Used TEL / TOKYO ELECTRON ACT 12 #9042727 for sale

URL successfully copied!

Tap to zoom

ID: 9042727

Wafer Size: 8"

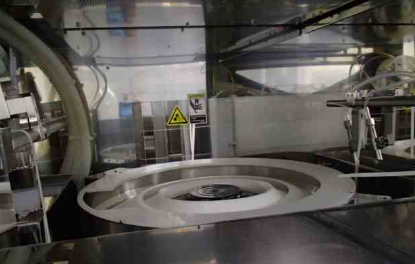

(2) Coater / (4) Developer track system, 8"

(2) BLK

(2) CT

(2) ADH

(6) CPL

(8) LHP

(4) CHP

(1) WEE

IF CSB(R)

Currently warehoused.

TEL / TOKYO ELECTRON ACT 12 is a photoresist equipment used in semiconductor manufacturing. It is made up of three major components: a submersion-type chamber, a high temperature baking system, and an auto-aligner. The unit is ideal for managing a multitude of photoresist processes, ranging from spin coat, bake, pre-bake, and development processes. The chamber within TEL ACT 12 is a pneumatically-operated, closed-loop, submersion-type. It is pressure-resistant and provides a secure environment for the processing of photoresists. Additionally, the circulation nozzle ensures even distribution of photoresist solution. This eliminates the need for mechanical stirring. The high-temperature baking machine provides uniform heating of wafers. It is powered by a single heater and uses a single stage, thermal zone baking controlled by a programmable cluster. Its temperature settings are well-suited for multi-stage temperature baking of photoresists. The auto-aligner quickly measures and aligns photomasks to the proper position. It is equipped with anauto-aligner driven by a precision motor. The wide-field vision used minimizes errors and misalignments. Additionally, an automatic wafer-position control is used to ensure that the proper alignment takes place. Overall, TOKYO ELECTRON ACT12 is suitable for photoresist application processes. Its pressure-resistant chamber results in secure, low-pressure processing. Additionally, its high-temperature baking tool can provide multi-stage temperature baking. Finally, its auto-aligner enables quick and accurate mask-to-wafer alignment. Together, these components make this photoresist asset an ideal choice for sensitive semiconductor manufacturing processes.

There are no reviews yet