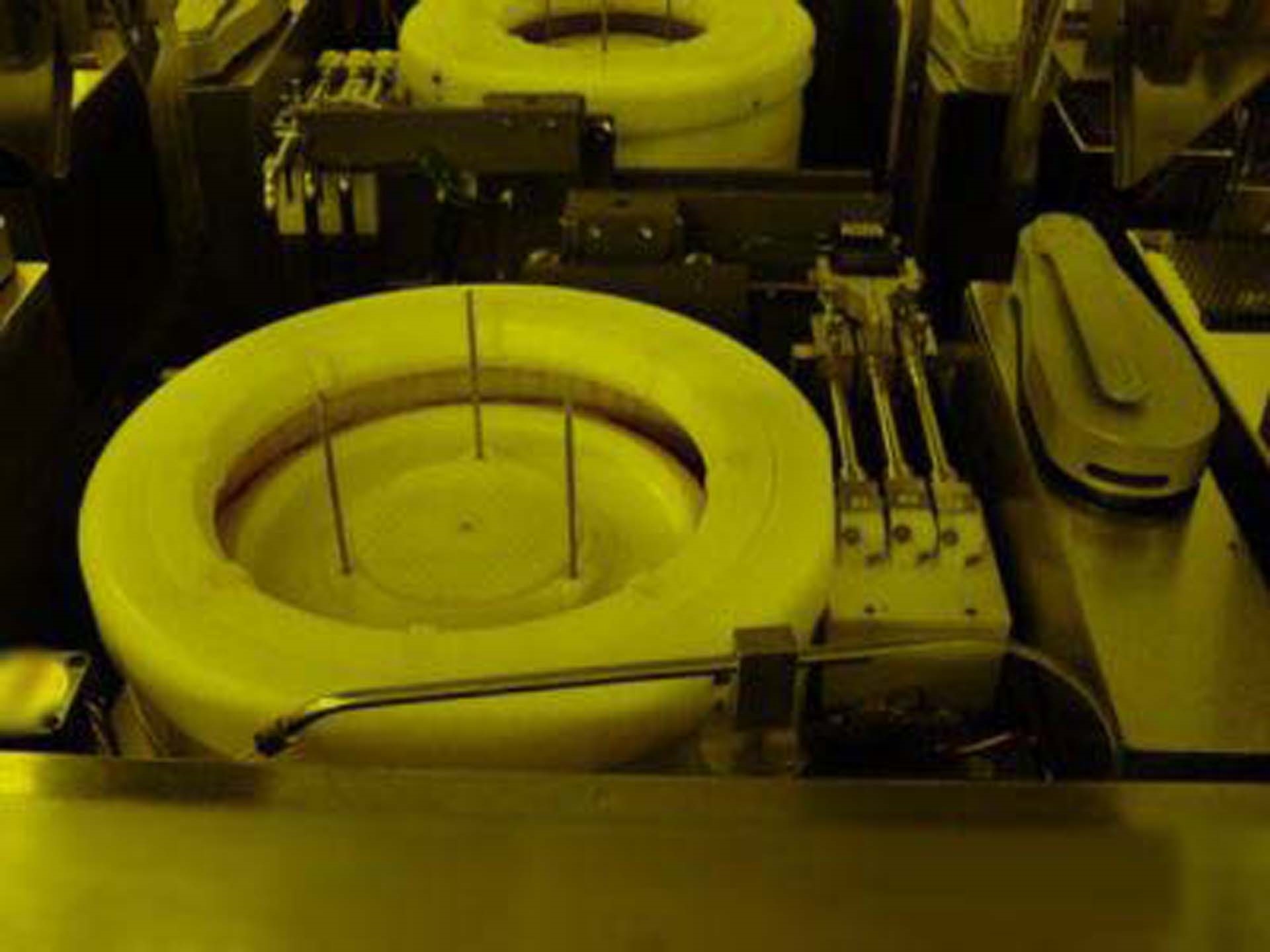

Used SVG 8800 #29252 for sale

URL successfully copied!

Tap to zoom

SVG 8800 is a next-generation photoresist equipment that enables advanced imaging capabilities for circuit board manufacturing. It combines the capabilities of electron beam lithography (EBL) used in conventional imaging systems and advanced etching techniques used in fine-line circuit board manufacturing. The result is an imaging system that provides the highest imaging resolution available in the semiconductor industry today. The imaging unit is based on a photoresist technique that utilizes intense ultraviolet (UV) light. The photoresist material is typically composed of a thin metal layer which absorbs the UV light. Photons from the UV light act on the metal layer and result in a change in the material's properties. This change allows for new electrical paths and etch marks to be formed in the metal layer to create circuit features. The intense UV light used in 8800 allows it to create circuit features with a greater precision than ever before. This is achievable because of its higher resolution than standard electron beam exposure systems. With this resolution, the machine enables the formation of incredibly small features and tracings which are essential for modern electronics manufacturing. Furthermore, SVG 8800 provides users with a range of exposure settings that can be adjusted according to the application. These settings provide the user with the flexibility to create the highest quality images in a wide range of circuit applications. A variable-aperture masking feature allows for the creation of multiple exposure settings on a single site with minimal effort. 8800 also includes a powerful data analysis tool for analysis of exposure settings and images. This analysis allows for rapid feedback during exposure settings phase and enables the user to make accurate decisions to optimize imaging results. SVG 8800 asset is capable of producing feature sizes from 40nm down to 1nm and its imaging resolution is sub-micron in size. This makes it ideal for applications such as Maskless Direct Write, where small feature sizes are critical, and for high-precision imaging for all semiconductor applications. Overall, 8800 is an advanced photoresist model that provides users with incredibly high levels of imaging resolution and etch accuracy. Its range of adjustable exposure settings and powerful data analysis equipment enable it to create precise images in a wide range of circuit applications, making it an invaluable tool for modern electronics manufacturing.

There are no reviews yet