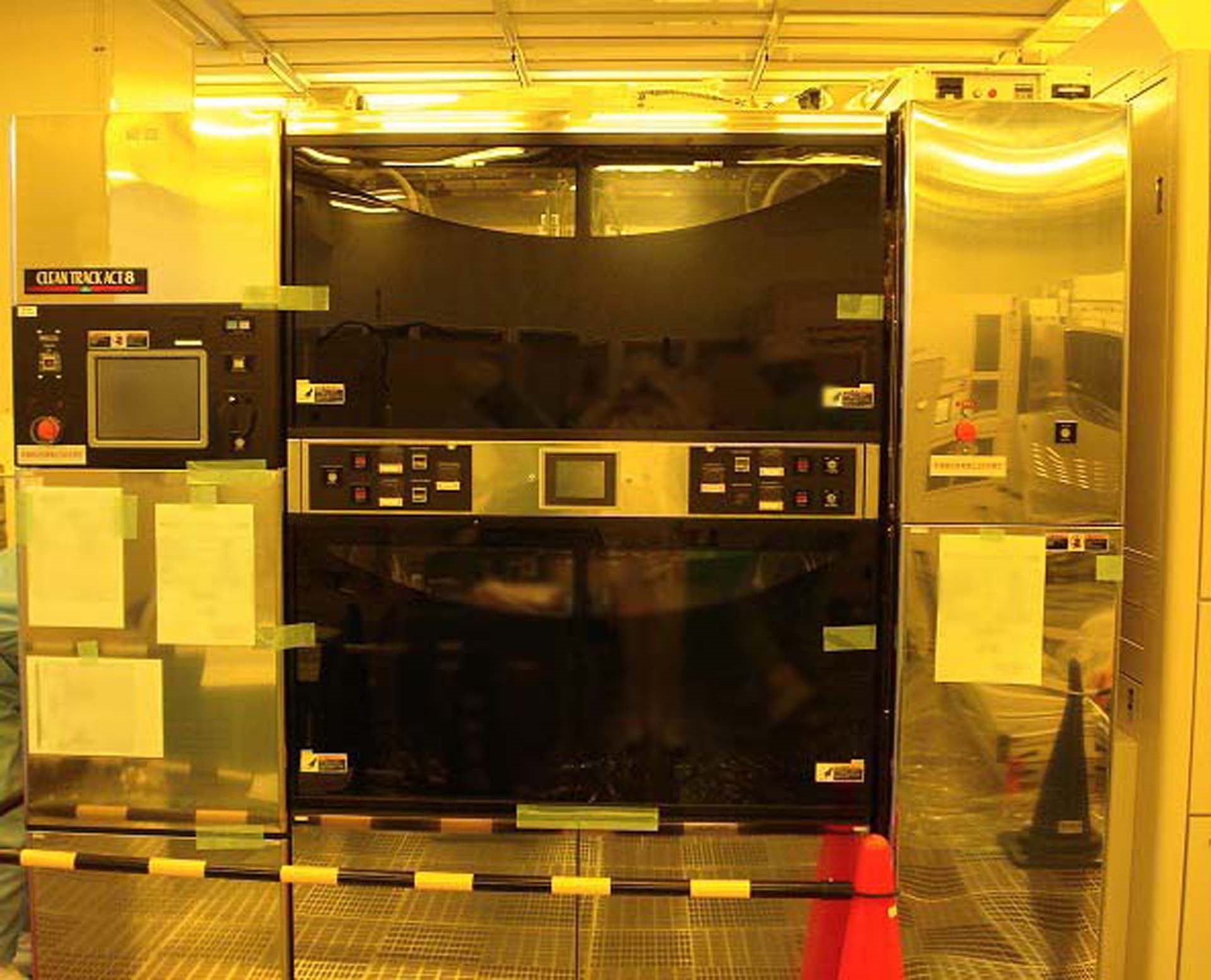

Used TEL / TOKYO ELECTRON ACT 8 #9235266 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9235266

Wafer Size: 8"

System, 8"

Wafer flow: Left to right

Wafer type: Notch / Flat

Cassette block (CSB): Open type

Process block (PRB): 1 Block

Interface block (IFB)

CANON FPA-3000 i5 Exposure system

Chemical box:

Solvent: (2) Buffer tanks and degas module

HMDS: Buffer tank and canister tank

Solution: (2) Buffer tanks and (2) Degas modules

Drain: COT Drain poly tank

With fire extinguisher system

Temperature and humidity 1: COSAM SPA-Series

No temperature and humidity 2

Temperature control unit (TCU) 1: INR Series

AC Power box

No back-up module in AC power box

(7) Parts boxes

Missing part in AC box

Cassette block (CSB):

No ULPA fan unit

Display panel

Alarm tower

Loader

No carrier reader sensor

CRA:

X, Y, TH, Z Motor set

X, Y, TH, Z Drive set

Tweezer

Mapping sensor

Wafer check sensor

No AGV system

MSE 343B DC Power box

CSB Chemical area:

Resist pump: (8) T-F200 Series RRC Pumps

Resist bottle: Gallon bottle and quart bottle

Resist filter:

(4) Impact type

(4) Housing type

(8) LE Tanks: 200cc

Process block (PRB) 2:

FAN Unit

TH Drive

PRA:

X1, 2, 3, Z Motor and drive

Pincette and wafer block

Wafer sensor

Coater (COT):

(4) Dispense nozzles

Nozzle arm 1 and 2

Chuck

Back rinse nozzle

No BARC coater (COT)

TARC Coater (TCT):

(2) Dispense nozzles

Nozzle arm 1 and 2

Chuck

Back rinse nozzle

CUP Set

Developer (DEV):

Dispense nozzle: H Nozzle

Nozzle arm 1 and 2

Chuck

Back rinse nozzle

CUP Set

Process block (PRB) 2: Oven

ADH

LHP

No HHP

No HCH

CPL

No PHP

No PCH

CHP

No TCP

TRS

CWH

IFB (Interface block):

FAN Unit

EIS Type: CANON

IRA:

X, TH, Y, Z Motor and drive

Tweezer and wafer block

Wafer sensor

WEE:

X Motor and drive

Chuck

Exposure type: DUV-Line

Exposure sensor: 254 UV.

TEL / TOKYO ELECTRON ACT 8 is a photoresist equipment that is used for the production of electronic printed circuits. The system is capable of enabling the production of devices ranging from small to large sizes, with repeatable and robust fabrication processes. TEL ACT 8 consists of a photoresist processor, a mask aligner, and a defect inspection unit. The photoresist processor enables the application of light to a surface of the circuit board, which assists in the selectivity and speed of the etching process. The mask aligner allows the user to precisely align the mask onto the circuit board, such that the photoresist material is applied in the correct positions for etching. Finally, the defect inspection machine monitors the photoresist material for defects and blemishes, ensuring that the end result is of the highest quality. TOKYO ELECTRON ACT 8 is designed to offer superior precision and accuracy. The tool supports high levels of accuracy, as it can resolve features down to 0.5 microns in size. This precision allows for very small and intricate circuits to be accurately produced. The asset also enables the flexibility to produce large panels in one step, with fast switching times and robust processes that are highly repeatable. TEL / TOKYO ELECTRON ACT 8 is a highly reliable and consistent solution for the production of prototype and production printed circuits. The model is compatible with a variety of photoresist materials, enabling users to customize their processes for best results. It is also capable of handling various substrates and board types, allowing it to be used across a broad range of applications. Overall, ACT 8 is a reliable and comprehensive photoresist equipment that is designed to enable the production of high-quality printed circuits. The system is highly accurate and repeatable, offering superior precision and accuracy for complex circuit designs, and it is compatible with a variety of materials and substrates for broad application versatility.

There are no reviews yet