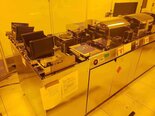

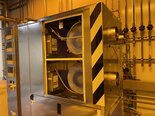

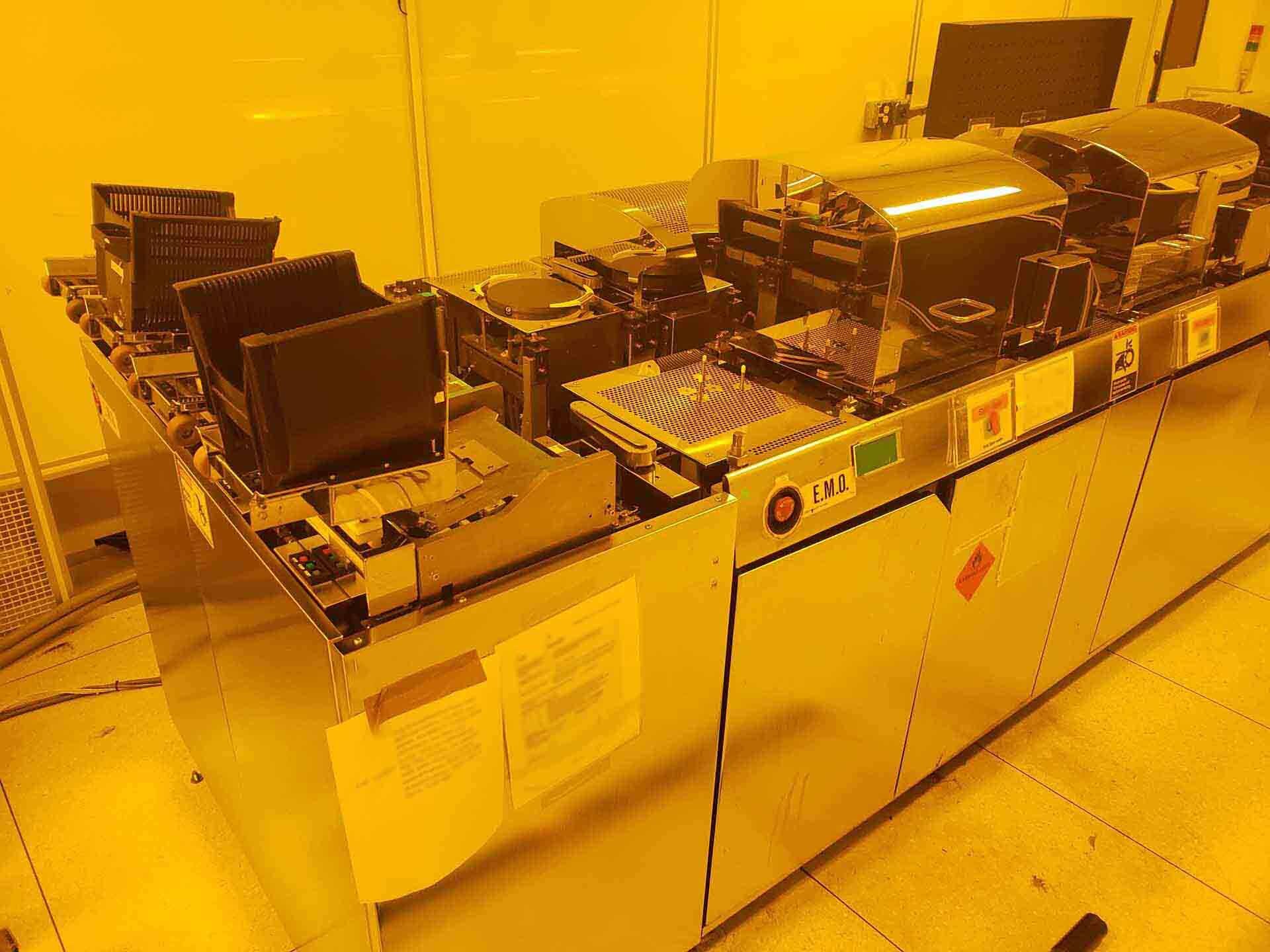

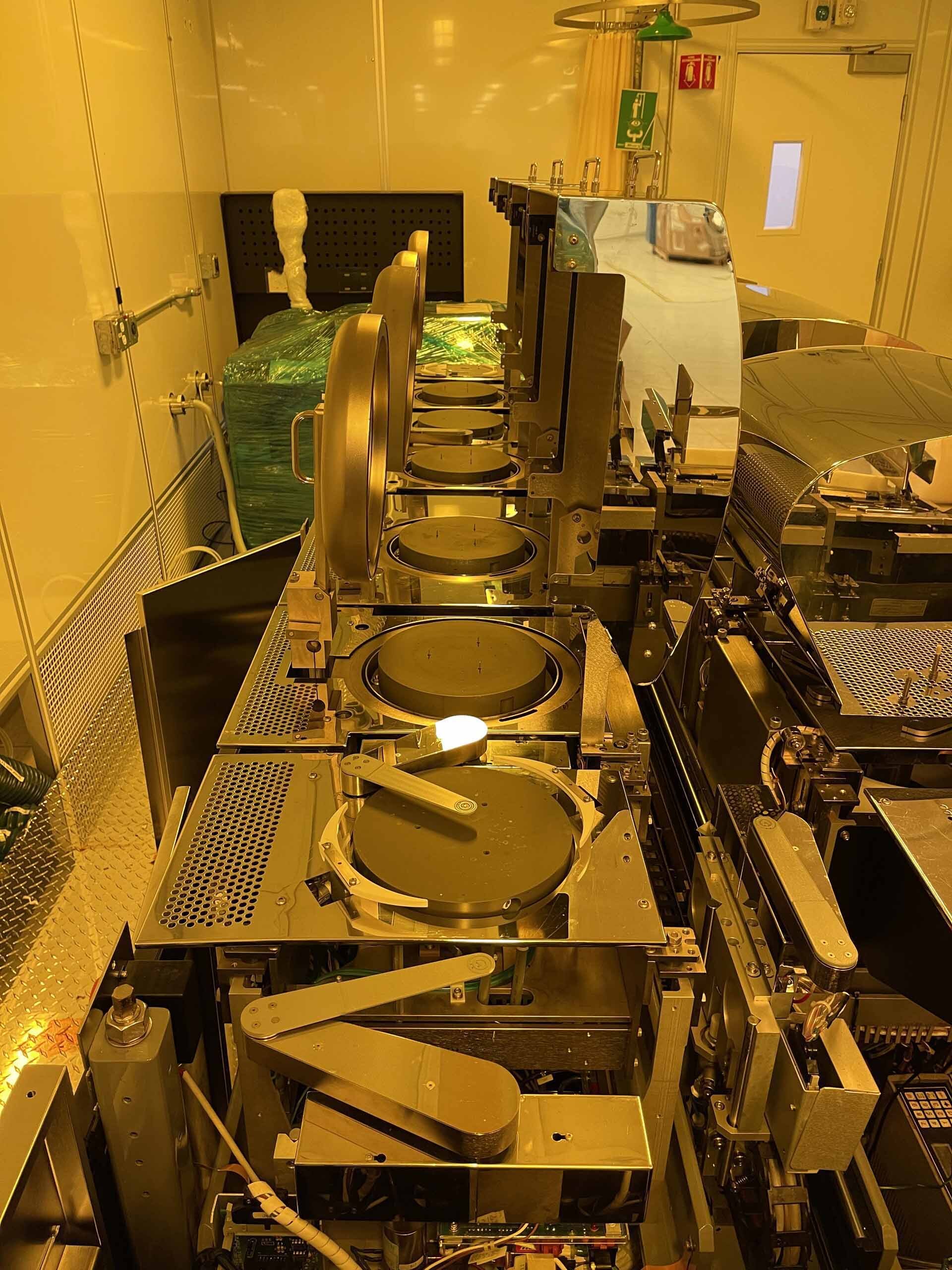

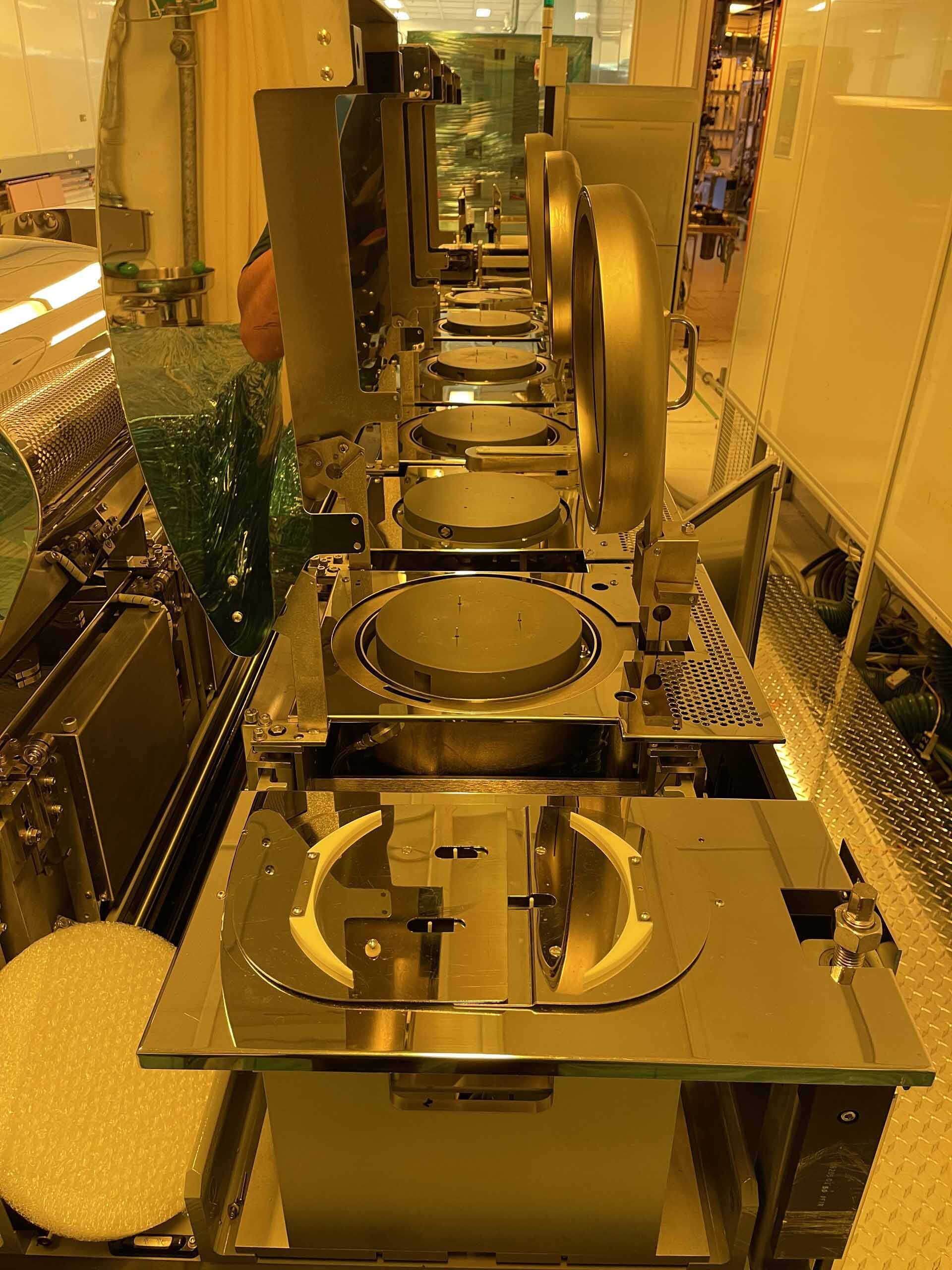

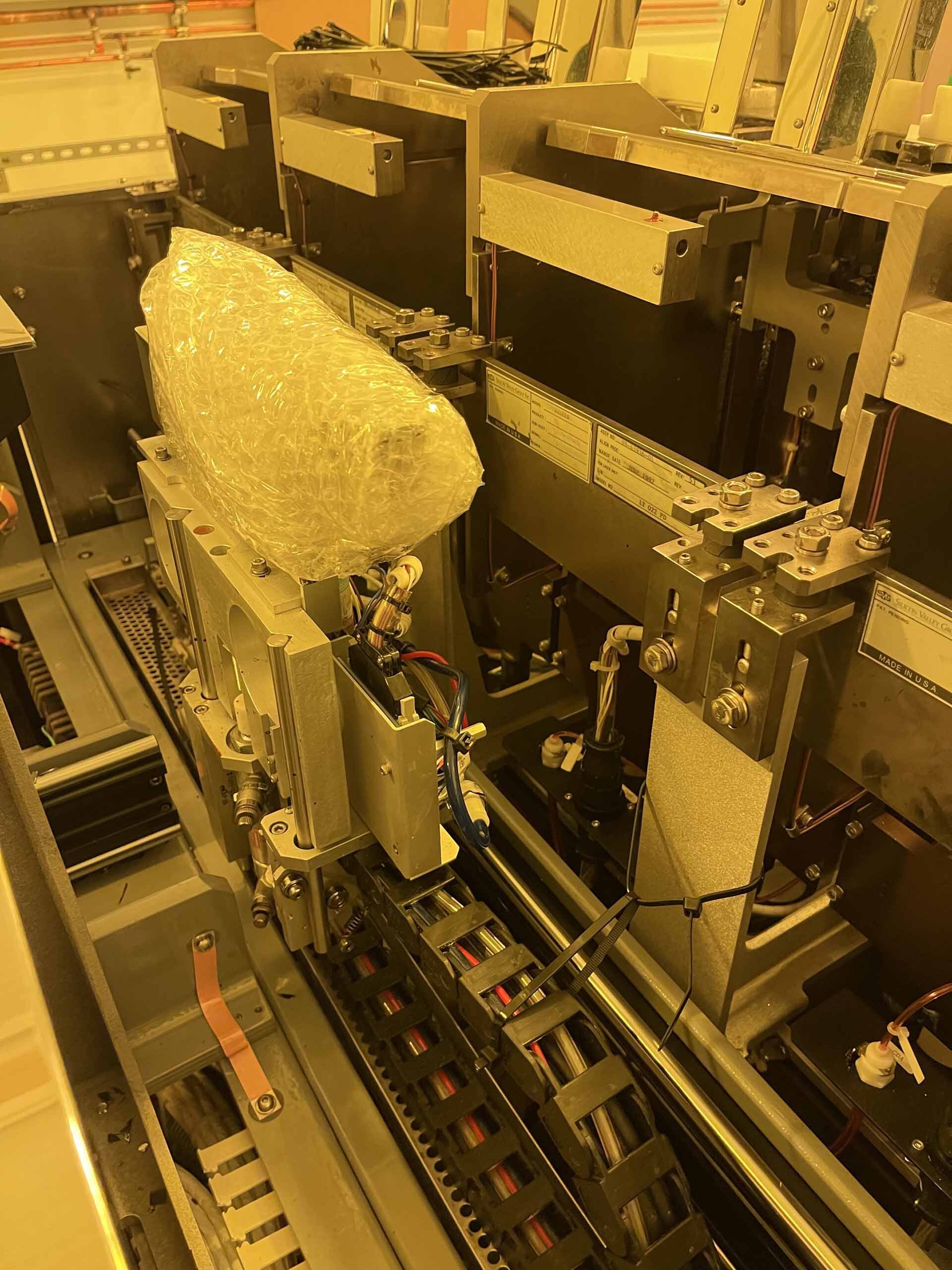

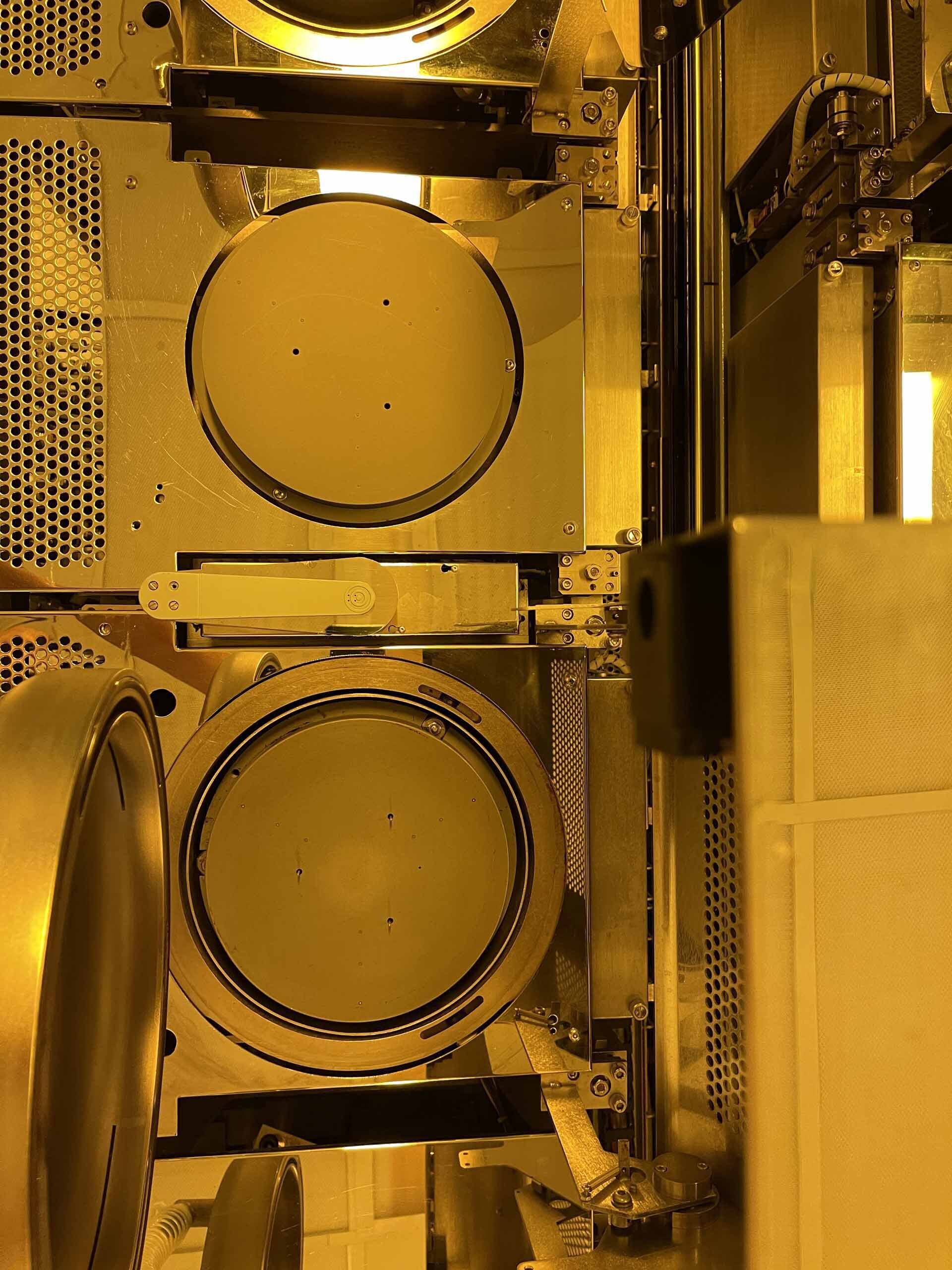

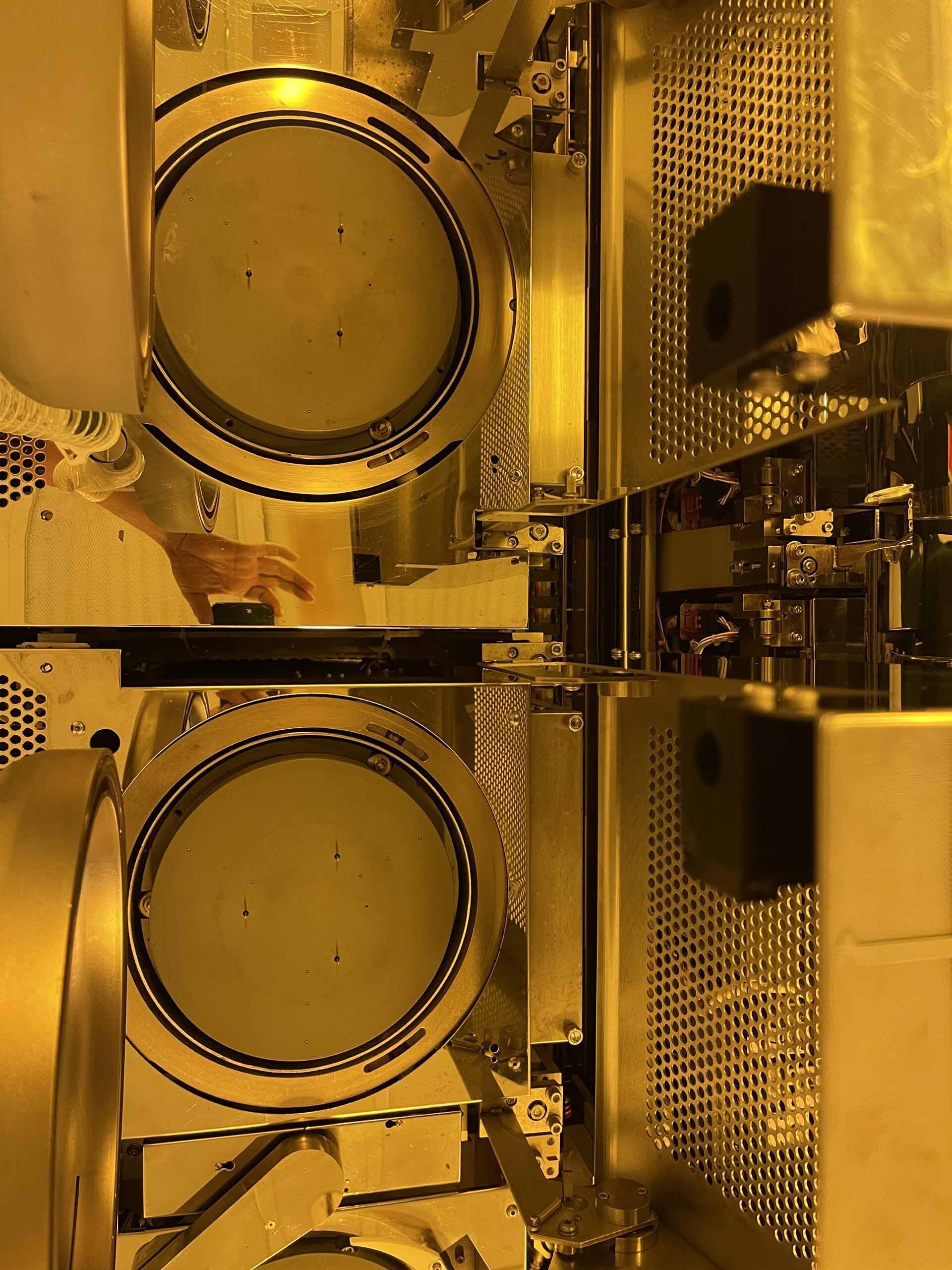

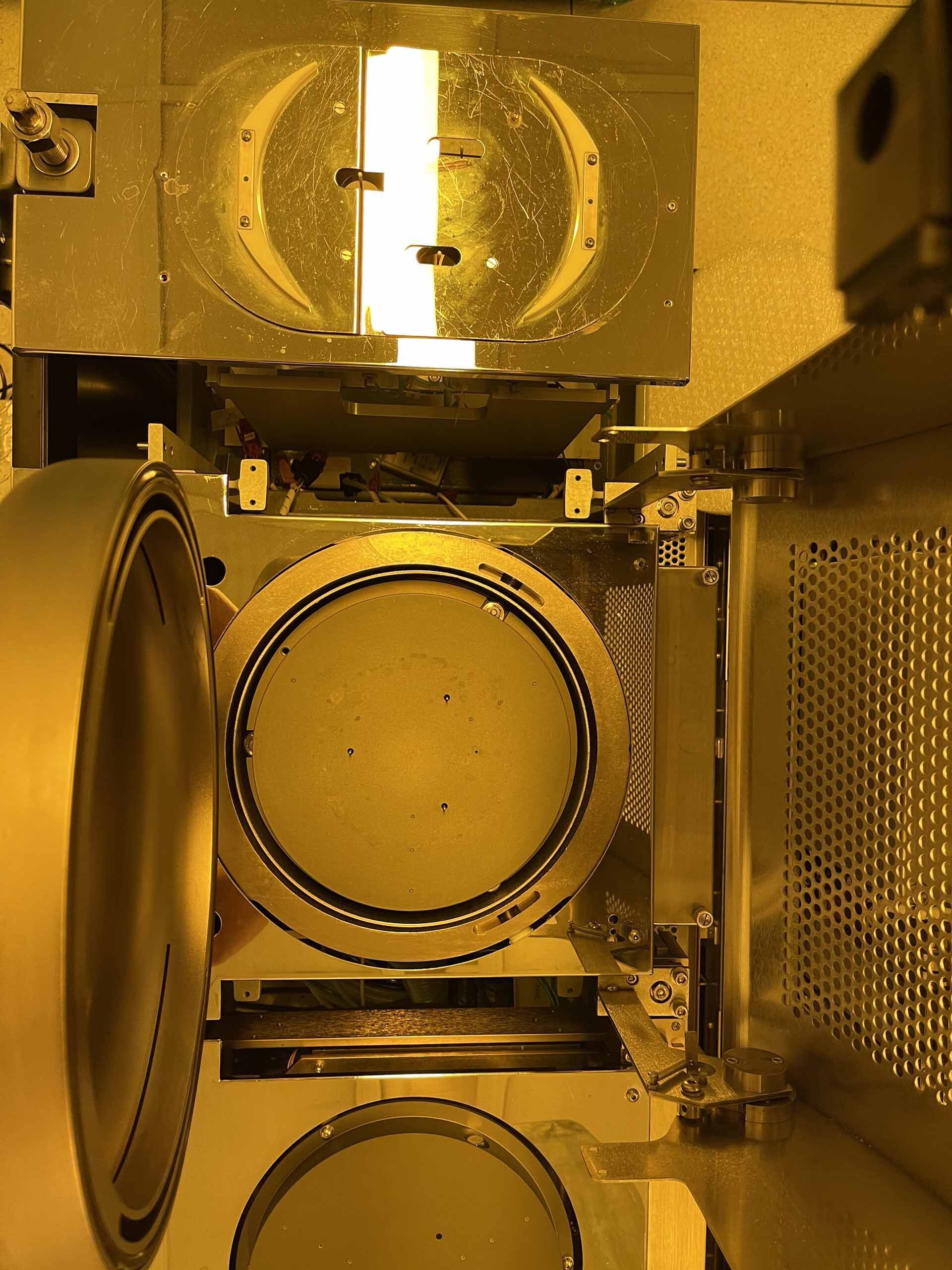

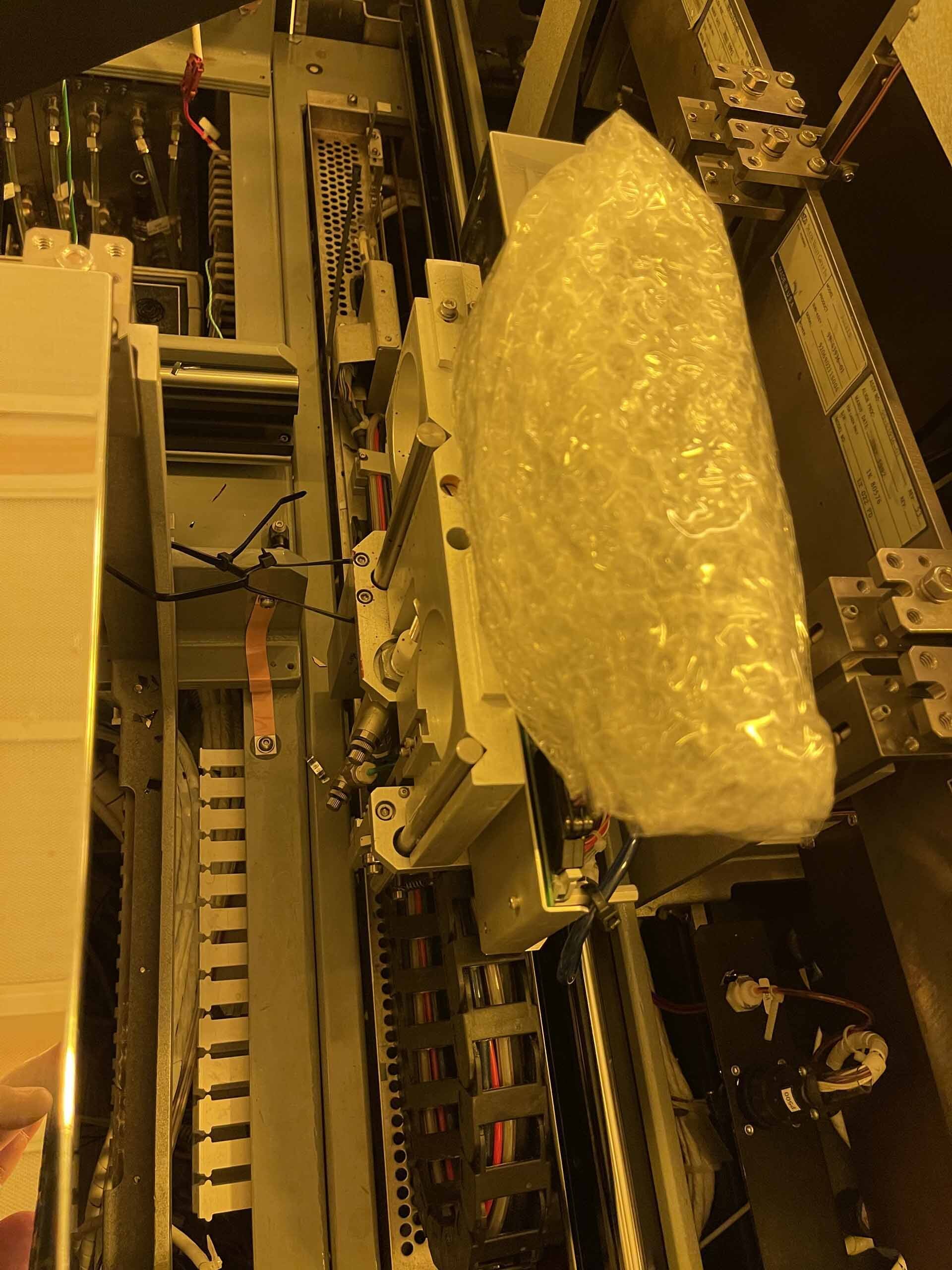

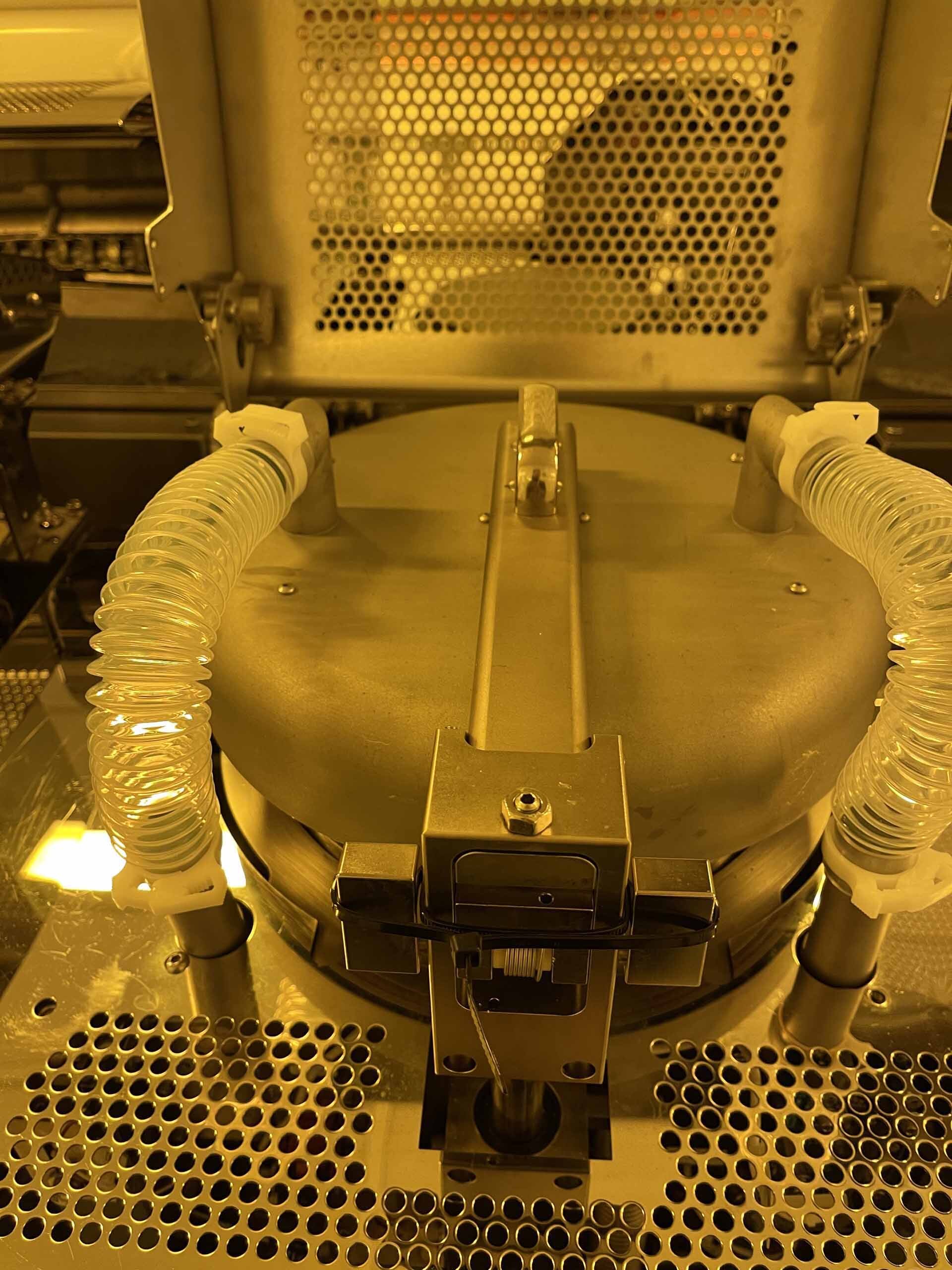

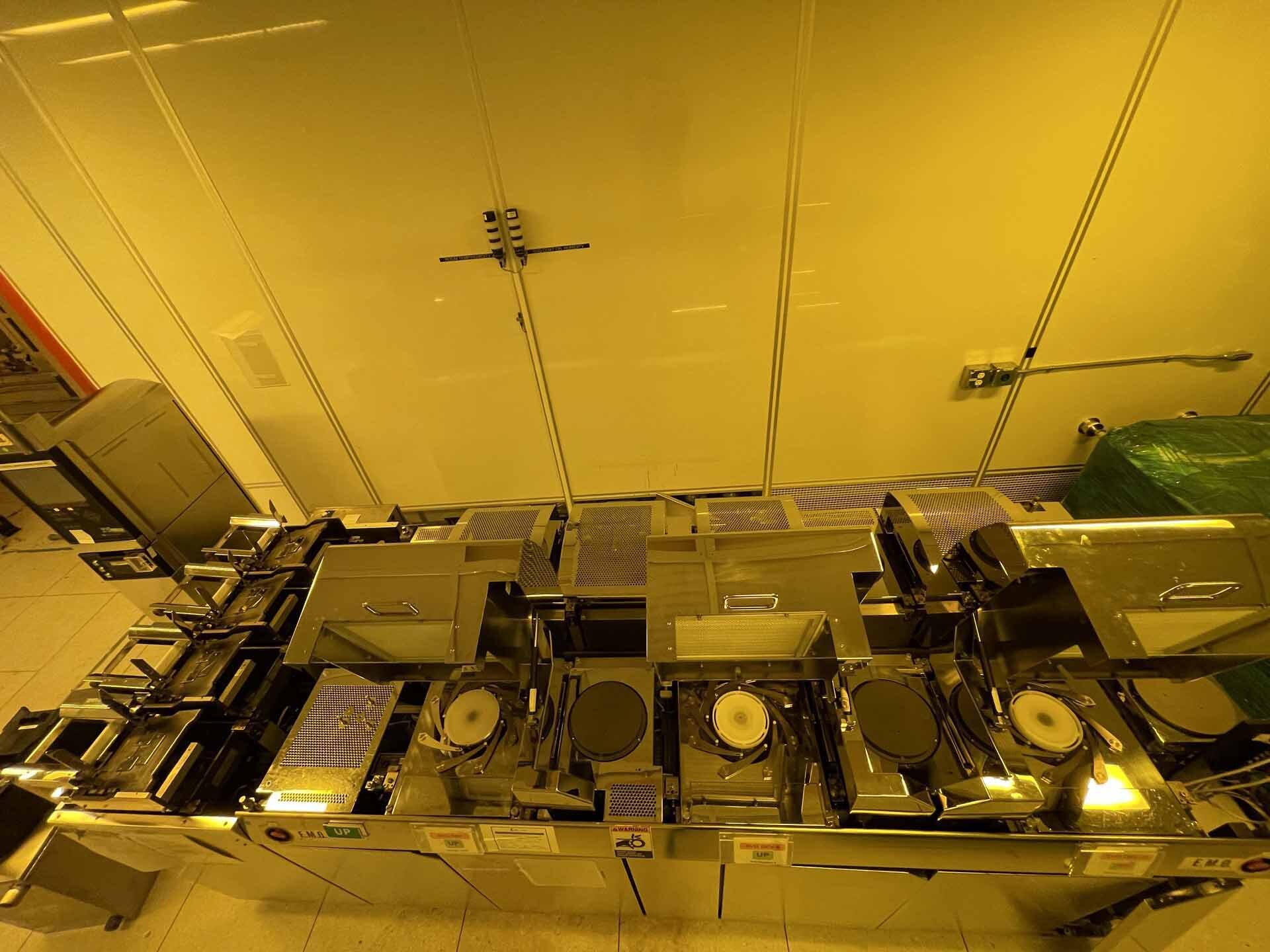

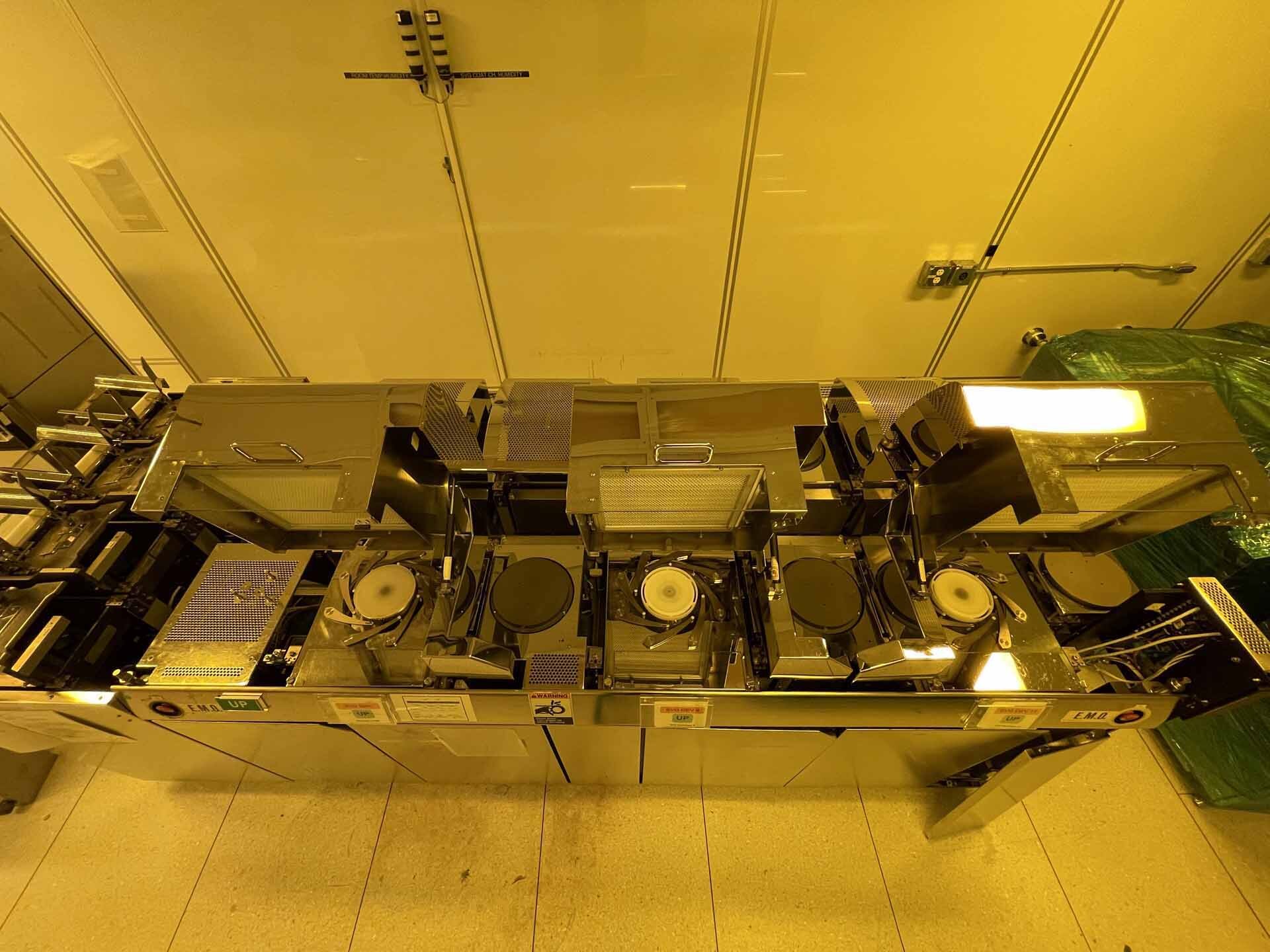

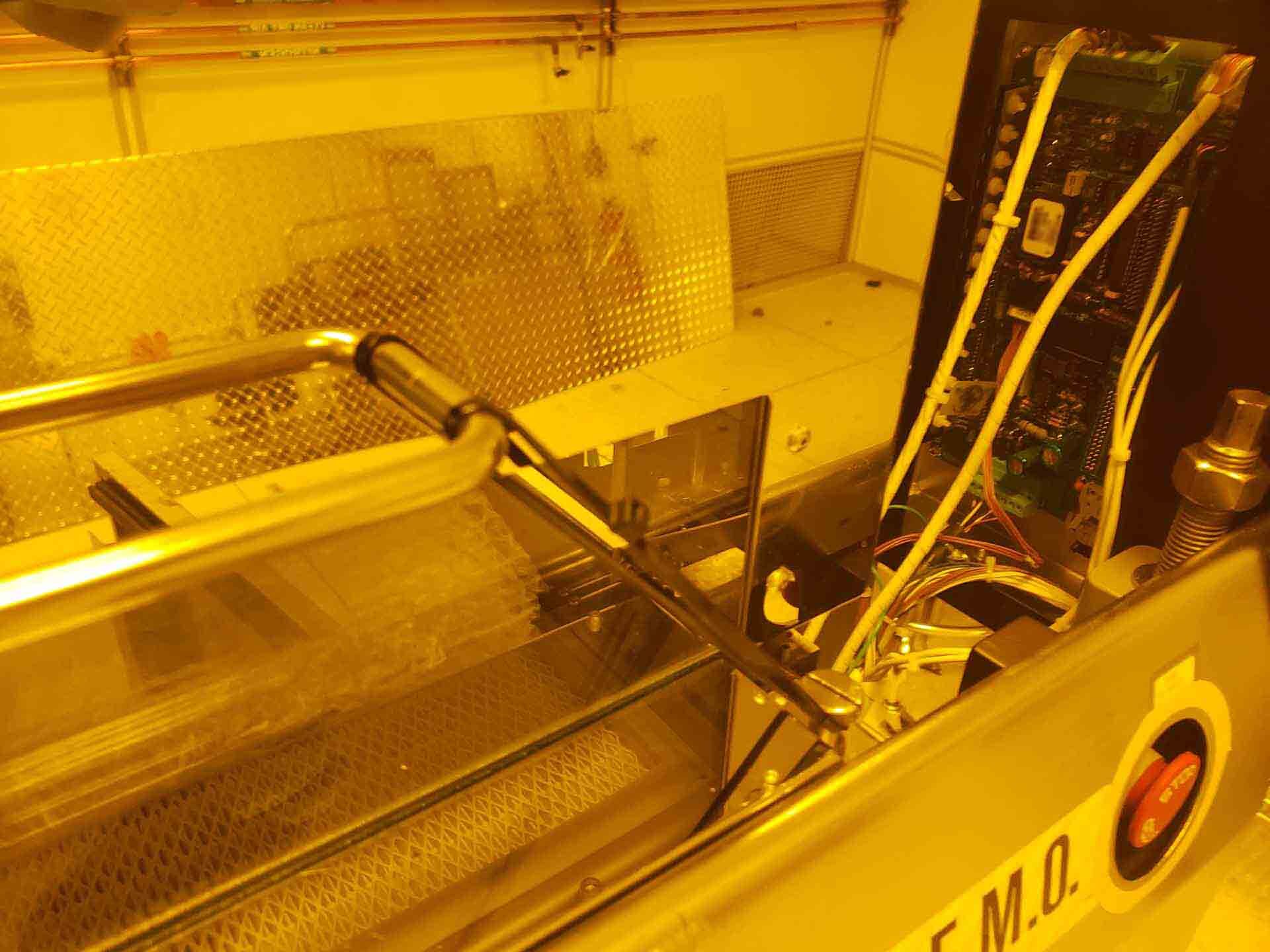

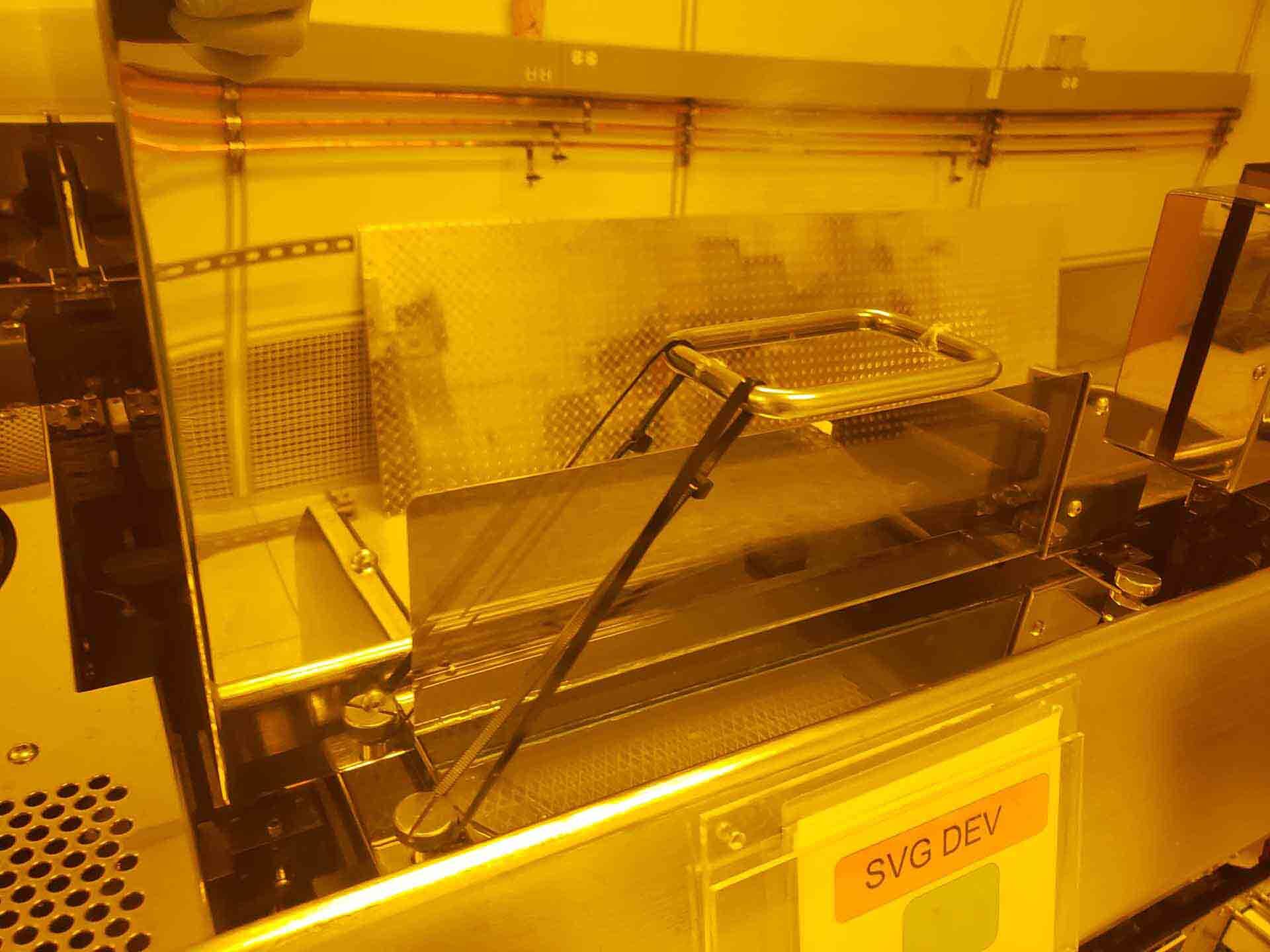

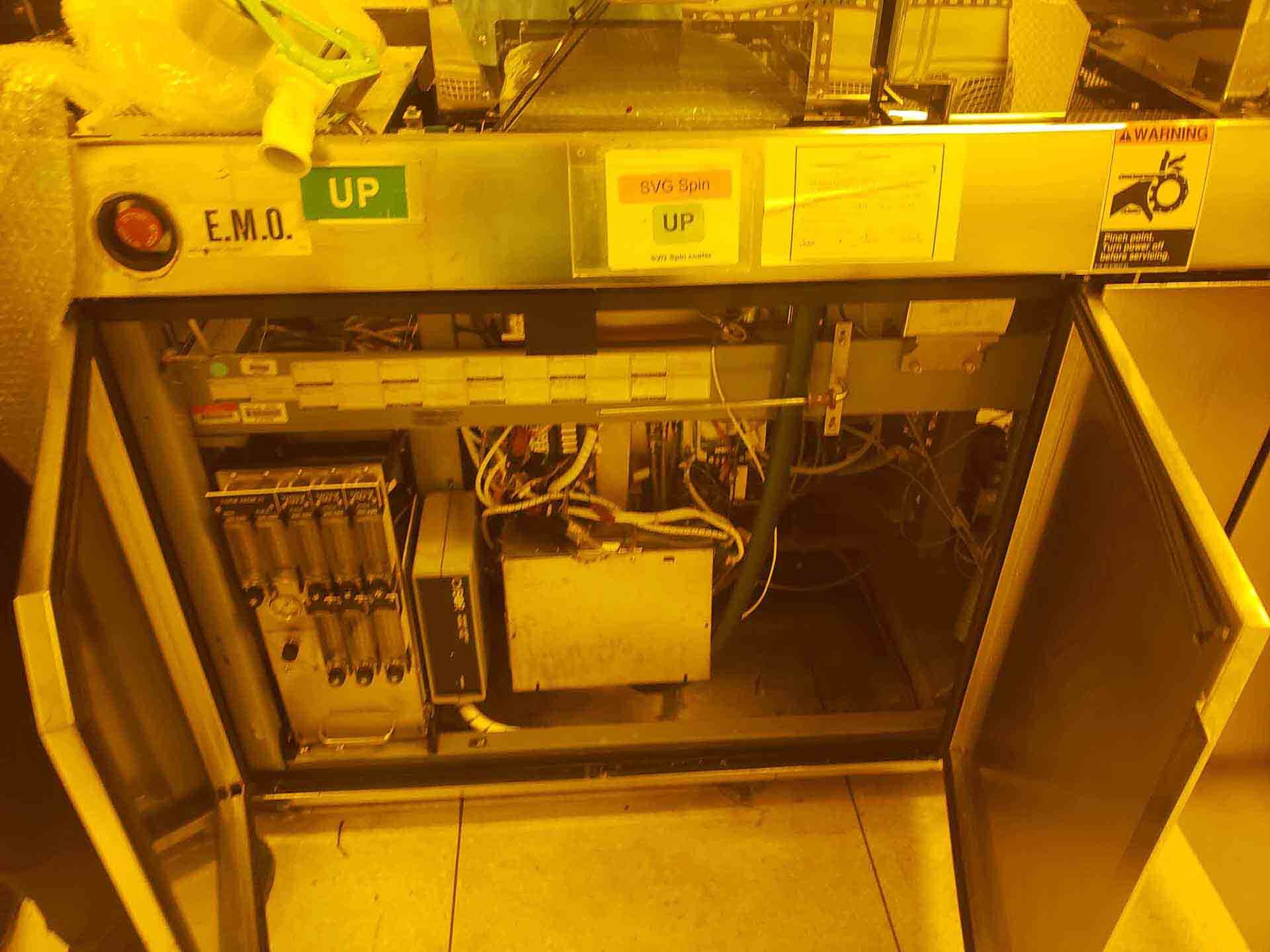

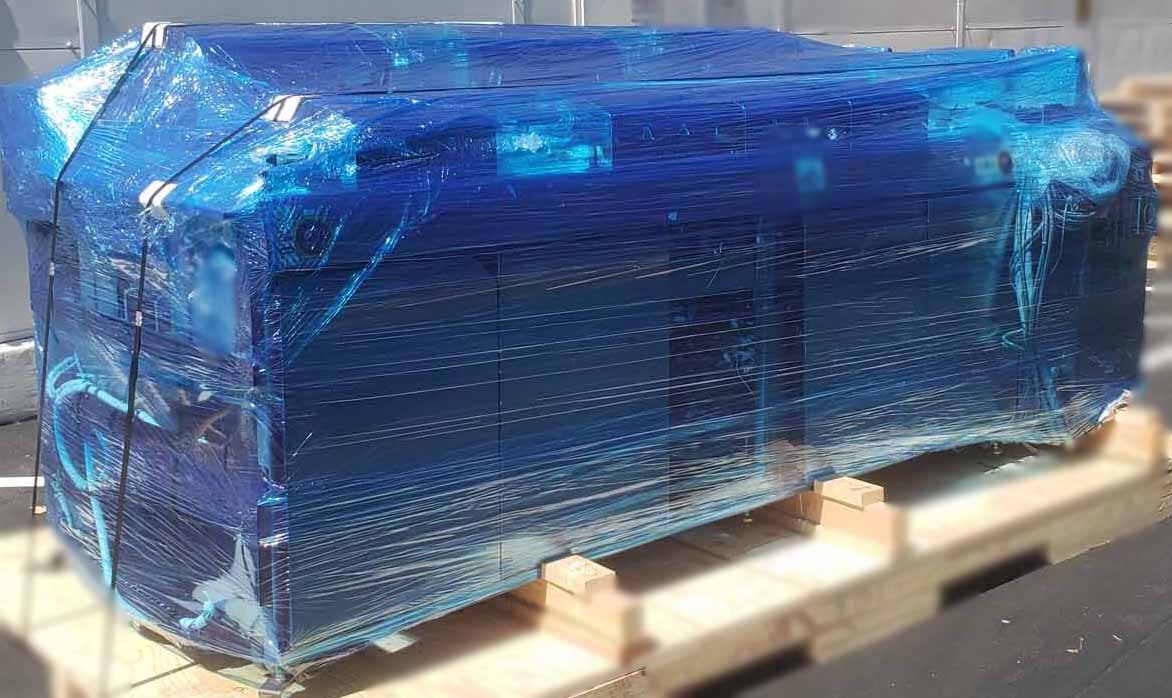

Used SVG 90 #9390343 for sale

URL successfully copied!

Tap to zoom

ID: 9390343

Vintage: 1992

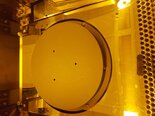

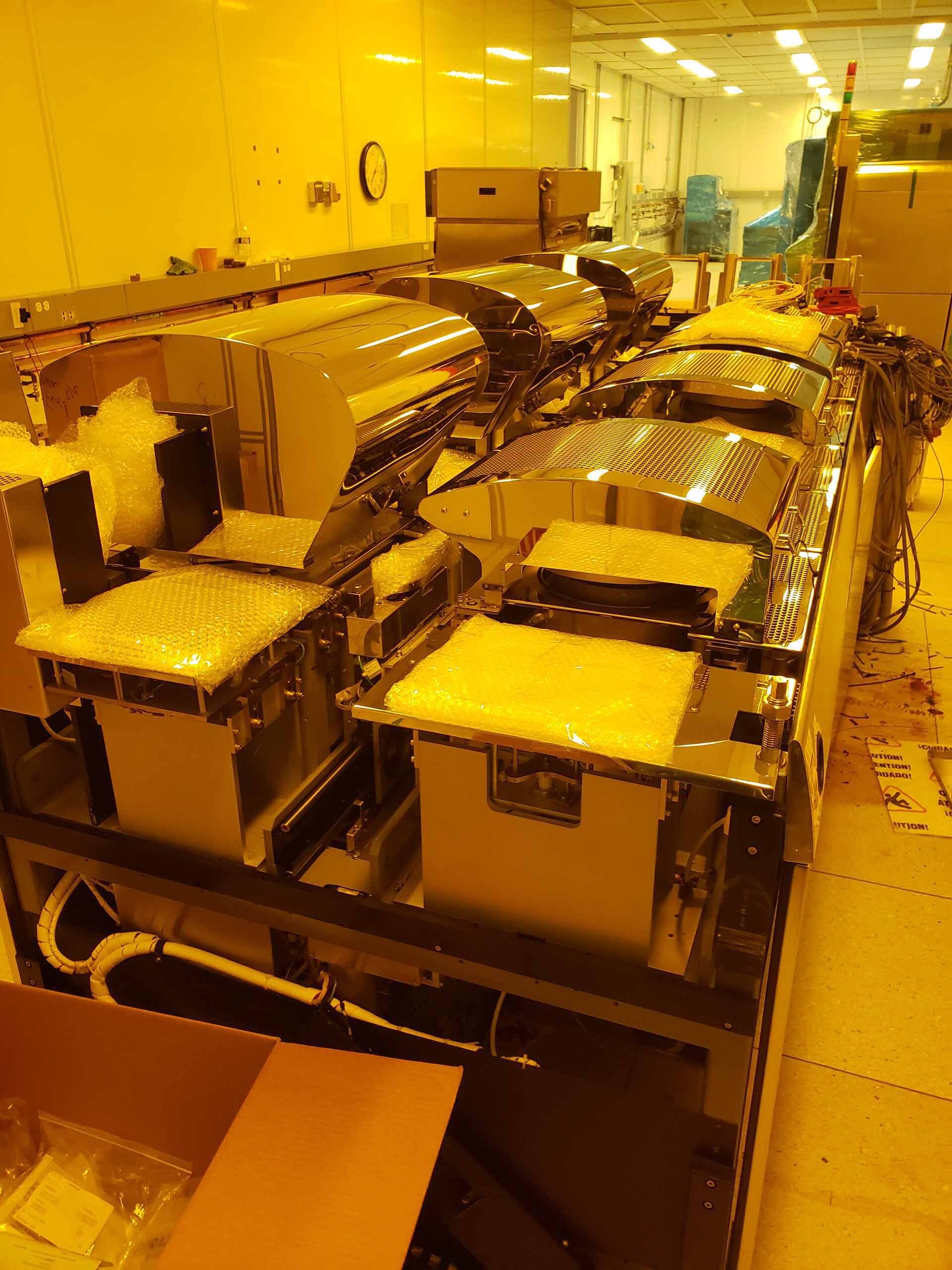

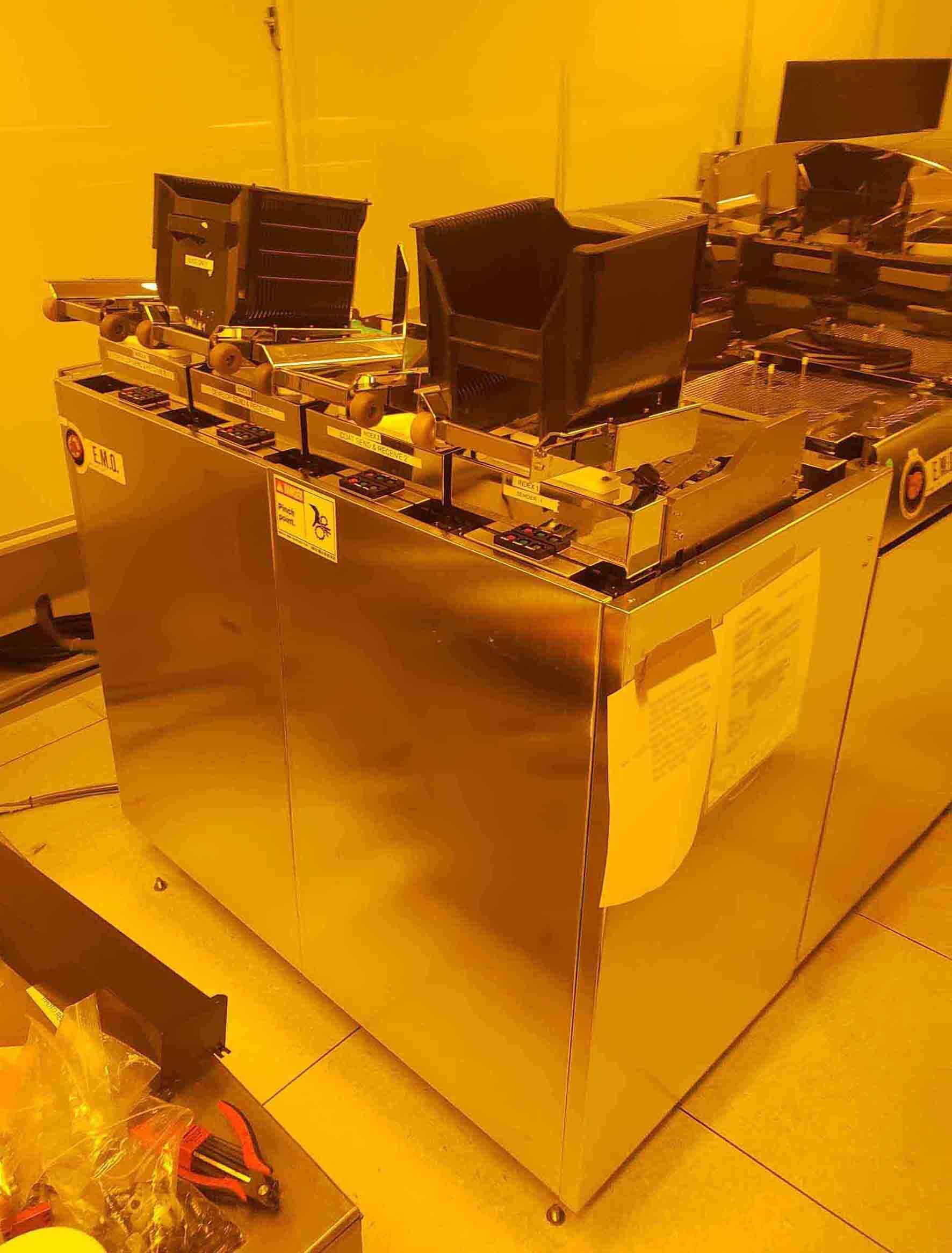

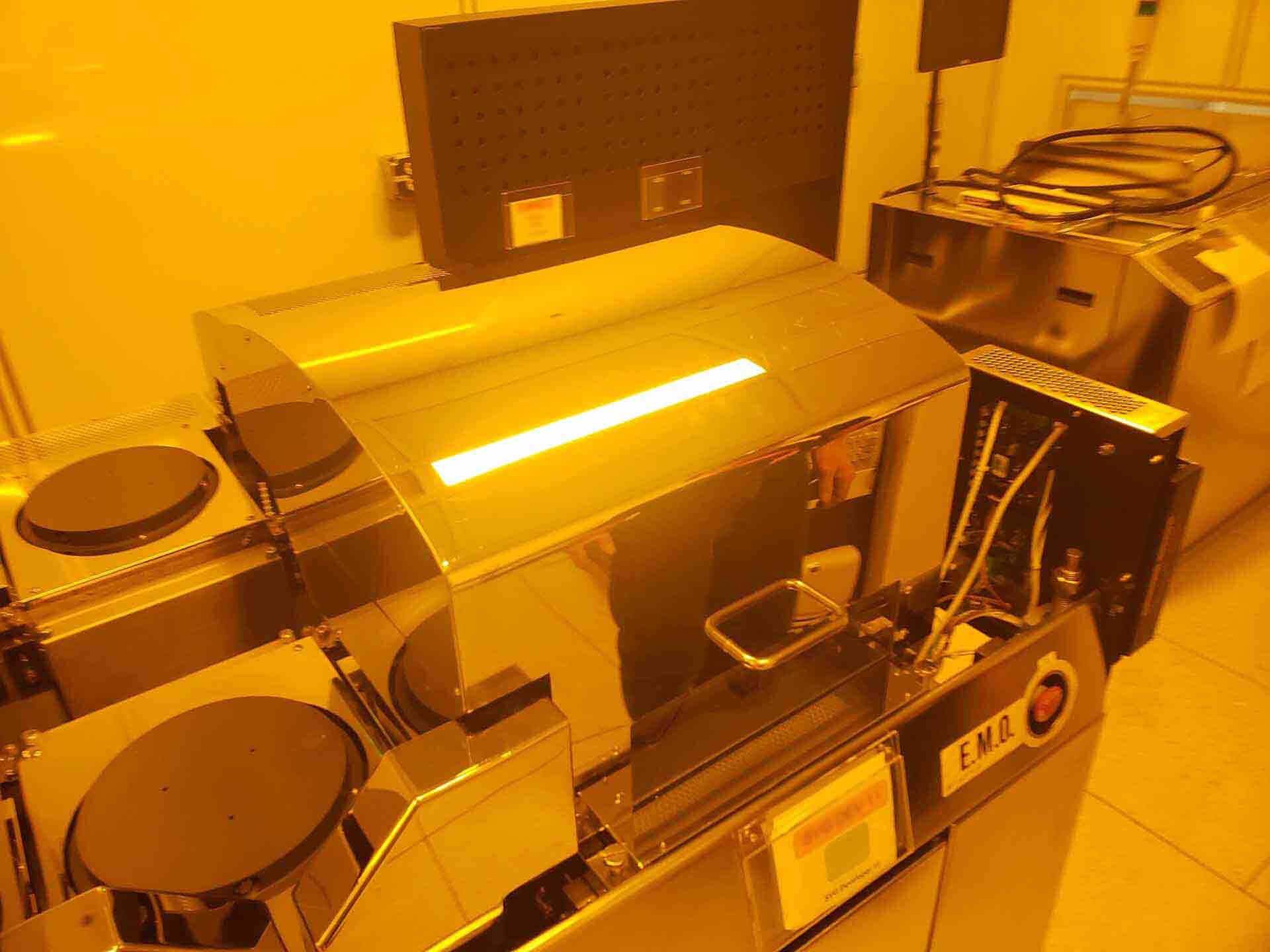

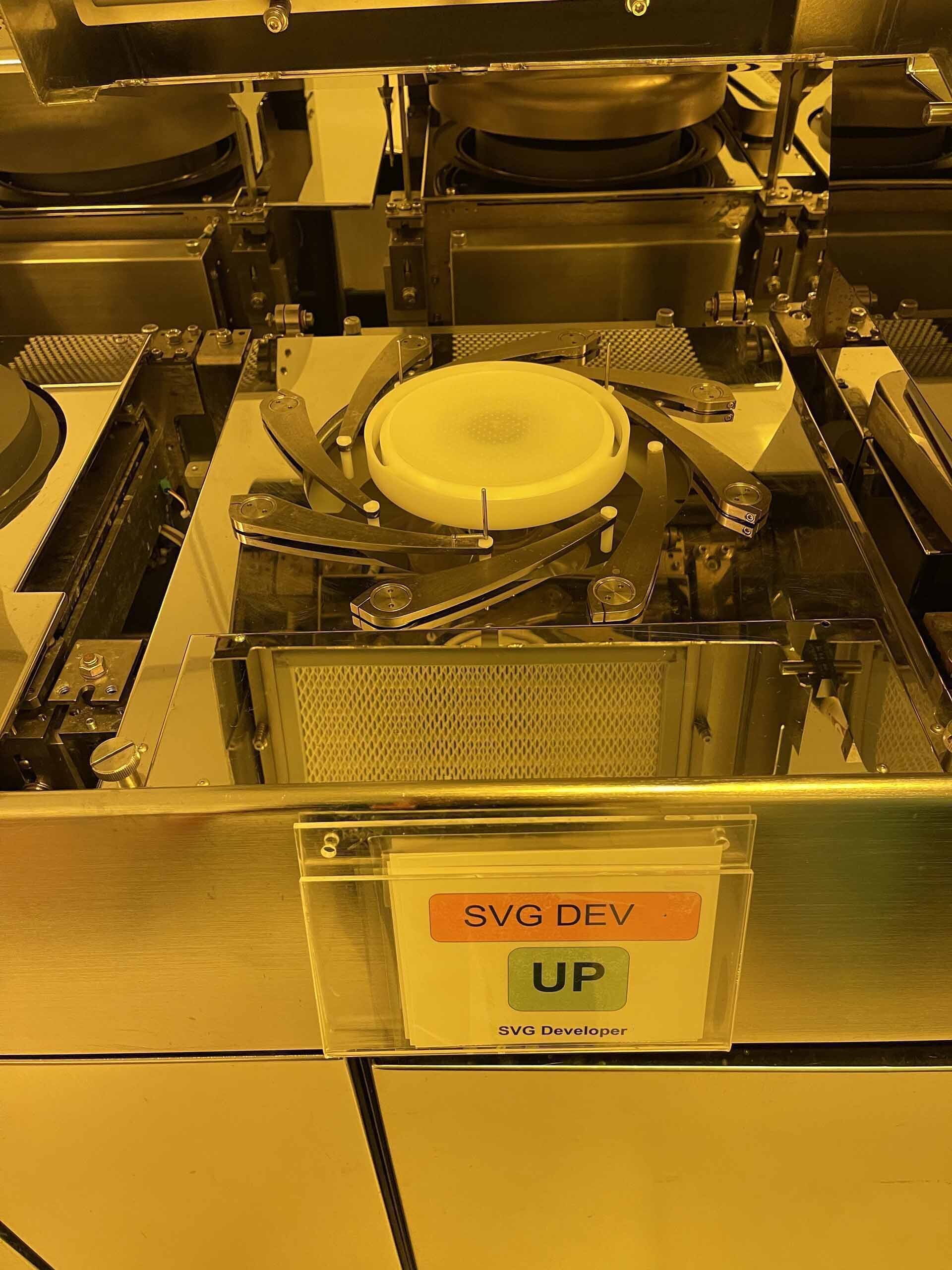

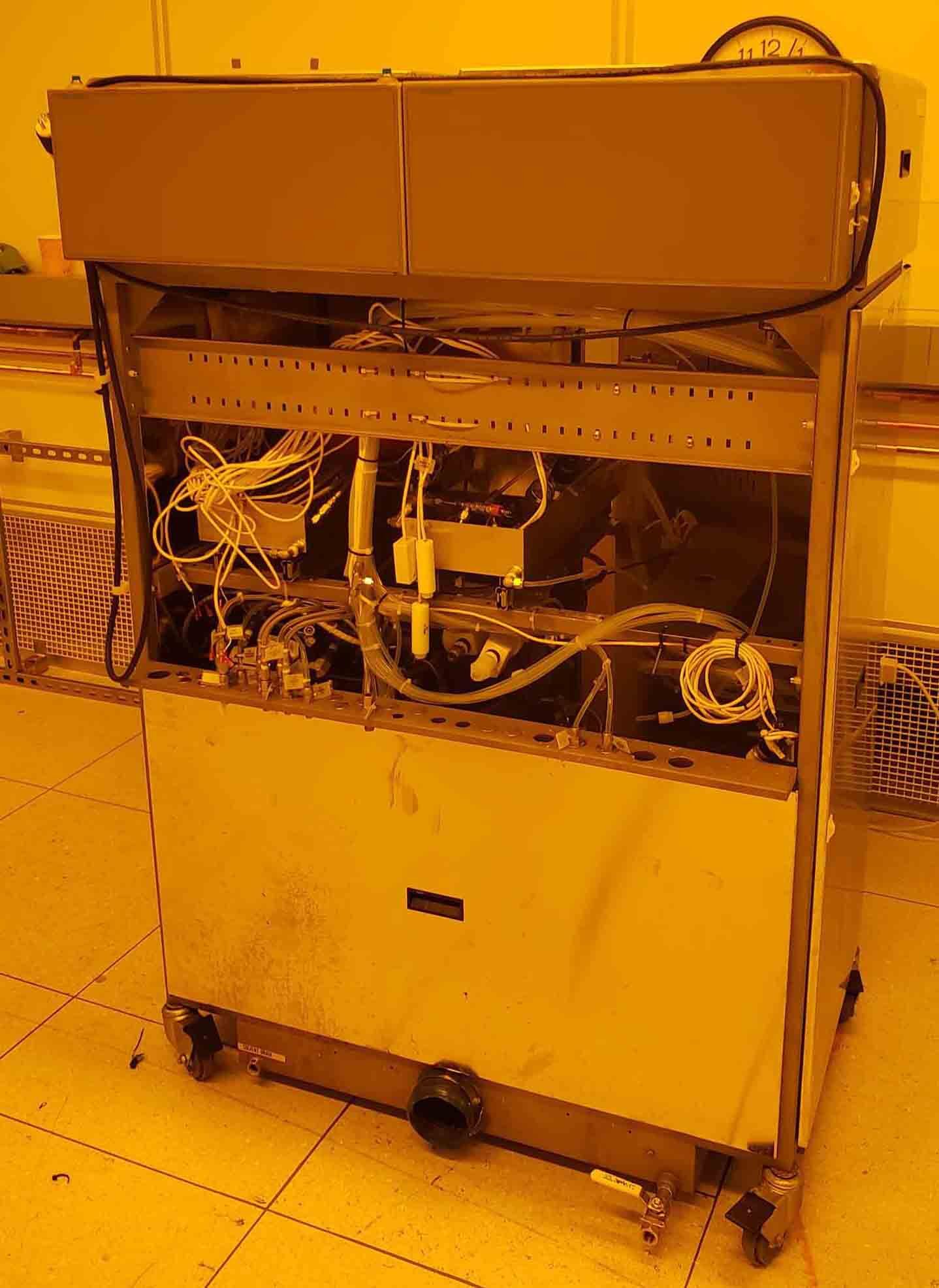

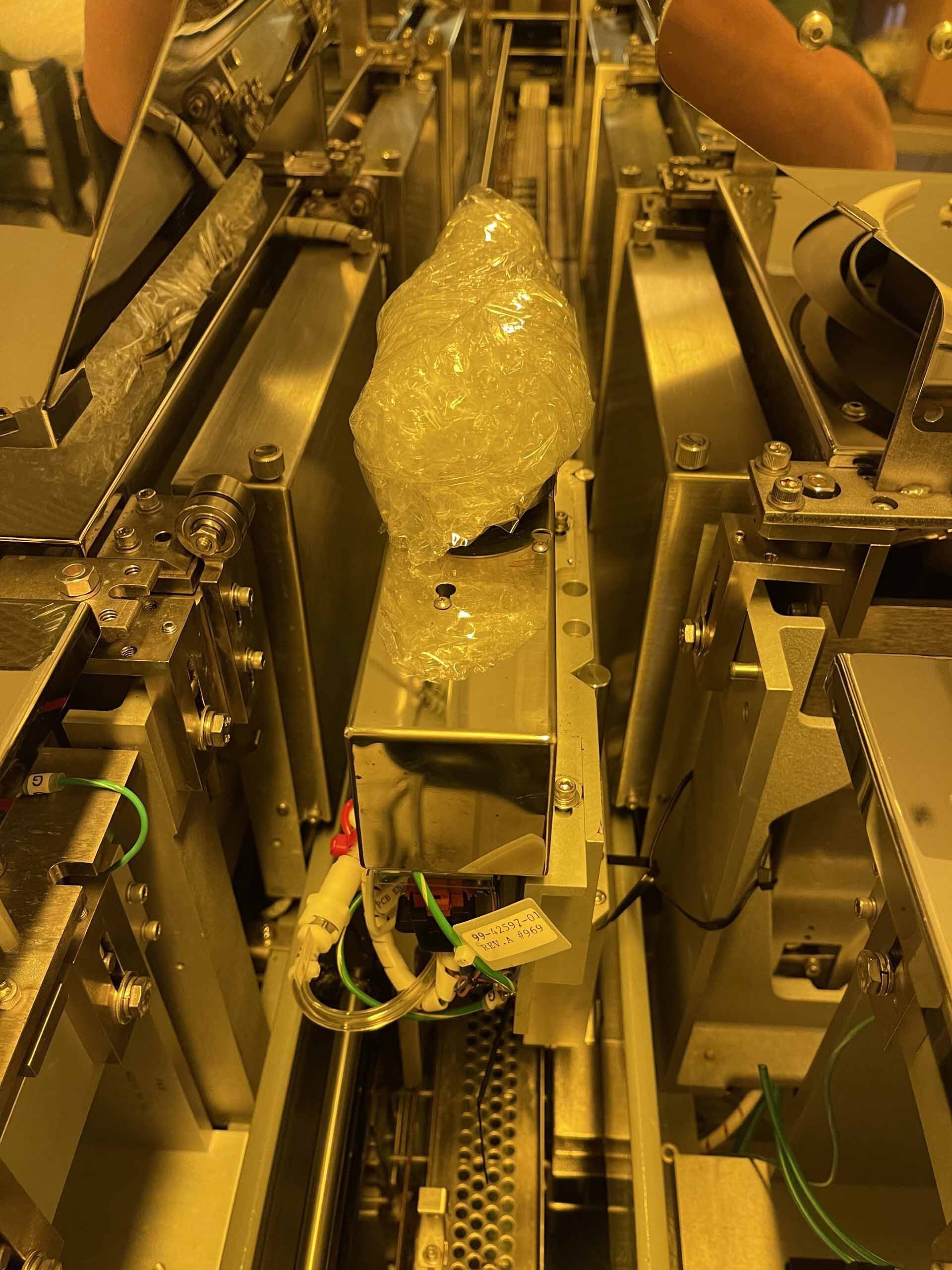

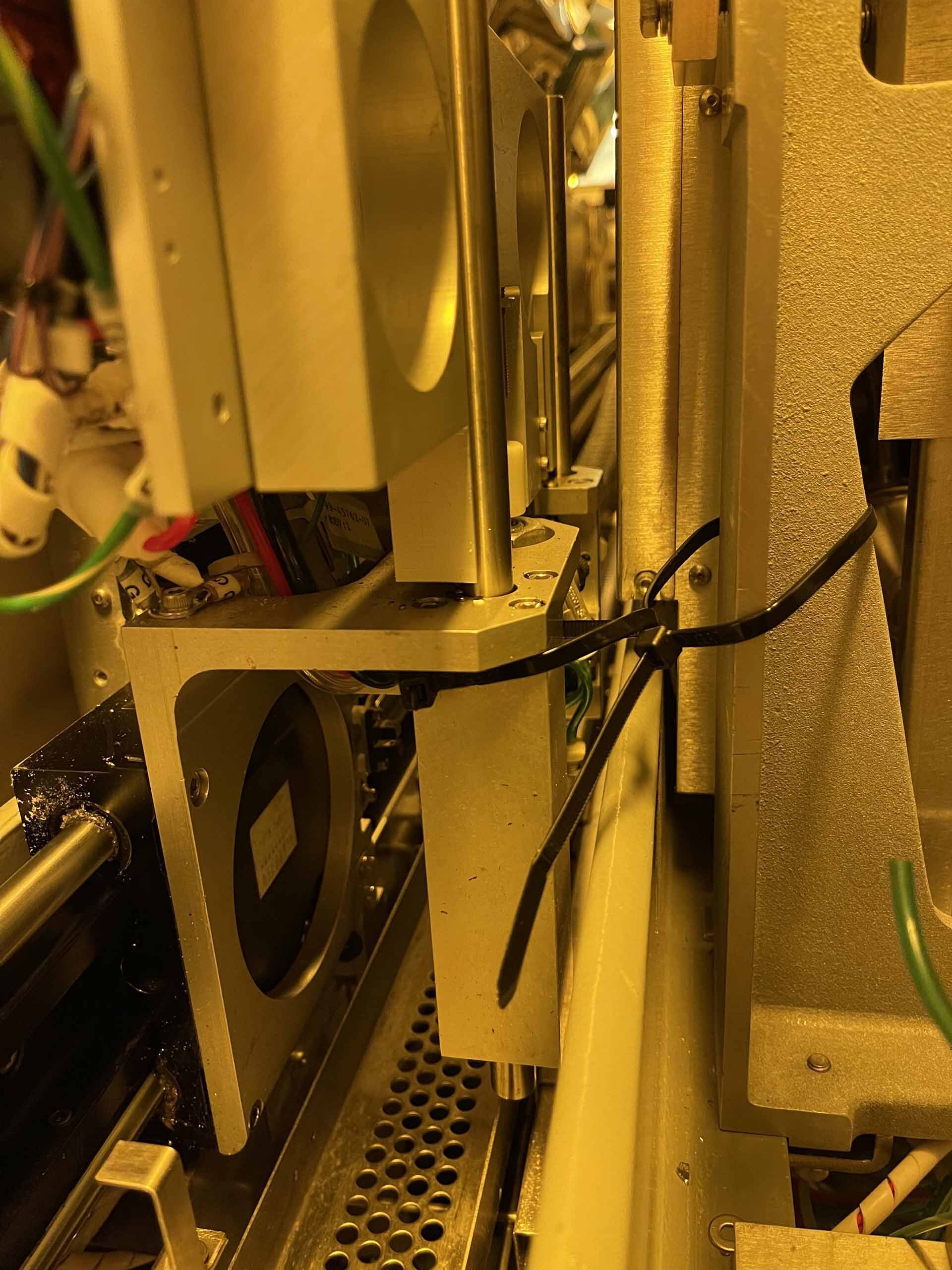

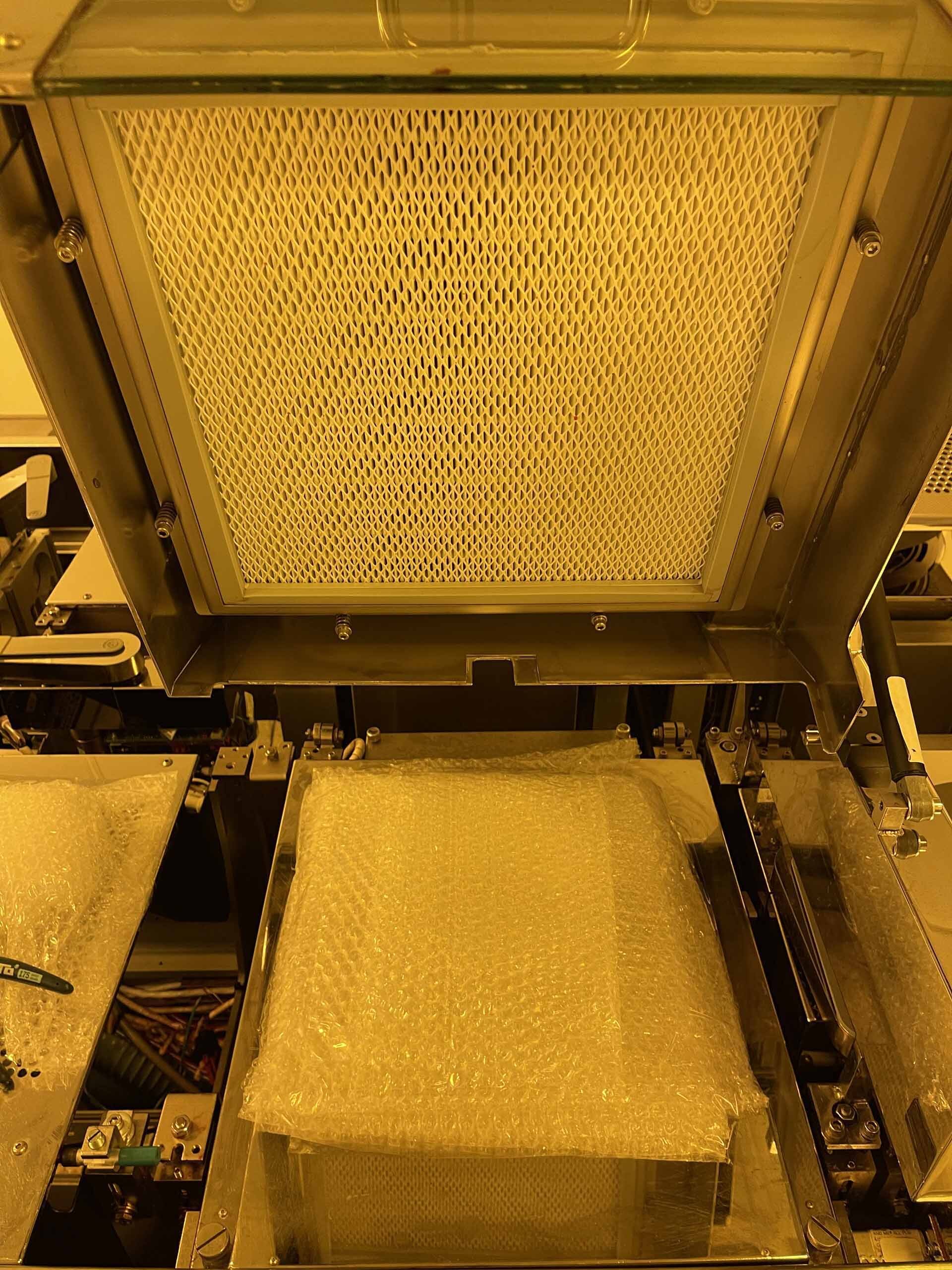

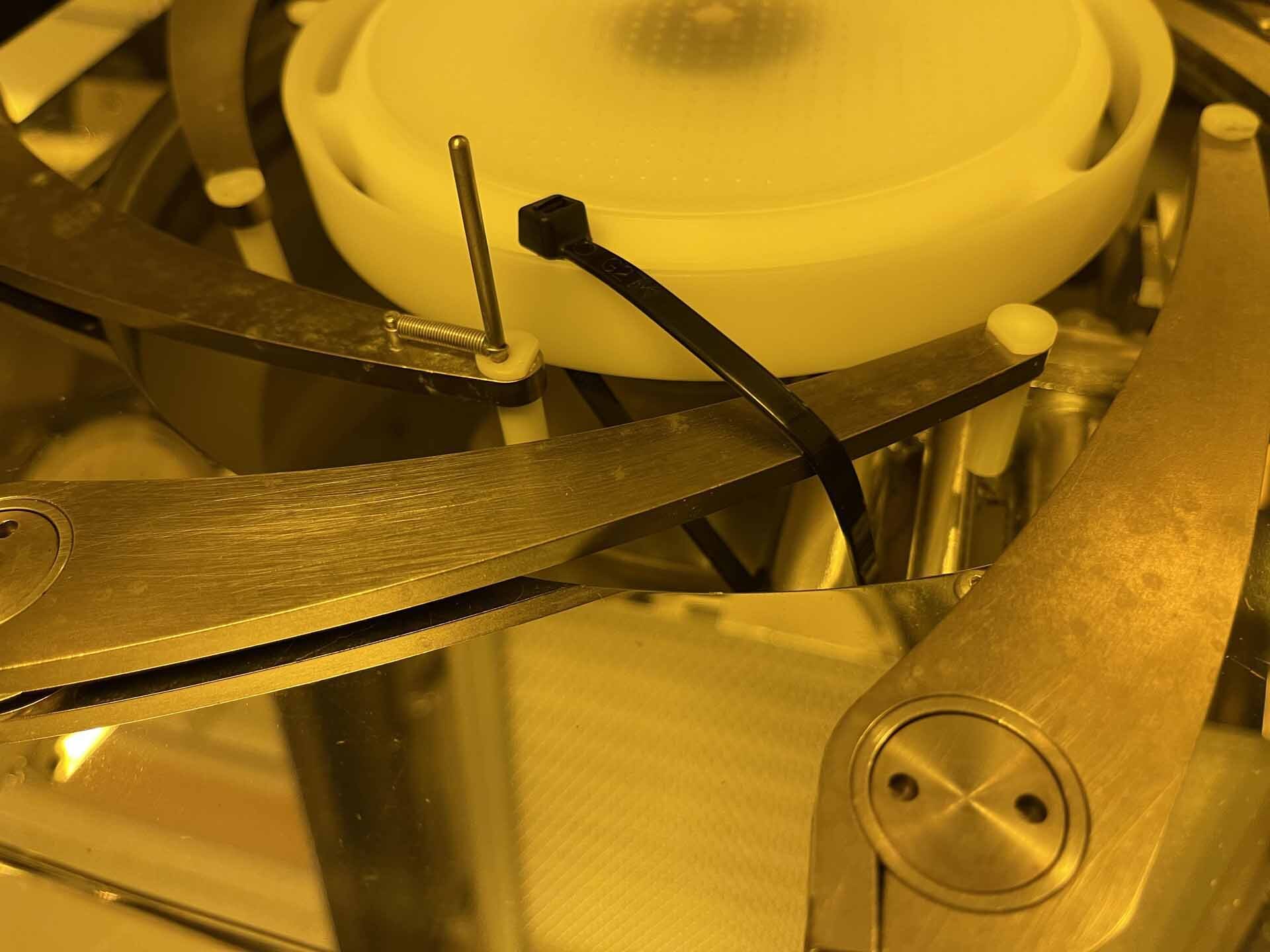

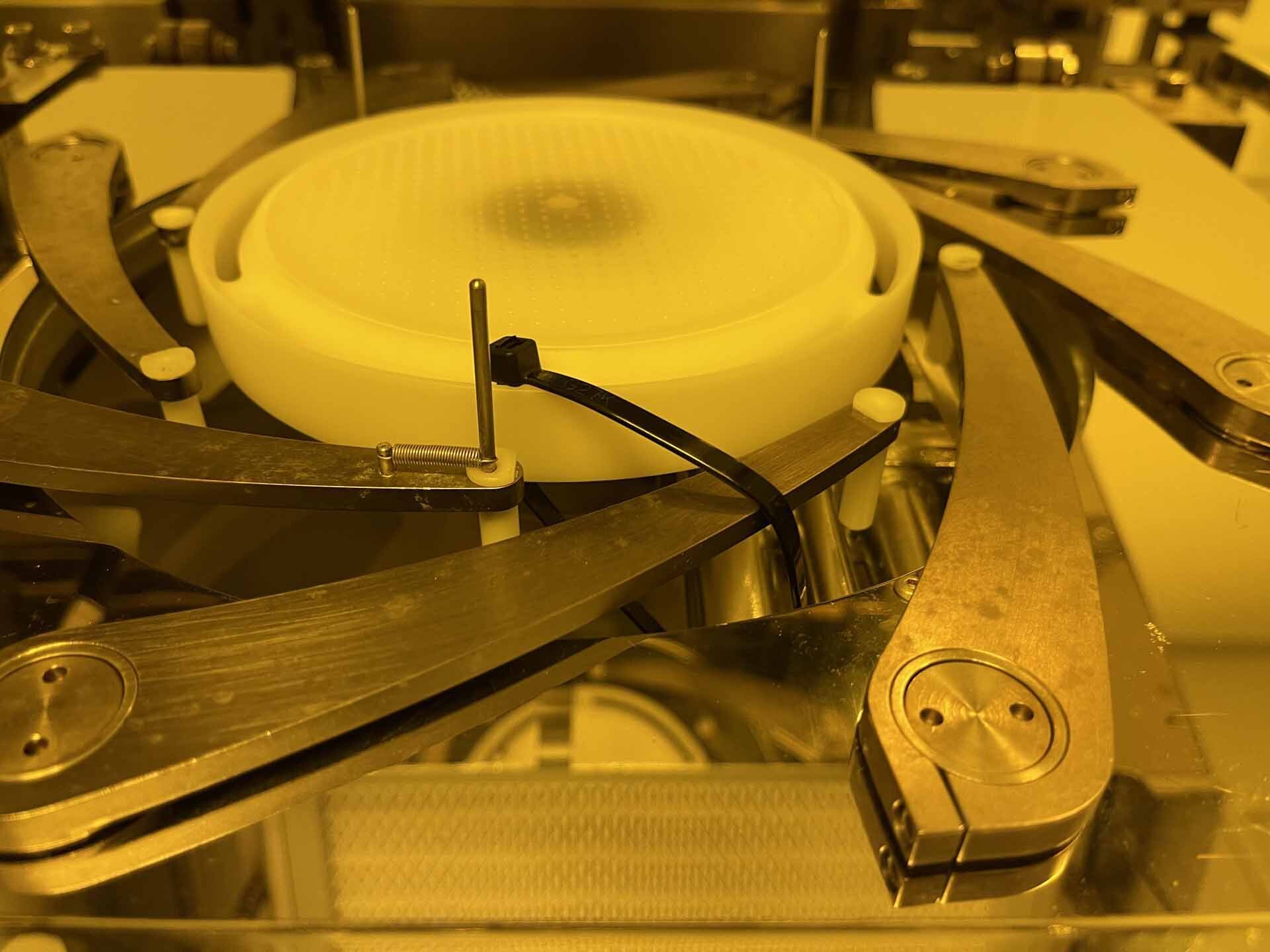

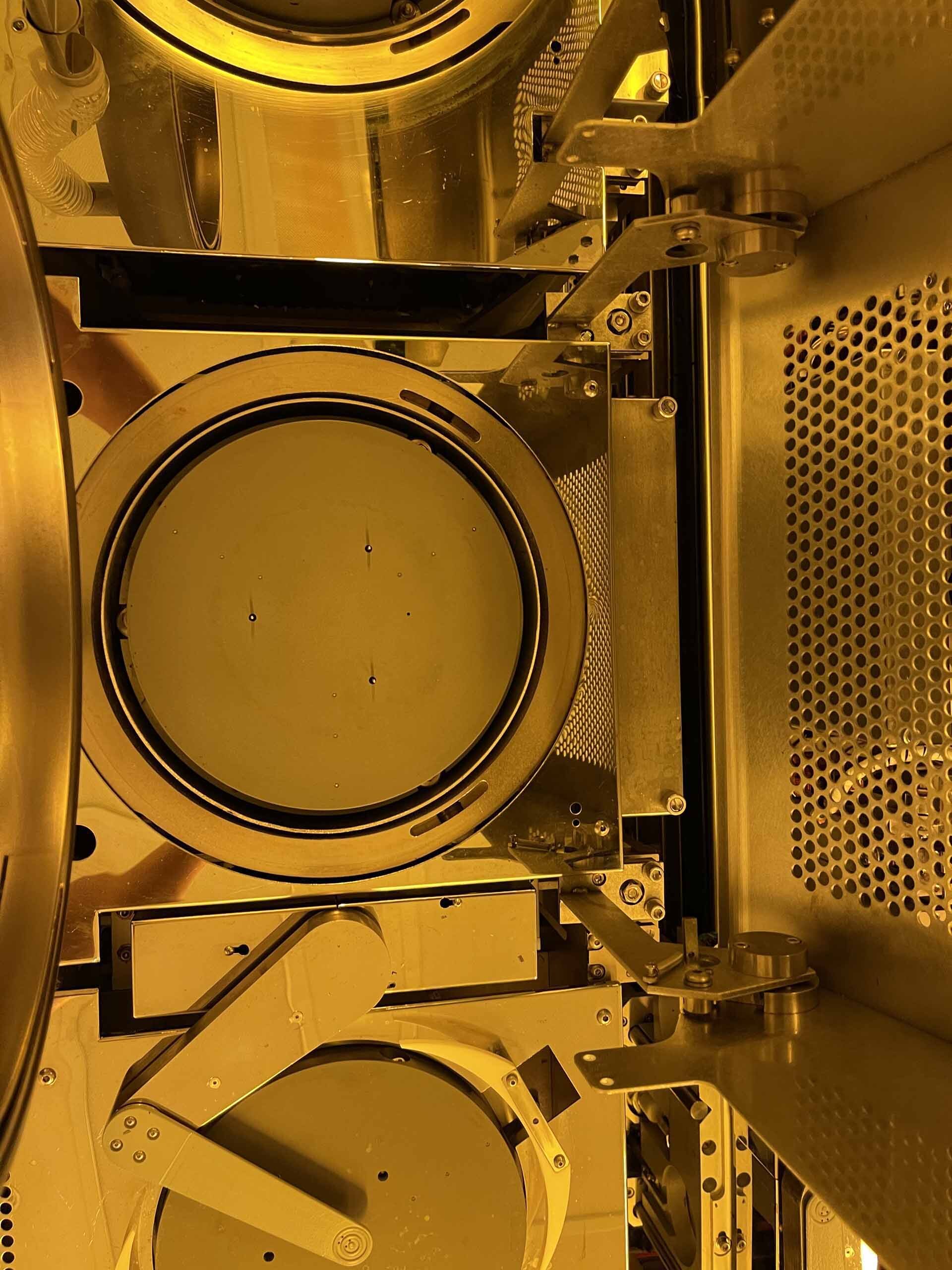

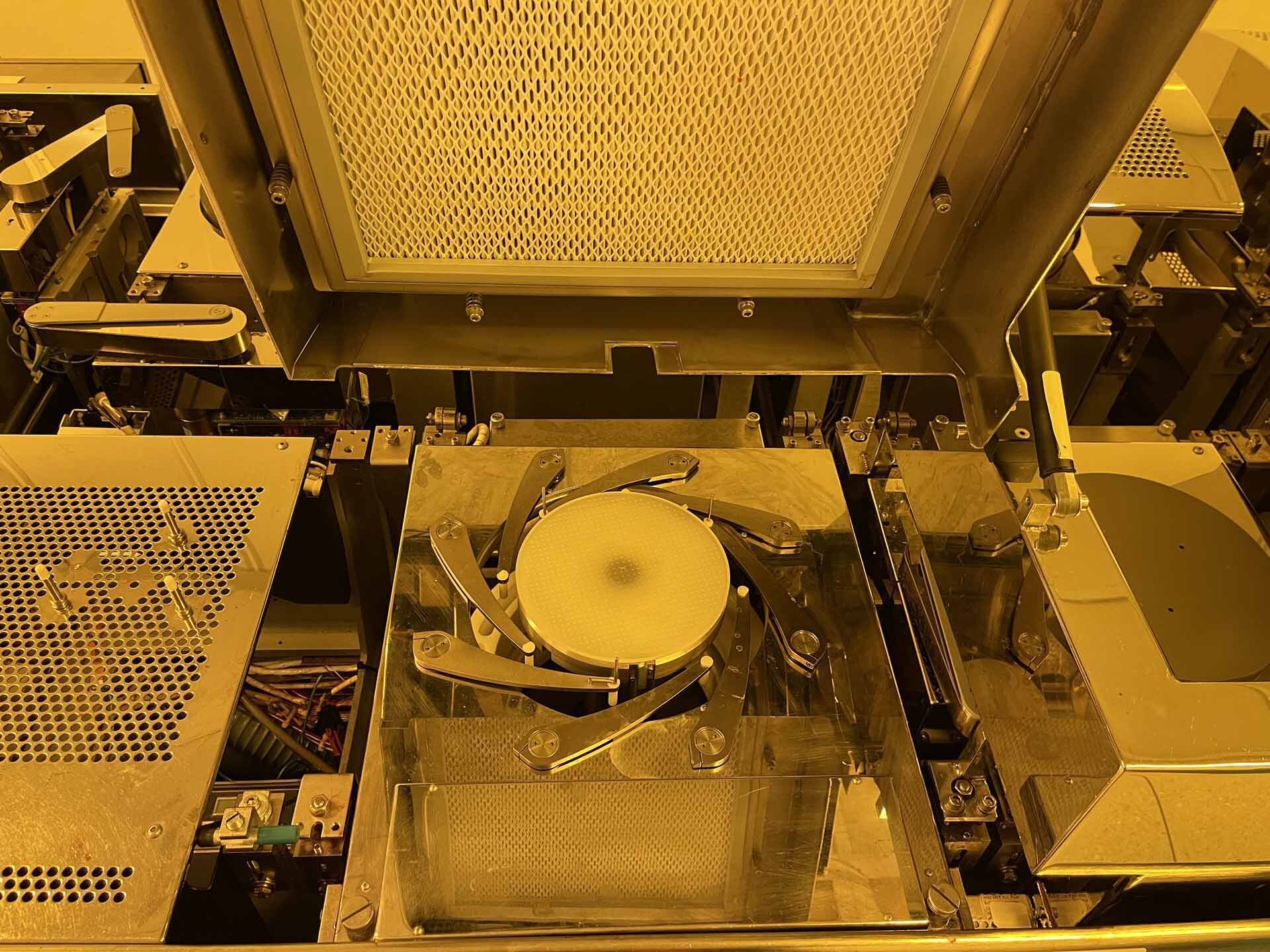

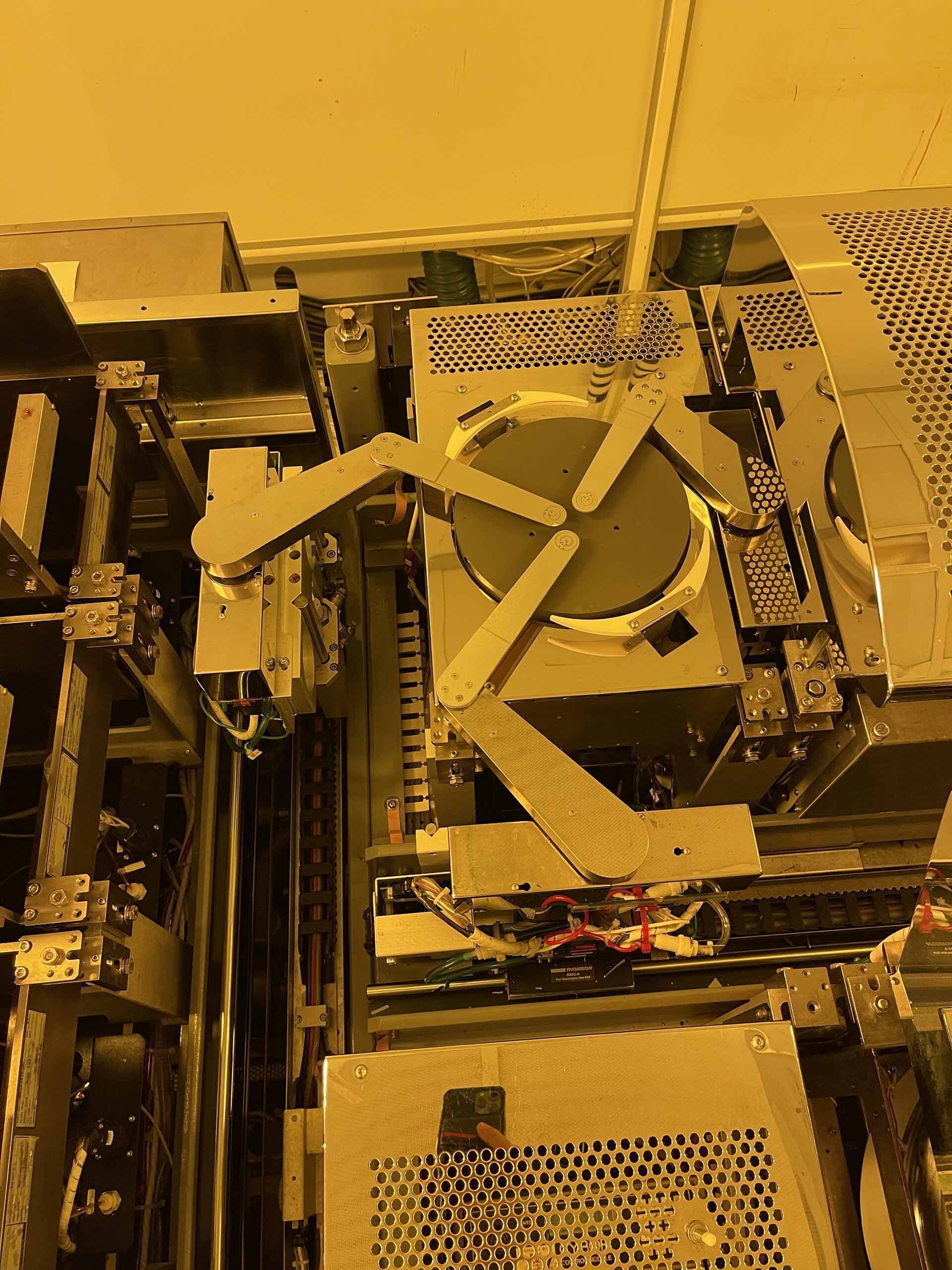

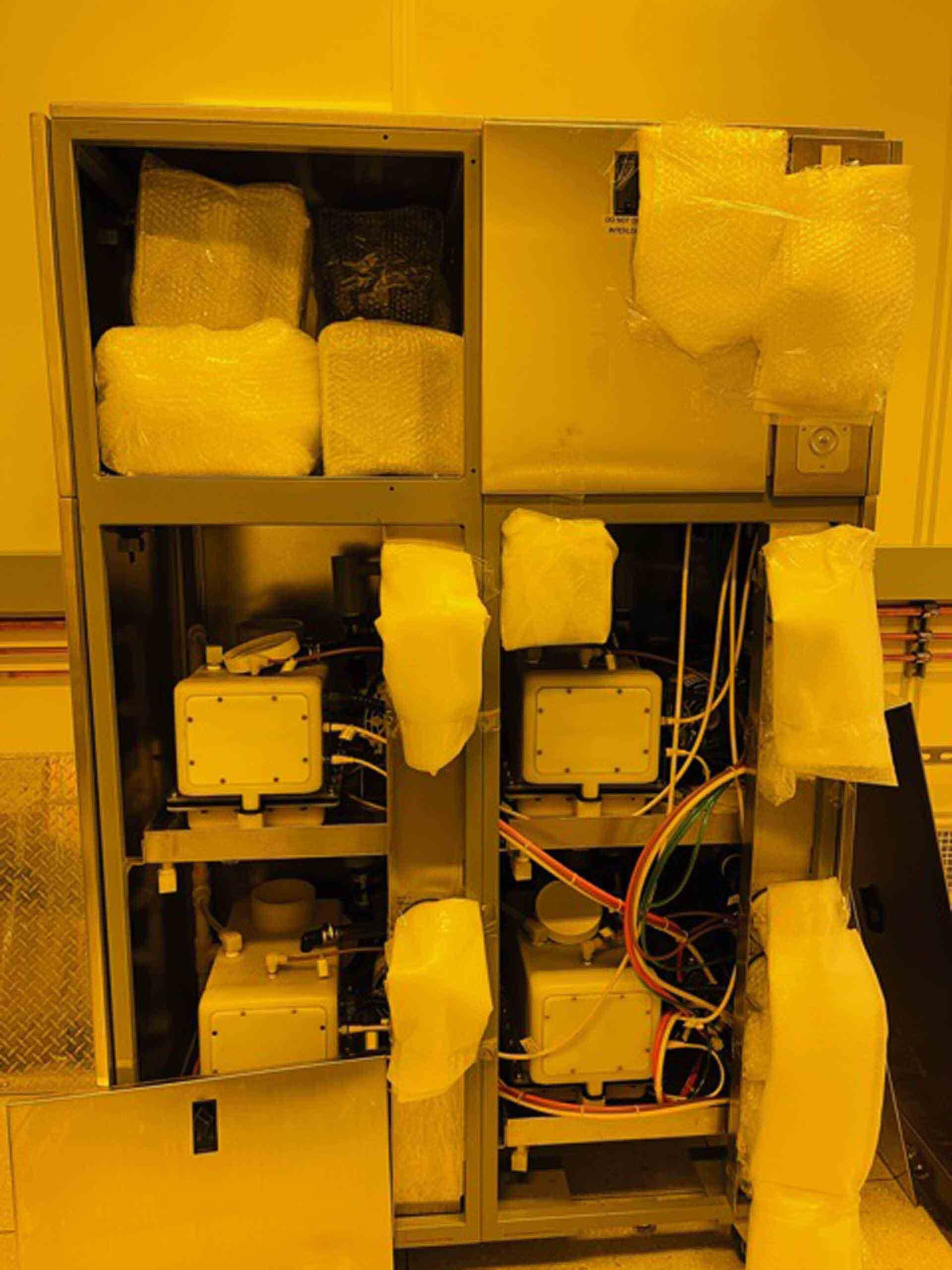

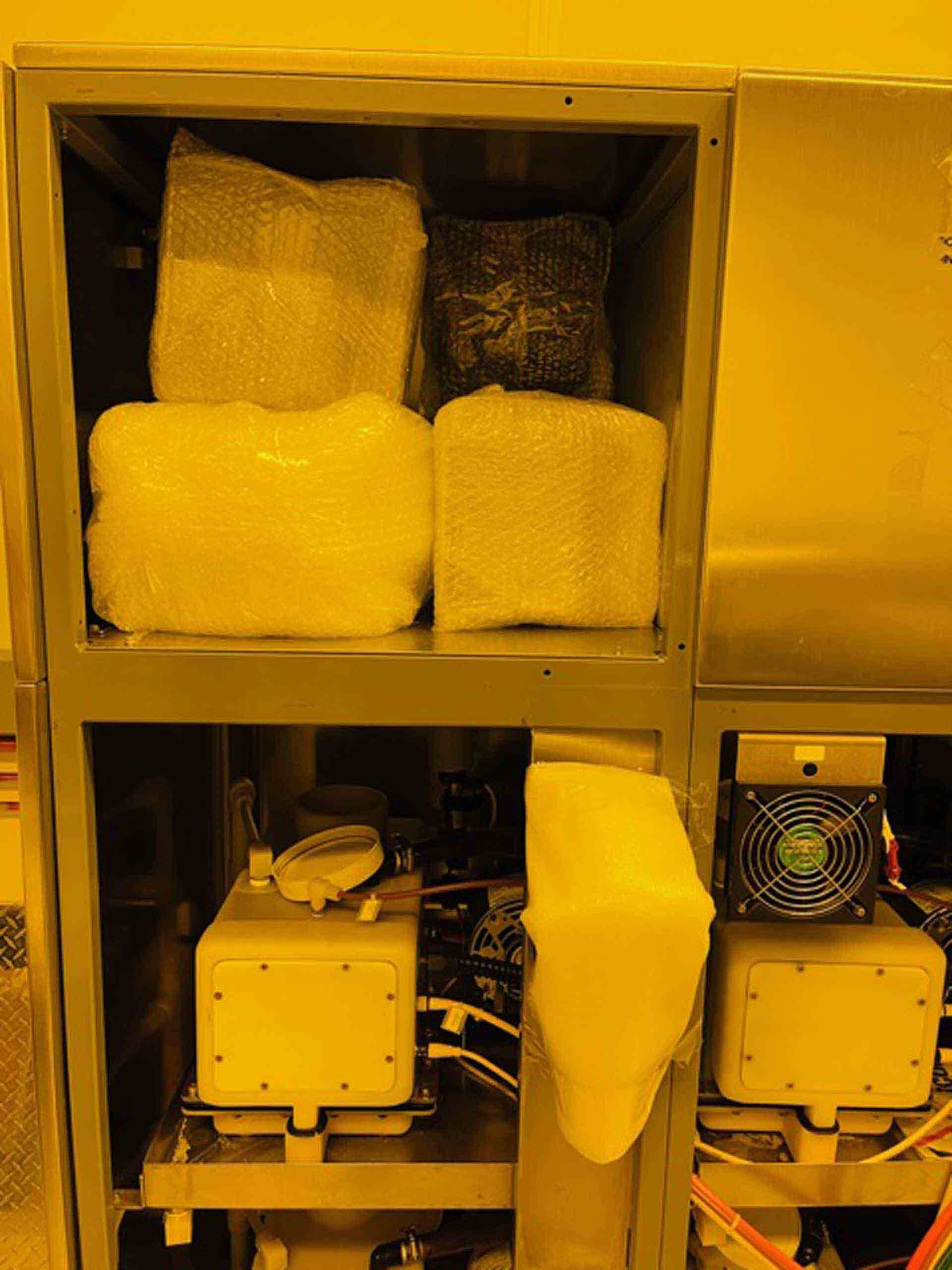

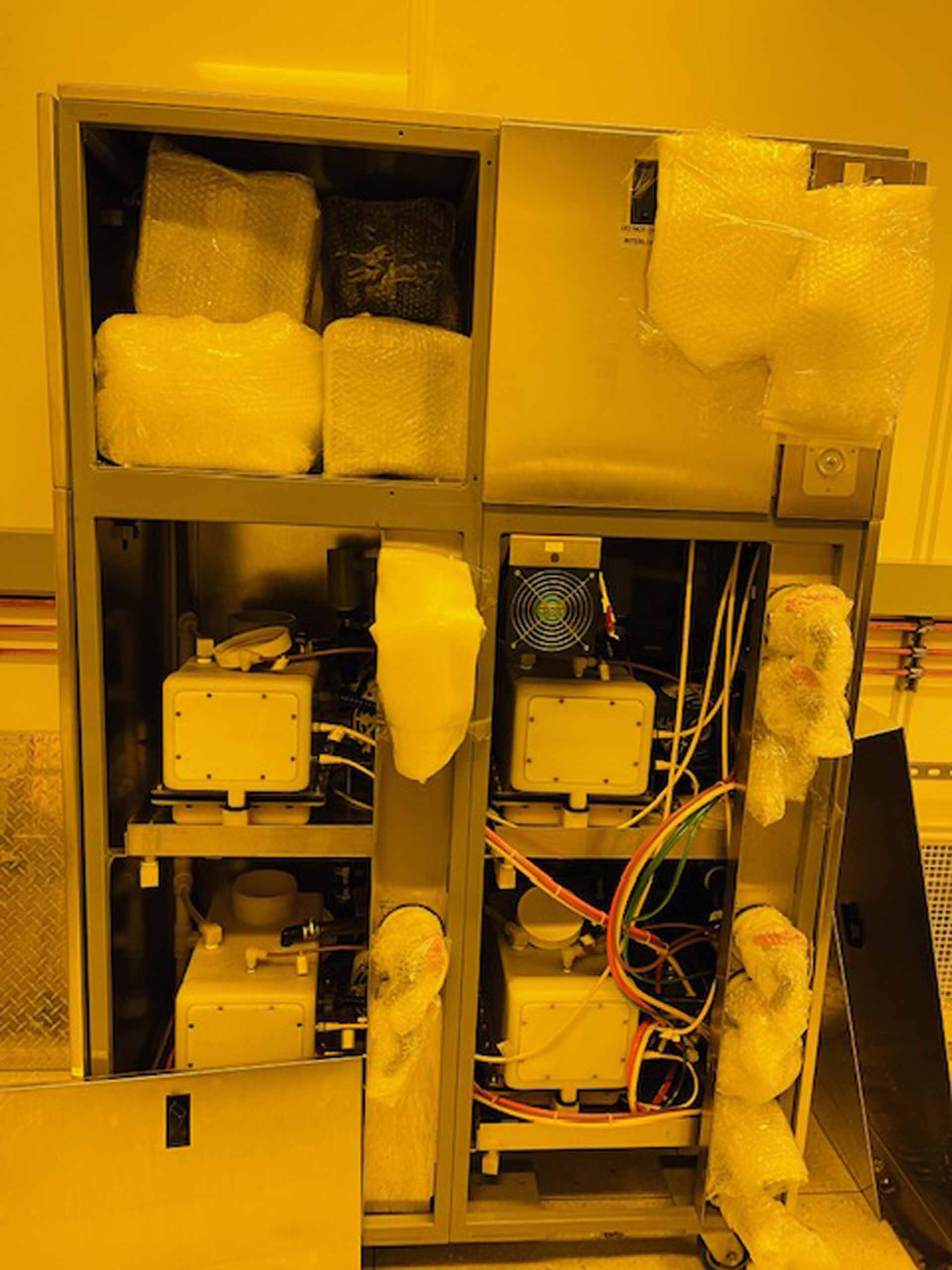

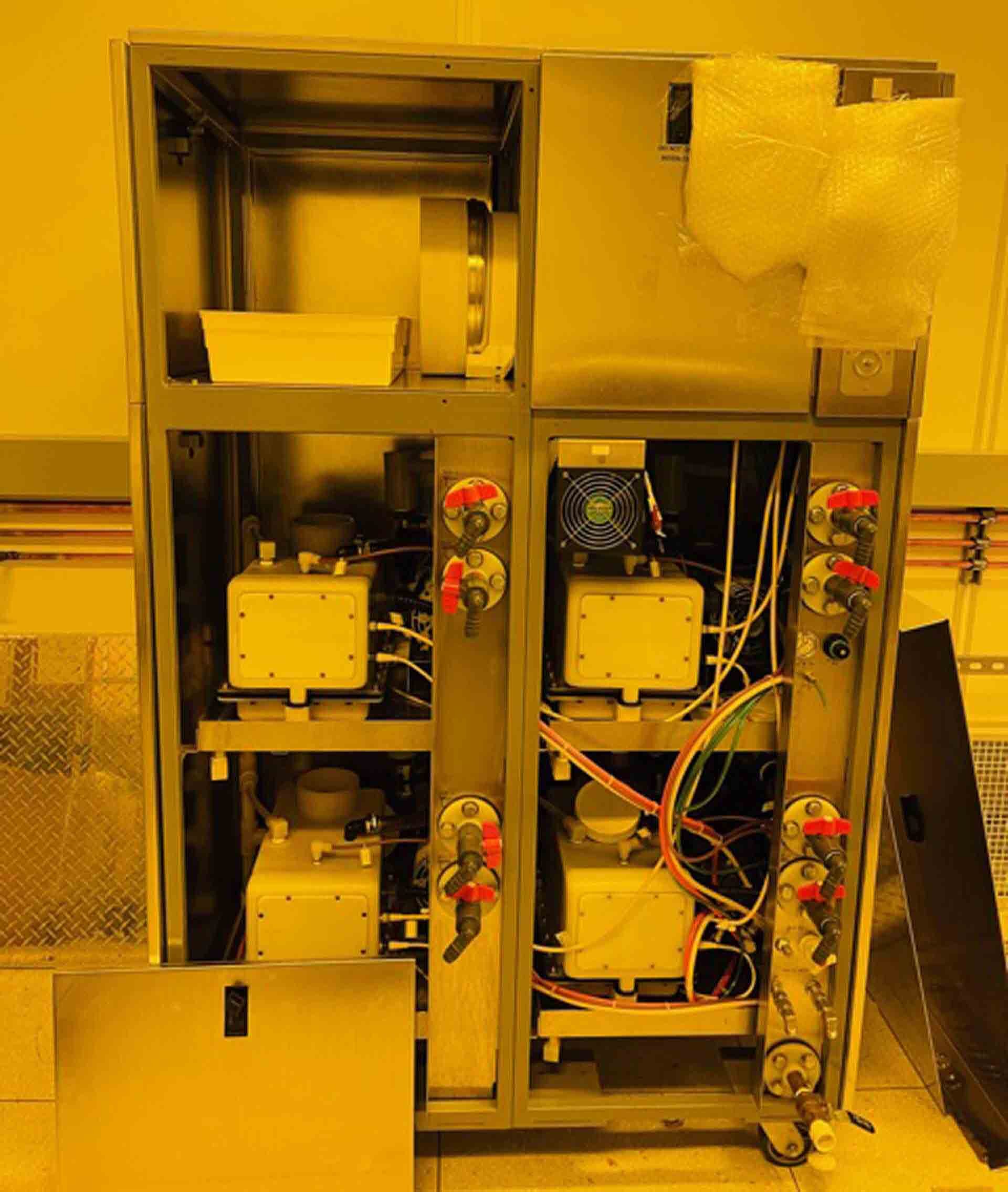

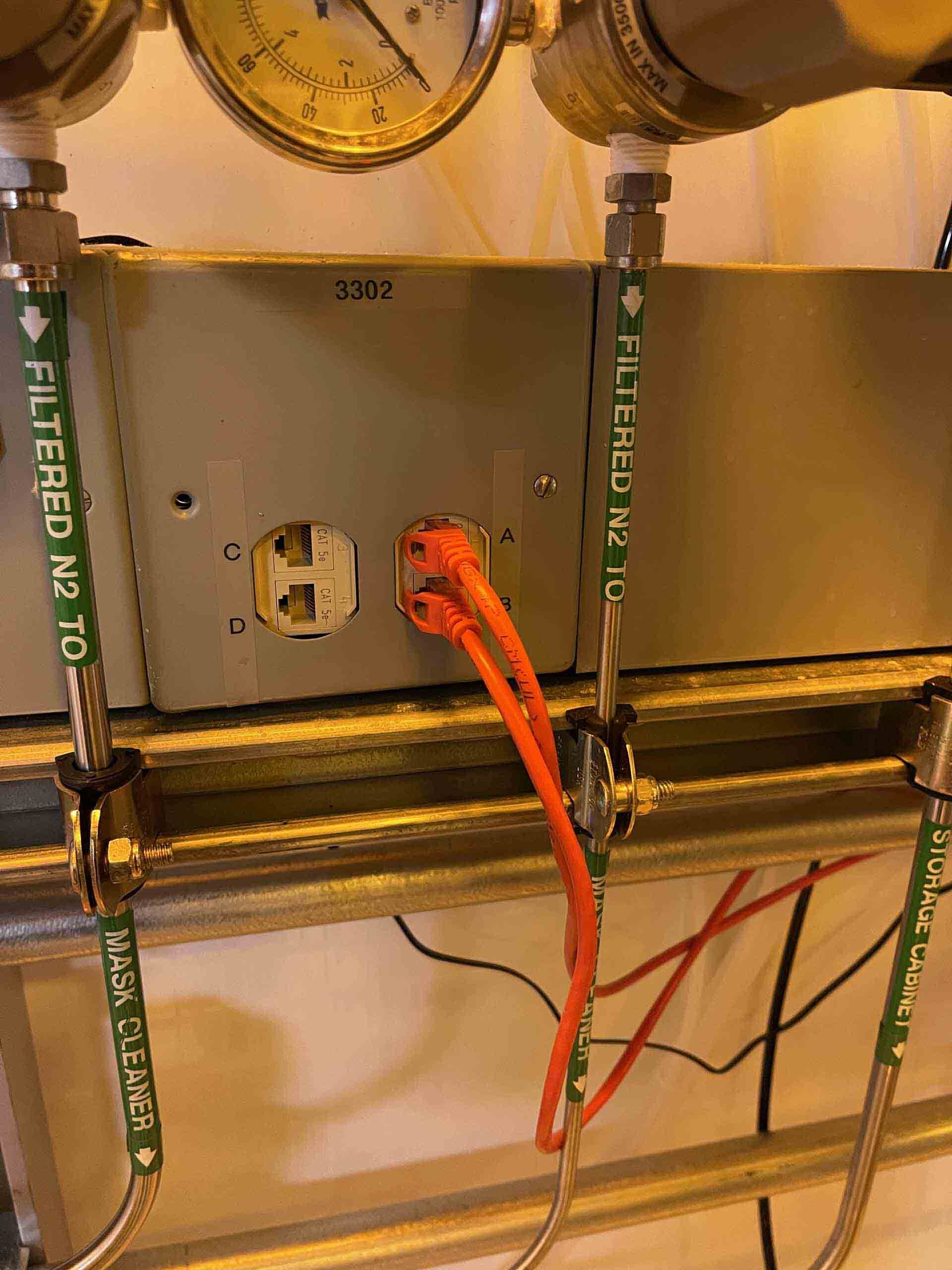

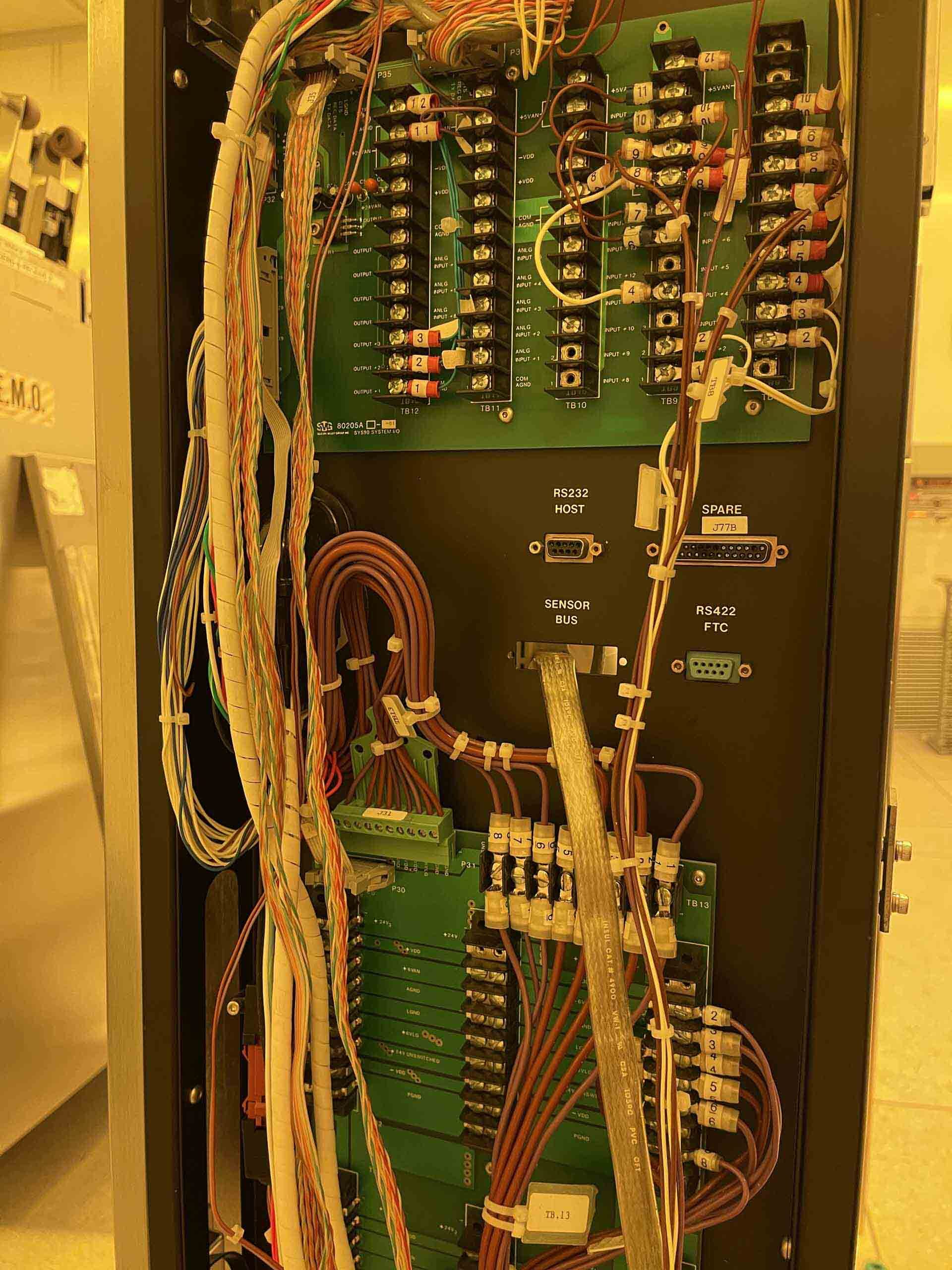

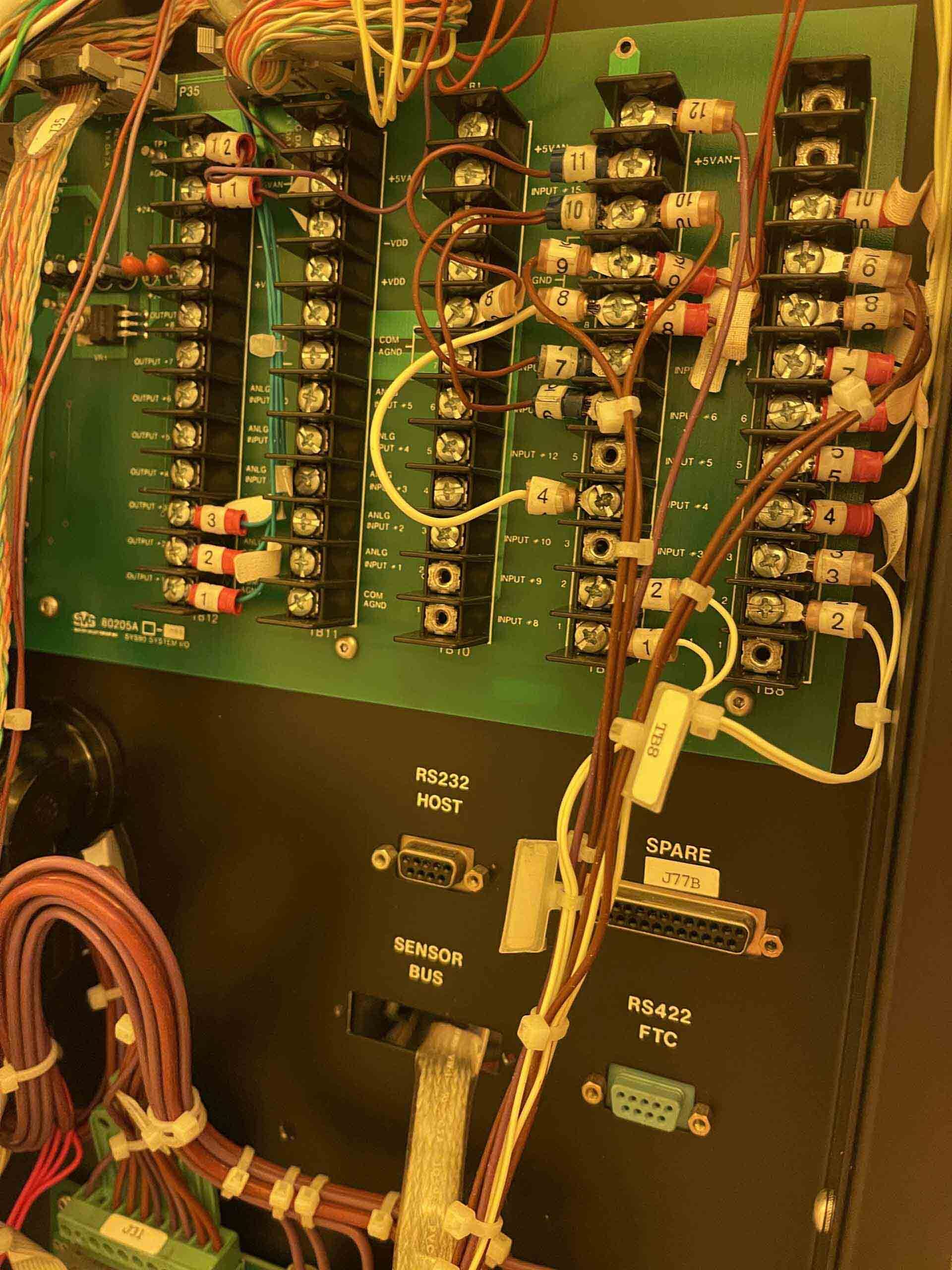

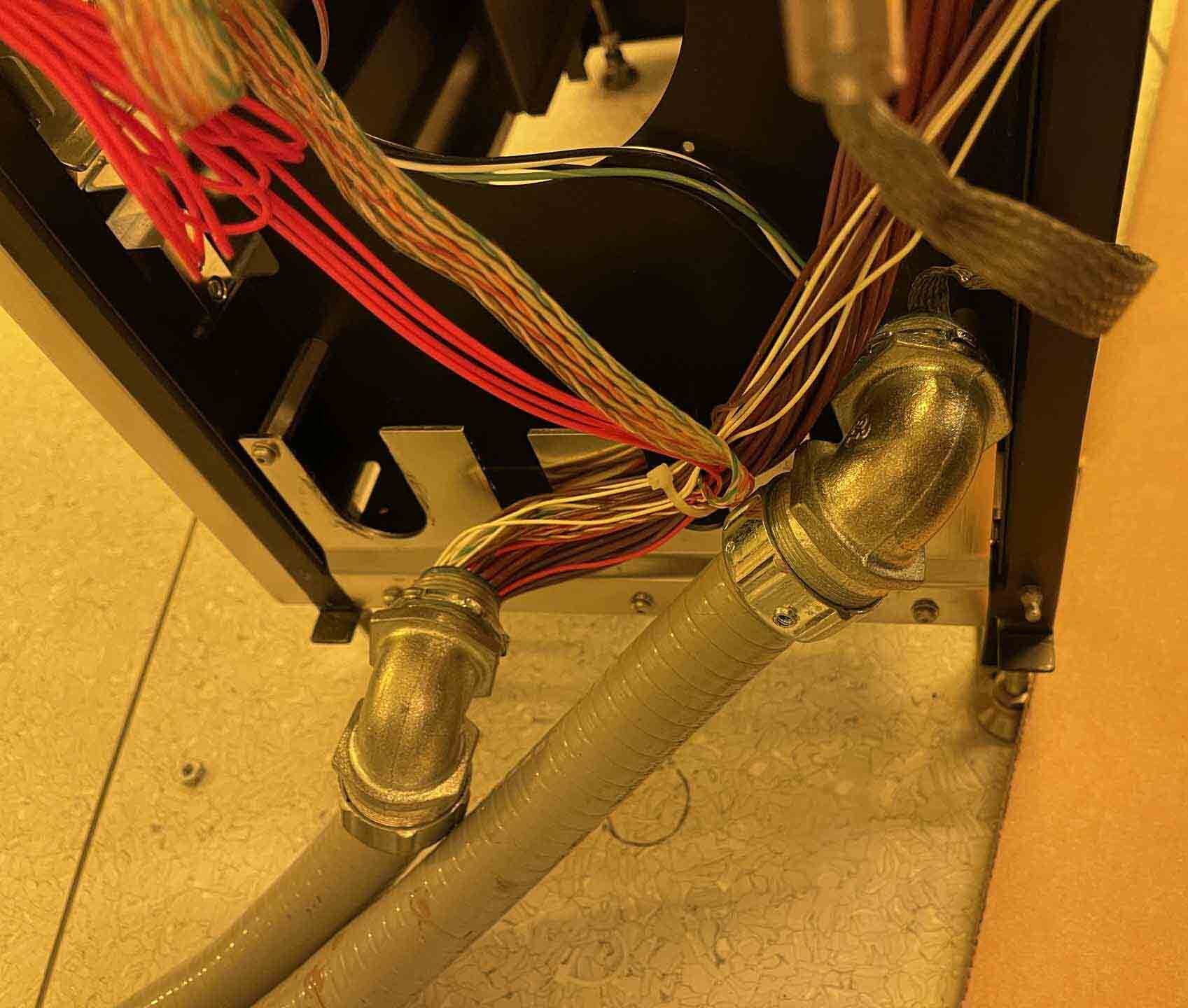

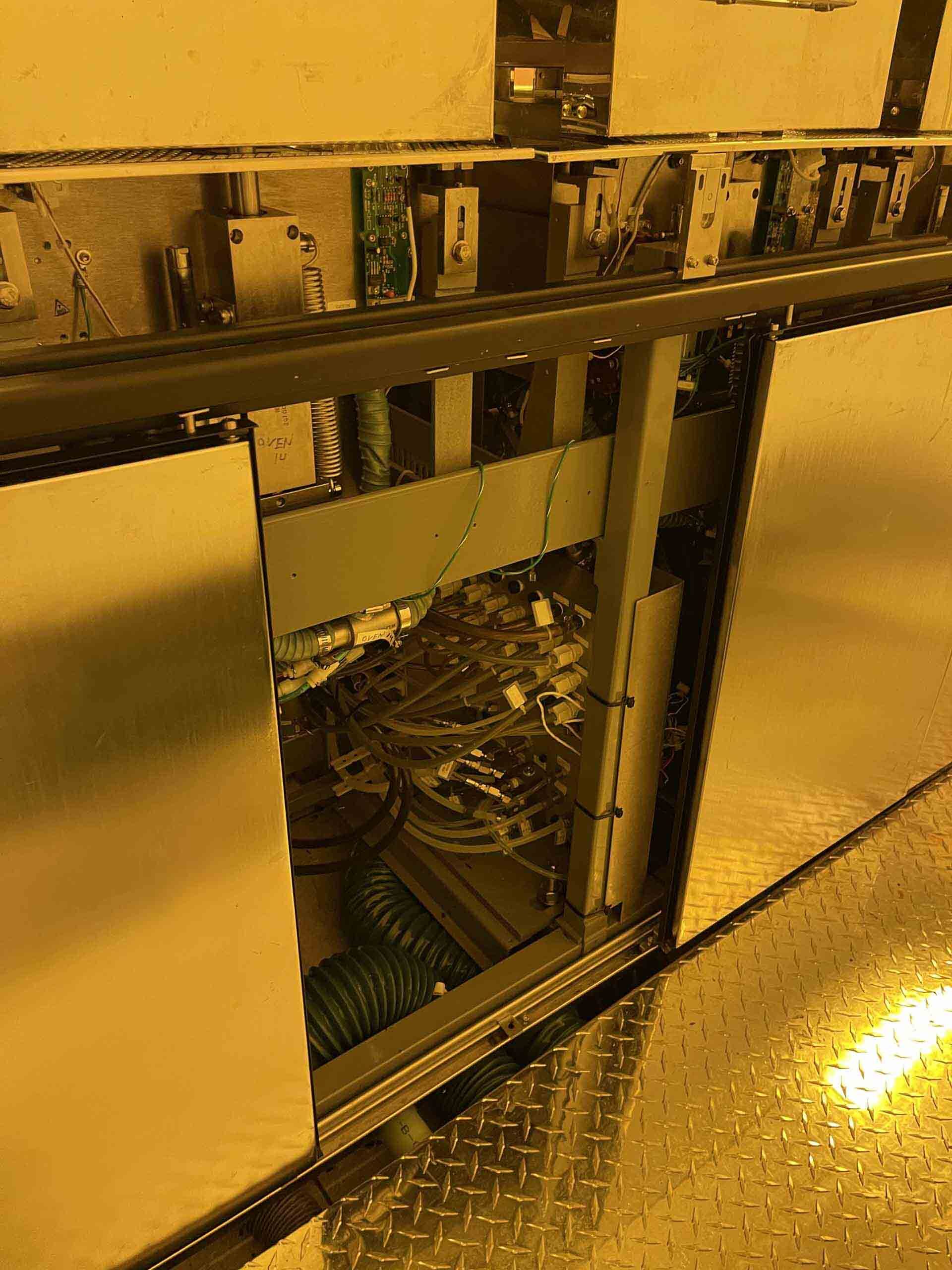

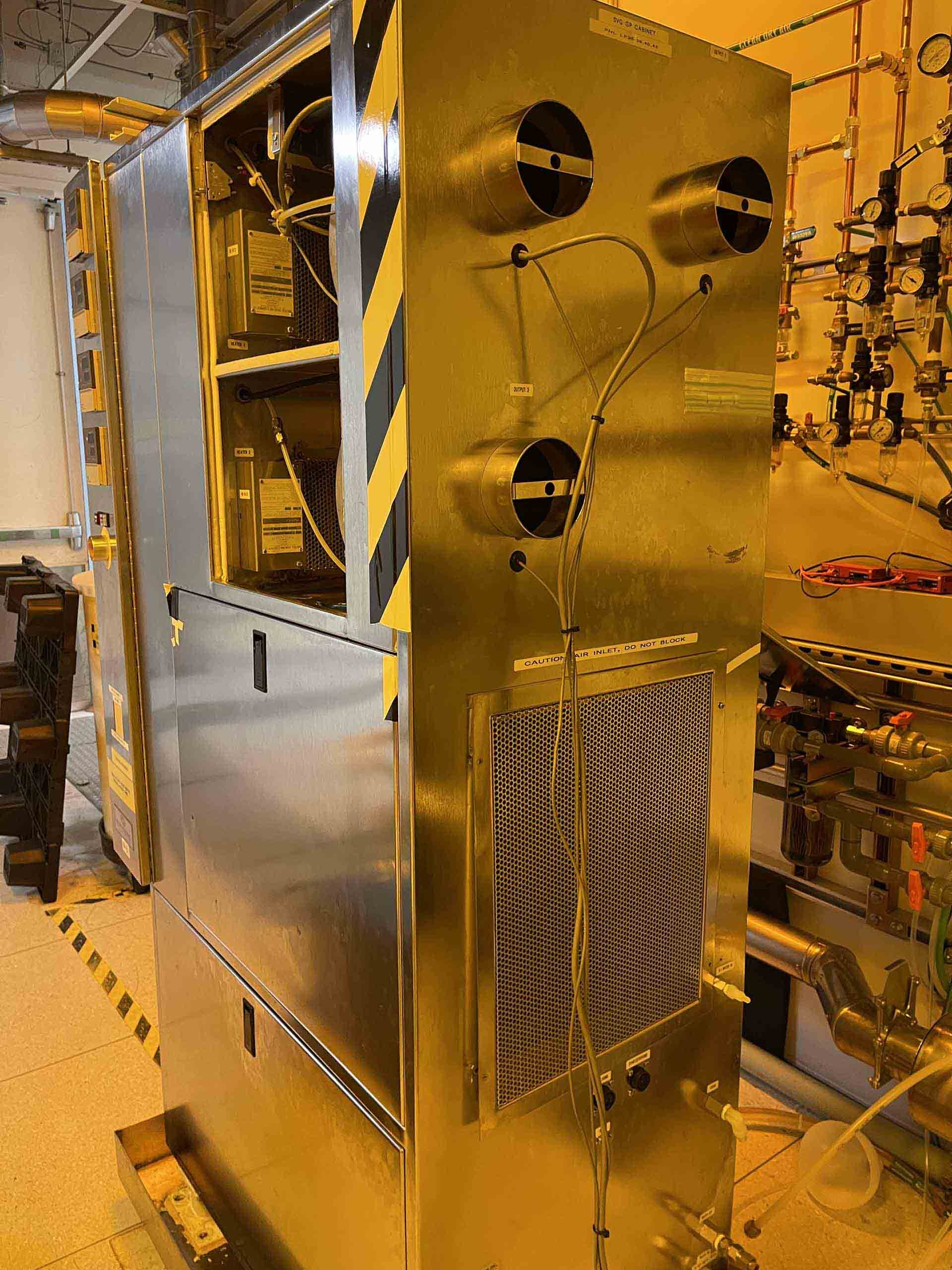

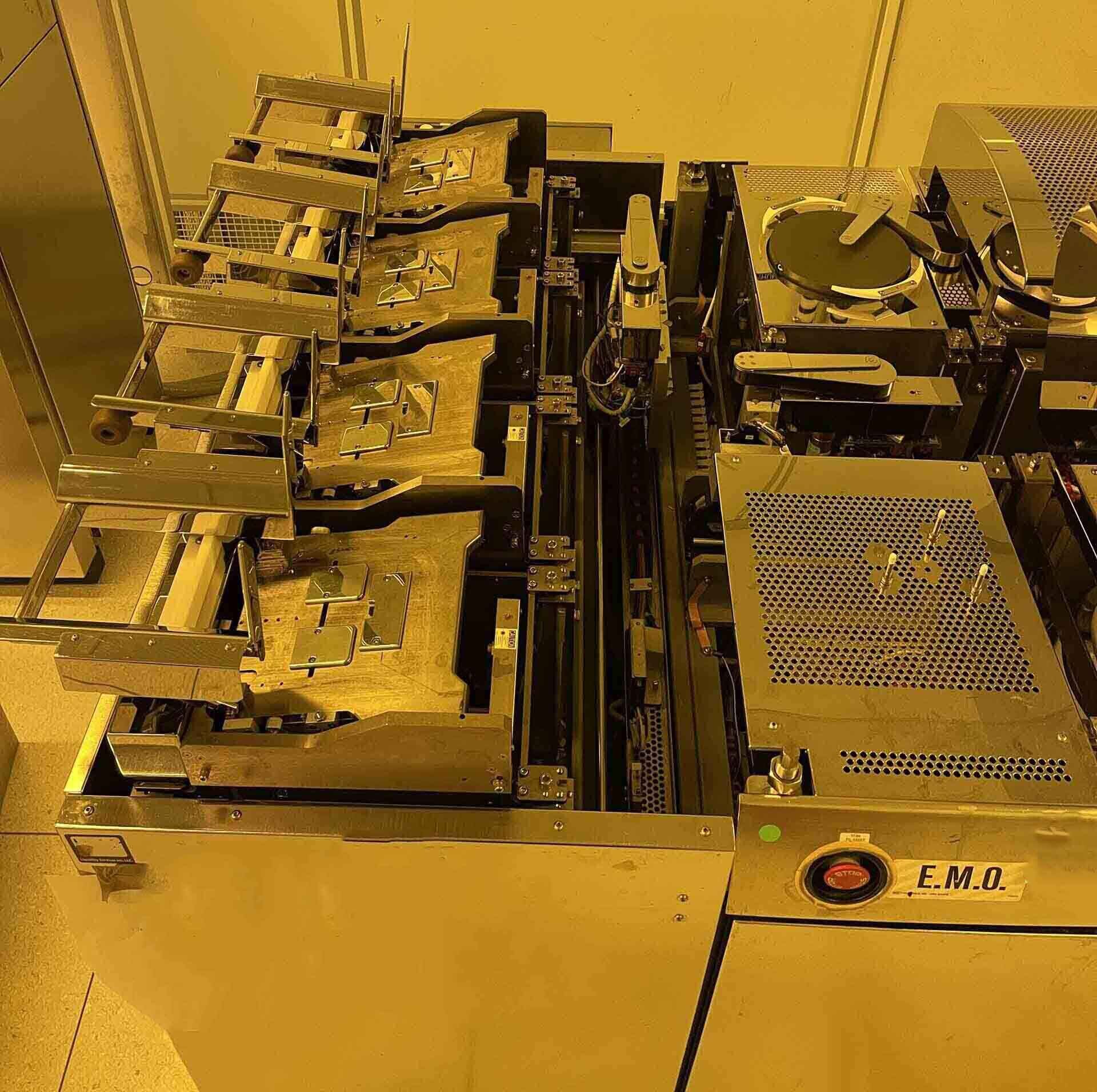

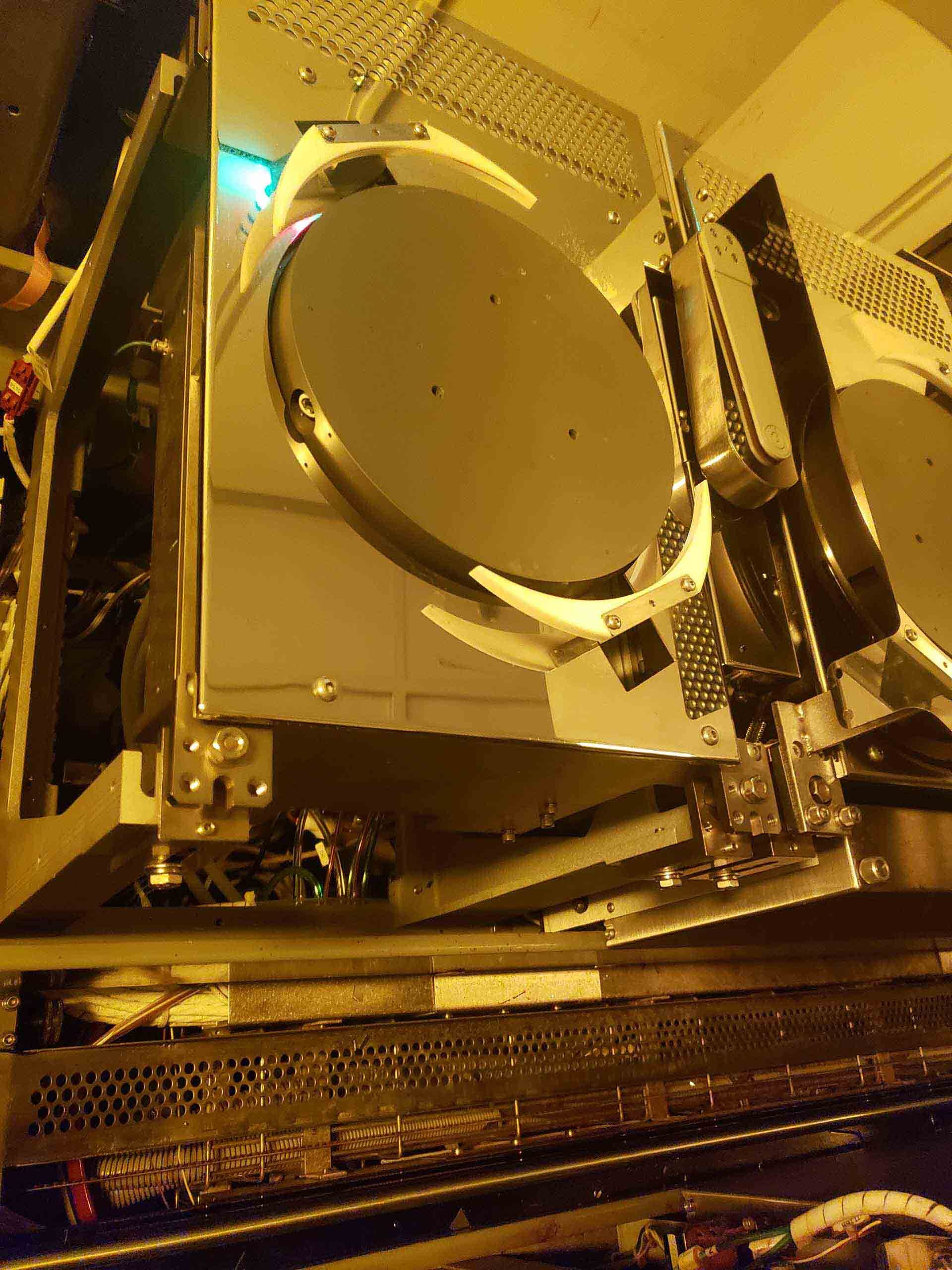

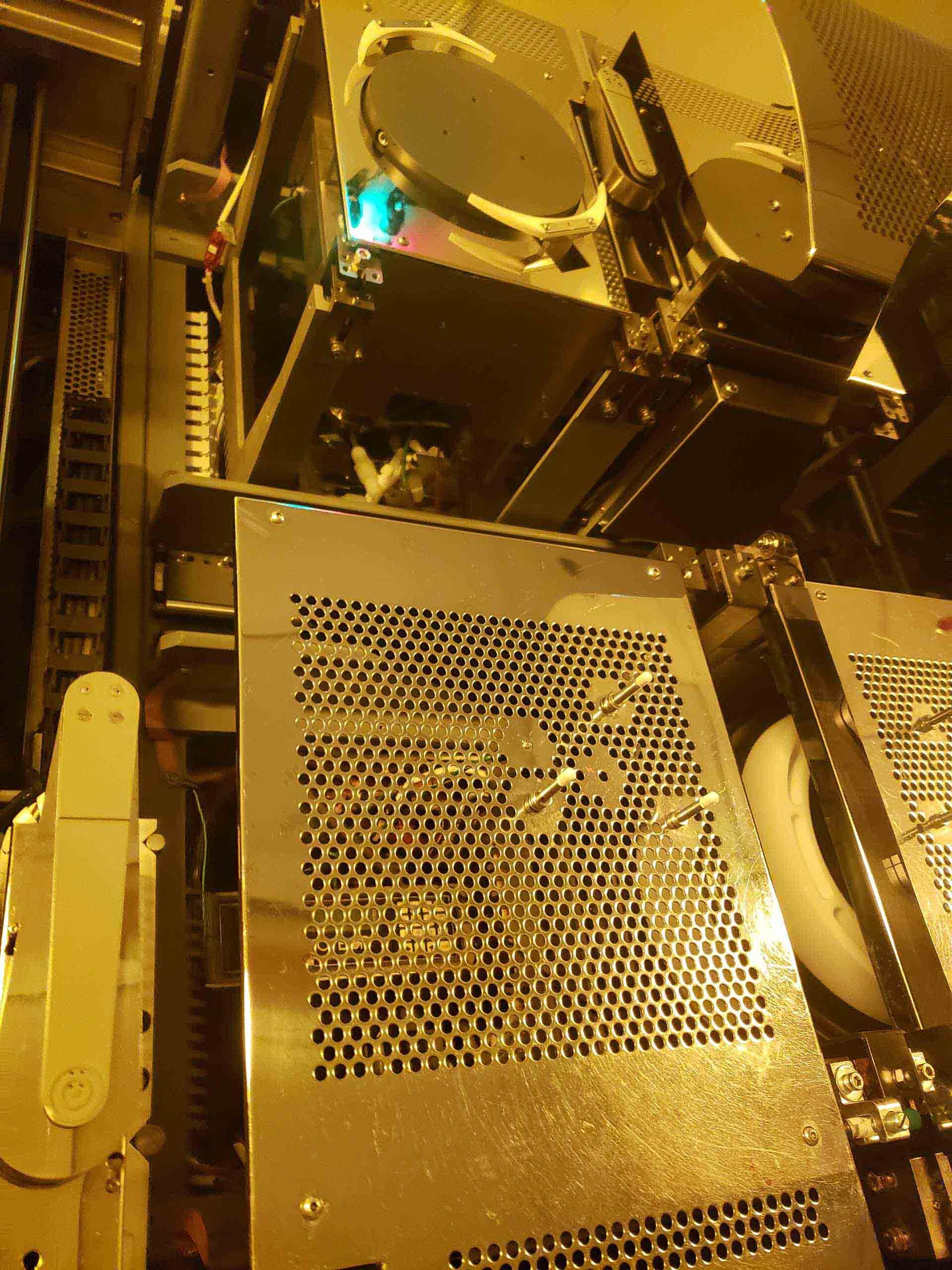

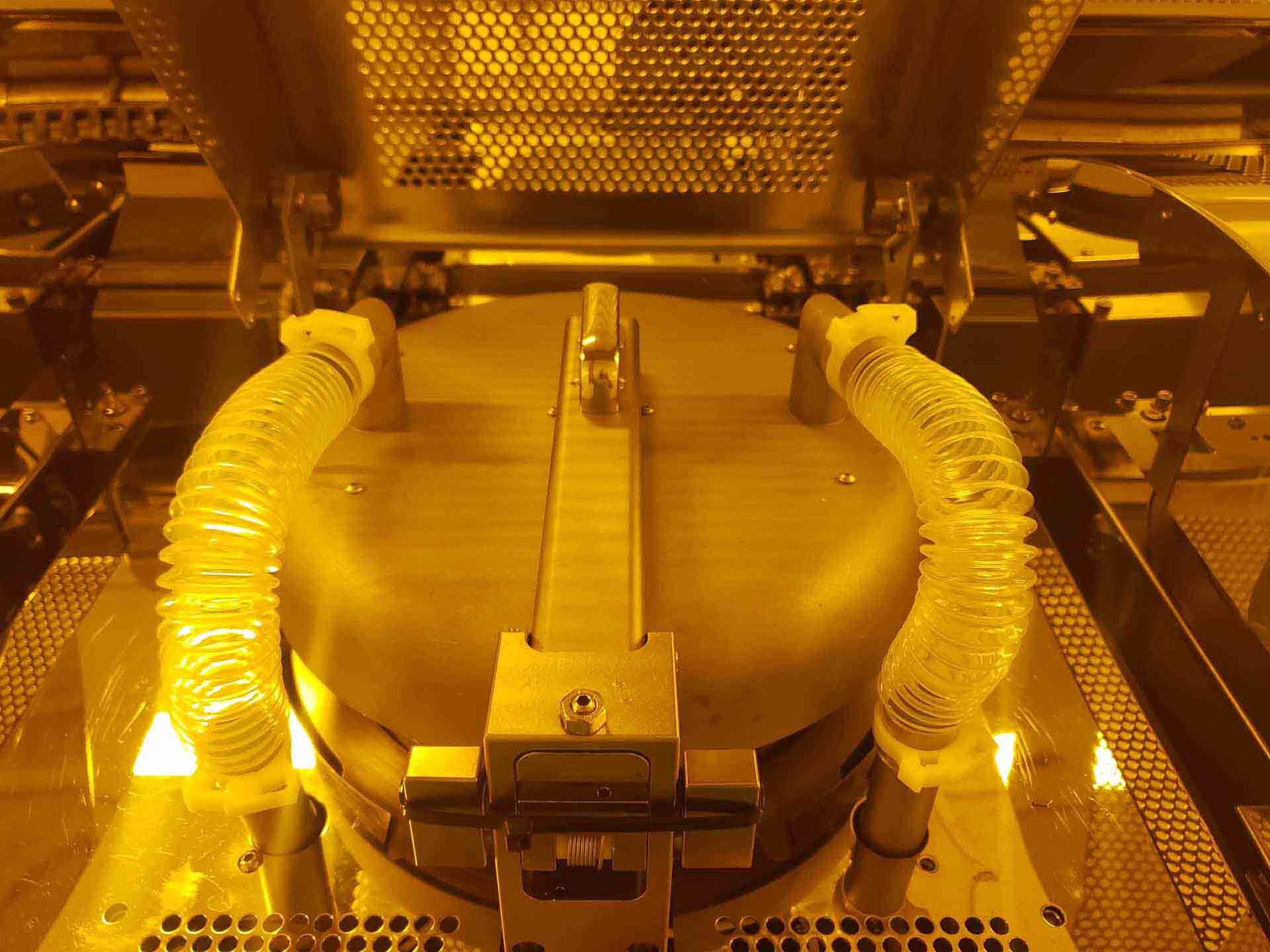

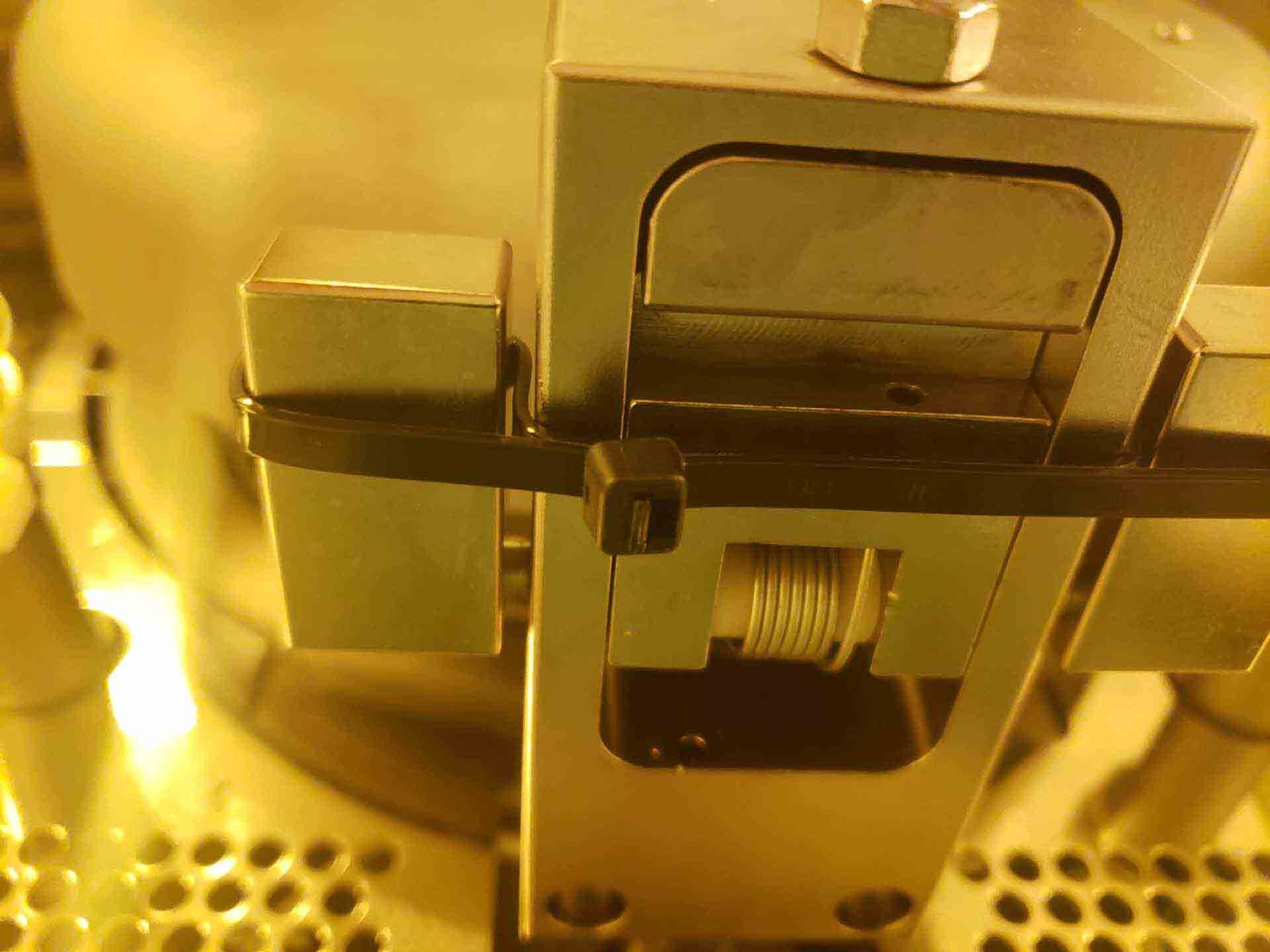

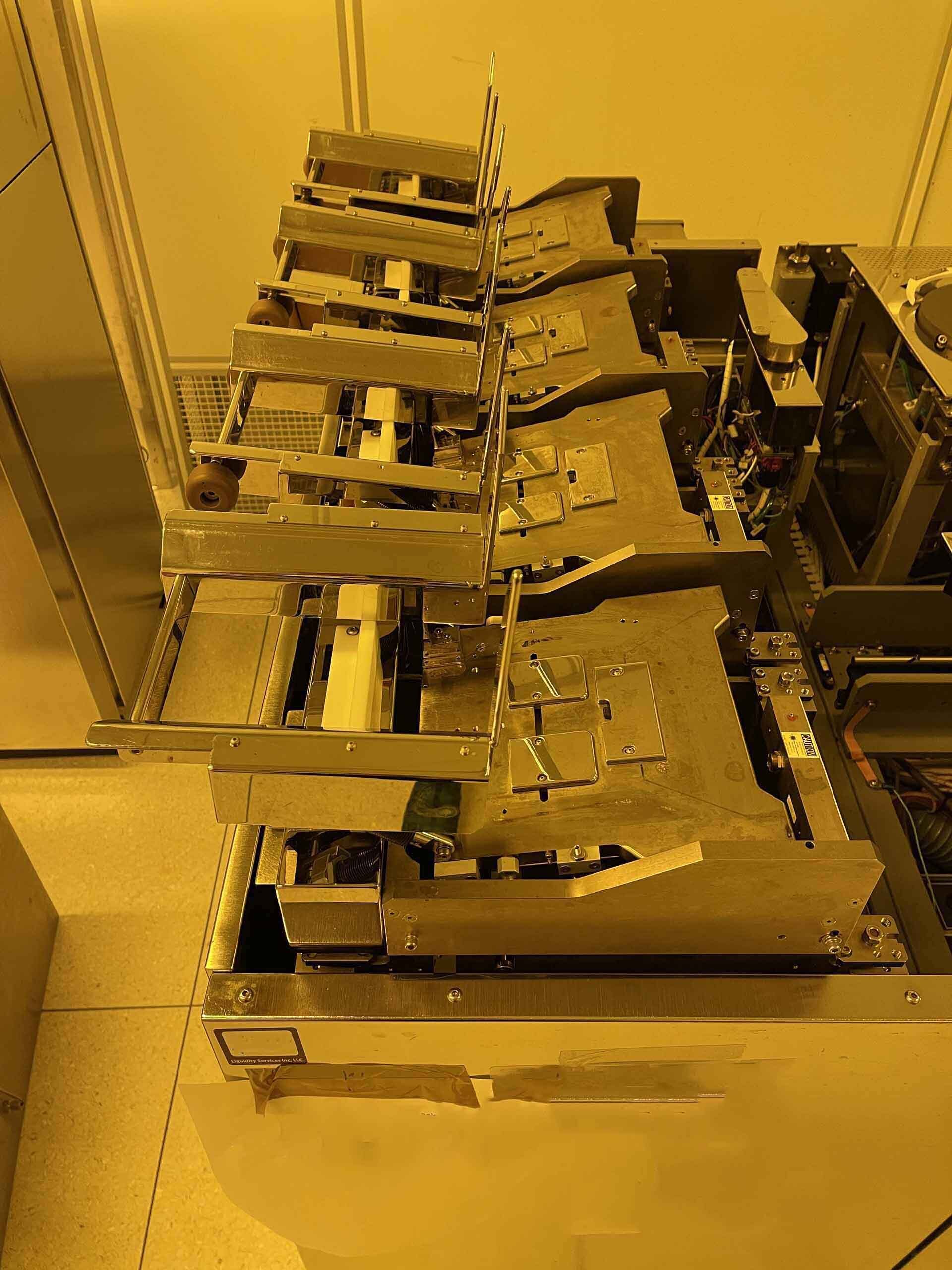

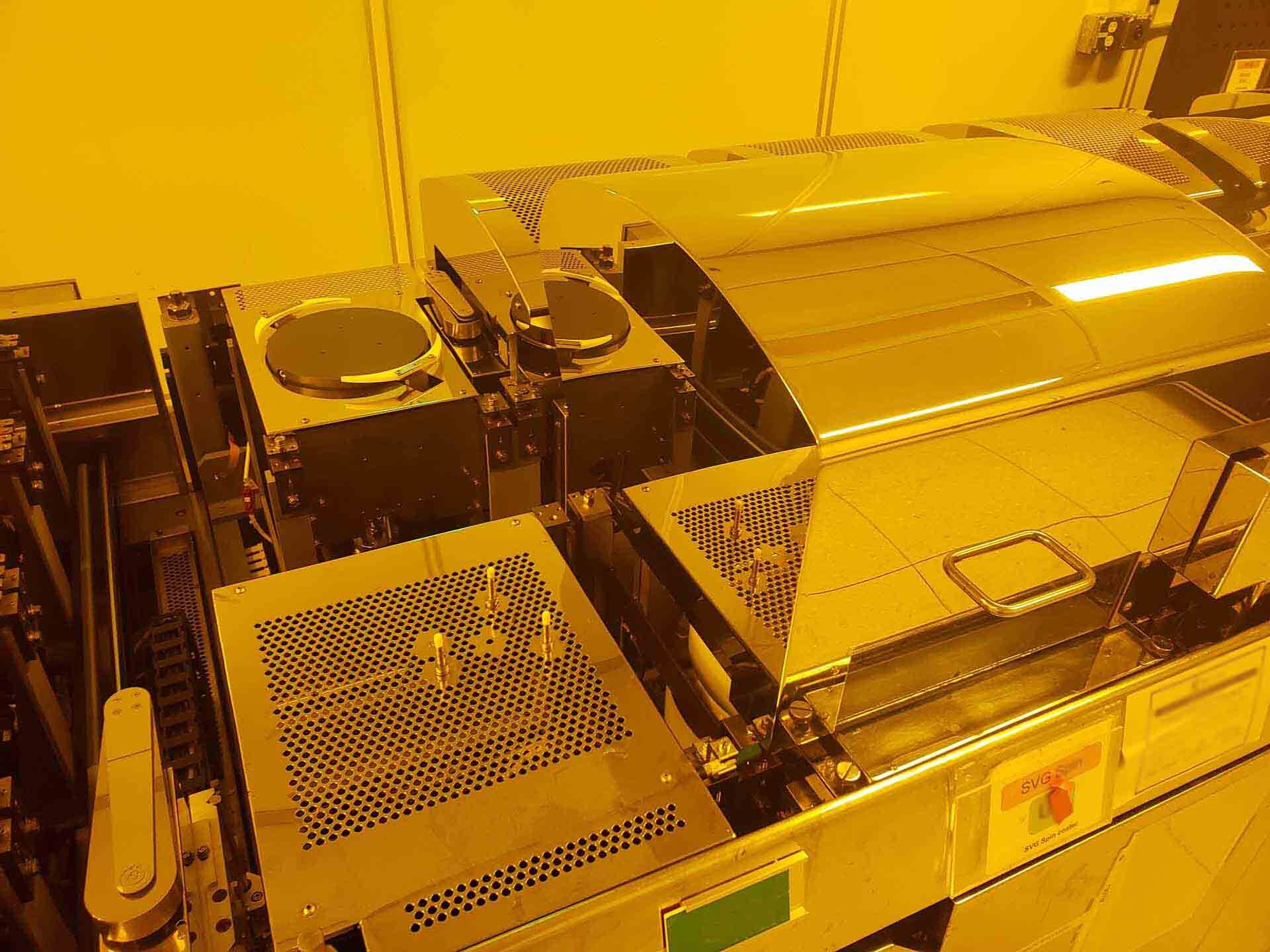

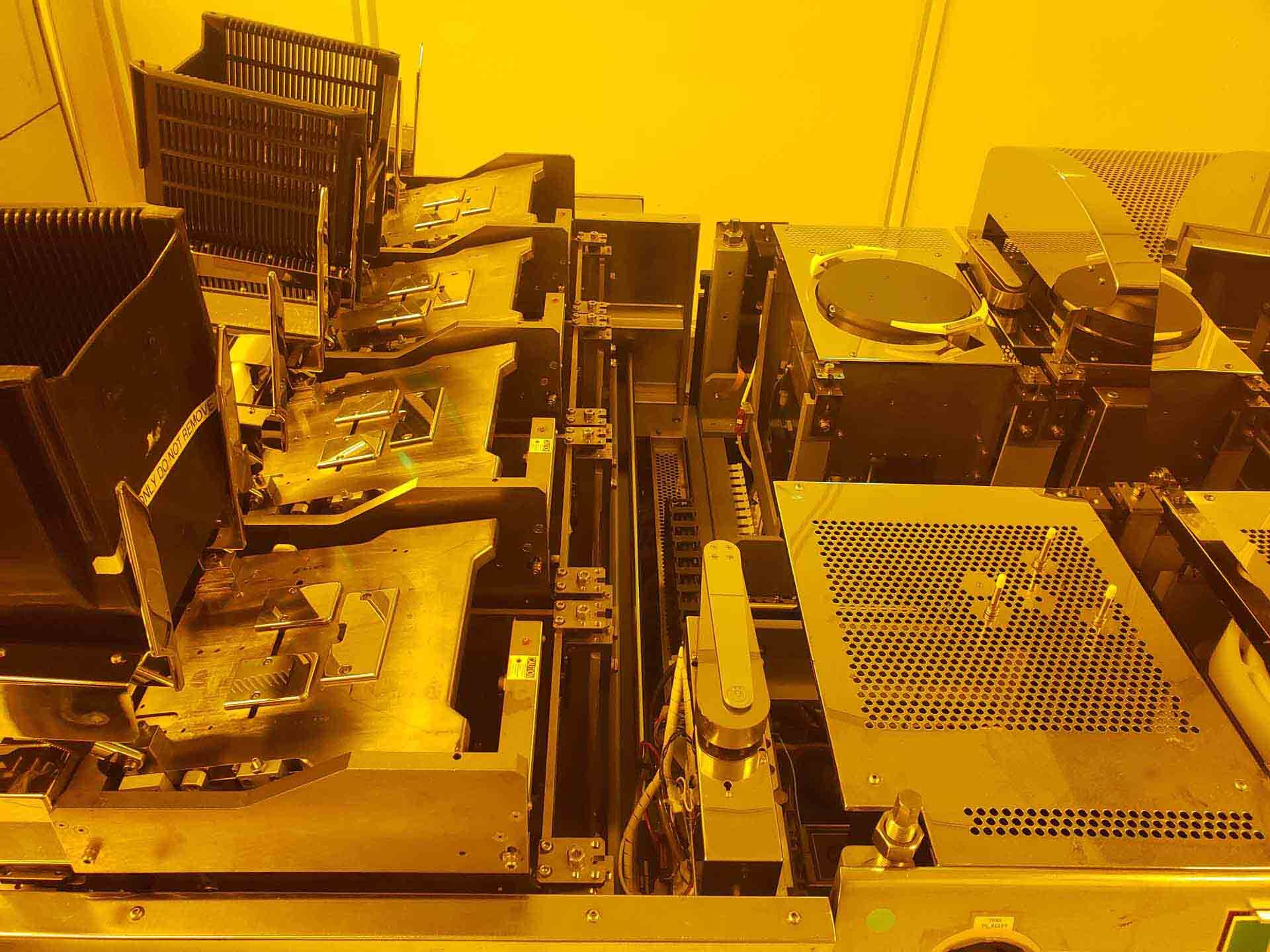

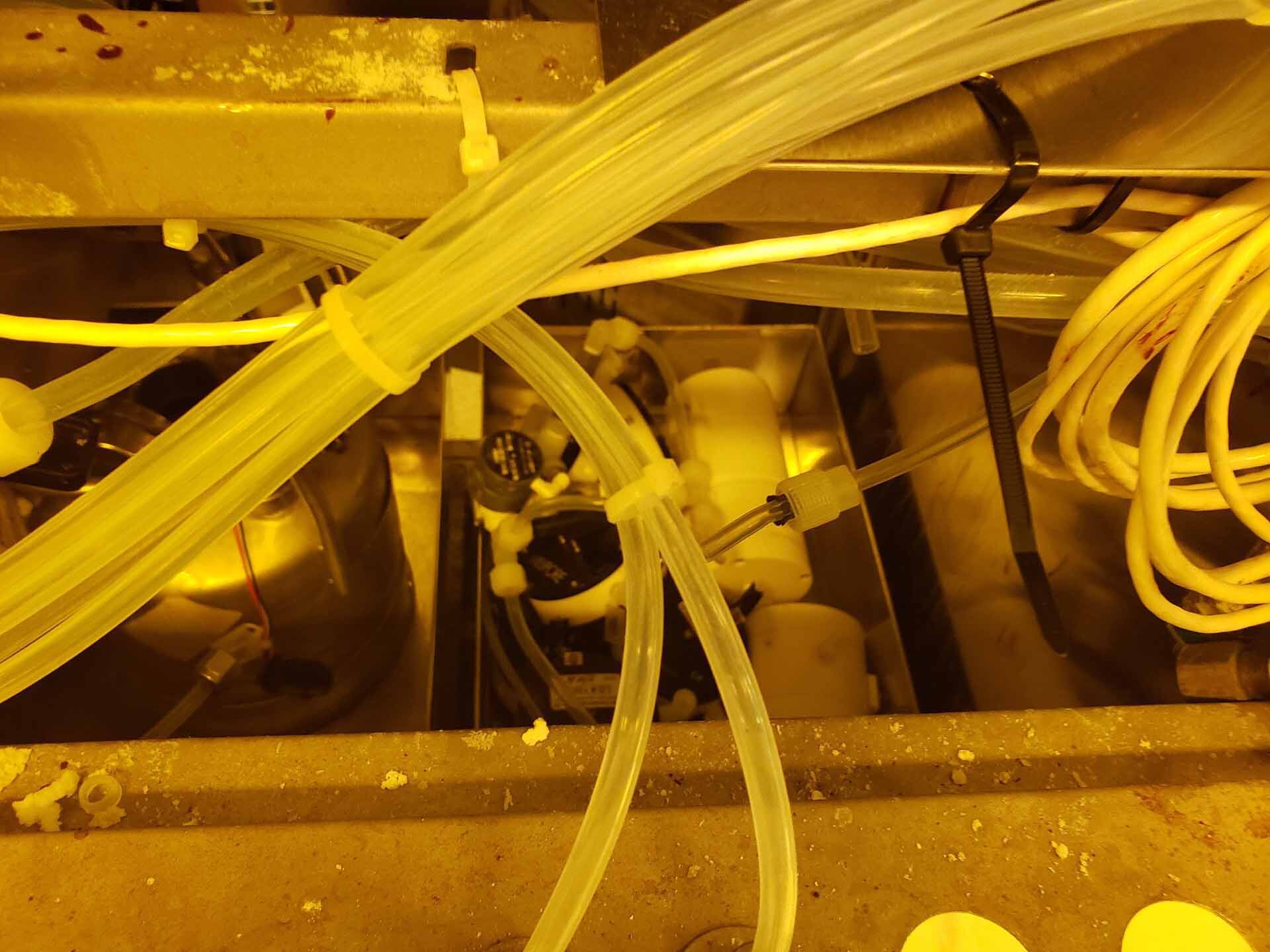

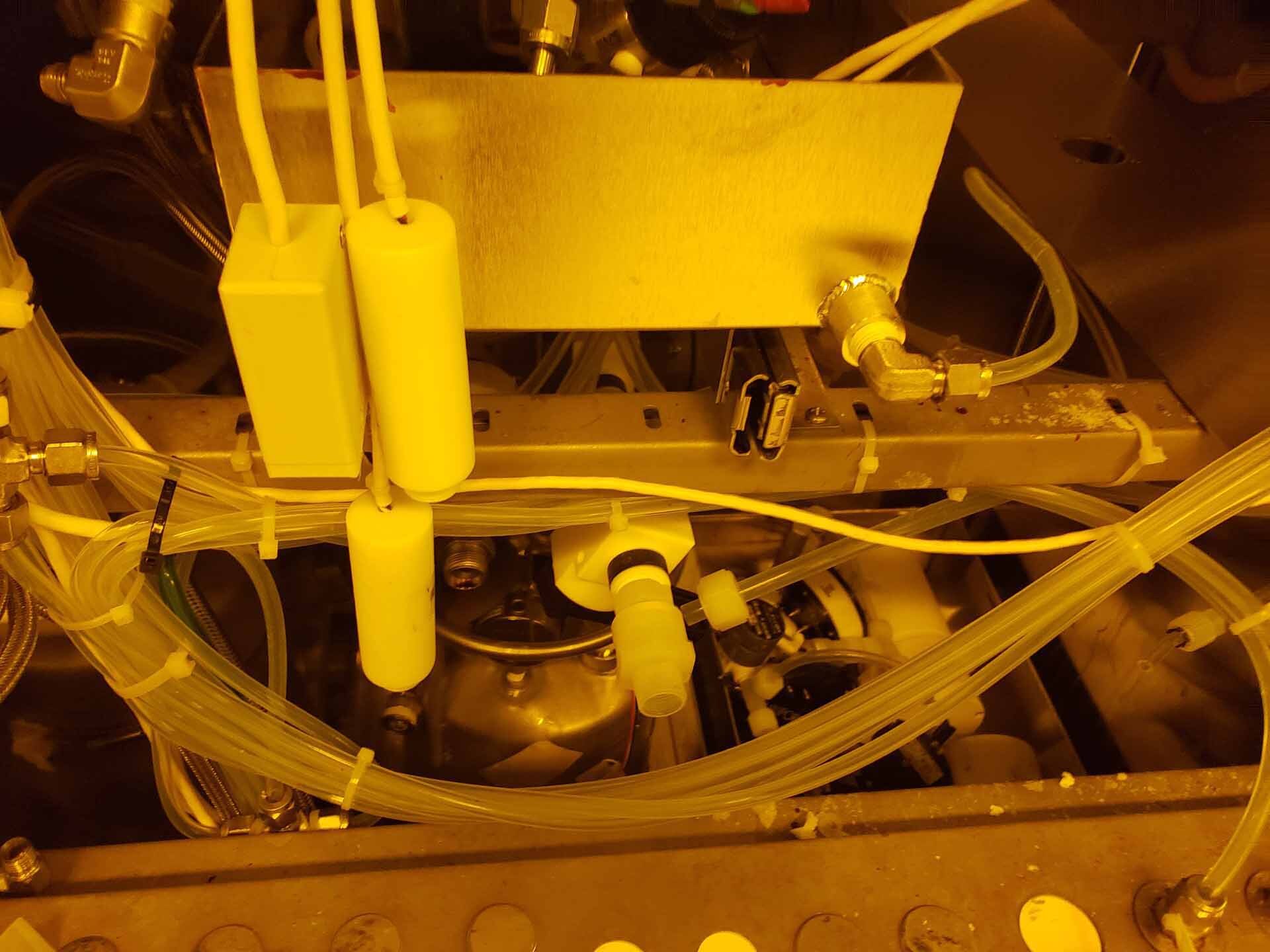

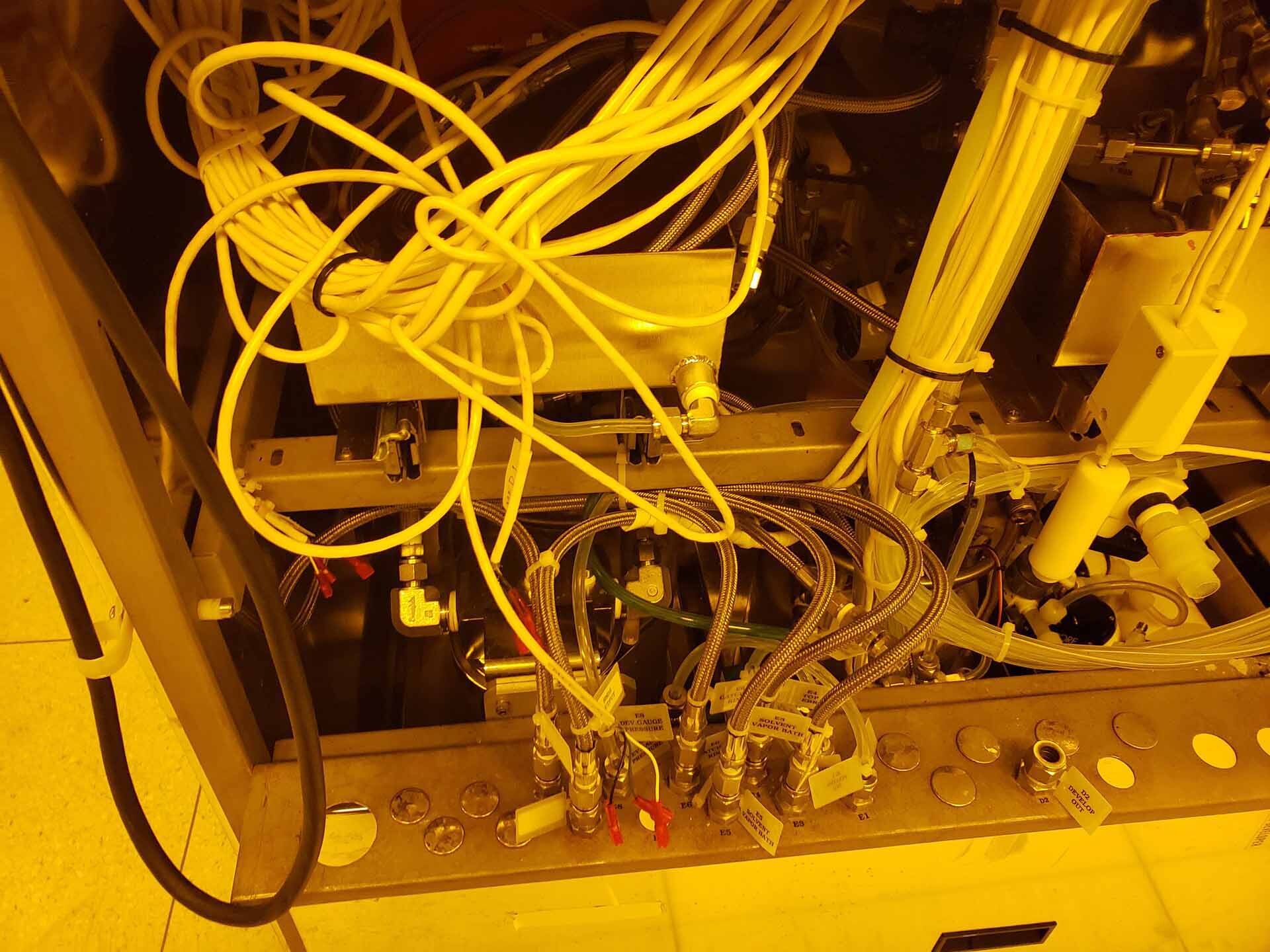

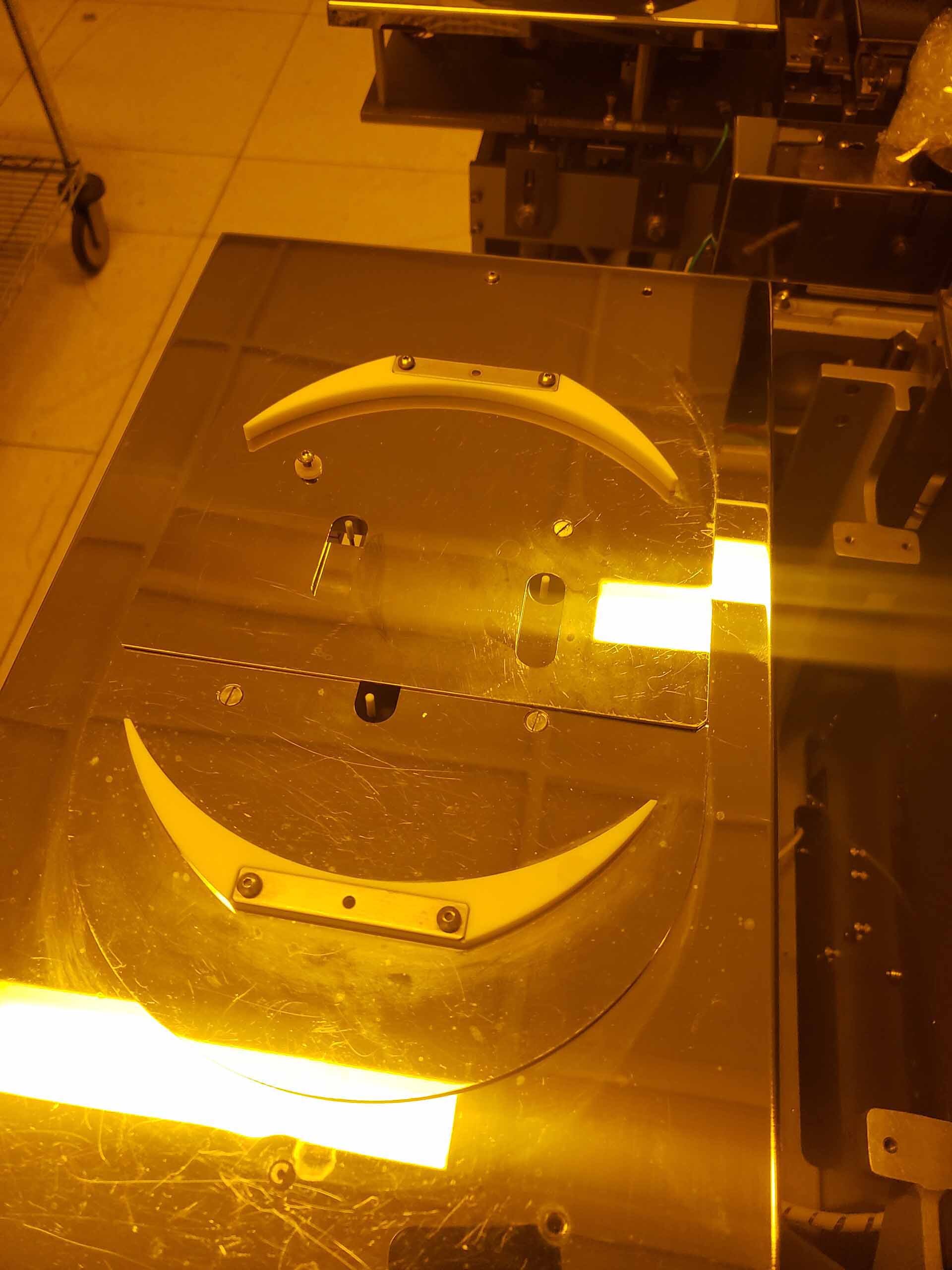

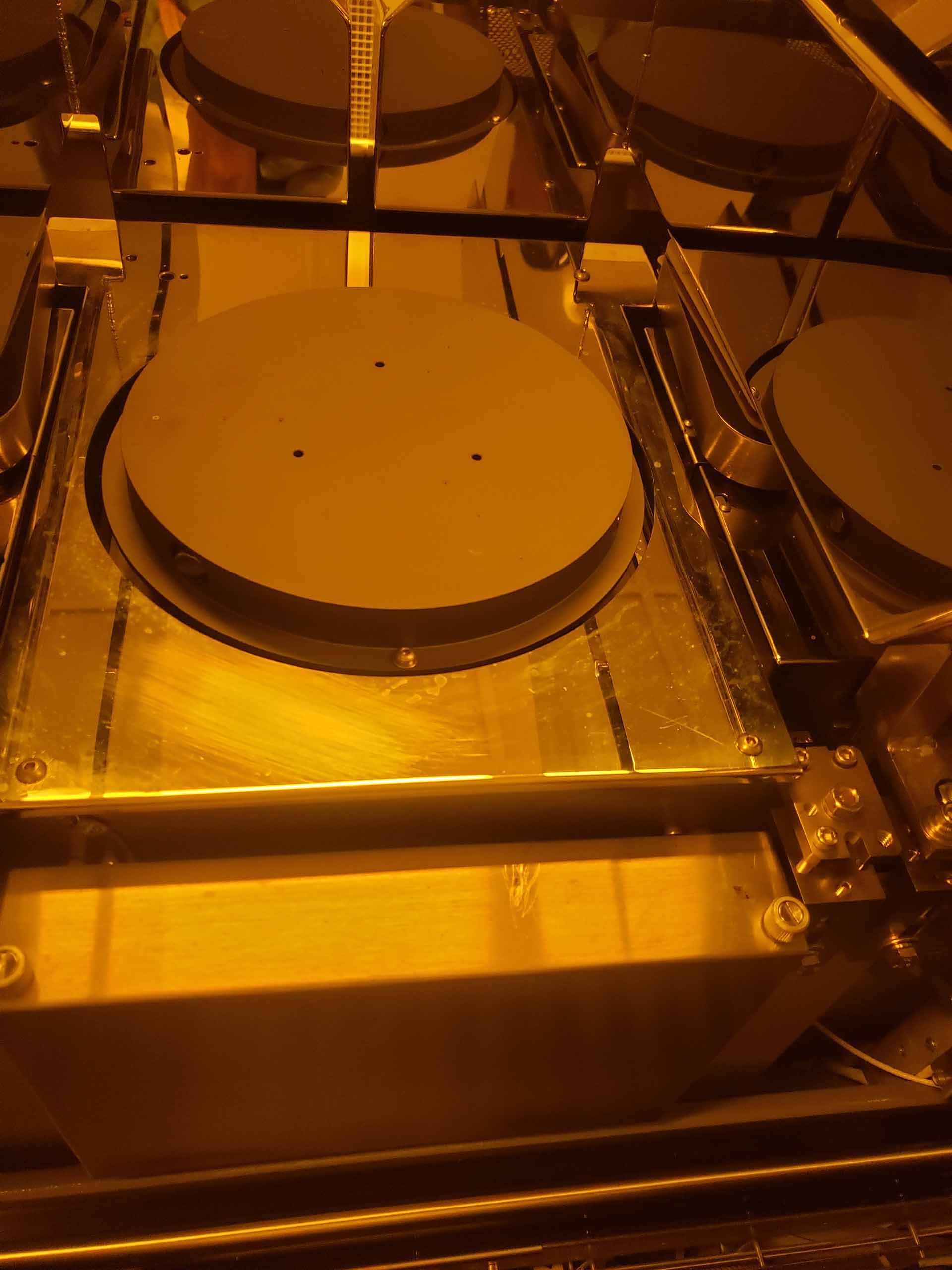

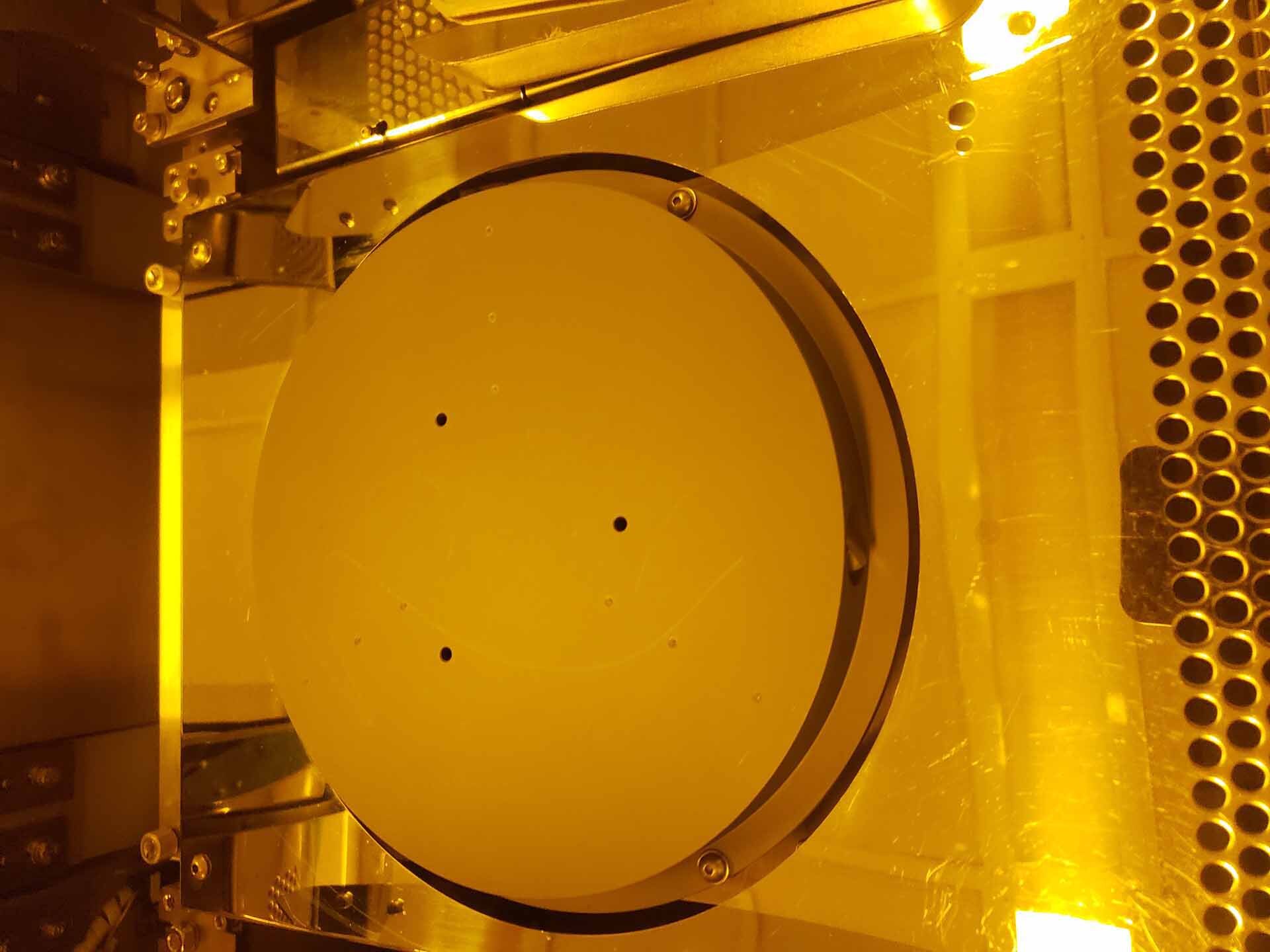

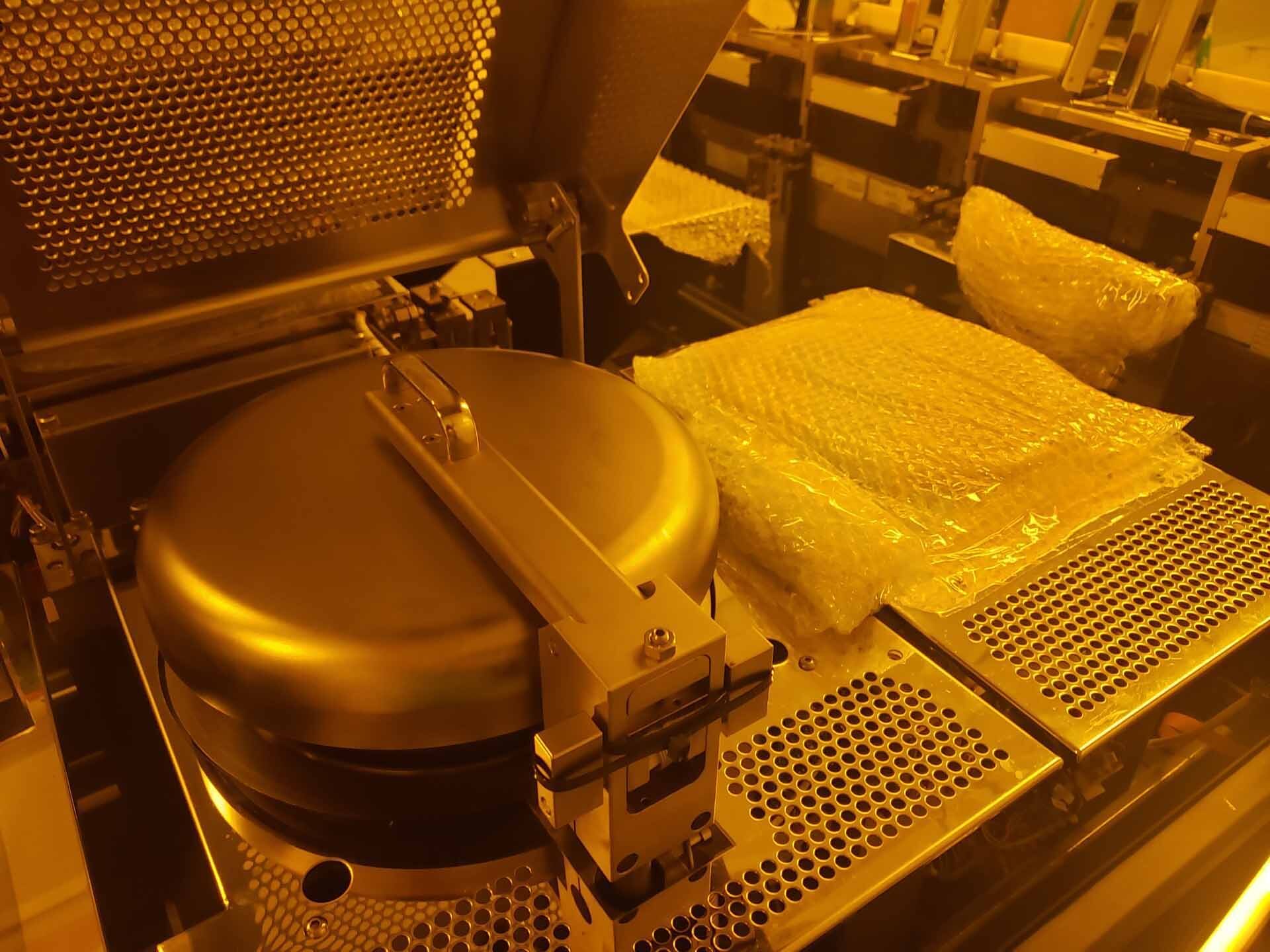

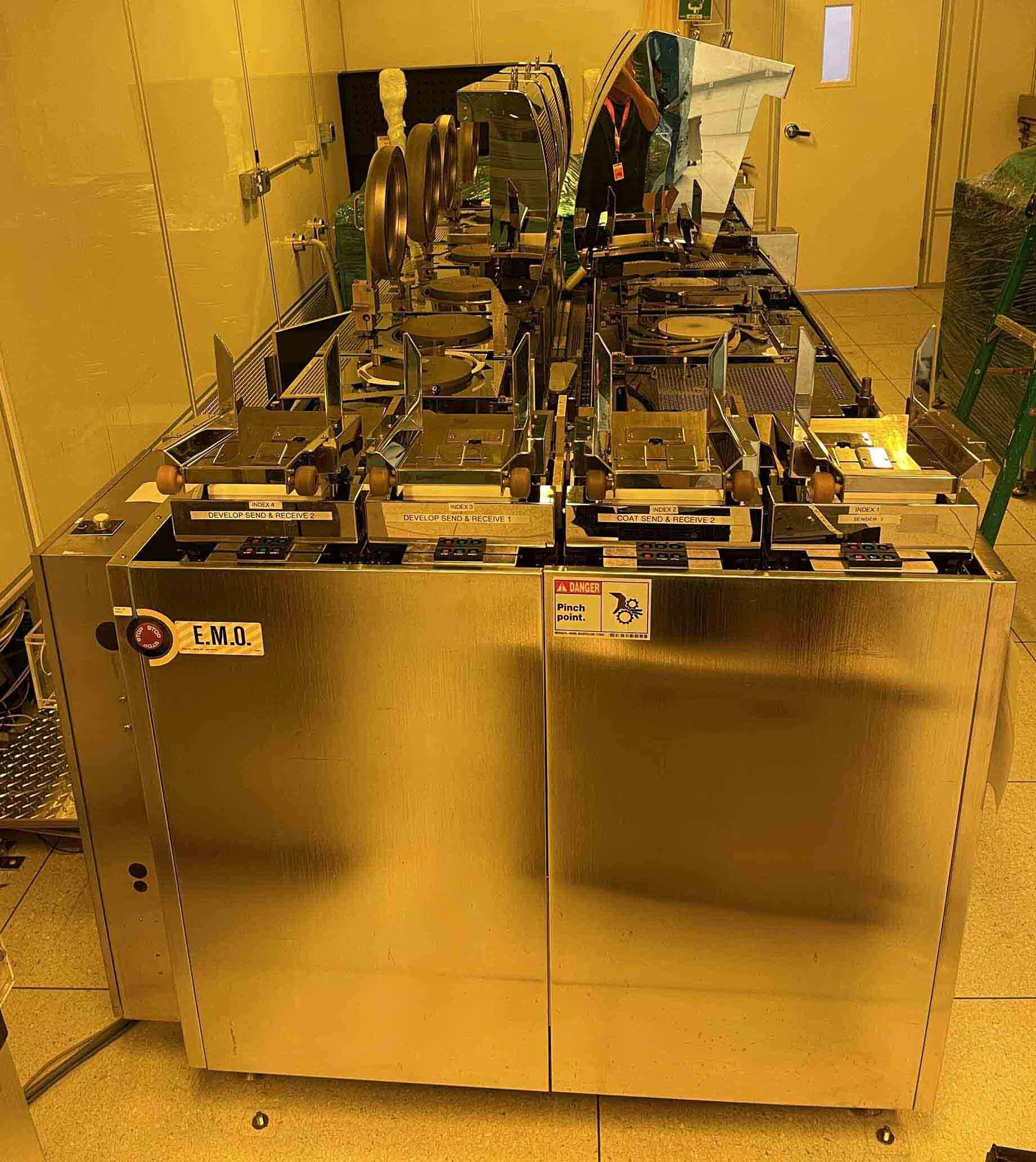

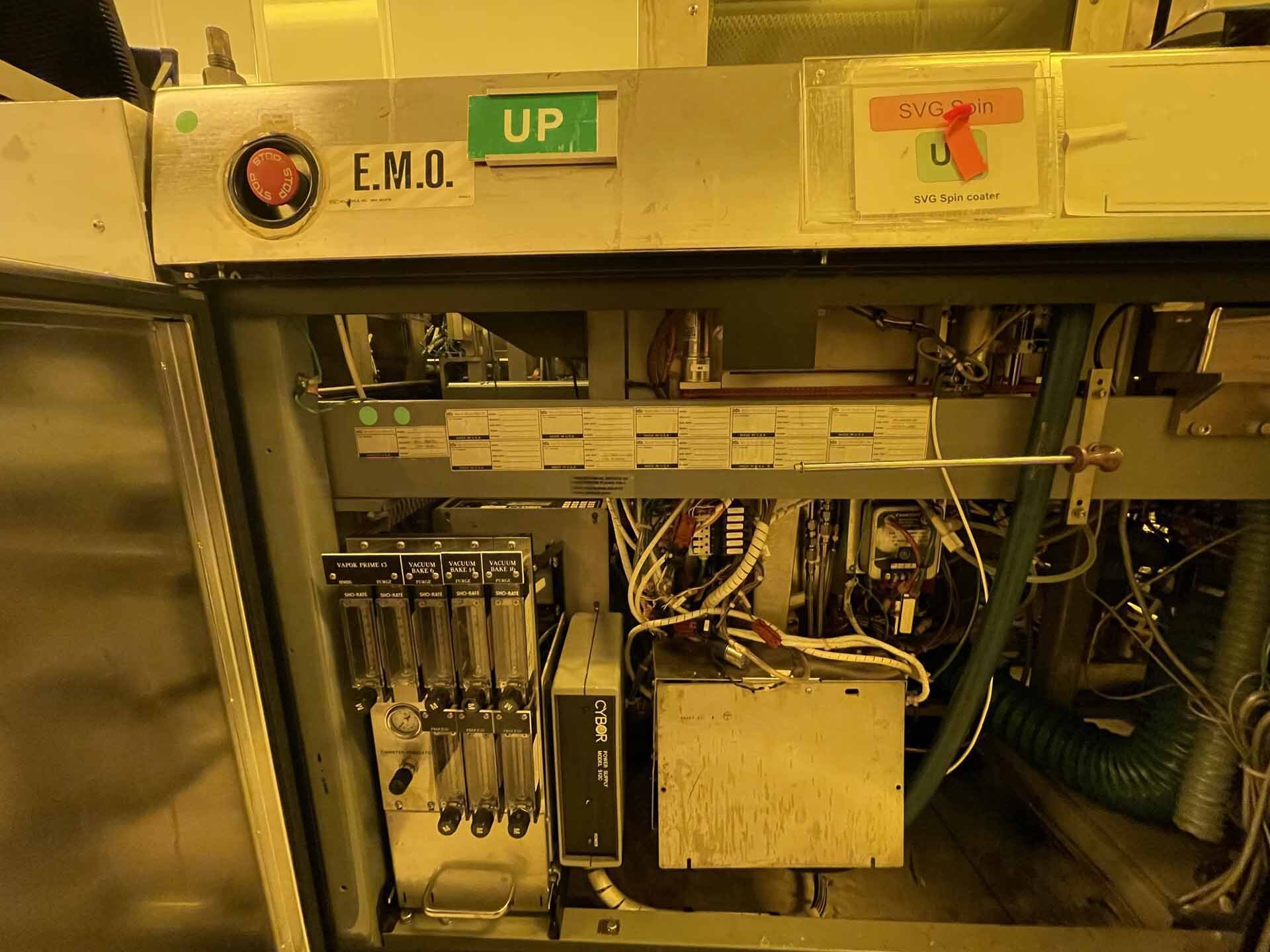

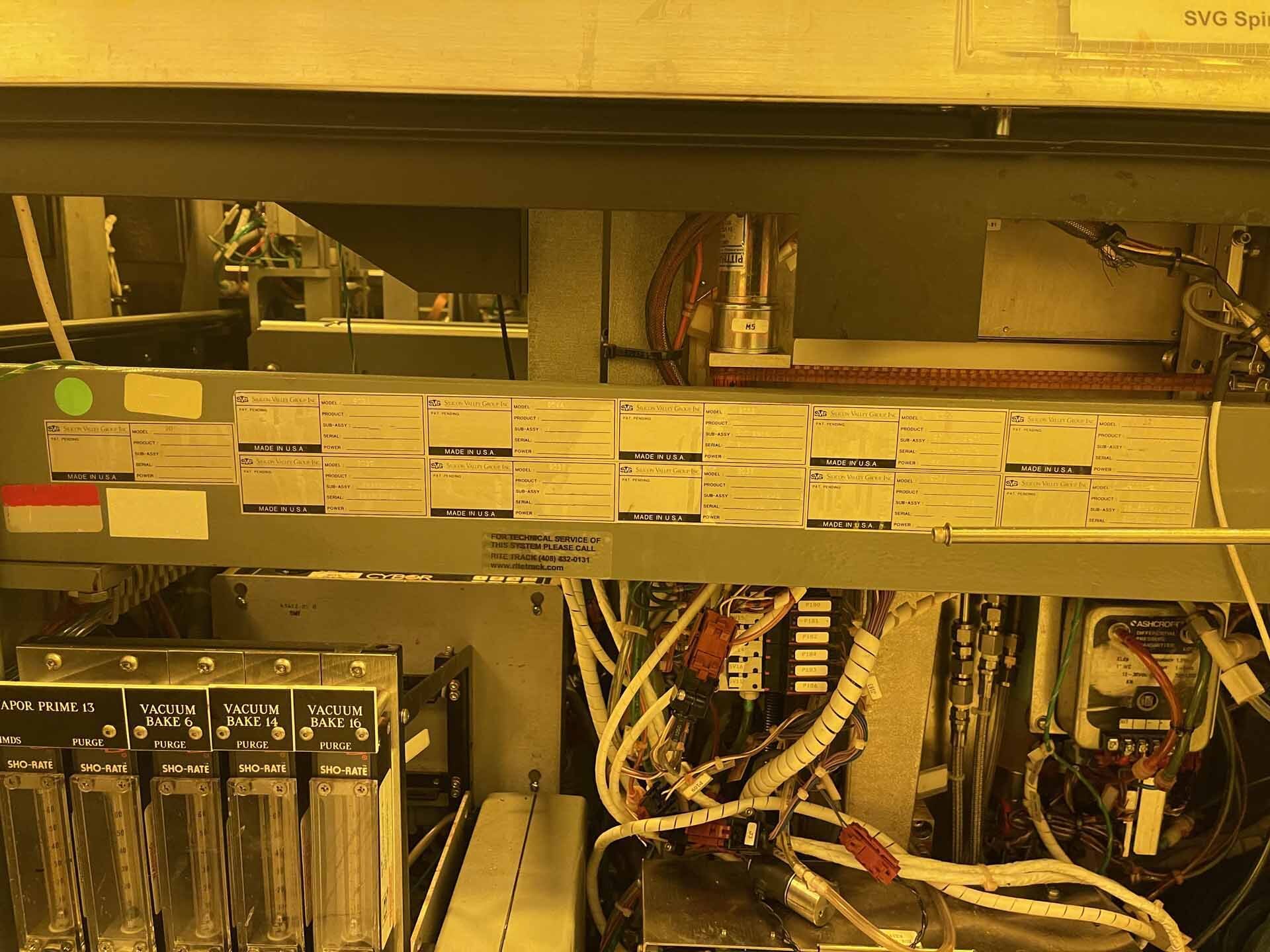

Coater / Developer system

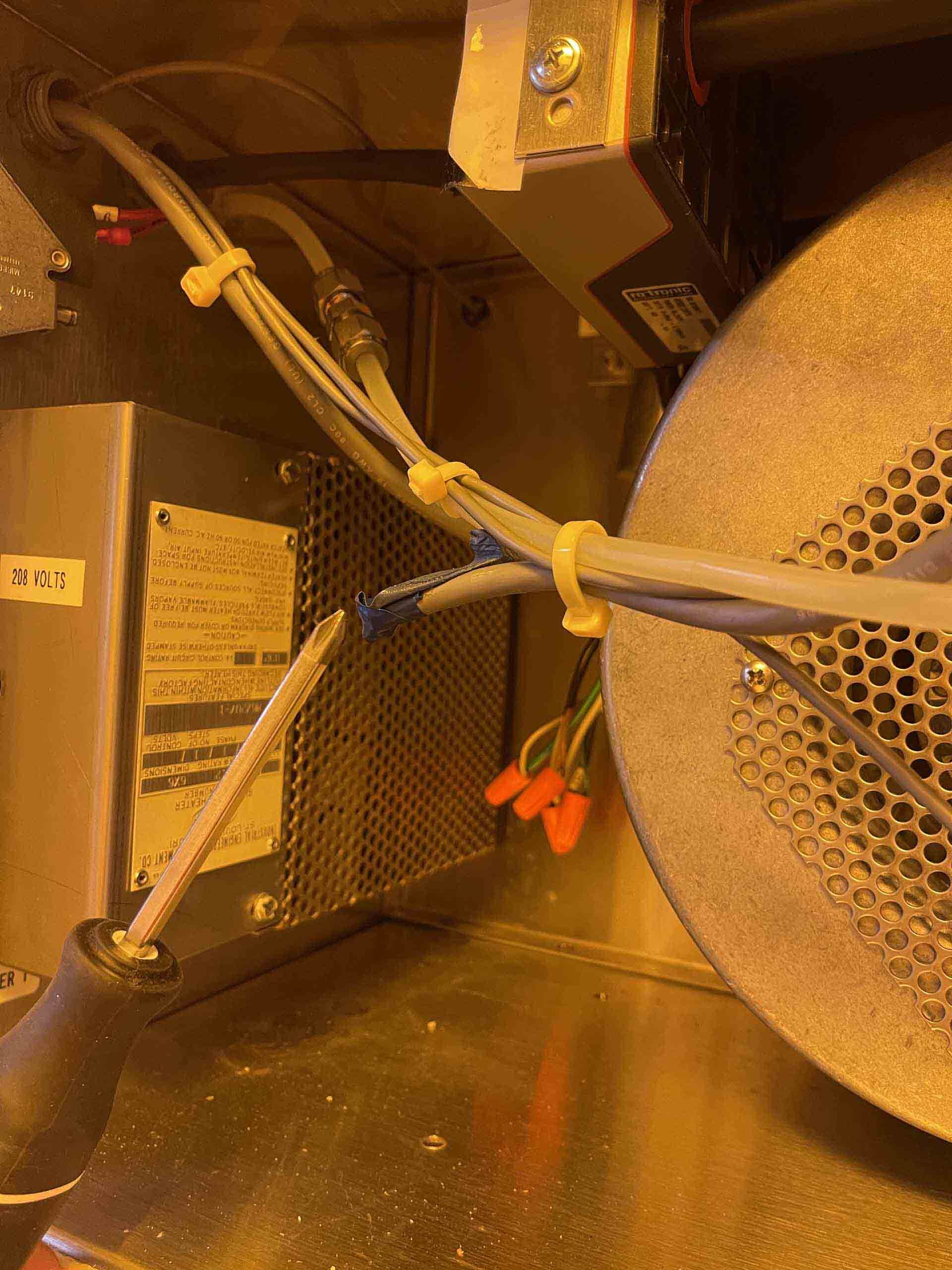

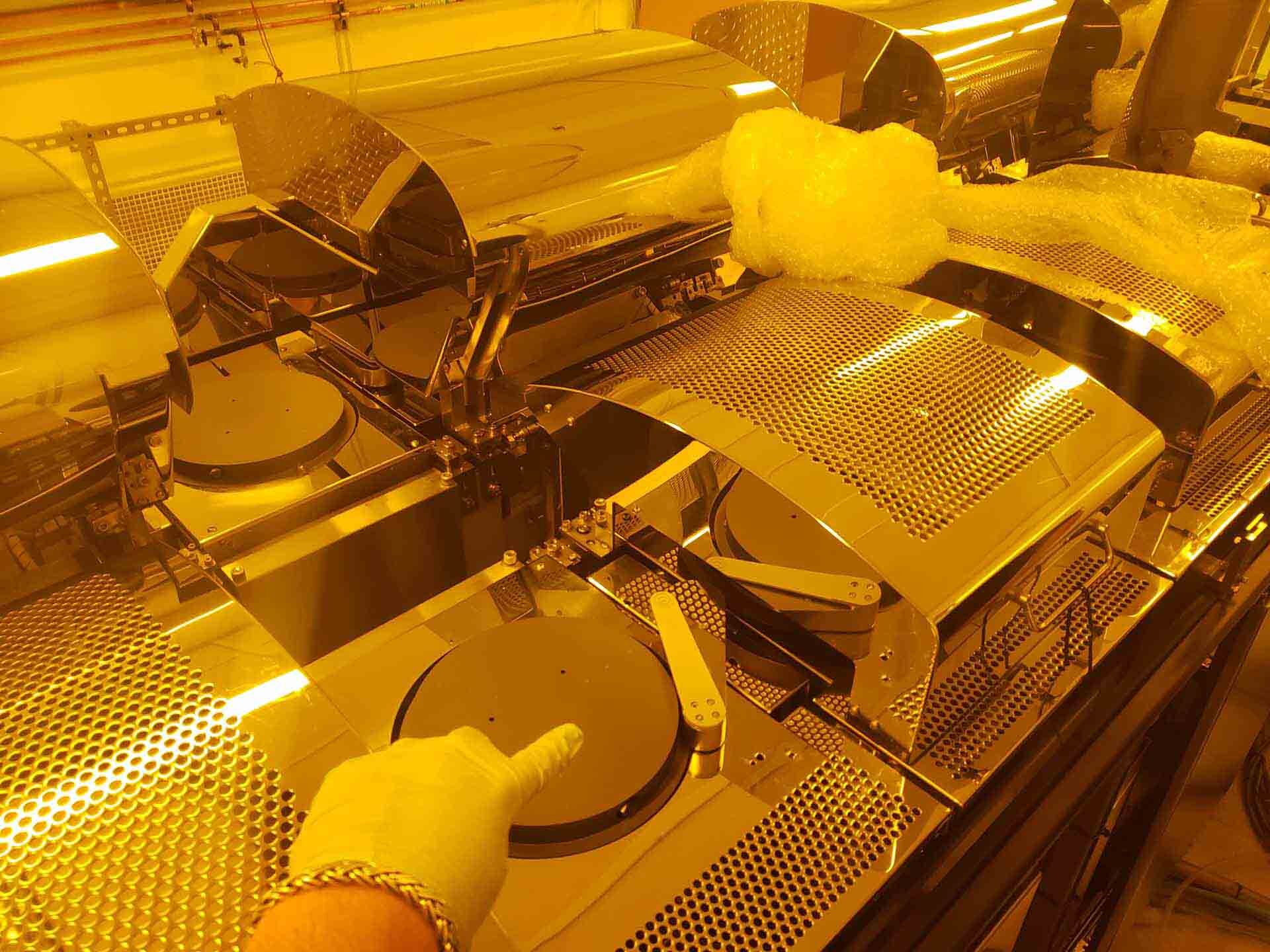

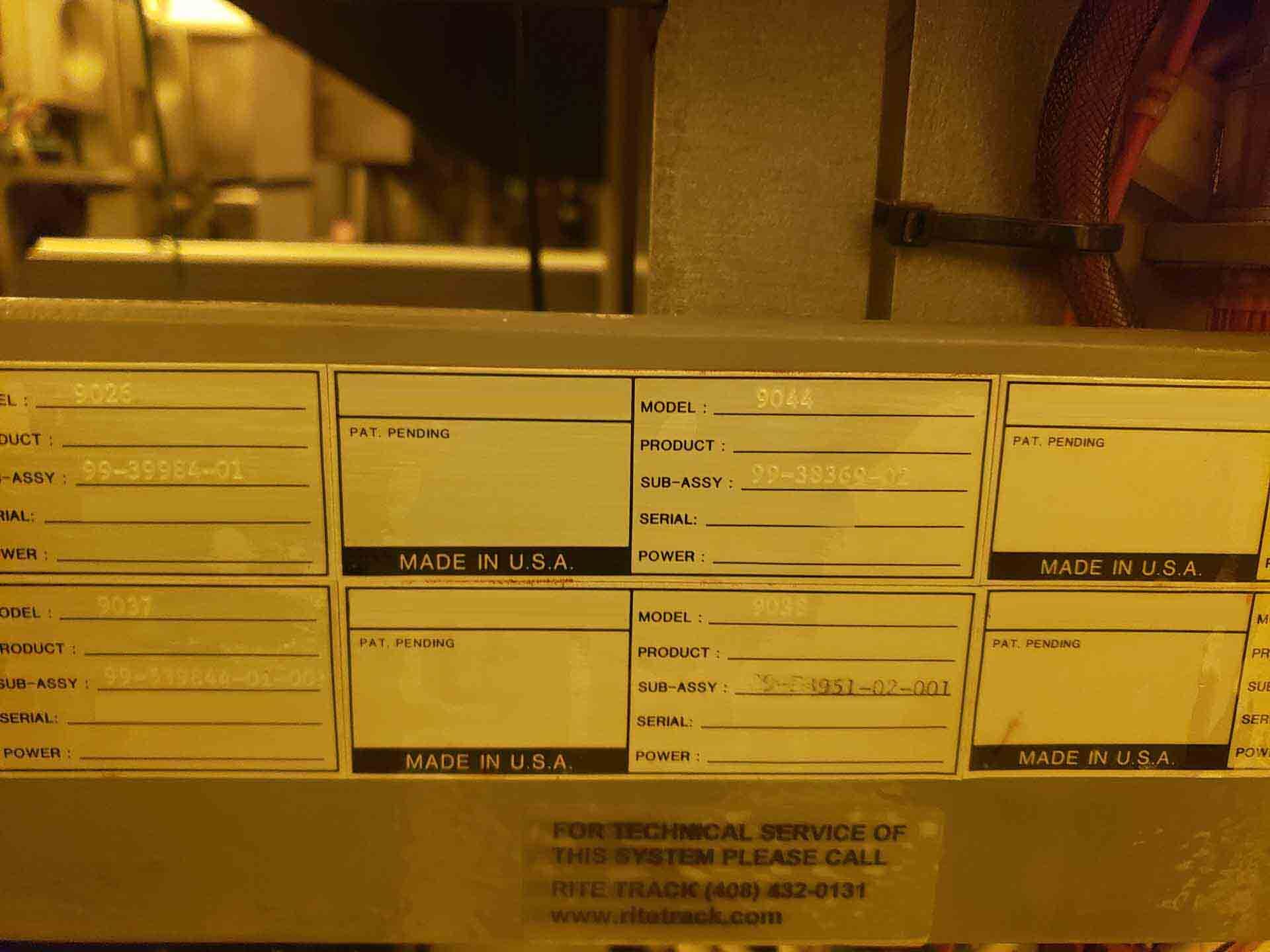

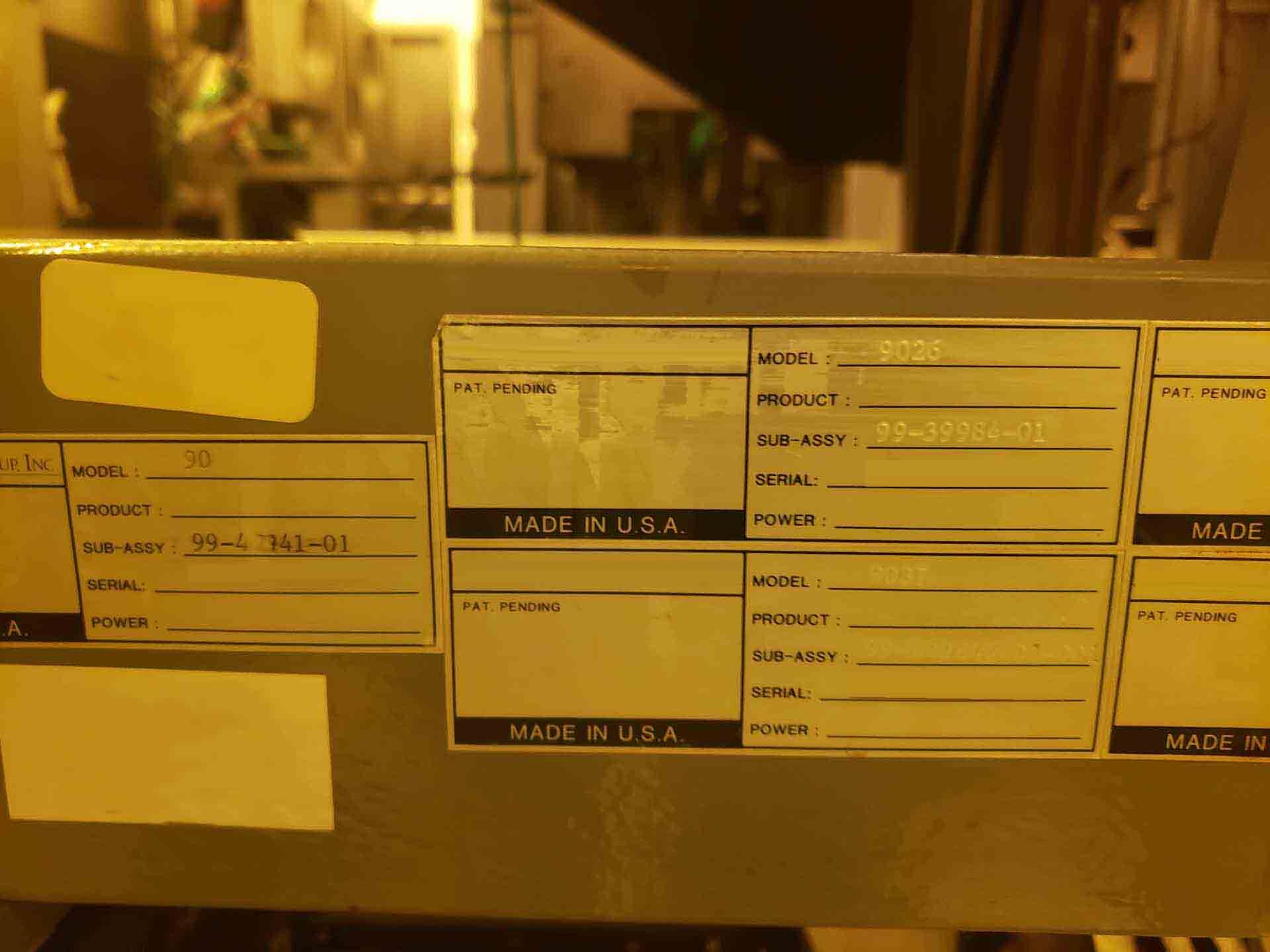

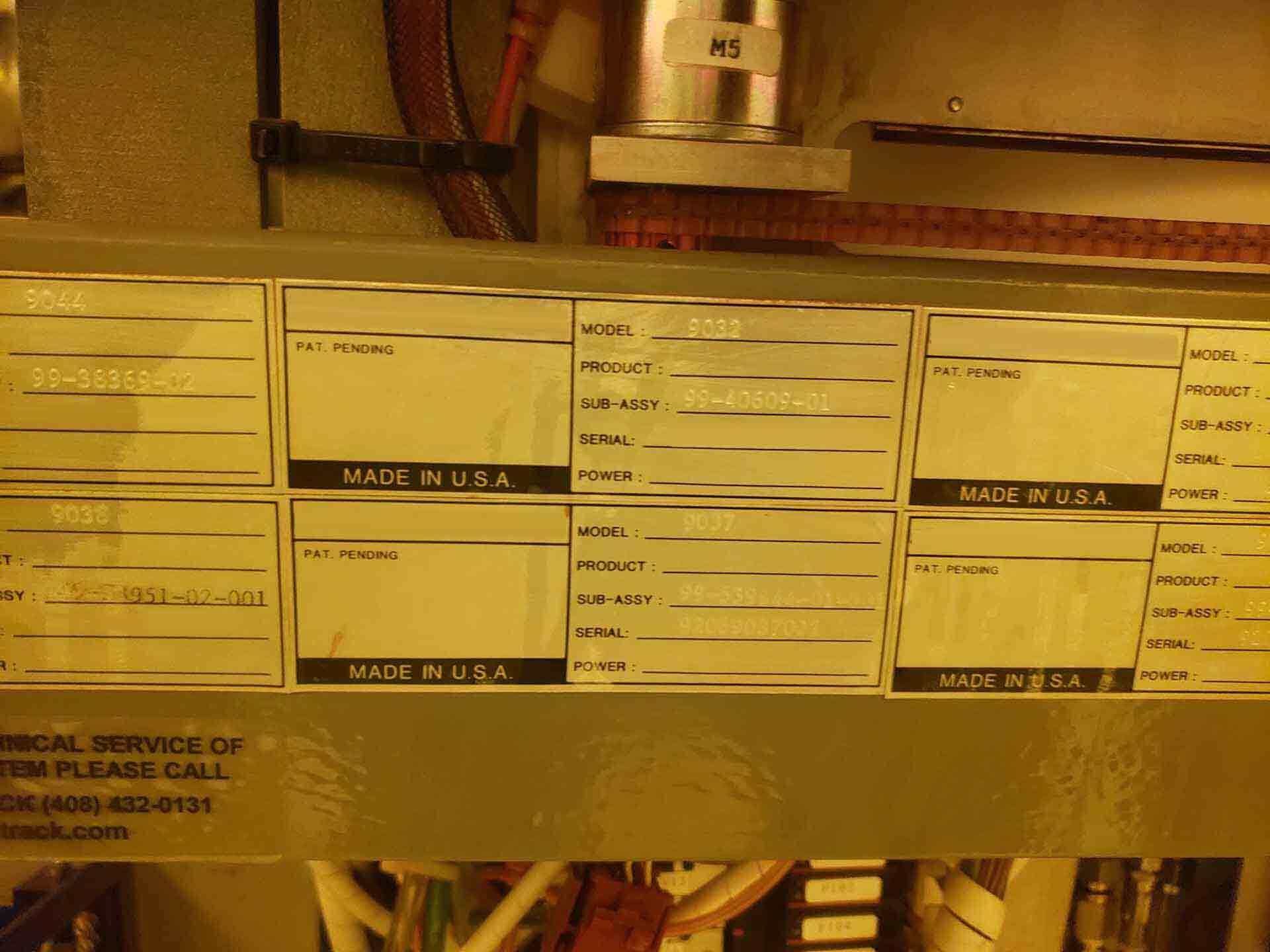

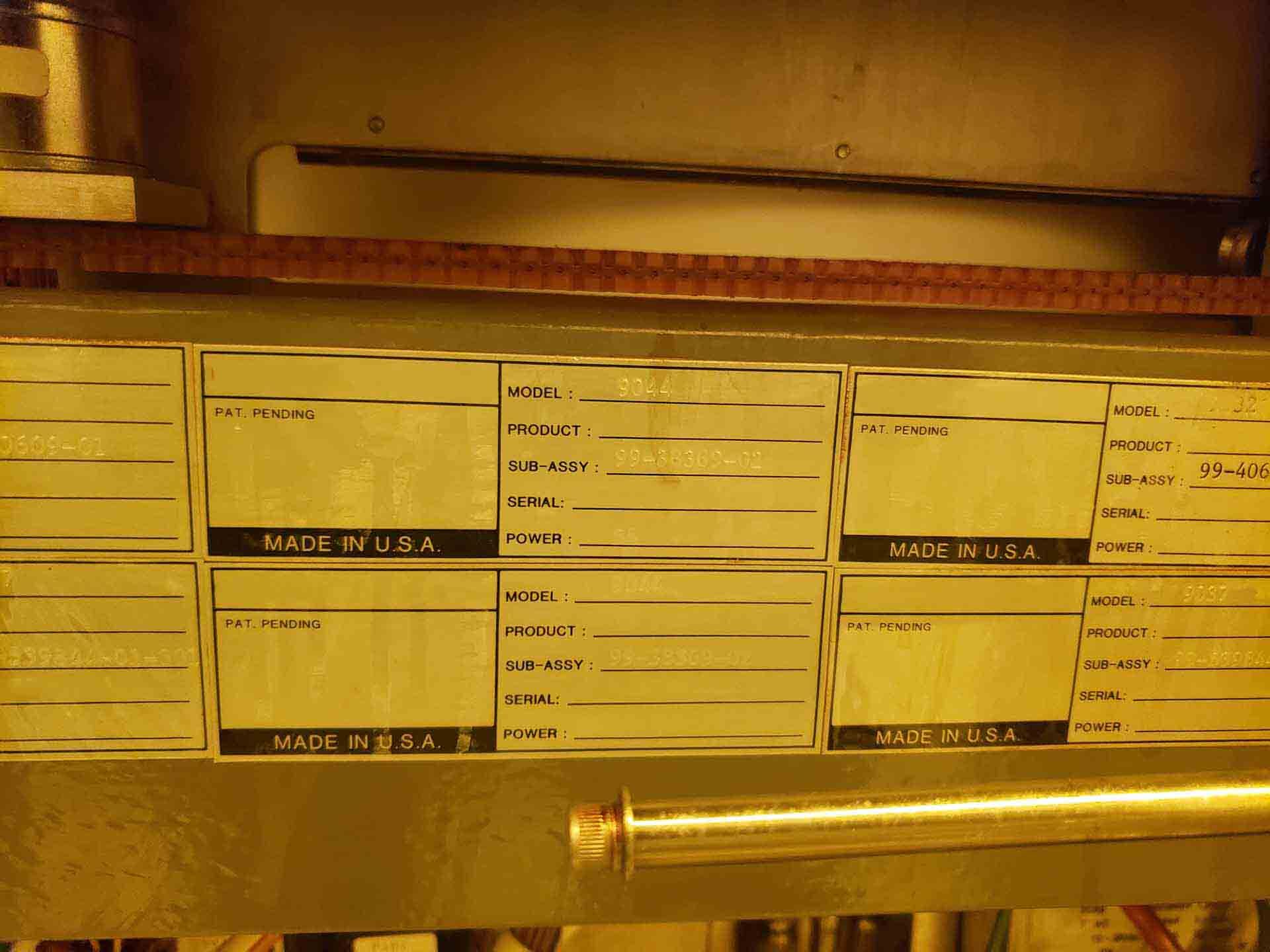

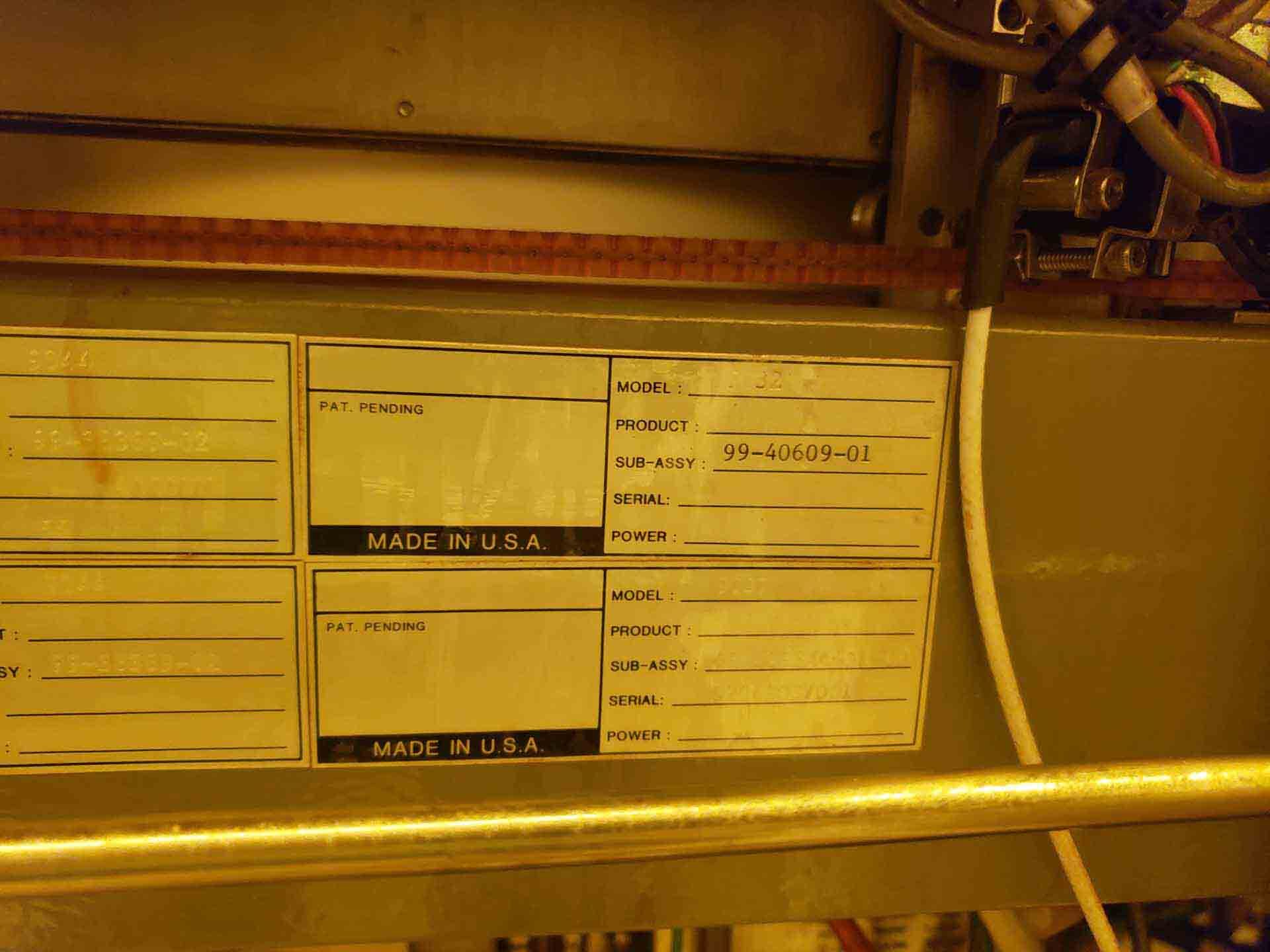

9026 Coat station

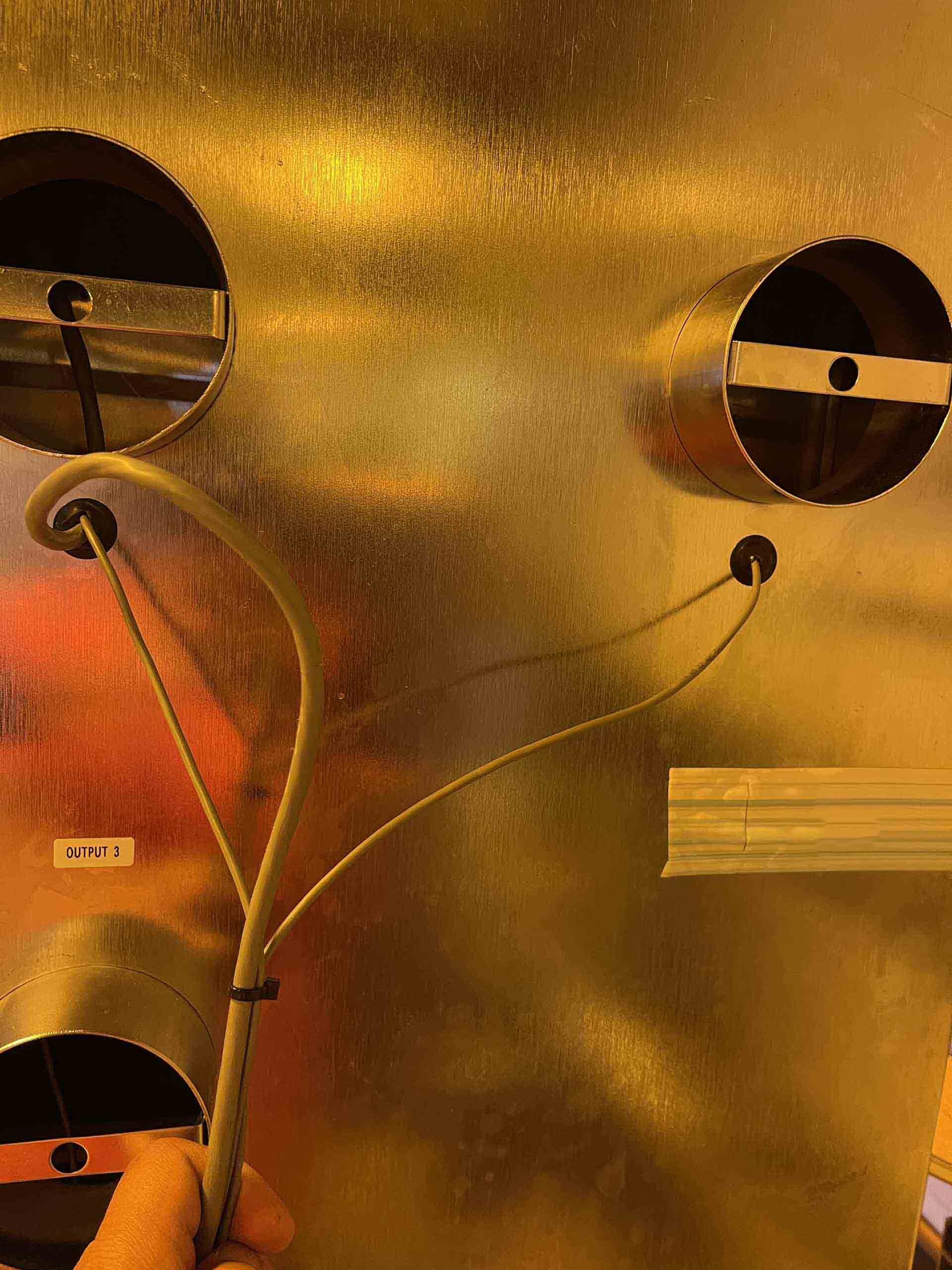

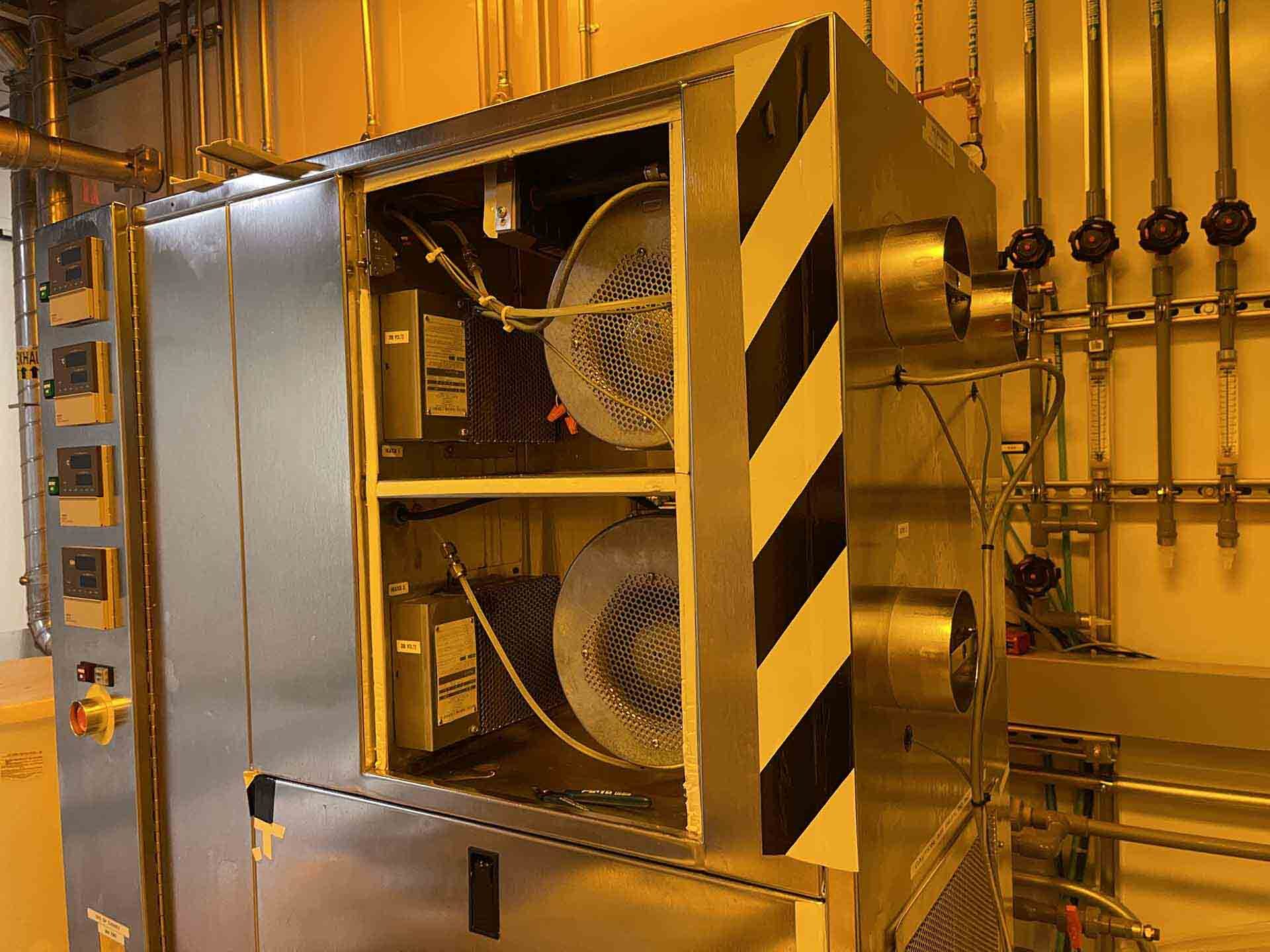

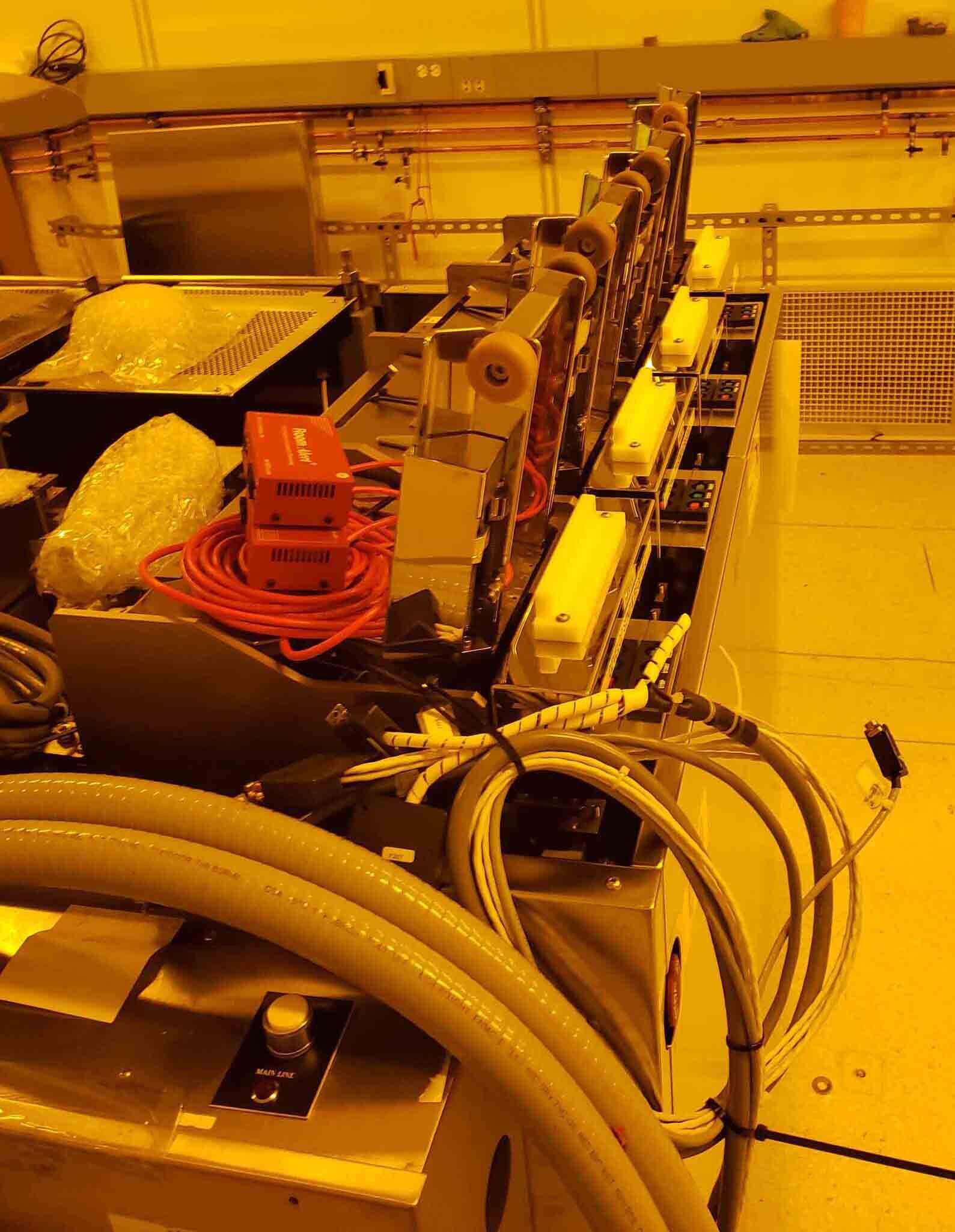

(3) 9037 Oven stations

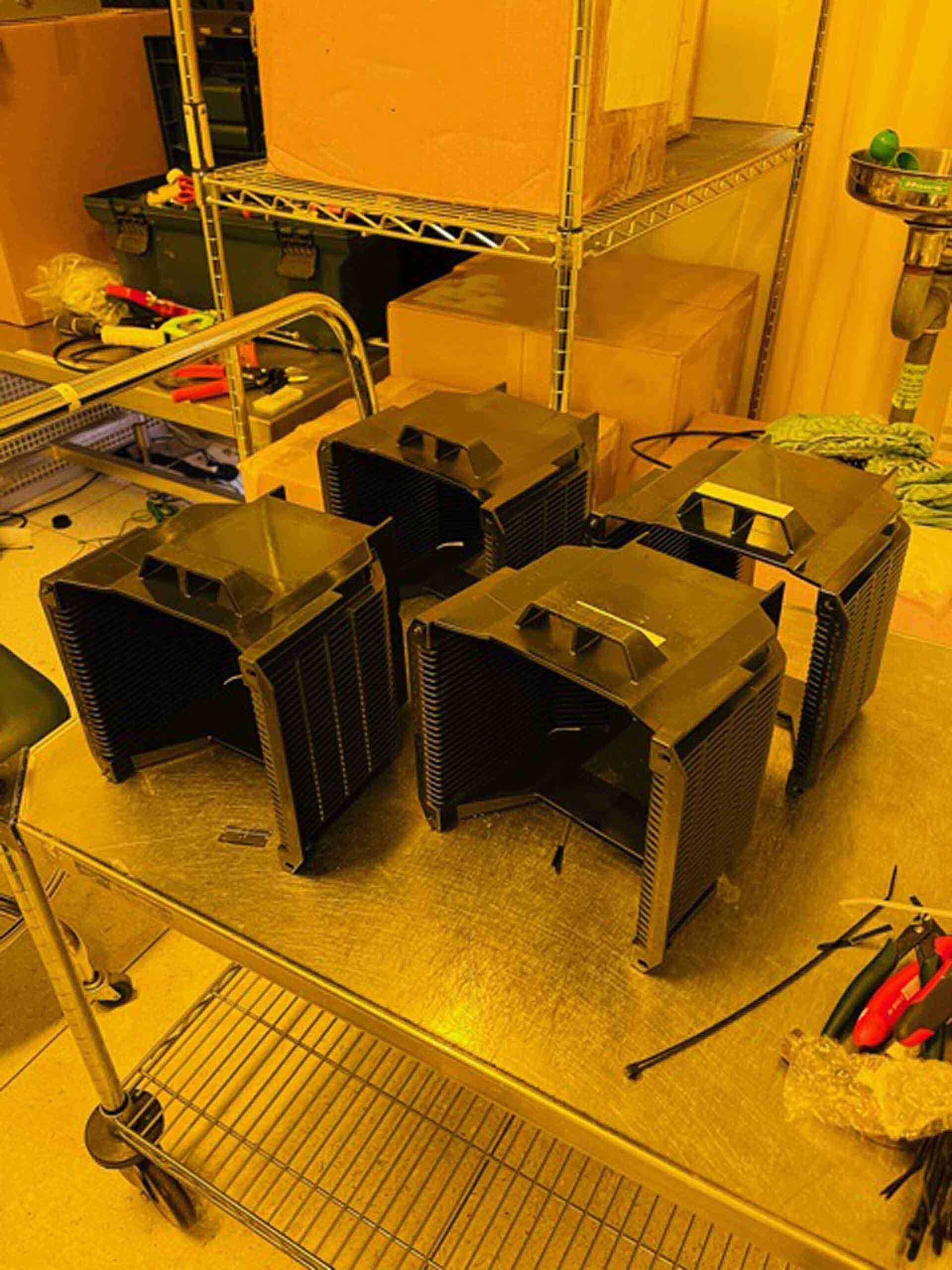

(3) 9044 CP Modules

9038 Chill module

(2) 9032 Coat stations

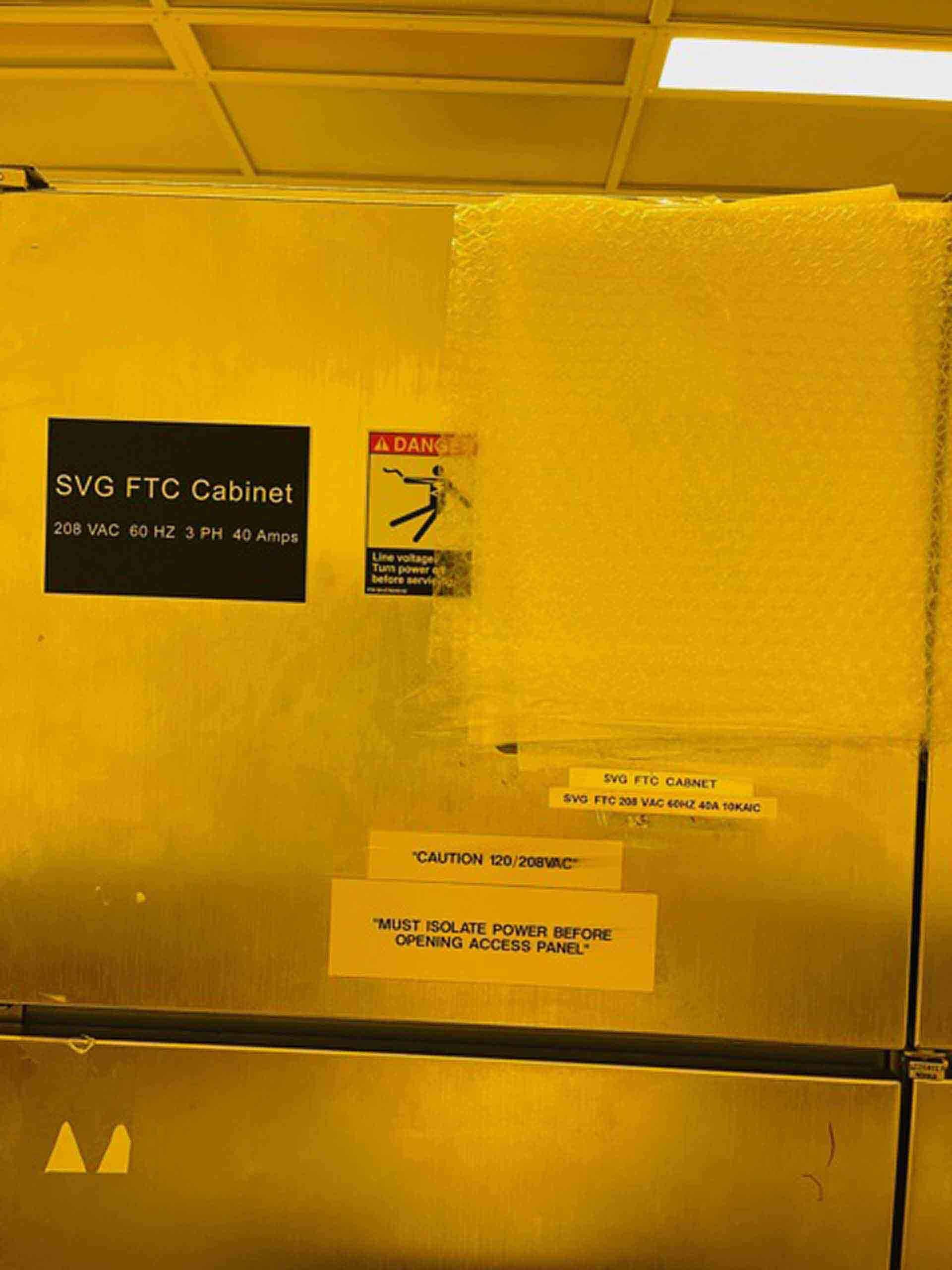

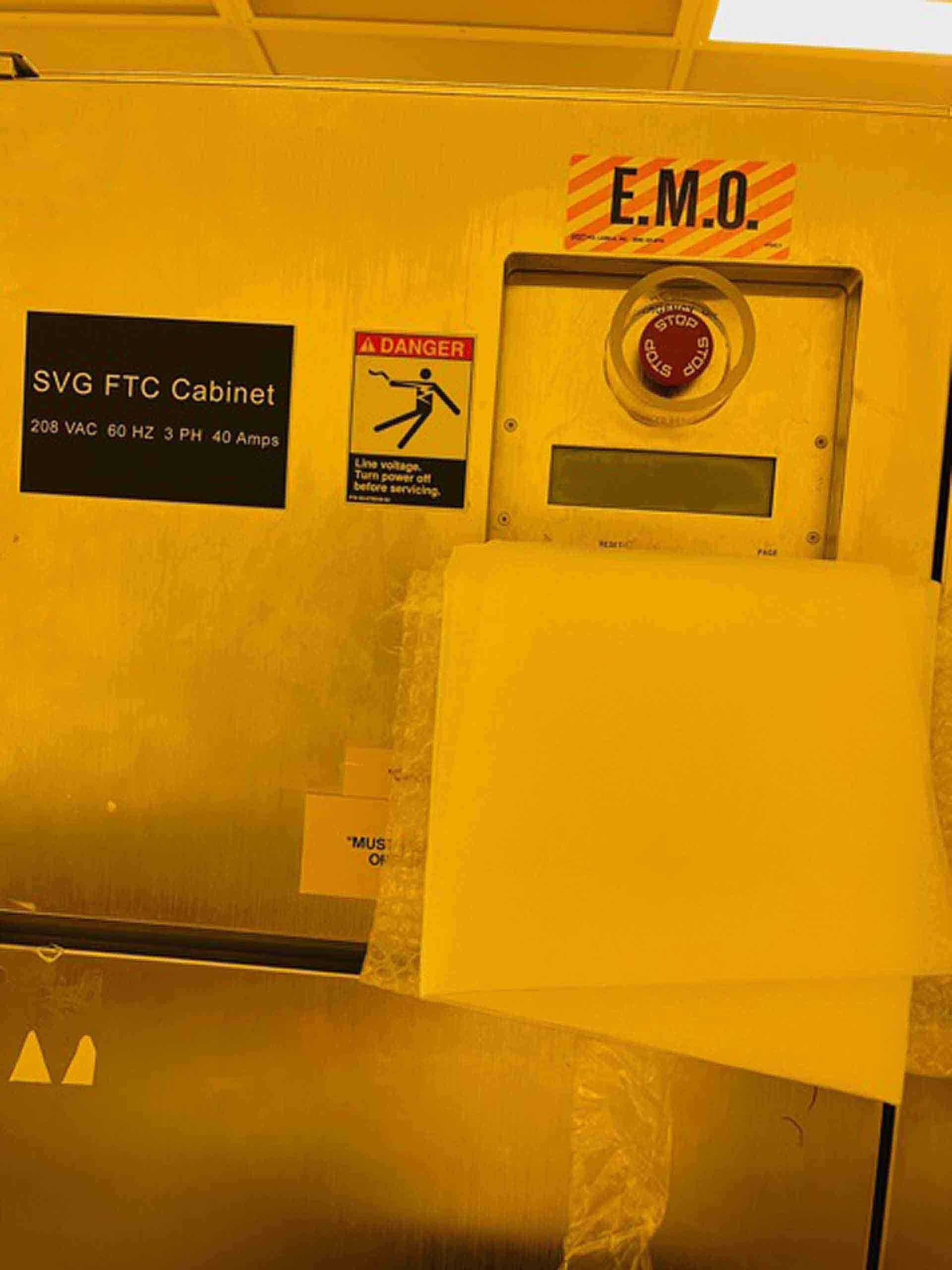

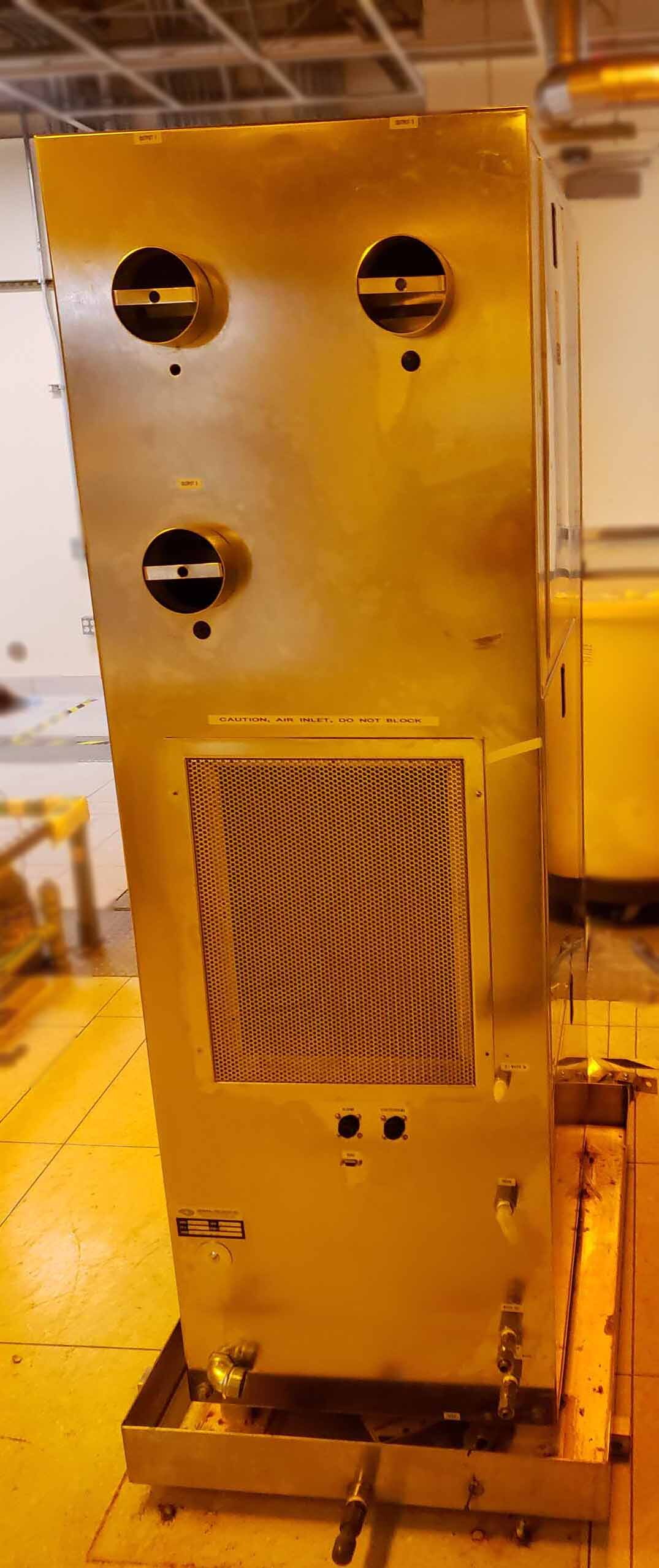

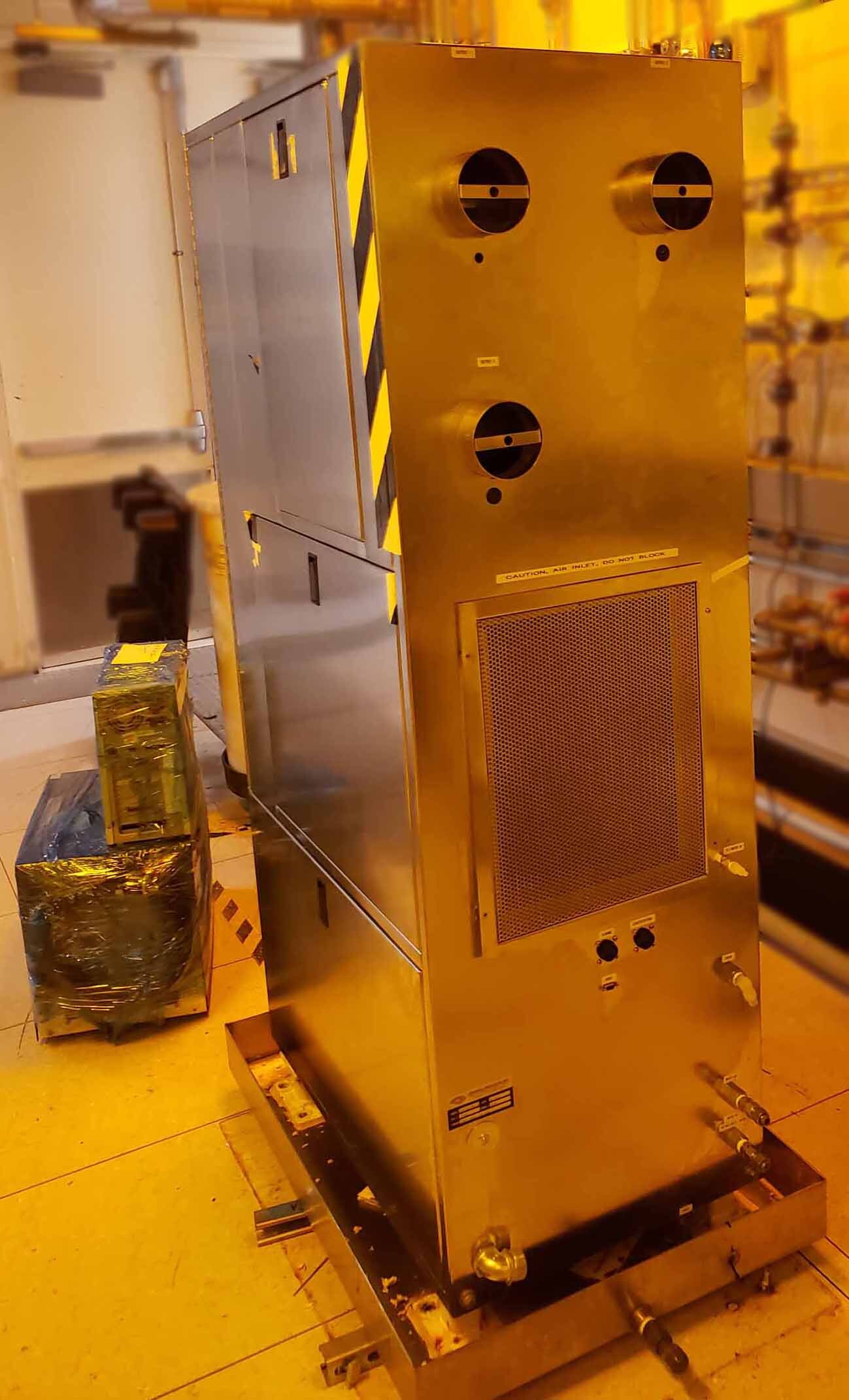

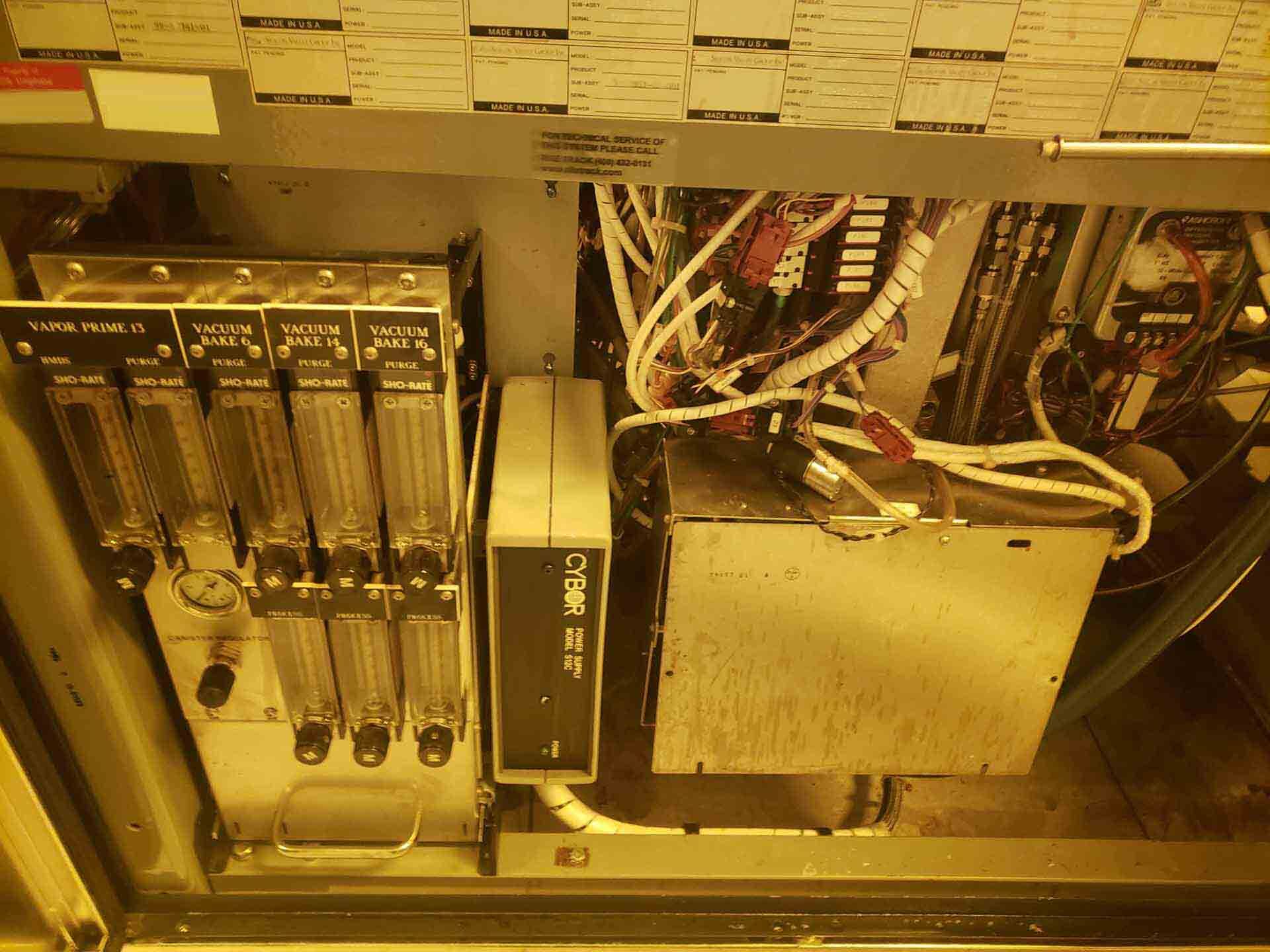

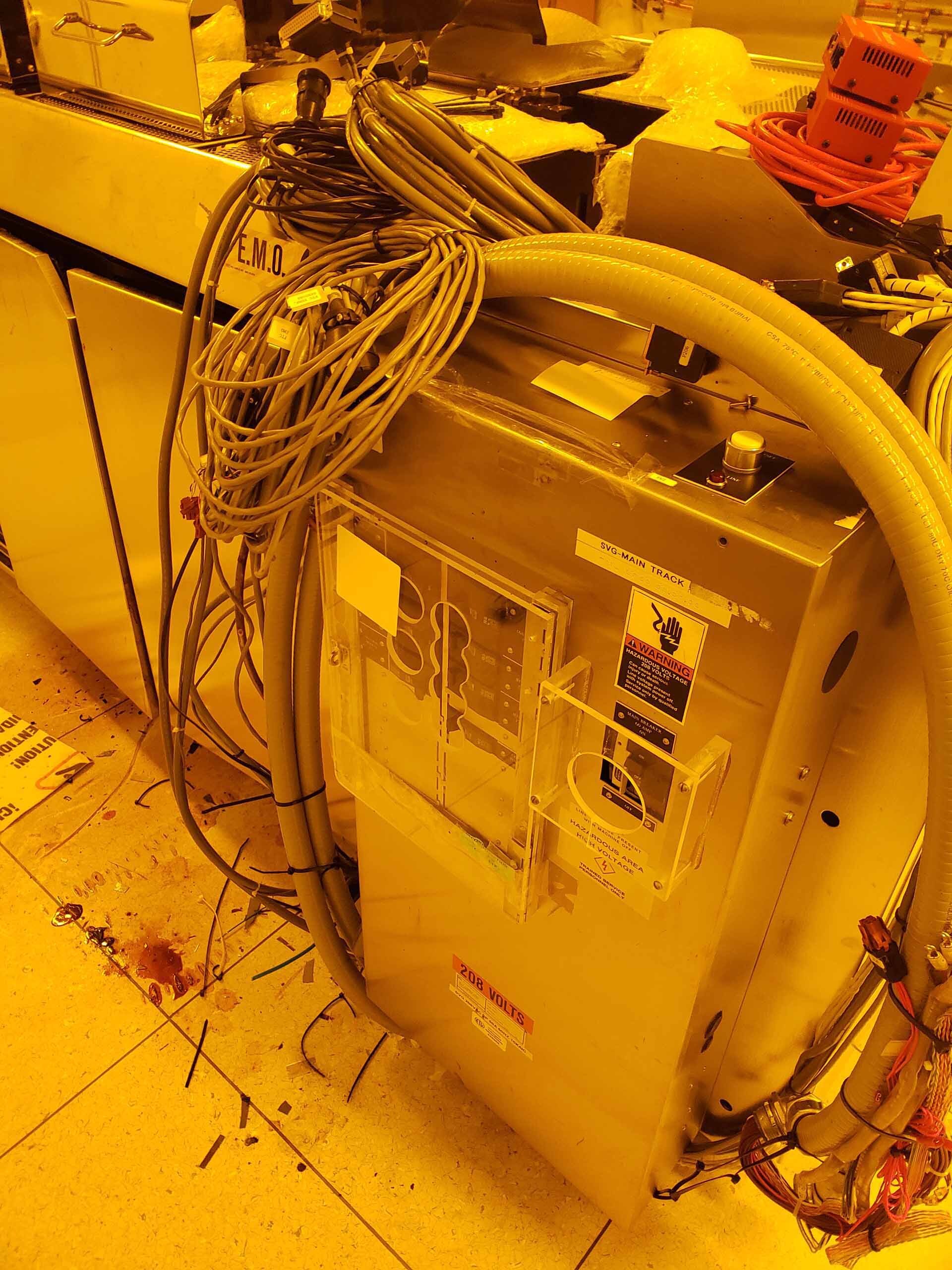

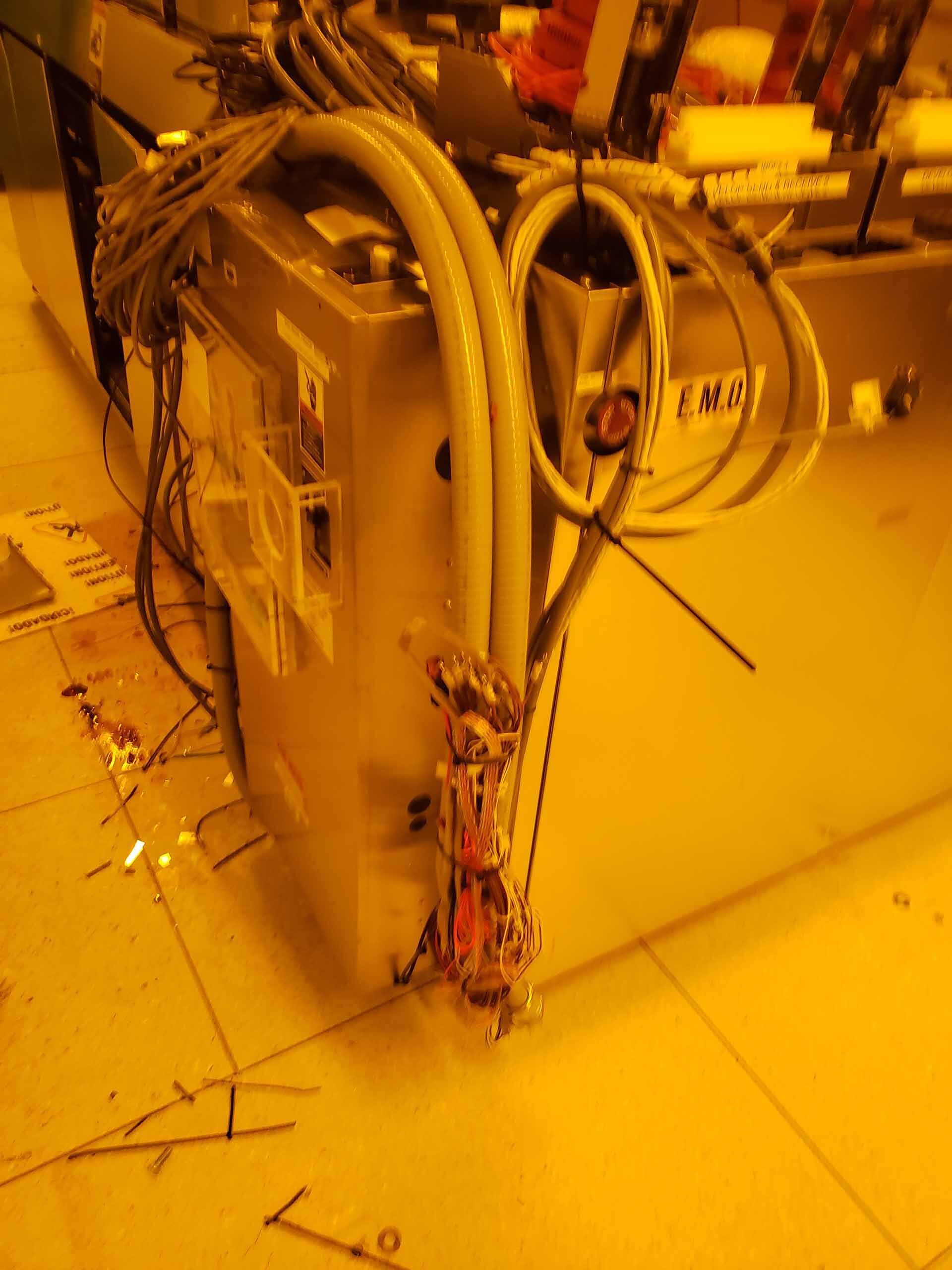

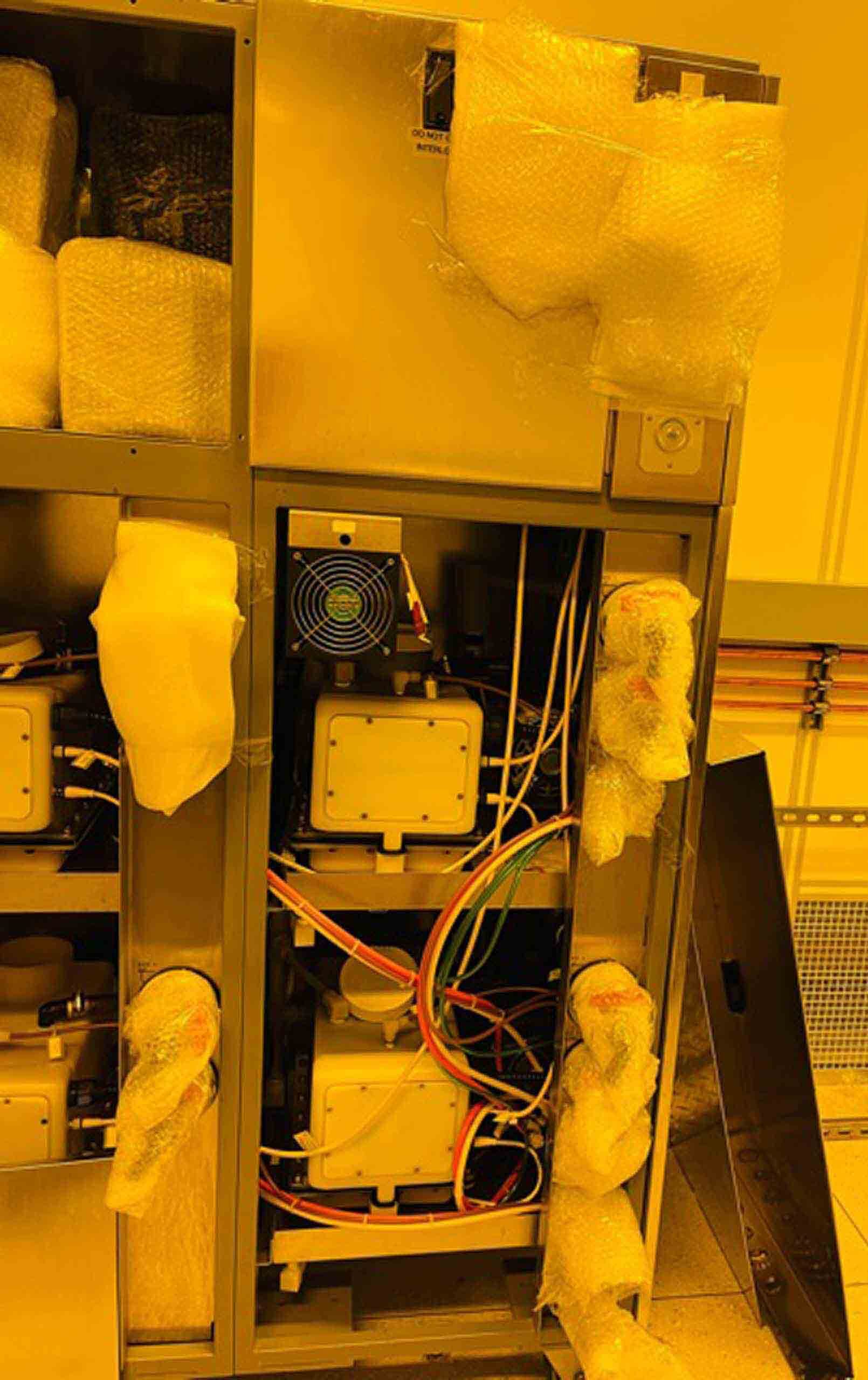

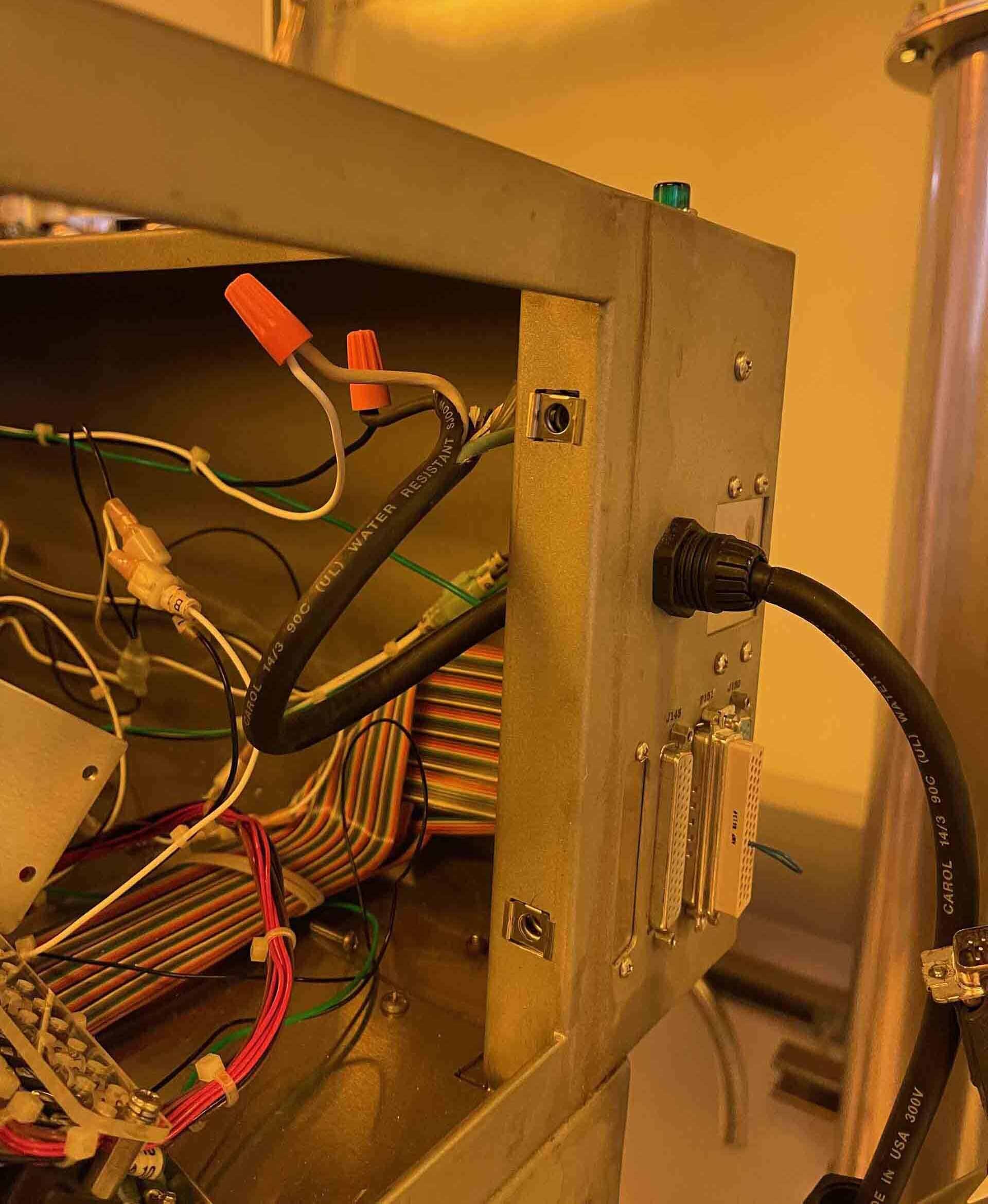

FTC Cabinet

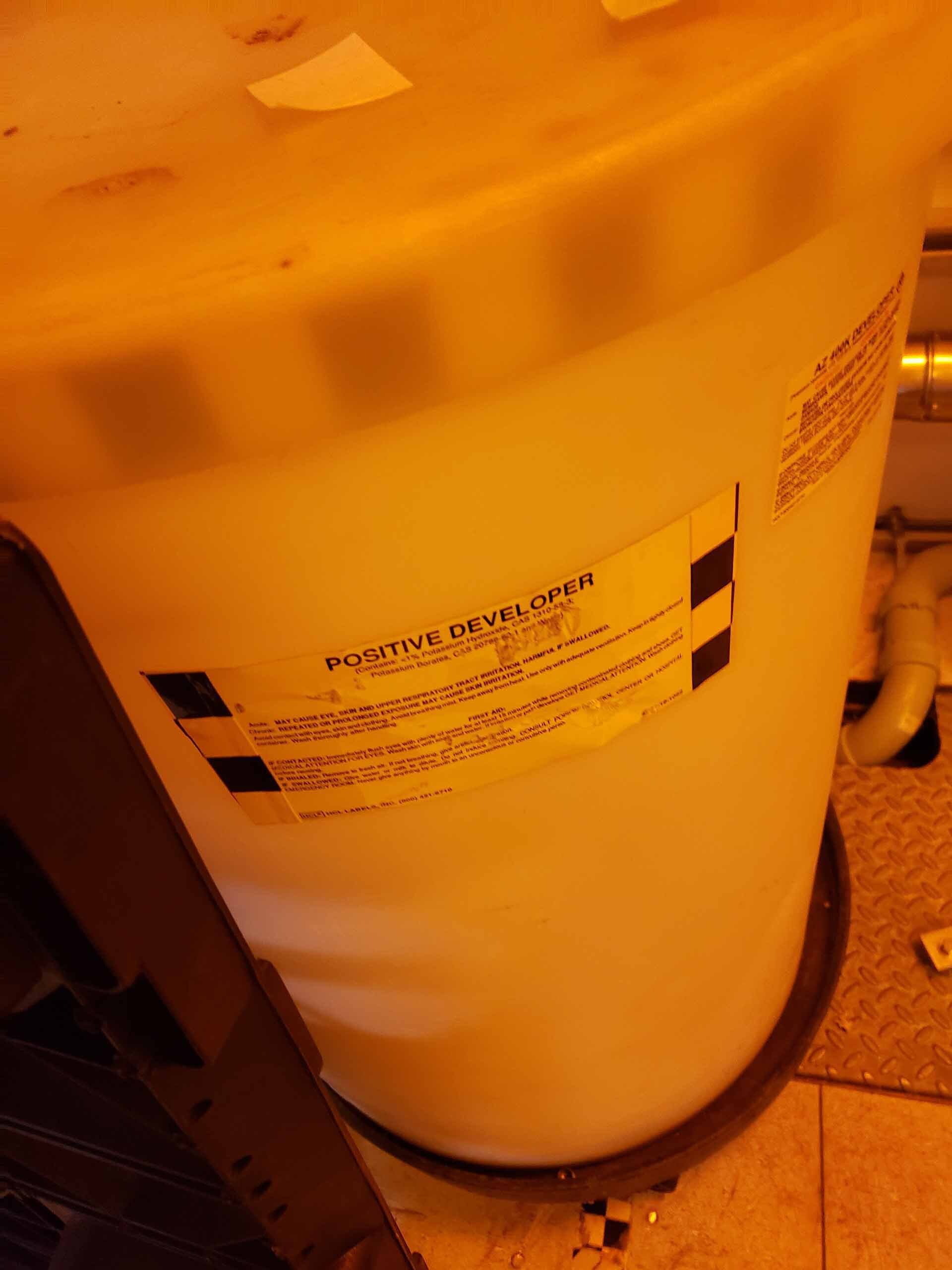

Chemical cabinet

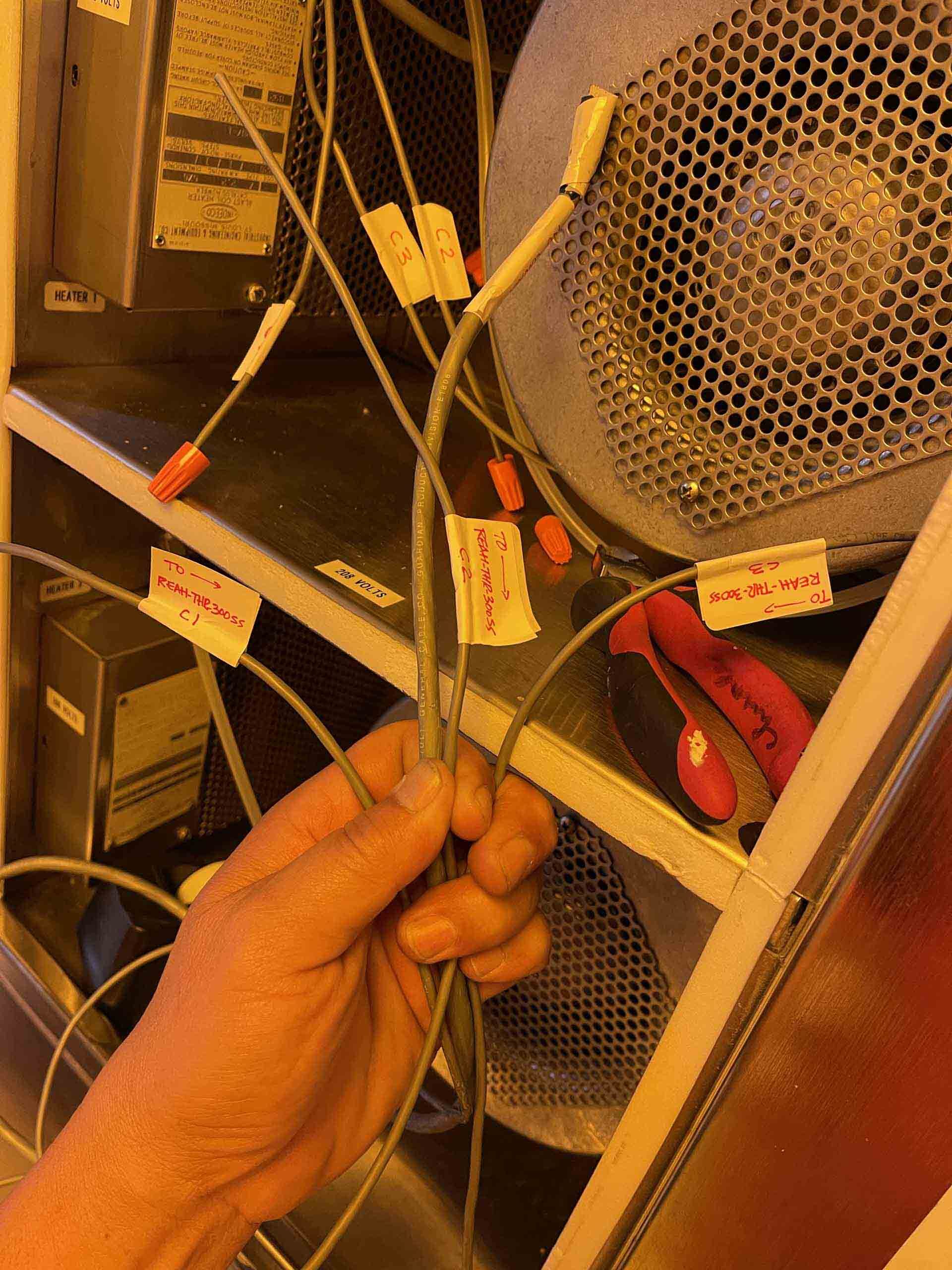

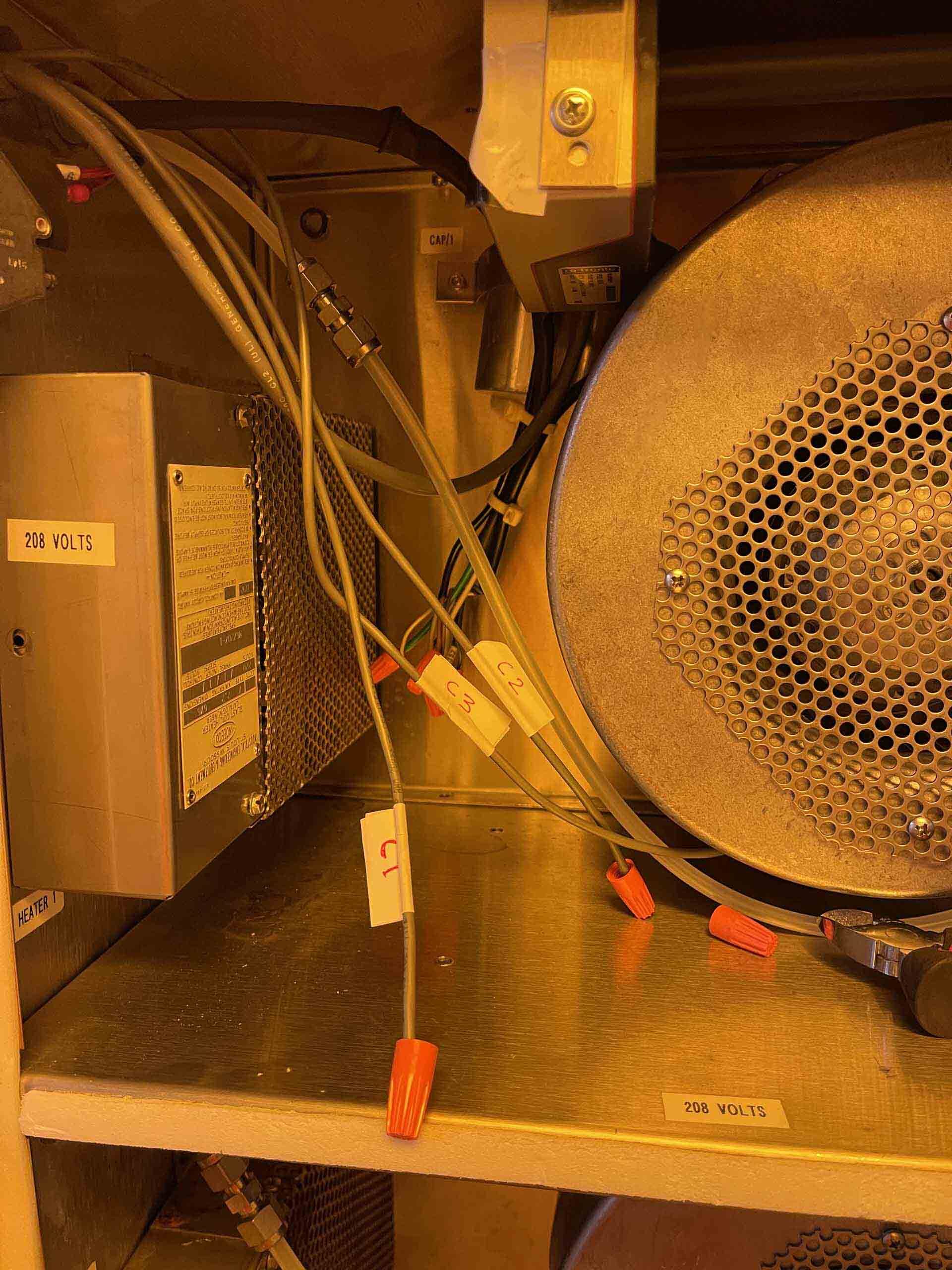

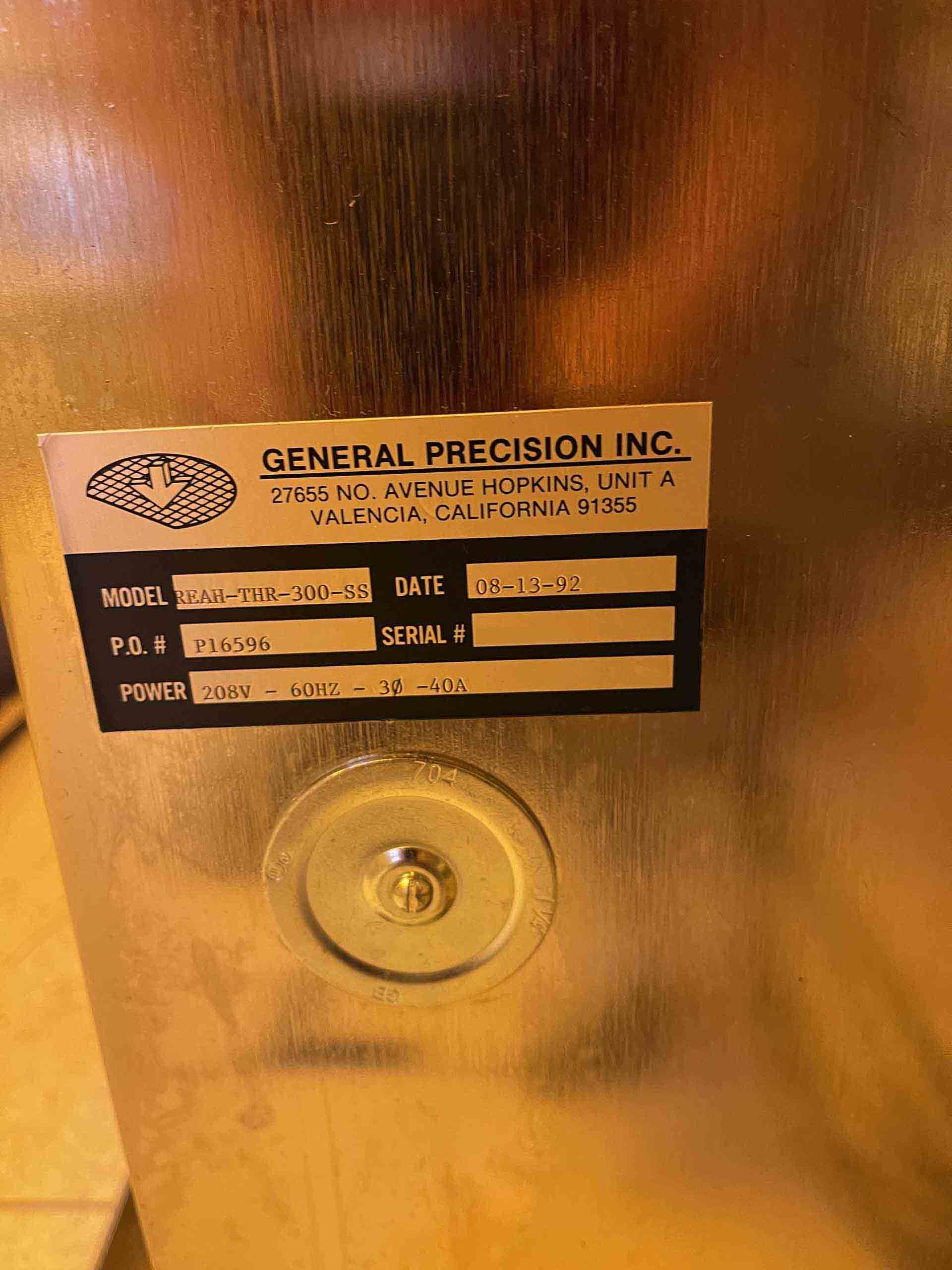

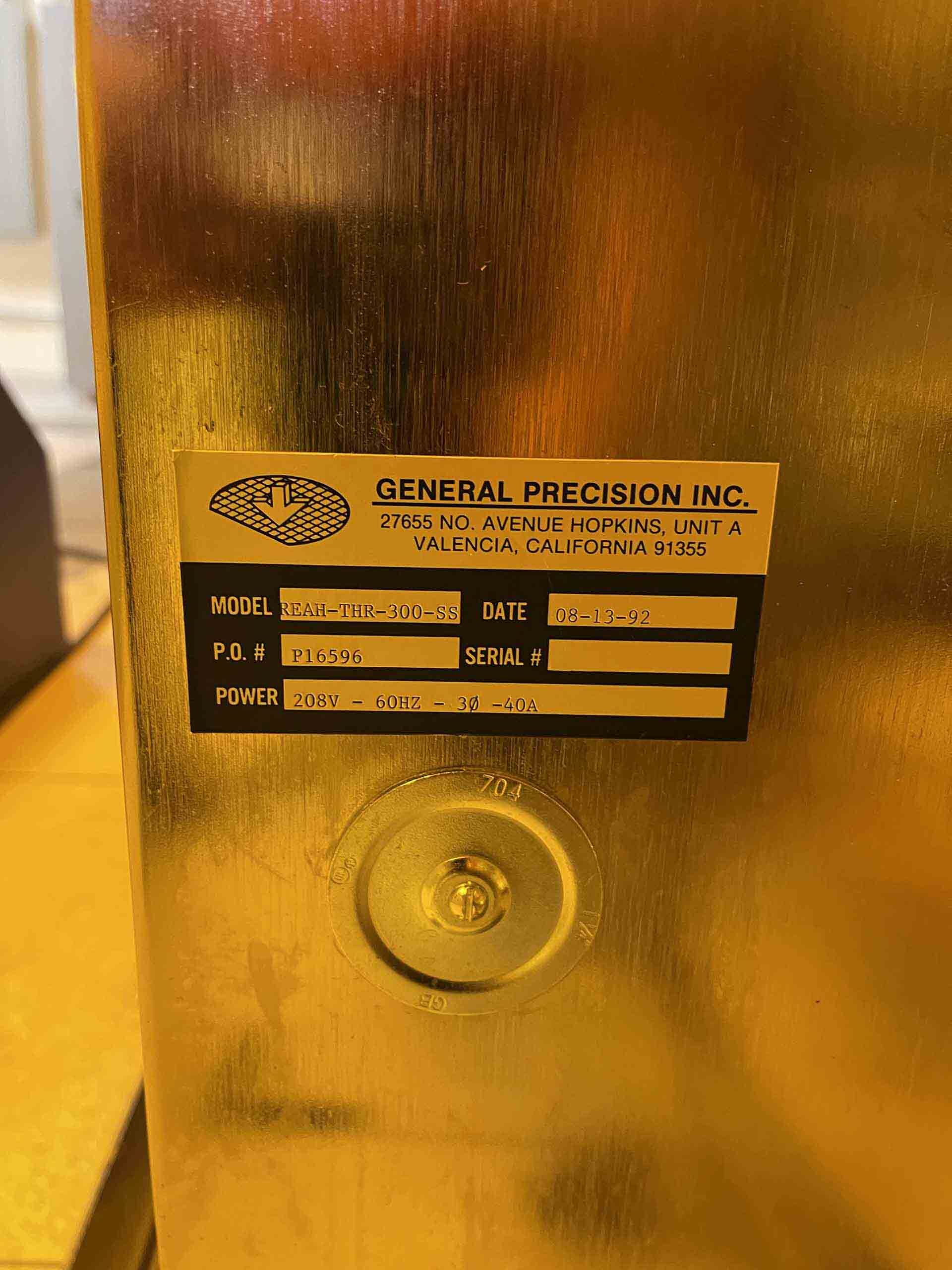

REAH-THR-300-SS Control cabinet

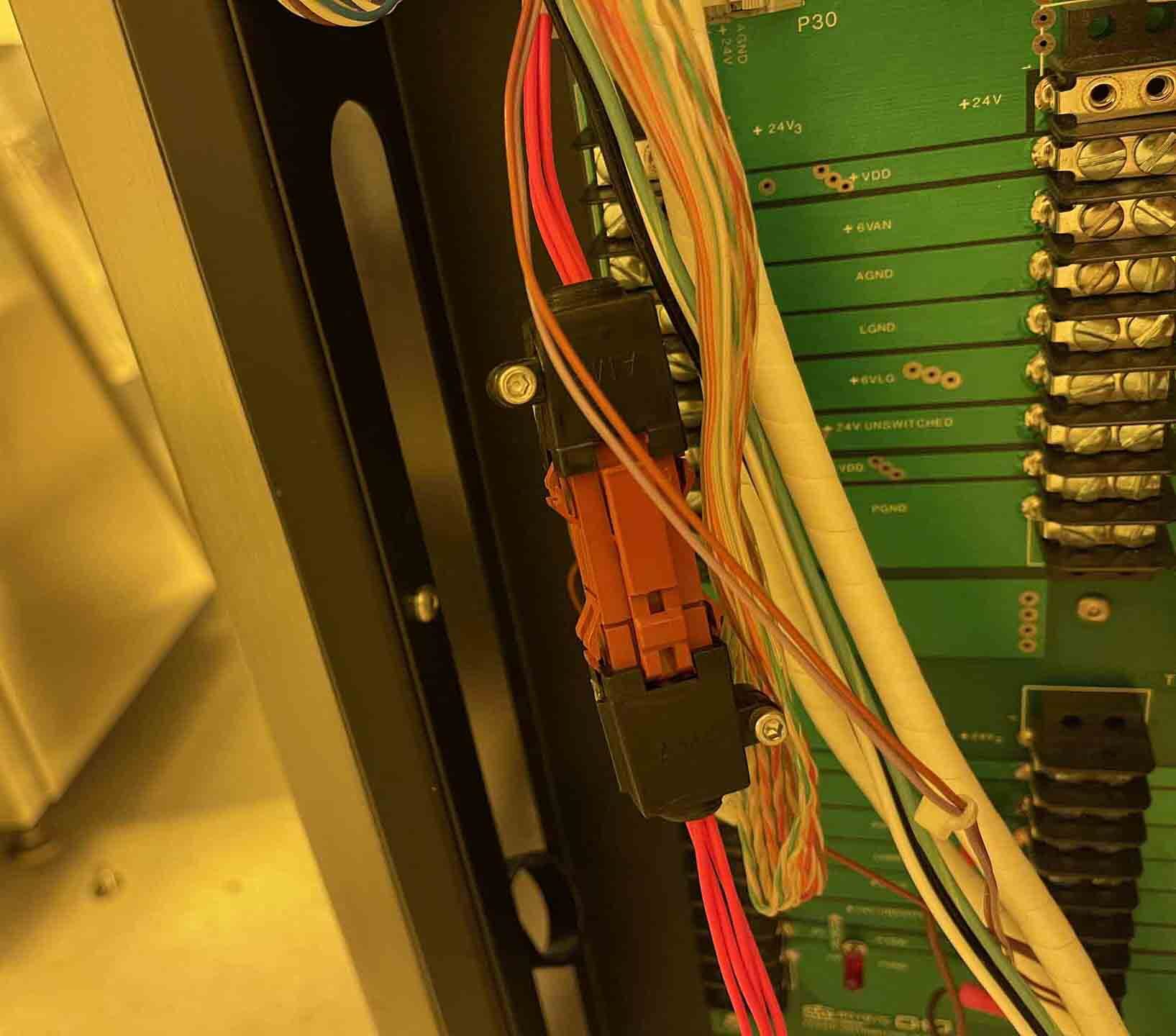

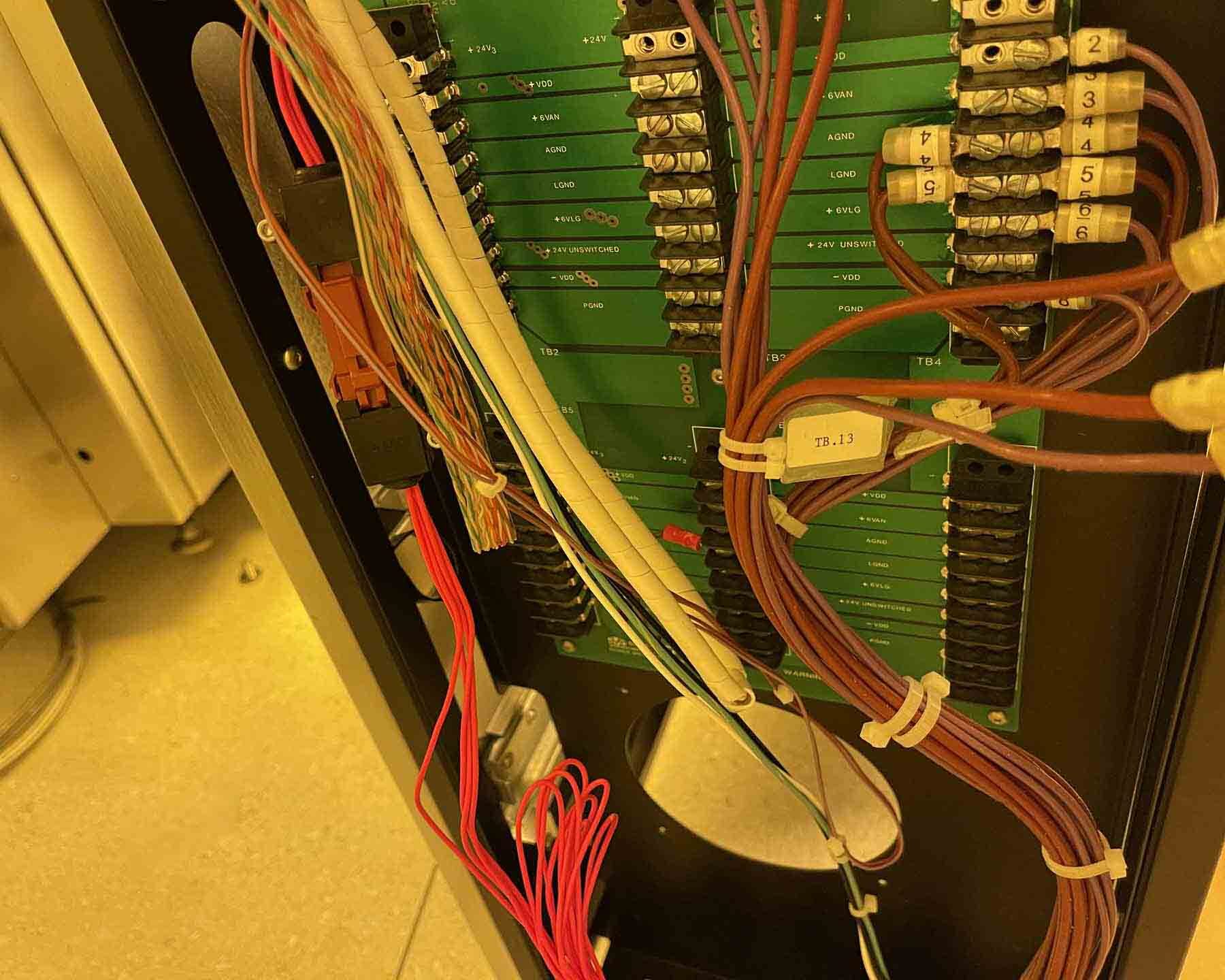

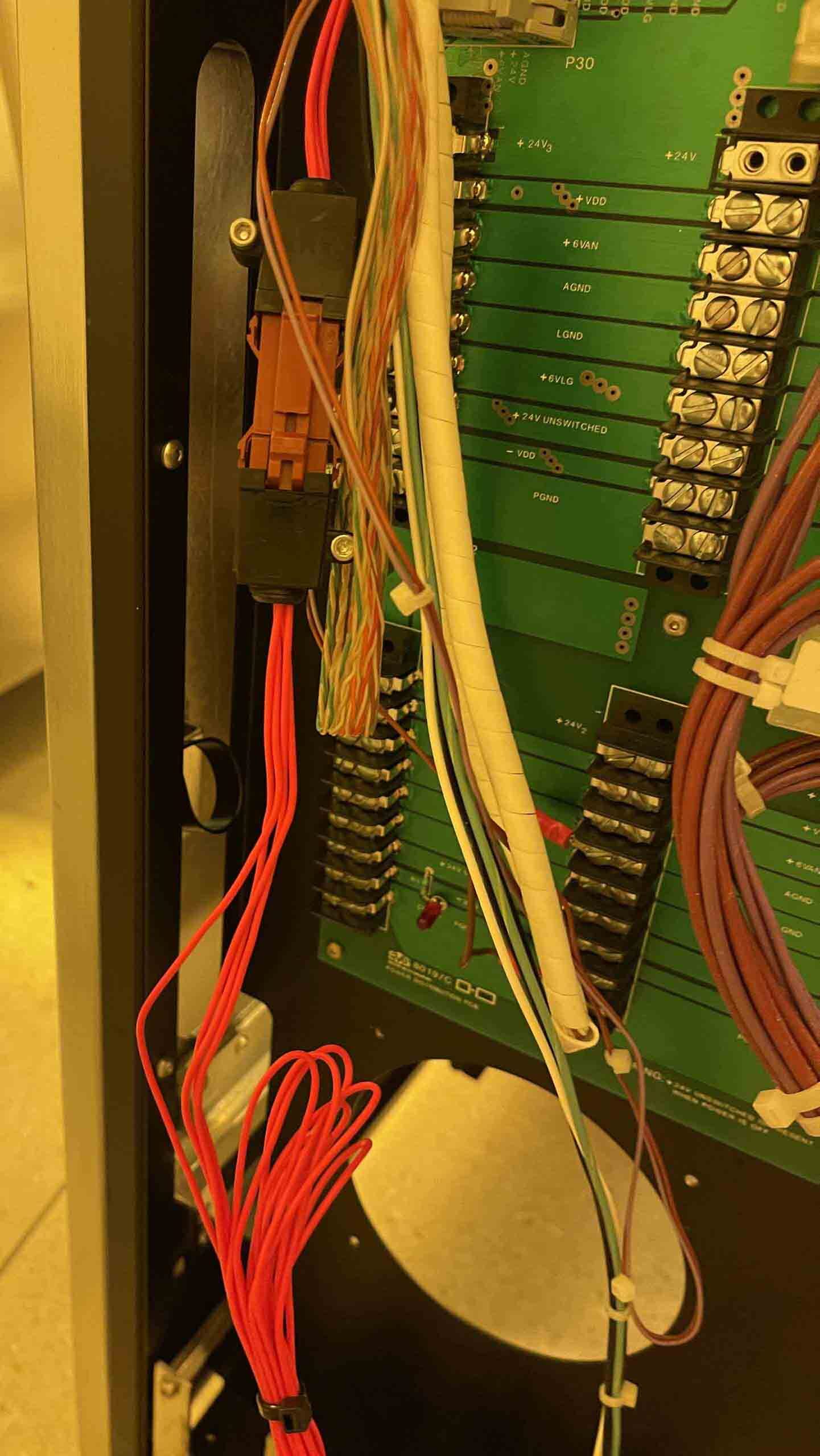

Cabinet: Power disc

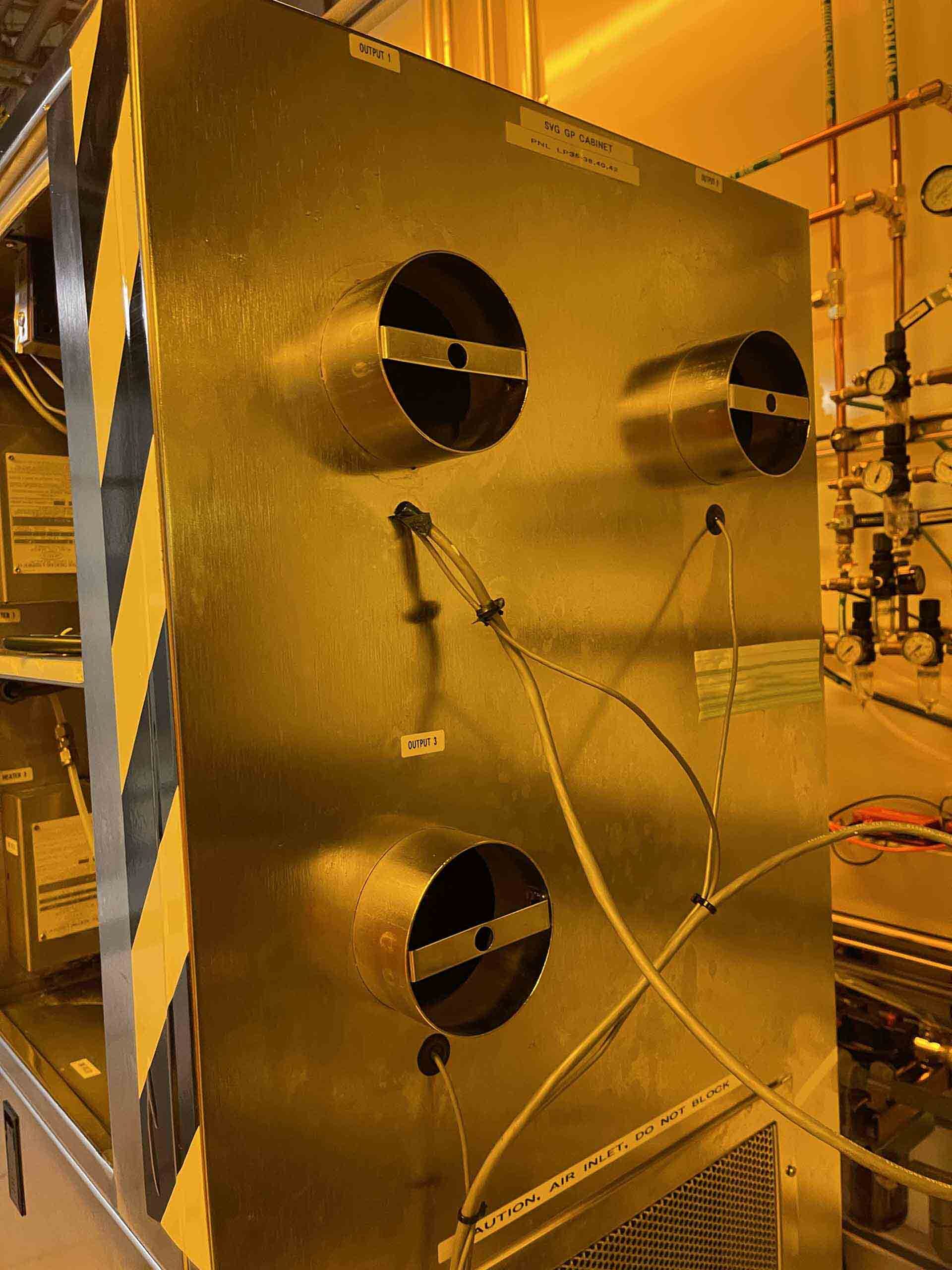

Main power GP cabinet

GUI Controller cabinet

Chemical waste tank

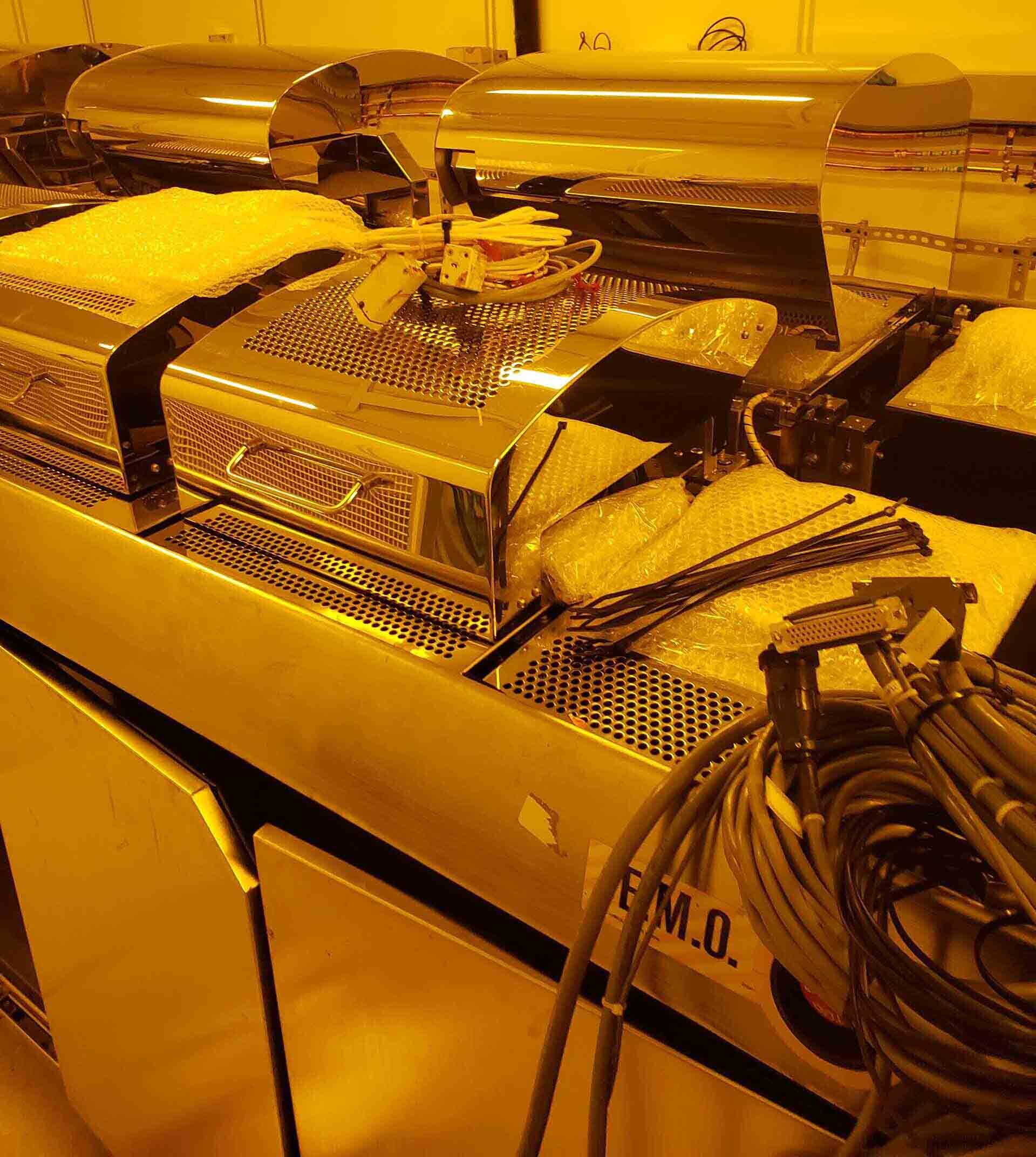

Spare parts:

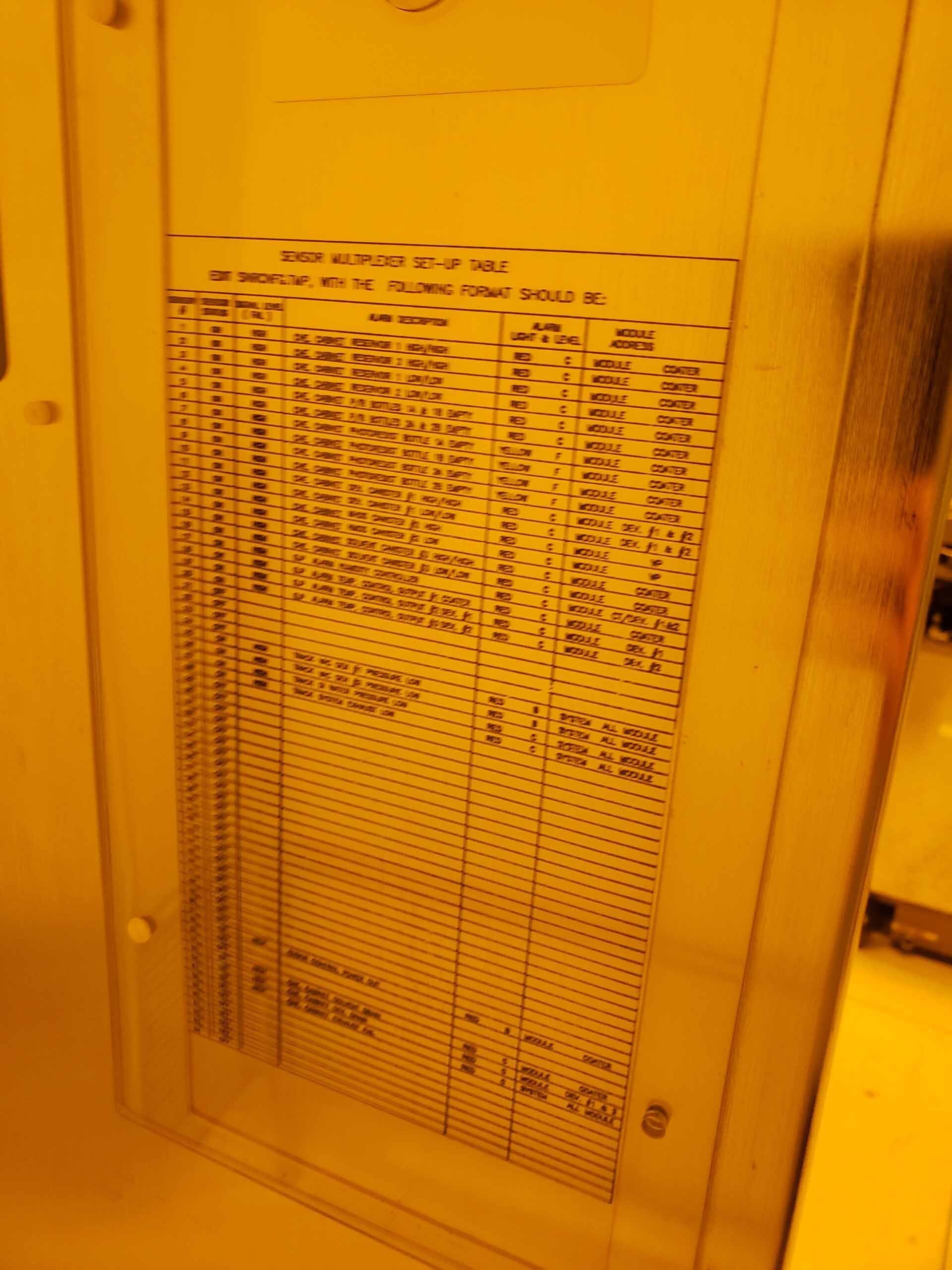

Qty / Part number / Description

(5) / 301 / Humphrey valve

(3) / 9279-SC513 / CHEMRAZ Origin

(1) / 99-80170-01 / PCB Assembly vacuum sensor

(1) / EP50-00000005-00 / Assembly, LCD Display

(5) / 80166F / Station CPU BD

(1) / 99-80266-01 / Station CPU

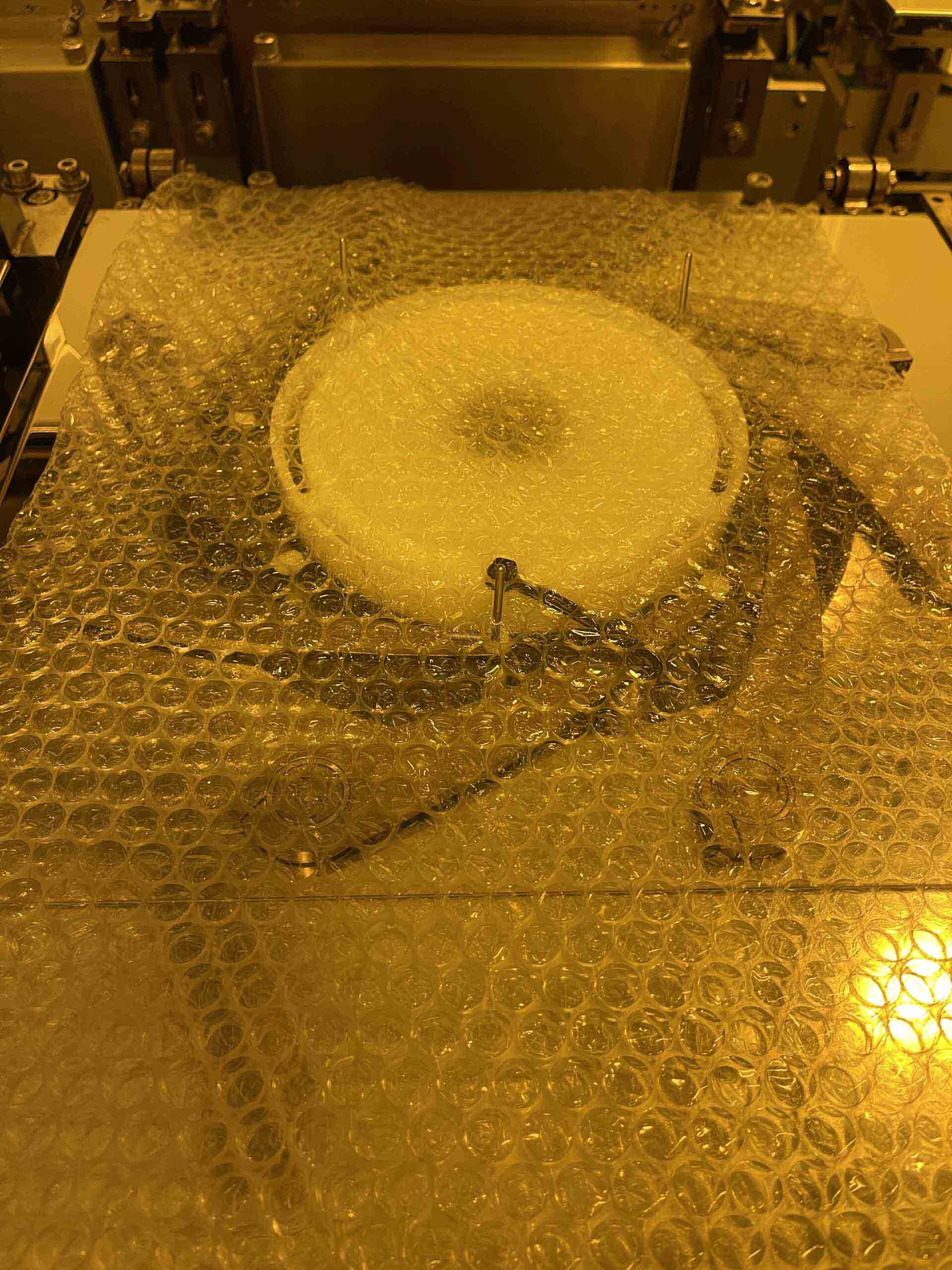

(2) / ME13-00000001 / Chuck 90 coater, 200mm

(1) / HF520DHXXX-1XX / Rotronic humidity transmitter SUGGPI

(1) / 240-044-0187 / Electro craft model E240

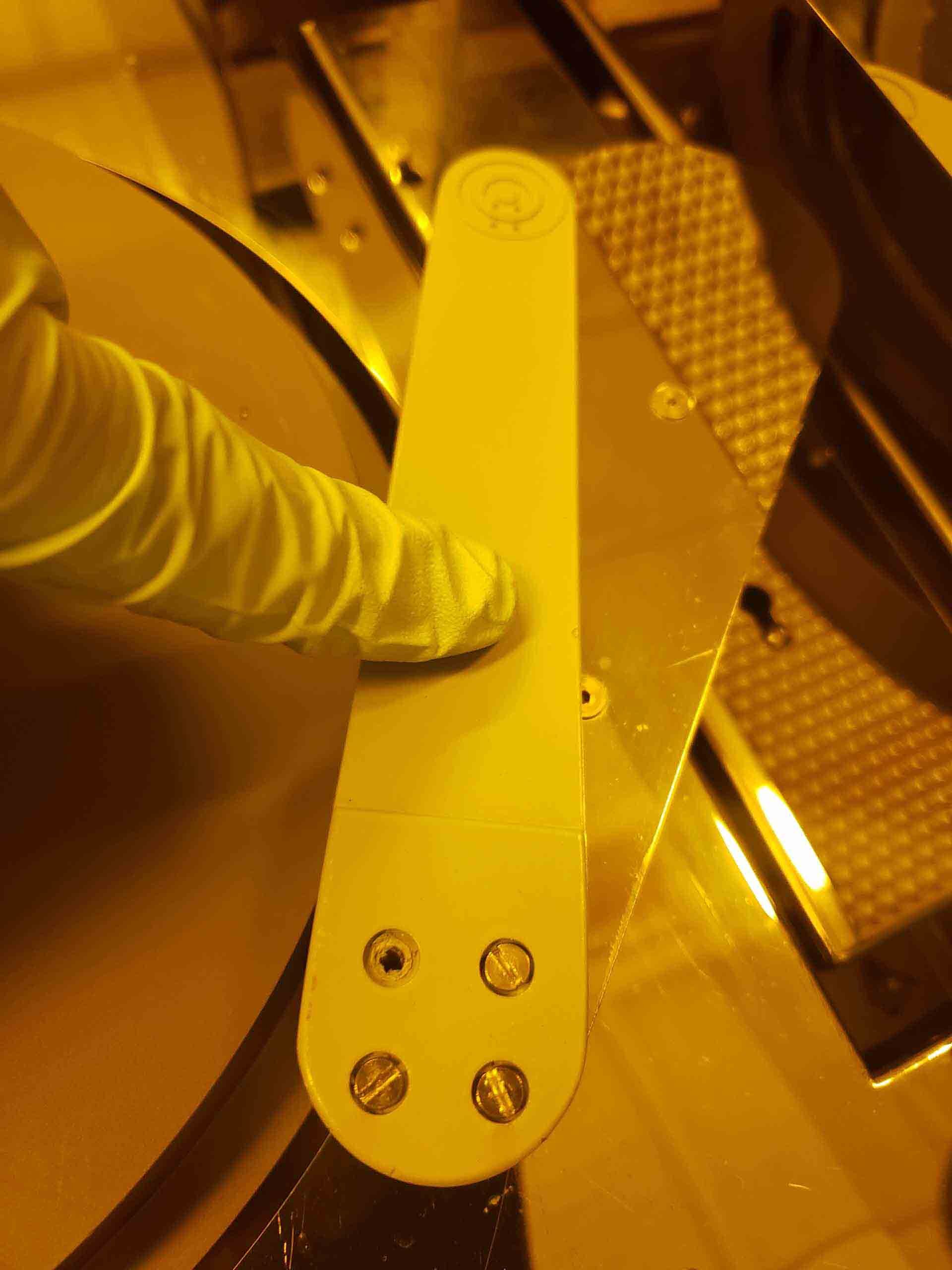

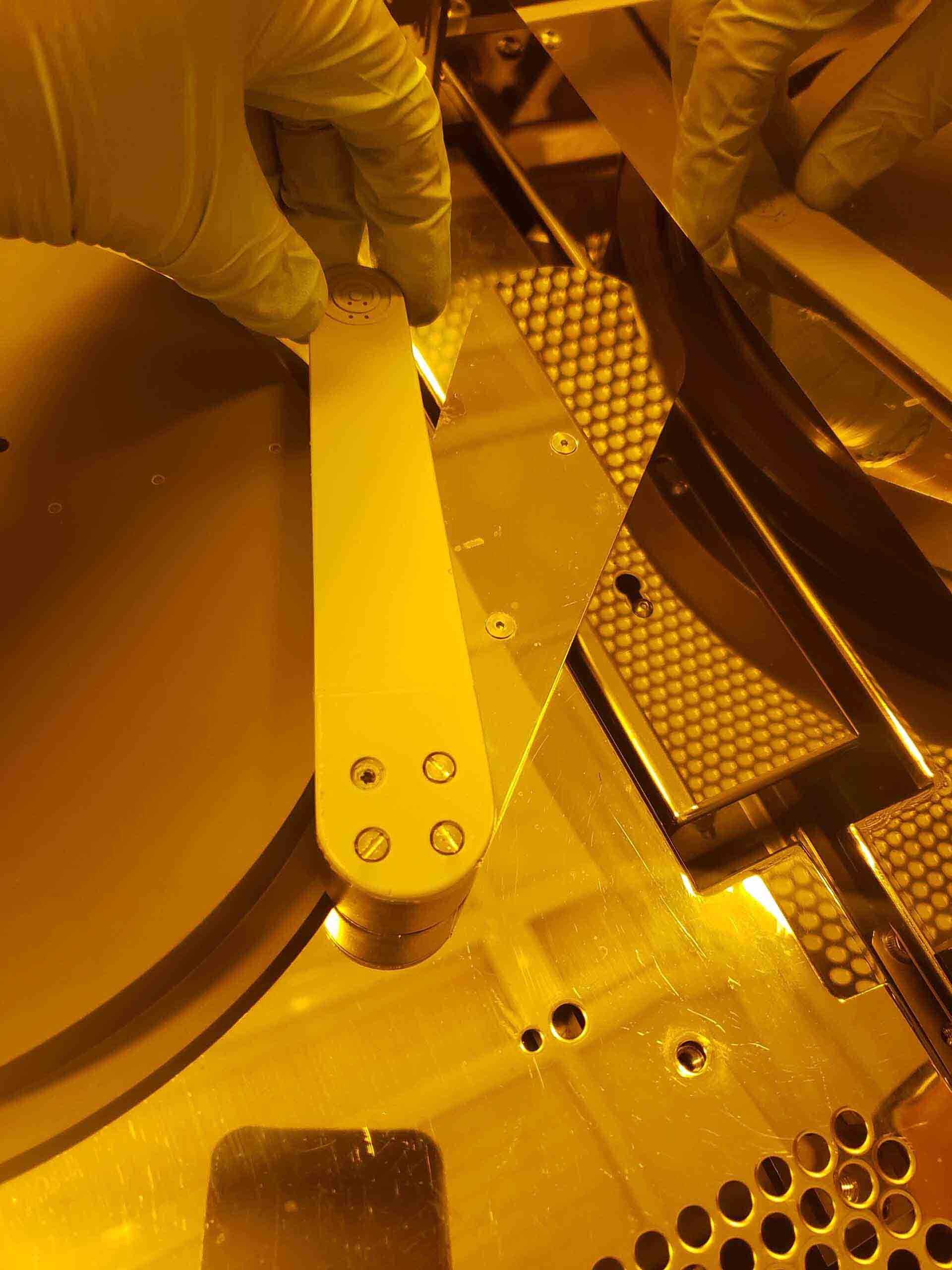

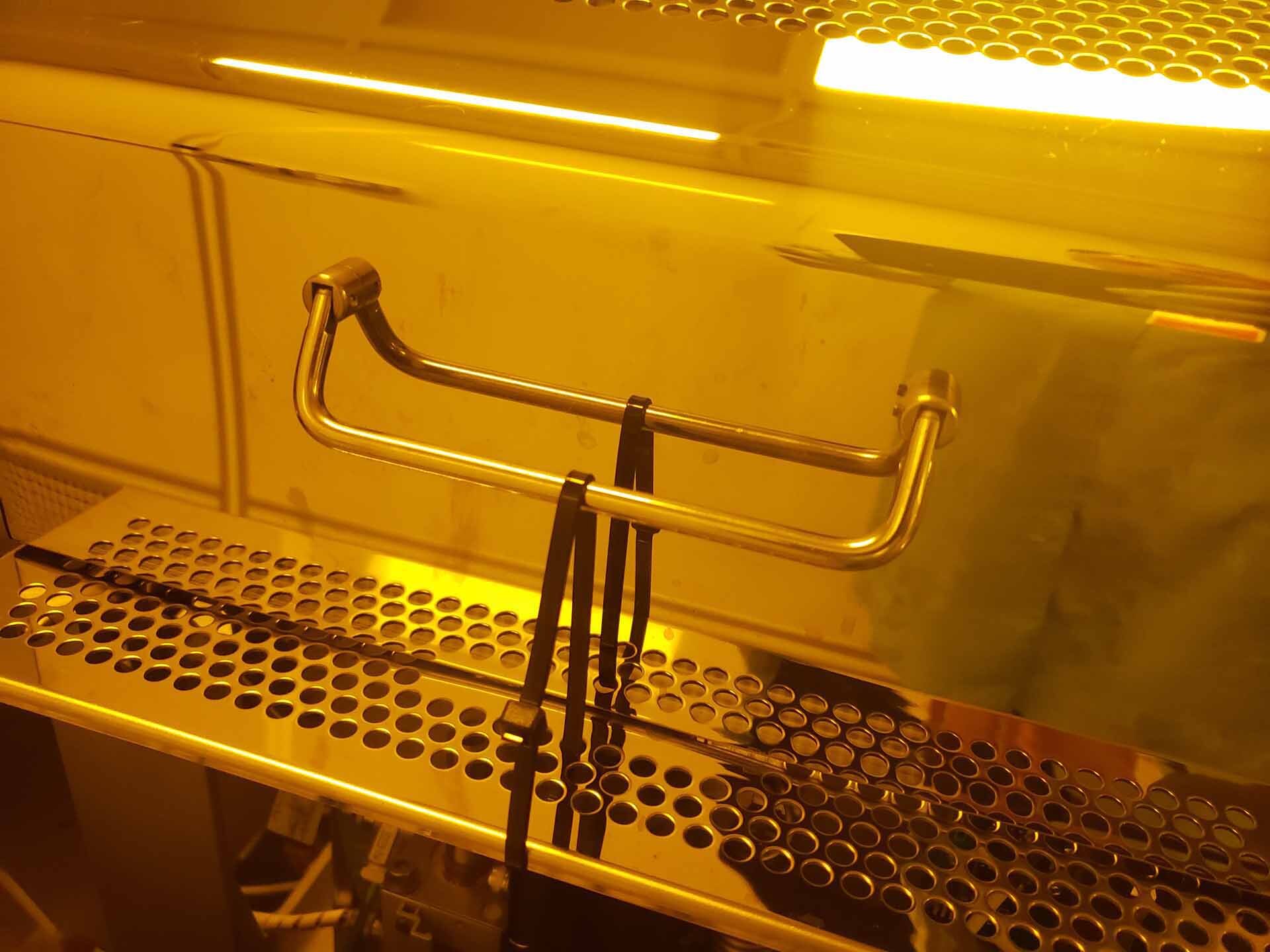

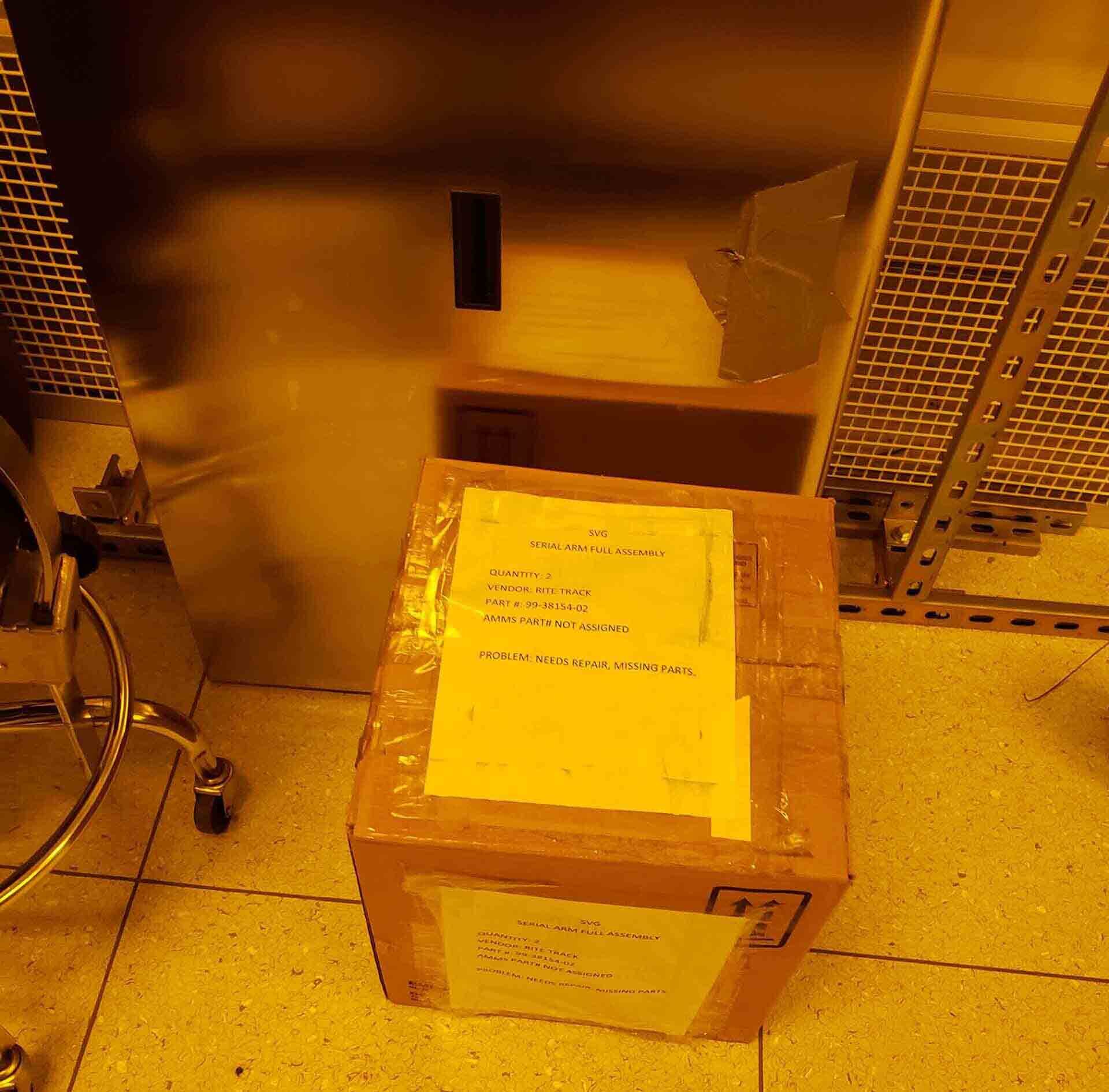

(3) / 99-414467-02 / Vacuum ARM Assembly blade long

(4) / 279C513 / Chimeras O-ring

(1) / SVG-99-80268 / System power supply board

(1) / RG10-00000006-00 / Flow meter, 65mm

(1) / EP20-00000051-00 / SCR Power controller

(1) / 99-45467-01 / Maxon DC Motor

(16) / BE10-00000008-00 / Shuttle bearing SUV Linear

(4) / EP310000005-00 / 24 VDC solenoid, 50ps

(3) / EP3100000006-00 / 24 VDC Solenoid two way valve

(2) / ME50-00000117-00 / Rite track motor

(4) / 99-23062-01 / GEM sensor control

(2) / 21190-01 / Bellow need LOC

(3) / VA02-00000008-00 / Vacuum solenoid new 24 VDC

(4) / 17-77246-01 / Valve

(2) / EP030000003000 / Spin station board

(1) / 99-4722201 / Assembly gear motor harness

(4) / BLP-00000002400 / Cable chain

(5) / CH00000 / Cable chain 80 pitch

(4) / 144-1003 / SUC Value

(1) / 85-48094-014 / Assembly keyboard 90s CES

(1) / EP1500000026-00 / RTD 3 Wire 1-8 sheath

(4) / 17.76280-01 / Kit flow meter 5-50GPH

(2) / EP13-00000009.00 / DC SERVO Motor , 75 V, 1.5 Amp

(1) / - / Miscellaneous

(1) / ME6700000003-00 / LID Chamber VP VB HPO

(2) / - / Care cassette, 8"

(2) / 762301 / Hot bake TEMP Controller

(1) / CYBOR / Cybor control module

(2) / CYBOR / Cybor pump and filter set

(1) / EPB-00000023-00 / Marathon motor

(2) / 105c20F51BD / Procon pump, 55 PSI

(1) / ME5000000042-00 / Vacuum ARM Assembly

(4) / BL10-00000020-00 / Belt timing SVG DEV Dispense ARM

(1) / EP0300000032-00 / Thermalogic TEMP Controller board

(7) / 43287-01 / Corrugated tube exhaust poly-bake, 9.5

(1) / 99-8026701 / Shuttle interface PCB

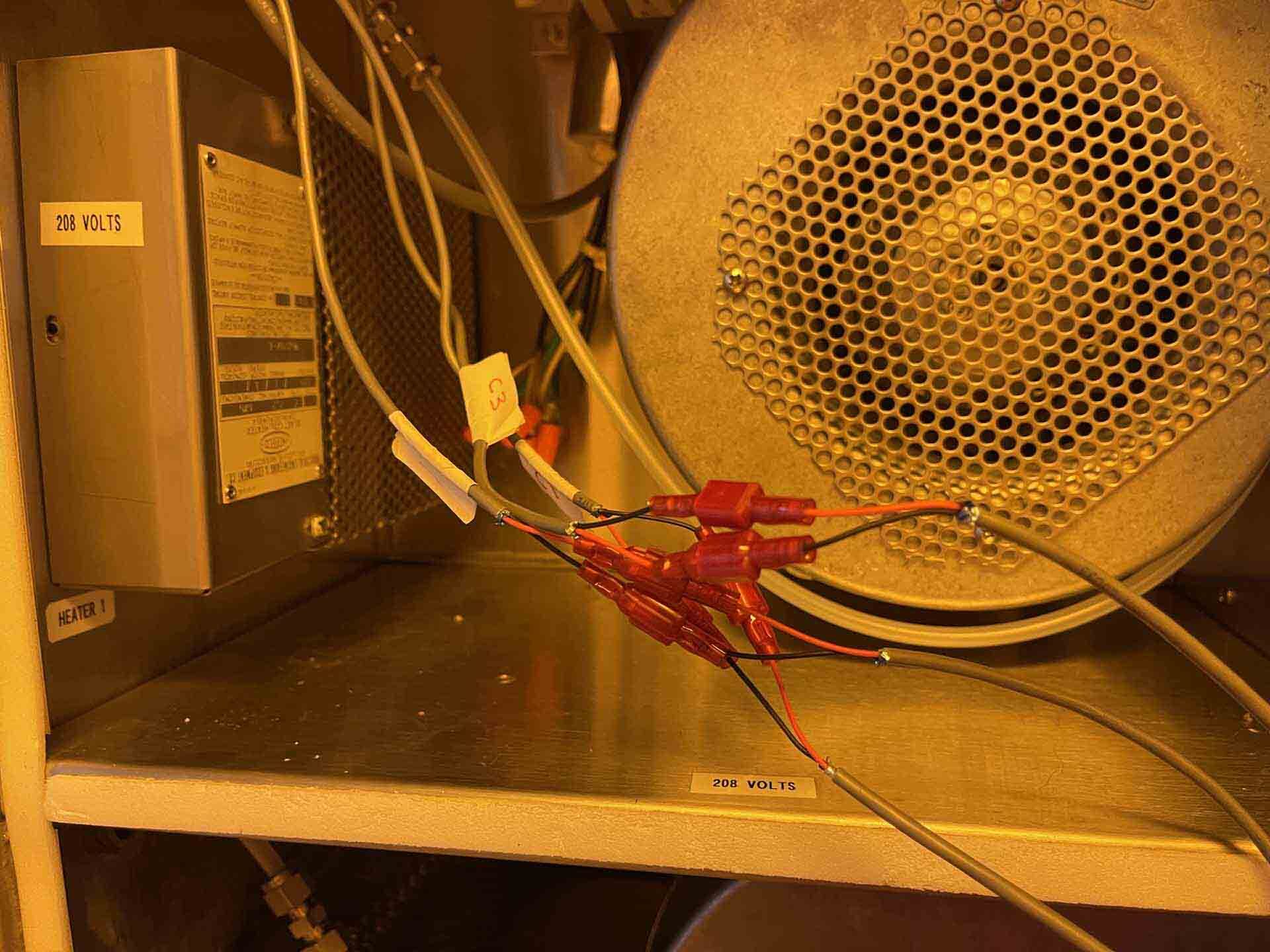

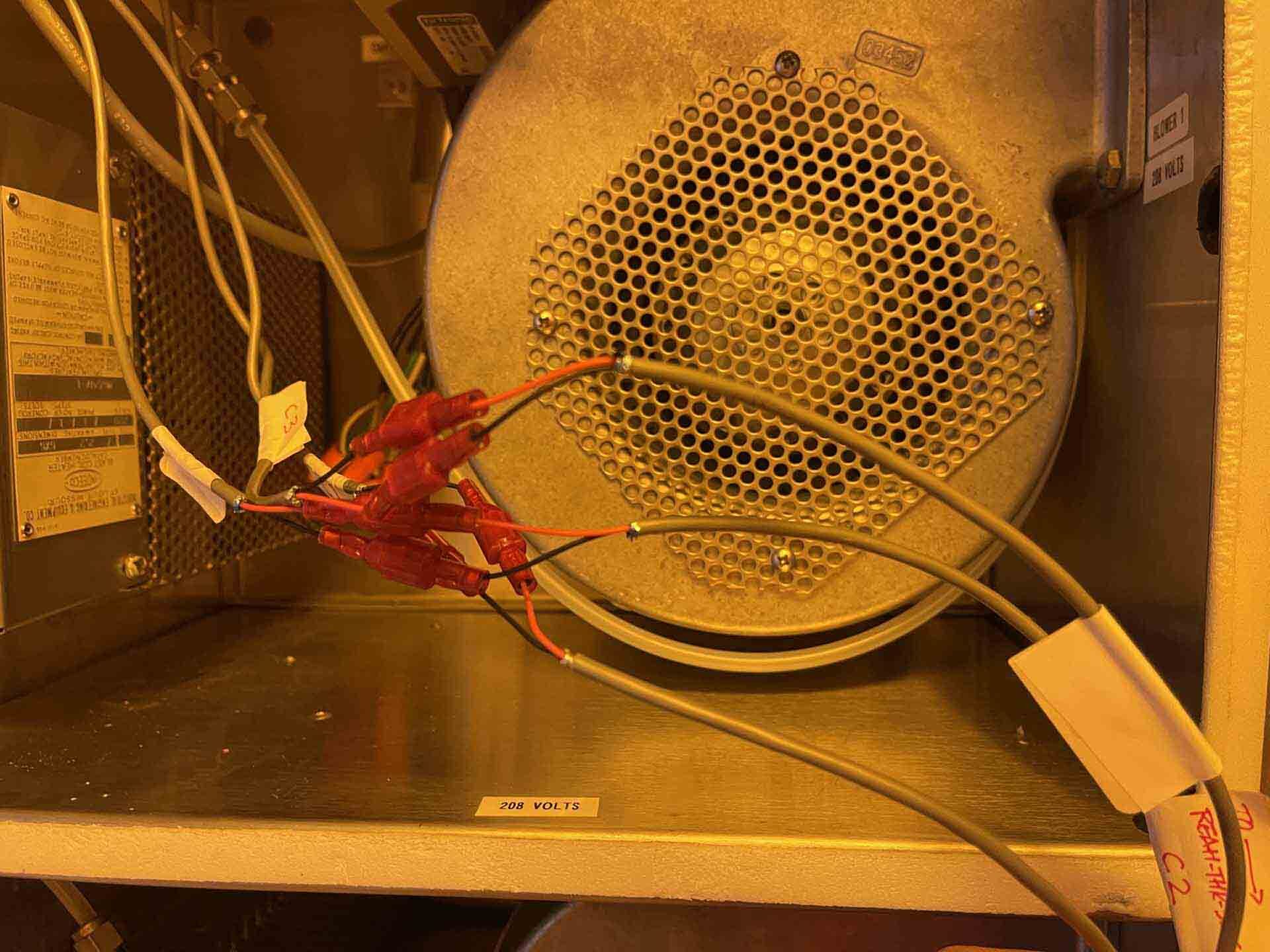

Power supply: 208 V, 60 Hz

1992 vintage.

SVG 90 is a type of photoresist equipment designed for automated optical inspection and electronic assembly processes. The system consists of a resist material; a light source, typically an LED; a camera; and a controller. The unit is designed to generate a temperature-stabilized, highly-accurate pattern of resist material on various substrates. The resist material used in 90 machine is a photovoltaic material, meaning that it absorbs light and produces an electric current. The resist is held securely in place on the substrate with a special type of adhesive. When the camera takes a picture of the substrate, the resist material absorbs the light and produces an electric current which is then read by the controller. The controller interprets the data and adjusts the light intensity accordingly. The resulting pattern is then imprinted onto the substrate. The LED light source in SVG 90 tool provides the accurate and temperature-stabilized illumination needed for creating the highly detailed and accurate patterns. The resulting patterns are crisp and clear, providing excellent resolution and accuracy, as well as reliable repeatability. The controller is responsible for controlling the precision and accuracy of the pattern produced by 90 asset. It allows for manual adjustment of various parameters, including light intensity, exposure time, and resist size. The controller also provides feedback on the status of the printing process, as well as detailed diagnostics on any errors that occur. The model is highly programmable, allowing for the fine tuning of various parameter sets. Overall, SVG 90 equipment provides a reliable and precise means of creating highly accurate and detailed patterns on a variety of substrates and devices. The system's ability to accurately and reliably produce a wide variety of patterns enables efficient and cost-effective manufacturing processes. The unit is widely used in automated inspection and assembly processes, providing reliable and consistent results without the need for manual intervention.

There are no reviews yet