to ensure that the best results are obtained. The photoresist model also has the ability to control the developer solution temperature, allowing for increased precision in the development process. In summary, STEAG Cluster 421 is a photoresist equipment specifically designed for the high-volume production of optical components. It offers excellent precision and speed, and the photoresist materials can be tailored to fit a variety of substrates. Furthermore, users have the ability to control the exposure and developing processes, ensuring the best possible results are achieved.

There are no reviews yet