Used TEL / TOKYO ELECTRON ACT 12 #9178577 for sale

URL successfully copied!

Tap to zoom

ID: 9178577

Vintage: 2002

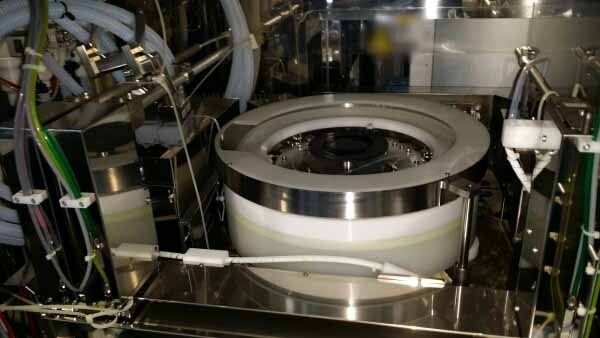

Polymide coater

CSB Unit

Main body block 1

Main body block 2

AC Power box

Temp controller

T&H Unit

Part pallet 1

Part pallet 4

Part pallet 2

Part pallet 3

IFB Unit

Chemical box 1

Chemical box 2

2002 vintage.

TEL / TOKYO ELECTRON ACT 12 is a photoresist equipment designed to precisely etch circuits and device patterns onto the surface of a substrate. The system uses a process of patterning a photosensitive polymer, known as photoresist, onto a substrate material. The substrate is coated with a film of photoresist and exposed to a light activating the photoresist in areas where etching is to occur. The unit then removes the unexposed photoresist material using a process known as development. TEL ACT 12 is a high-accuracy etching machine controlled by an intuitive graphical user interface. TOKYO ELECTRON ACT12 features a 10-bit color depth that can achieve accuracy and high resolution down to 0.005μm. It has a mix and match of image input devices -- from a motorized X/Y table stage to a stepper motor, a manual Z stage, and a DriverPC. With its modular design, users have greater flexibility and scalability when it comes to adapting to specific requirements and applications. TEL ACT12 also comes with advanced control features. It can be remotely controlled via a network connection to allow cloud-based software updates. The accuracy of the machine can also be controlled programmatically, with automatic calibration and verification. With integrated functional safety controls, the tool can be operated in hazardous environments or after hours. ACT 12 is designed for a range of applications including advanced Semiconductor and MEMS (micro-electro-mechanical systems) technology. It can be used for etching complex 3D circuits, structures, and components on rigid, thin, or curved substrates. The asset is also helpful for device and medical device assembly, as it increases production throughput and yields production quality. TOKYO ELECTRON ACT 12 is a reliable solution for high-precision etching and is highly regarded for its accuracy, quality, usability, and safety. It is designed to reduce downtime and ensure a smooth, efficient production process. With its many flexibility options, ACT12 can offer customized solutions for various etching projects.

There are no reviews yet