Used SURFTECH / DAEDALUS Star4 #293608633 for sale

URL successfully copied!

Tap to zoom

ID: 293608633

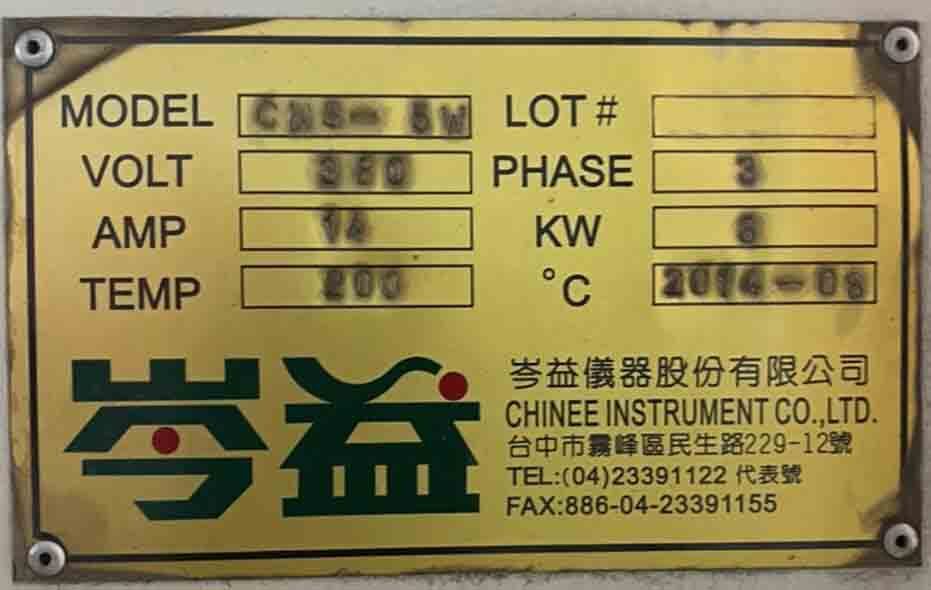

Ion coating system

Coating technology:

Special coating recipe: AlTiCrN, TiSiN, TiN, CrN

Process chamber:

Type: Stainless steel double walled chamber with shutter

Chamber size: 900 x 850 mm

Usable plasma zone: 600 x 550 mm

Arc source:

Deposition source: (4) Circle cathode targets, 6"

Power supply: (4) Digital DC power supplies

Auto trigger detection system

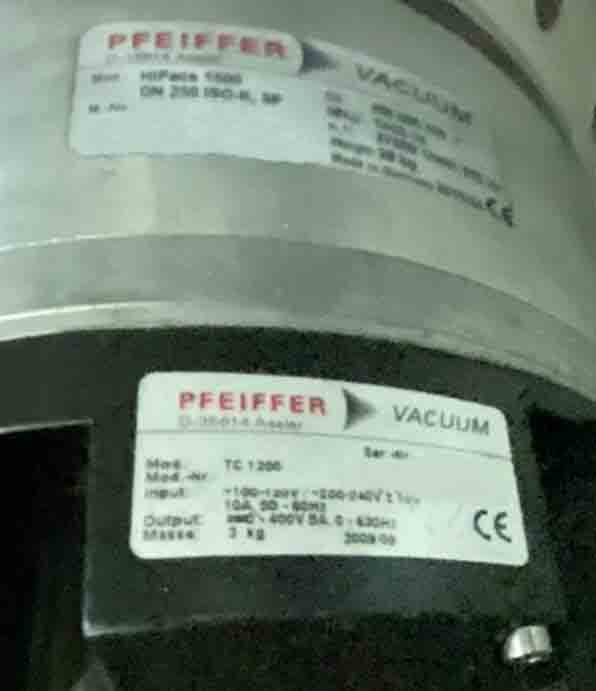

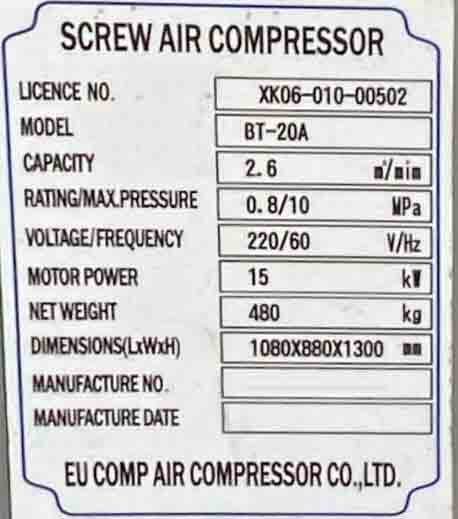

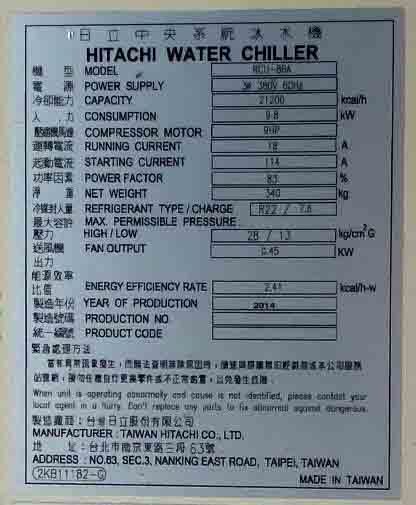

Pump:

ALCATEL / ADIXEN / PFEIFFER Turbo molecular pump, 1500 L/s

ALCATEL / ADIXEN / PFEIFFER Primary pump, 65 m³/h

ALCATEL / ADIXEN / PFEIFFER Booster pump, 250 m³/h

Vacuum measure:

SUCO Piezo gauge

(2) ALCATEL / ADIXEN / PFEIFFER Pirani gauges

ALCATEL / ADIXEN / PFEIFFER Penning gauge

MKS Baratron Gauge

Gas control:

MKS Mass Flow Controller (MFC), Ar and N2

(2) Heaters, 18 kW:

Measure: (2) Thermocouples

PID Temperature controller

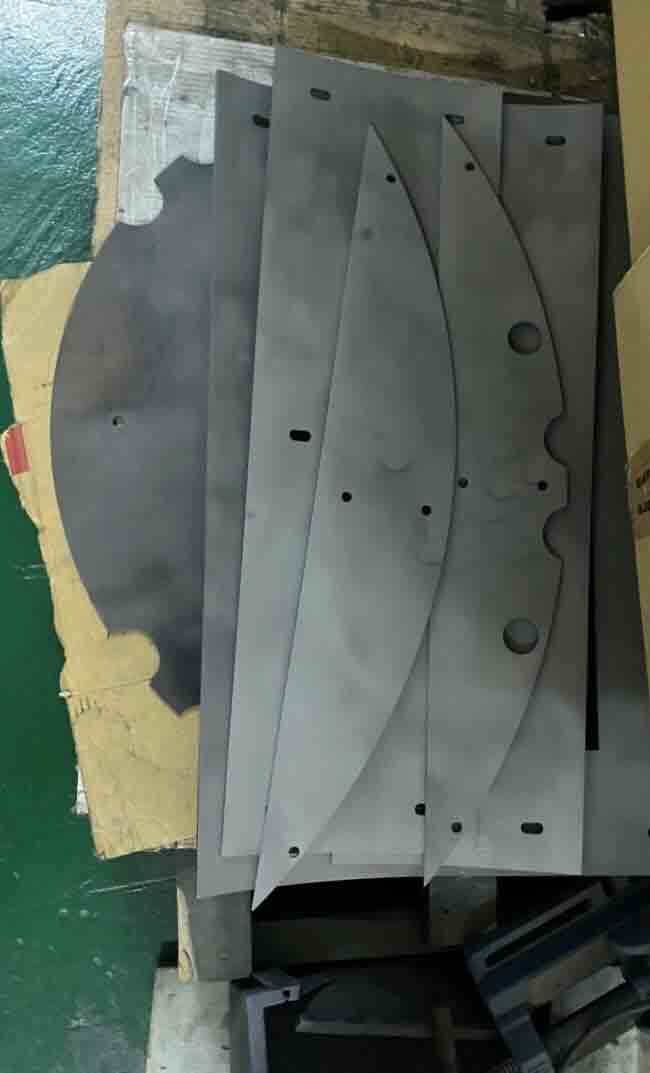

Substrate and carousel:

Carousel: 580 x 600 mm

Loading capacity: 500 kg

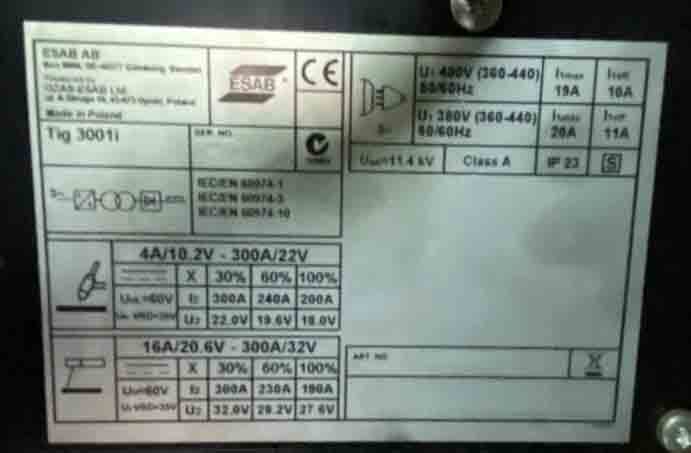

BIAS Power supply: Integrated ARC suppression, 15 kW, DC 1000 V, 25 A

Touch panel PC, 17"

Power supply: 380/400 V, 50/60 Hz, 45 kW, 3-Phase.

SURFTECH / DAEDALUS Star4 is a high-performance photoresist equipment designed primarily for precision commercial semiconductor lithography. Photoresists are light-sensitive materials used in the fabrication of semiconductor devices and circuits. SURFTECH Star4 provides exceptional uniformity and process stability, with best-in-class resolution down to 0.1 um. DAEDALUS Star4 features a patented Quad Light Source™, which emits an extremely uniform, broad UV light spectrum for superior process consistency. This is combined with advanced optics for superior light uniformity and higher throughput. Star4 also offers a high-precision wafer stage for accurate, repeatable alignment and focus. SURFTECH / DAEDALUS Star4 includes extensive process control and collection capabilities. The system offers a choice of robot or manual loading and a powerful controller for managing recipes and repeatable processes. Built-in software systems provide analysis and data retention, enabling operators to review and adjust recipes through real-time analysis. In addition, optional motorized optics for precise focus control further accelerate process development and improve accuracy. SURFTECH Star4 also comes equipped with process controls that provide high throughput and transparent access to equipment set points. Built-in defect inspection systems detect out of spec product before optimization, thus improving yield. The unit can easily be integrated into a factory's existing product lines, allowing for rapid integration. DAEDALUS Star4 is easy to operate, maintain and upgrade, with a wide variety of options to suit any application. The machine also provides diagnostic information thru on-screen and off-screen methods, as well as a large library of in-depth resources suitable for a variety of users. The tool is designed to exceed SEMI 2000 lithography standards. Overall, Star4 is a highly-capable photoresist asset that delivers robust performance, process control and repeatable uniformity. Superb resolution, reliable defect detection and extended lifetime characteristics ensure that the model is suitable for any semiconductor production needs.

There are no reviews yet