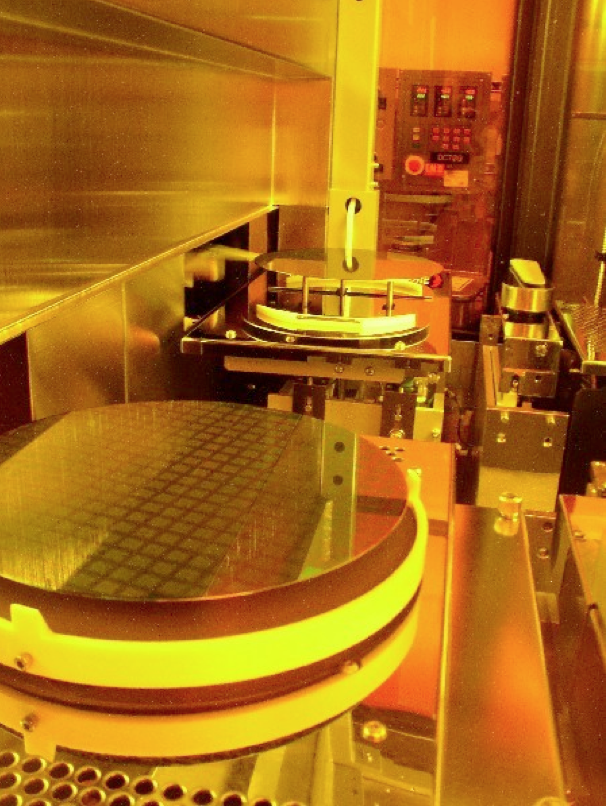

Used SVG / ASML 90S #9032372 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9032372

Coater / Developer track system, 8"

Wafer Size: 200mm, notched, System on floor

Right hand only unit

104” Stand-Alone Cabinet

2 Coat Modules w/chemical edge bead removal, 2 Develop

Modules, 6 Vacuum Back Ovens, 2 Vapor Prime Ovens, 3 chill

Plates, 1 OEBR Module

Photoresist Temperature control

Air Temperature and Humidity control(Coater and Developer)

Complete air recirculation environmental control over all modules

4 serial arms and 1 90SE serial arm

Floor is solid SS spill containment w/overflow sensors

Solid doors in front of gauges and flow meters

Control Module on CES, (left or right-integrated)

Interface is rear pull

208 volts, 3-phase 60Hz

Coater direct floor drain (Tee in cabinet)

Developer direct floor drain (Tee in cabinet)

Full clogged drain sensor on each coater

Full SEMI S2-93 Containment for solvent/pump drawer enclosures, bulkhead

Facility sensors for vacuum generators, DI water and

Caustic exhaust

SECS Communication Port

Millipore controller / resist pump upgrades

1997 vintage.

SVG / ASML 90S is a photoresist equipment developed by SVG to provide superior performance and reliability for semiconductor manufacturers at a competitive price. The system is a fully automated, high-precision, computer-controlled exposure unit that uses a scan-able slit mask to allow the accurate transfer of calculated optical patterns onto photoresist surfaces during microelectronic device fabrication. The machine uses a specially designed light source to expose the photoresist, with a customizable combination of laser light and electron beam imaging. SVG 90S provides superb feature resolution and control due to the well-defined accuracy of the scanning slit mask, which can be modulated for different levels of exposure, and for its ability to compensate for any exposure variations. This tool also allows for backside biasing of substrates that can affect feature critical dimension (CD) and exposure latitude. ASML 90S provides high uniformity and repeatability due to its scanning motion and all-aluminium lamellar mirror, which can be used to direct a wide range of doses from a single point source. Its repeatable synchronization of the scanning masks and light source provides excellent repeatability of CD and exposure latitude over a wide range of substrate shapes and sizes. The asset also supports numerous processing chambers that can optimize image quality, reduce particle and defect levels, and improve overall yield. The photoresist model's dose accuracy is remarkable due to its ability to compensate for any exposure variation, and its high-resolution source points, as well as its optimized light source and chamber design. Overall, 90S photoresist equipment provides excellent reliability and performance due to its computer-controlled exposure system, wide range of doses, high uniformity and repeatability, and its optimized chamber design. Its advanced capabilities enable semiconductor manufacturers to fabricate high-quality integrated circuits with accurate features and controlled substrate responses.

There are no reviews yet