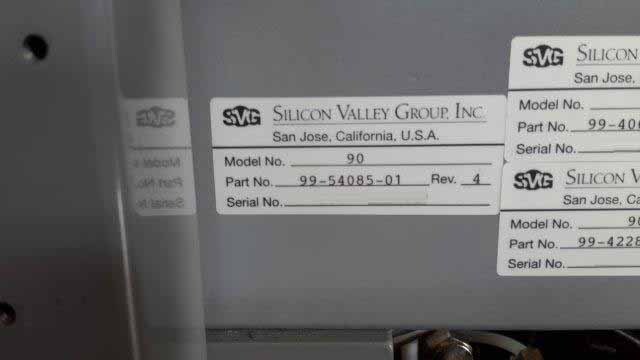

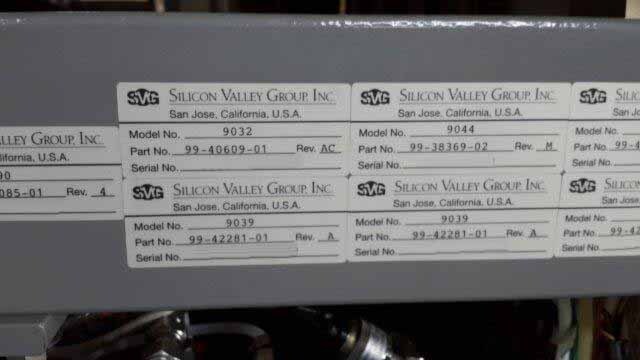

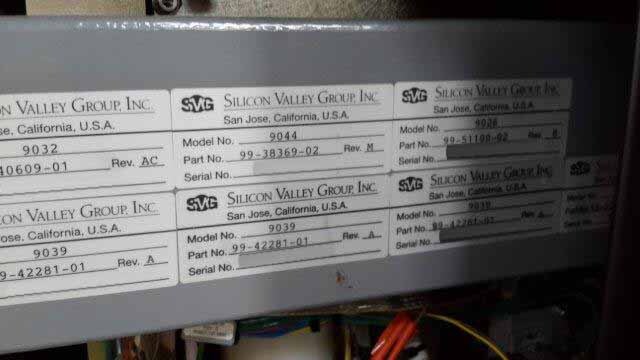

Used SVG / ASML 90 #9070809 for sale

URL successfully copied!

Tap to zoom

ID: 9070809

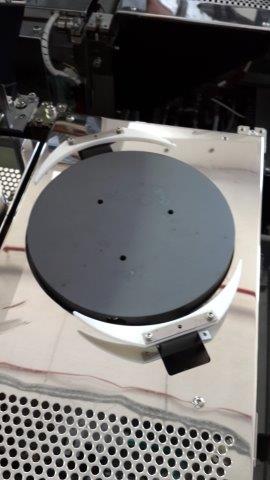

Wafer Size: 8"

Track system, 8"

Wafer: notched

(5) Vacuum Bake Ovens

(1) Vapor Prime Oven

(1) Chill Plates

(12) Stations, interfaced

(7) Serial arms

Facilities location: through the floor

Coater and developer direct floor drains with exhausted drain box

IRS rotators and platforms

(1) Coater:

Photoresist Temperature Control

Air Temp / Humidity Control

(2) FAS / Millipore model 250 pumps w/ programming pendant

100cc TEBR Millipore unfiltered pump

(2) 100cc BEBR Millipore unfiltered pumps

(1) 25cc Millipore unfiltered WCDS pump and controller for Track Adhesion Promoter

SVG 25cc Millipore unfiltered pump

Dispense line OD (nozzle tip = 3/8² for Lines # 1.2; = 1/8² for Line # 3)

SVG Pumps and controllers

(1) SS non-coated 3 gallon un-pressurized vessel with 4 liquid level sensors

(2) Developers:

Air Temp / Humidity controller

High flow (2 stream) nozzles and dual chemistry developer fluid dispensing system

(2) Stainless Steel Tefzel coated, 3 gallon pressurized canisters with 4 liquid level sensors

0-60 psi canister gauges

Degasifier on Develop lines

Floor: solid SS spill containment with overflow sensors

Control Module integrated on end station

MCE on IES

SECS I/II interface

Power Requirements 208 volts, 3-phase, star, 60 Hz.

SVG / ASML 90 is a photoresist equipment used in the manufacturing of integrated circuits. It is composed of a vacuum scanning system with advanced multi-stage gate technology, laser scanning exposure, and computer-controlled processing. This unit is ideal for the high precision and tight control required in the manufacture of fine line patterns typically found in advanced semiconductor production. SVG 90 scanning machine uses a serial beam to achieve uniform exposures with minimal shot noise. The tool can run at speeds up to 1000 lines/second, and the beam size can range from 6 to 15 µm. The stage asset can move the die from exposure to development with a maximum speed of 25mm/s, and provides a non-contact transition with high positional accuracy and repeatability of 10 microns. The model's computer-controlled scanning and exposure parameters allow for precise control of the patterning process. ASML 90 utilizes a laser scanning exposure equipment with variable laser power and spot size. The exposure time is programmable with flexibility to accommodate the customer's process needs. The system is then followed by a programmable developing process which ensures uniformity and is equipped with advanced image jet processing technology to pre-qualify recovered reticles. Finally, the processed reticles are subjected to an automated sorting process. The combination of 90's advanced scanning, exposure, and processing capabilities provide a level of control and accuracy that makes it ideal for the production of high precision patterns and fine line features. The unit's flexibility allows for different exposure options, expanded process parameters, and improved quality control programs. SVG / ASML 90's intuitive user-friendly interface makes it easy to integrate into existing production lines and enables engineers to be able to quickly view and adjust their settings for the best results. The high throughput and accuracy provided by SVG 90 make it a great choice for semiconductor production applications.

There are no reviews yet