Used TEL / TOKYO ELECTRON ACT 12 #9351398 for sale

URL successfully copied!

Tap to zoom

ID: 9351398

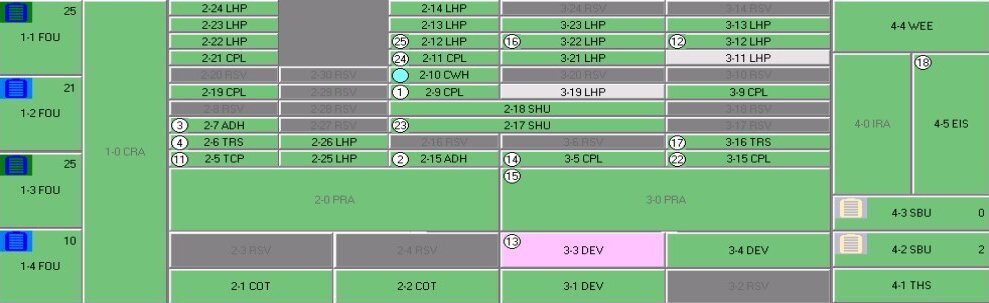

Coater system

(8) RRC Pumps

(2) Pump I/O board

Load port board

Load port CONN board

Load port DC / DC CONV board

Controller: Type 3

Spin motor: PANASONIC Motor

AC Power

Chemical box

(2) T & H ME2 Temperature controllers.

TEL / TOKYO ELECTRON ACT 12 is a photoresist equipment that utilizes a high-energy electron beam to expose a photoresist film. The photoresist is then used to fabricate a variety of electronic devices and devices with nanometer precision. This system exploits the properties of a direct-write electron beam lithography (DWEL) unit to expose photoresist films. The machine utilizes an electron gun that is constructed using a special filament that emits electrons. The generated electrons are accelerated through the gun by a high voltage electric field resulting in a high-energy electron beam that strikes the photoresist film. The energy of the electron beam is monitored using an energy analyzer that can also control the electron beam. The systems energy range is from 10 to 600 KeV, and the spot size ranges from 50nm to 0.5μm. The electron beam exposure is following an actinic exposure, which consists of controlling the beam voltage and current, its spot size, and the duration of exposure. Additionally, the tool is able to precisely control the exposure dose, by controlling the current density and the position of the electron beam so that the pattern geometry and features are accurately and uniformly exposed. The photoresist film uses a two-step deposition process, which uses a standard photoresist spin-coated on the film and then selectively exposed to the electron beam. After this is done, the exposed areas are developed and used to pattern the electronic components. Furthermore, the nature of the photoresist asset allows for higher spatial resolution, preserving intricate details of the fabricated electronic components. This model is suitable for constructing very small electronic components, which benefit from the high energy of the electron beam and the smaller spot size, which allows for higher resolution and accuracy in fabrication. Furthermore, the equipment has a template pre-programmer to record and store the patterns of electronic devices that have been previously constructed, allowing for easy retrieval and fabrication of devices. As such, this system is suitable for applications such as quantum dot fabrication and nanostructures. The cost of the unit is also reasonable, making it an attractive choice for those looking to produce small electronic components.

There are no reviews yet