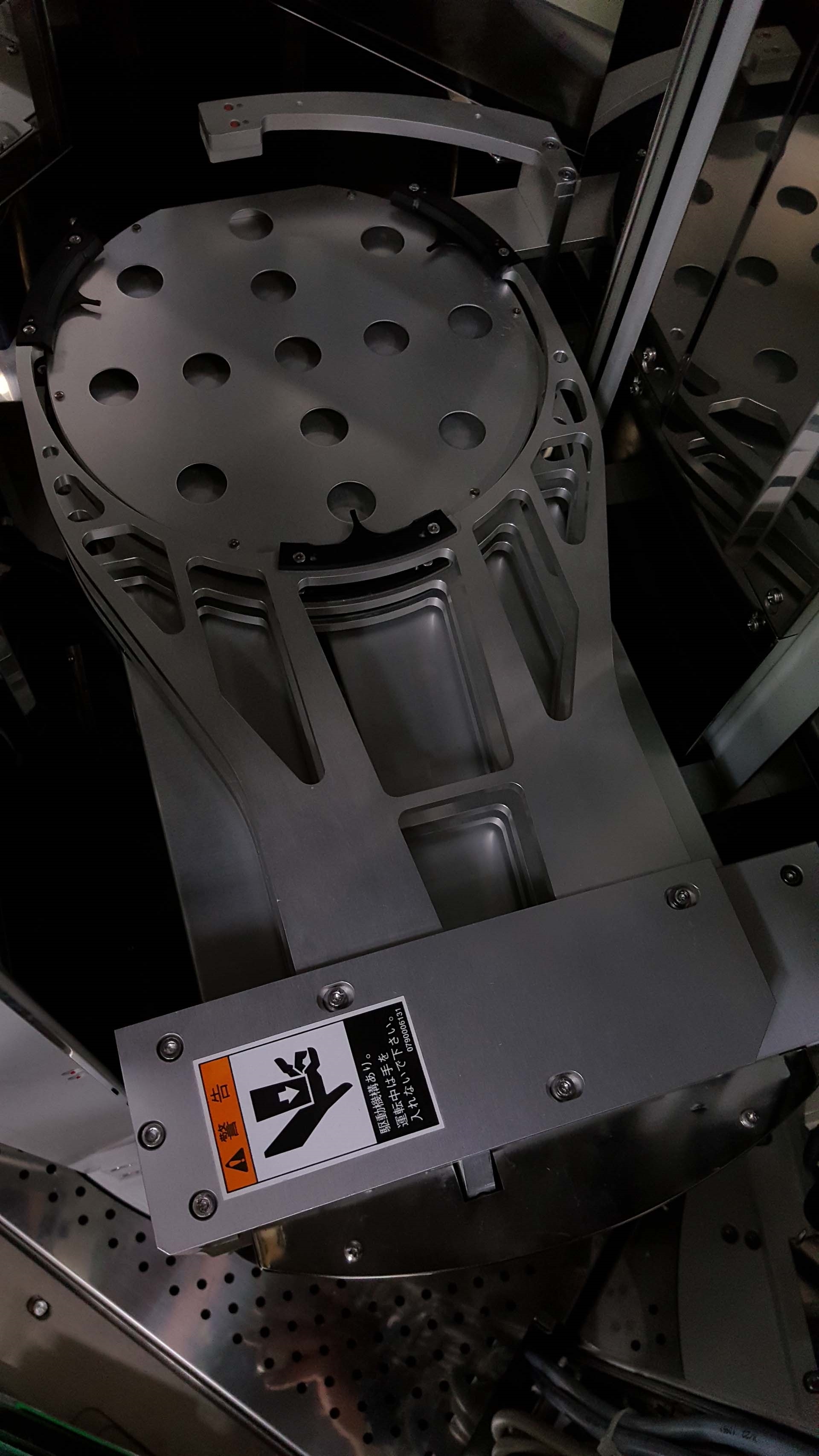

Used TEL / TOKYO ELECTRON ACT 8 #9279593 for sale

URL successfully copied!

Tap to zoom

ID: 9279593

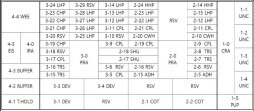

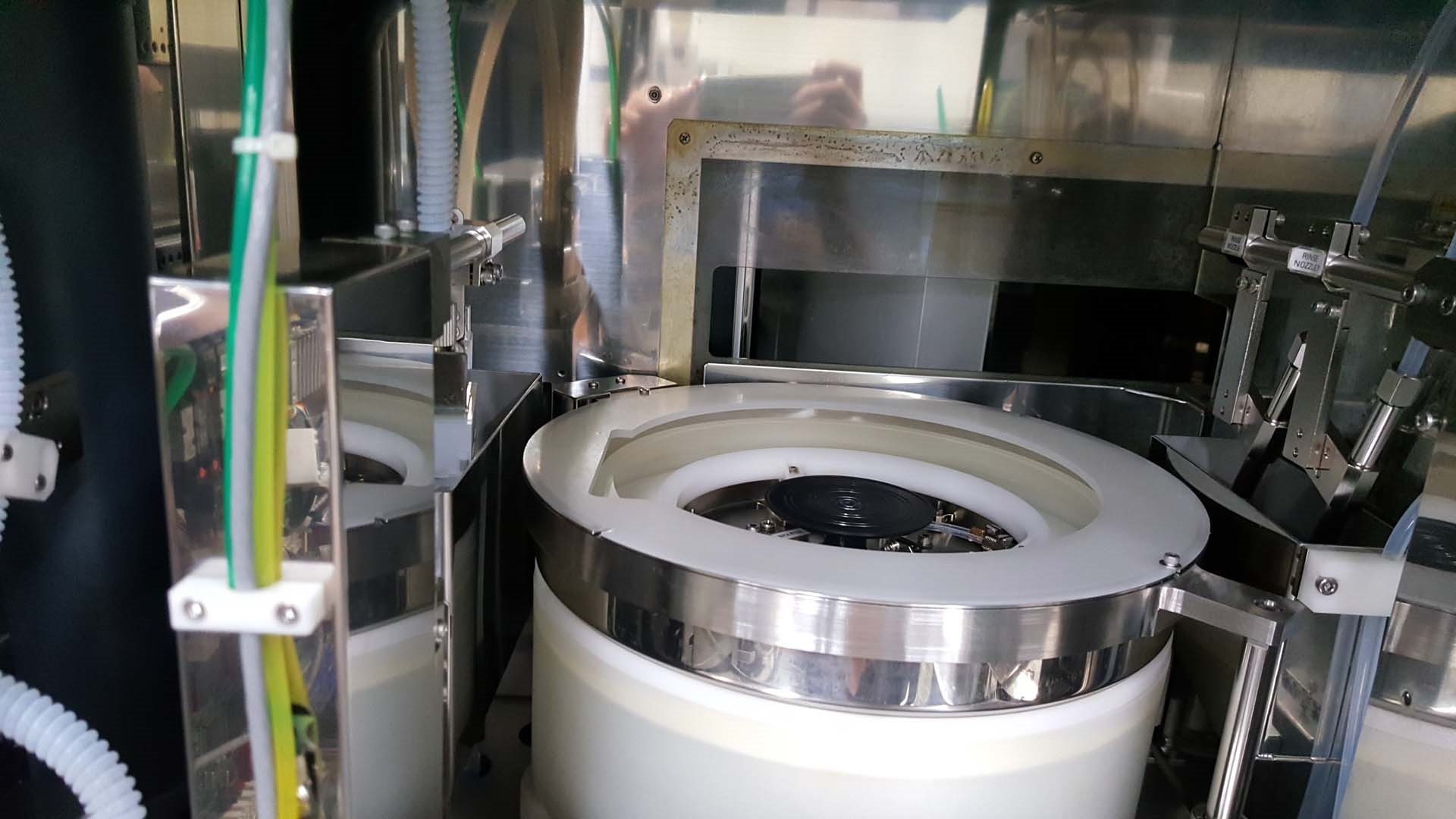

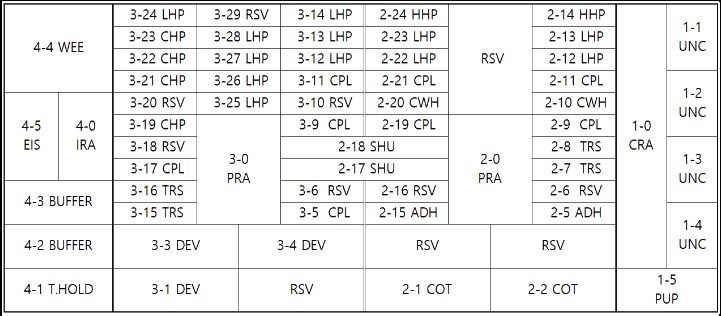

(2) Coater / (3) Developer system, 8"

R Type

In-line

Block: 2

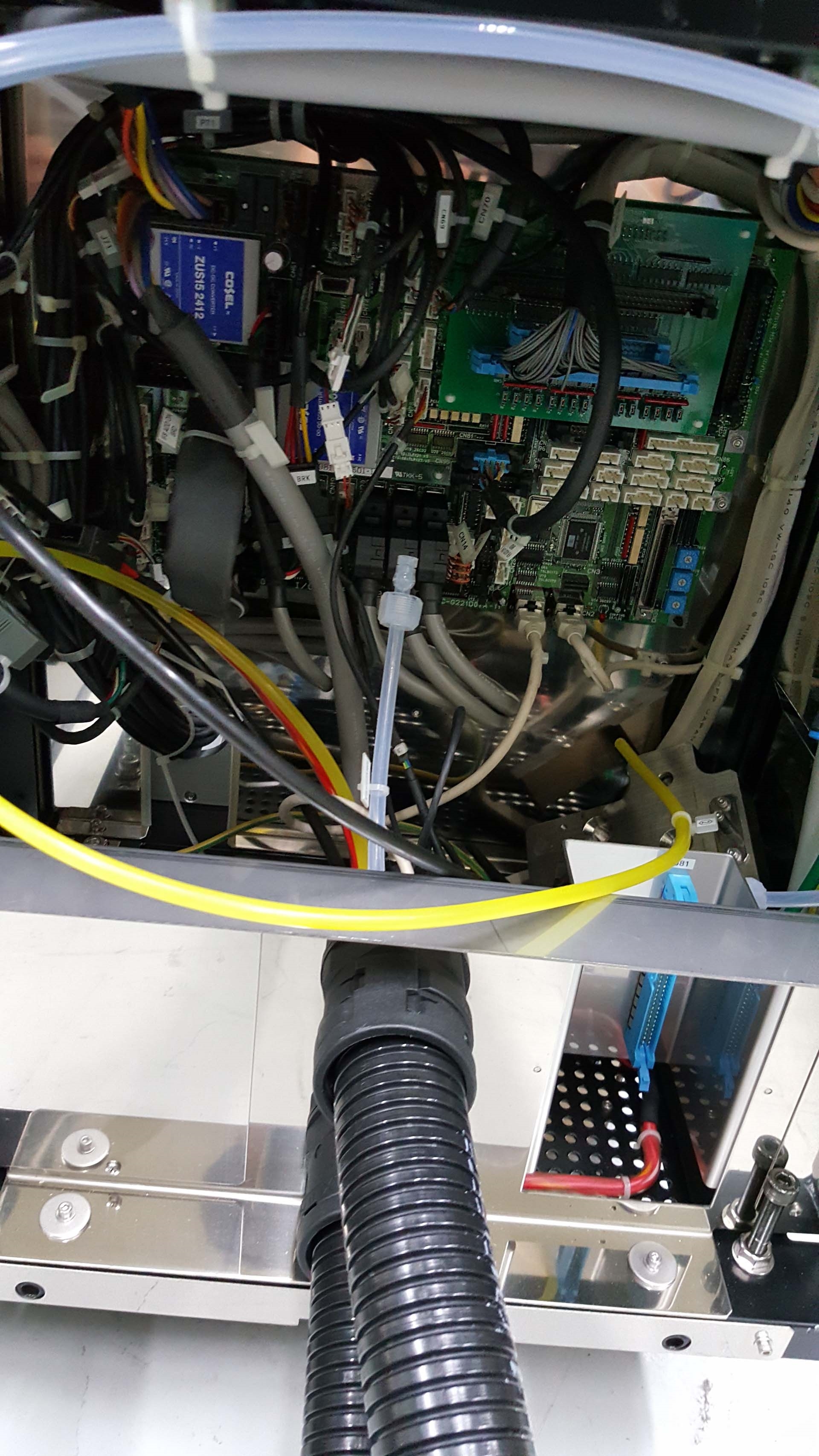

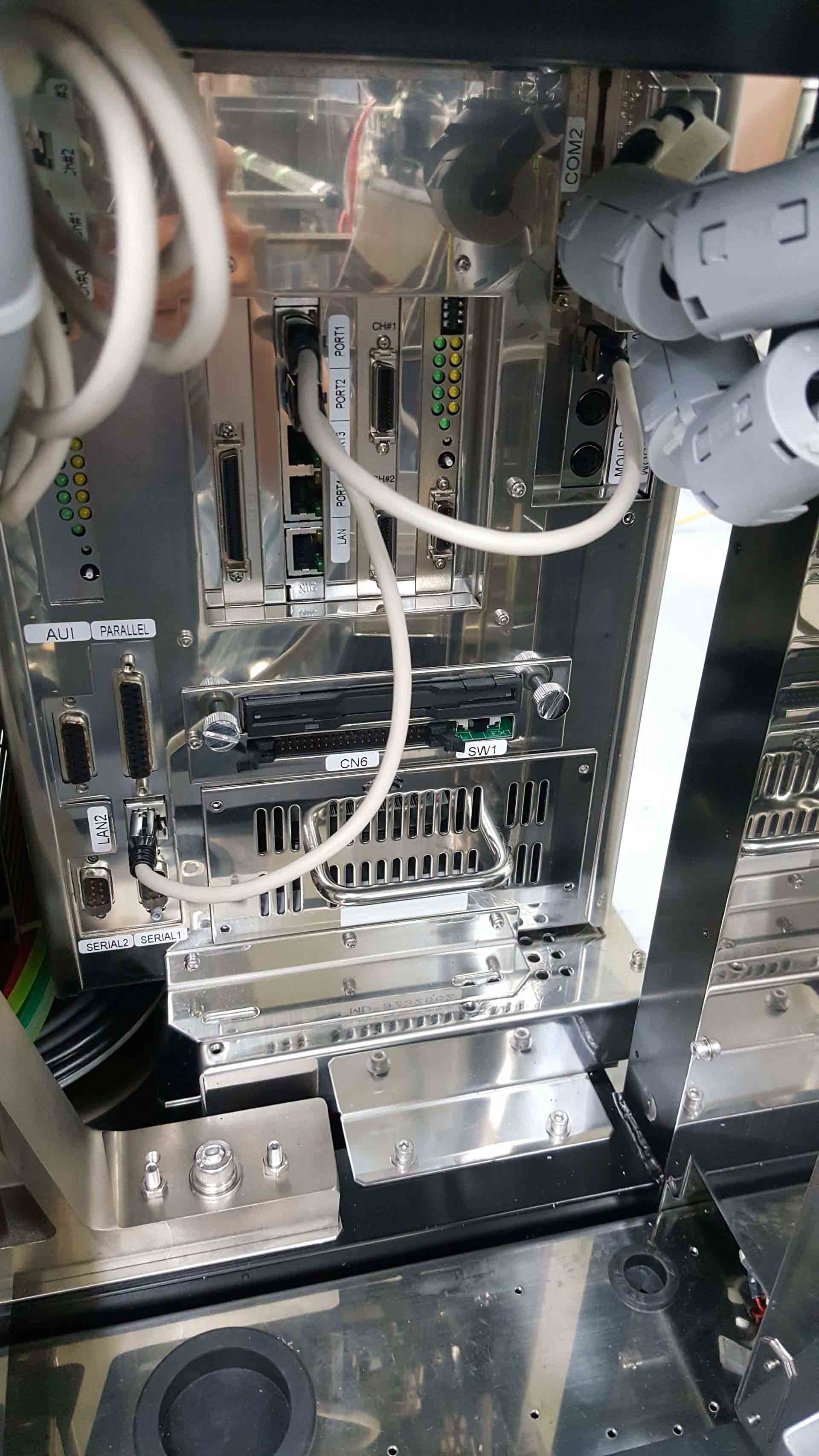

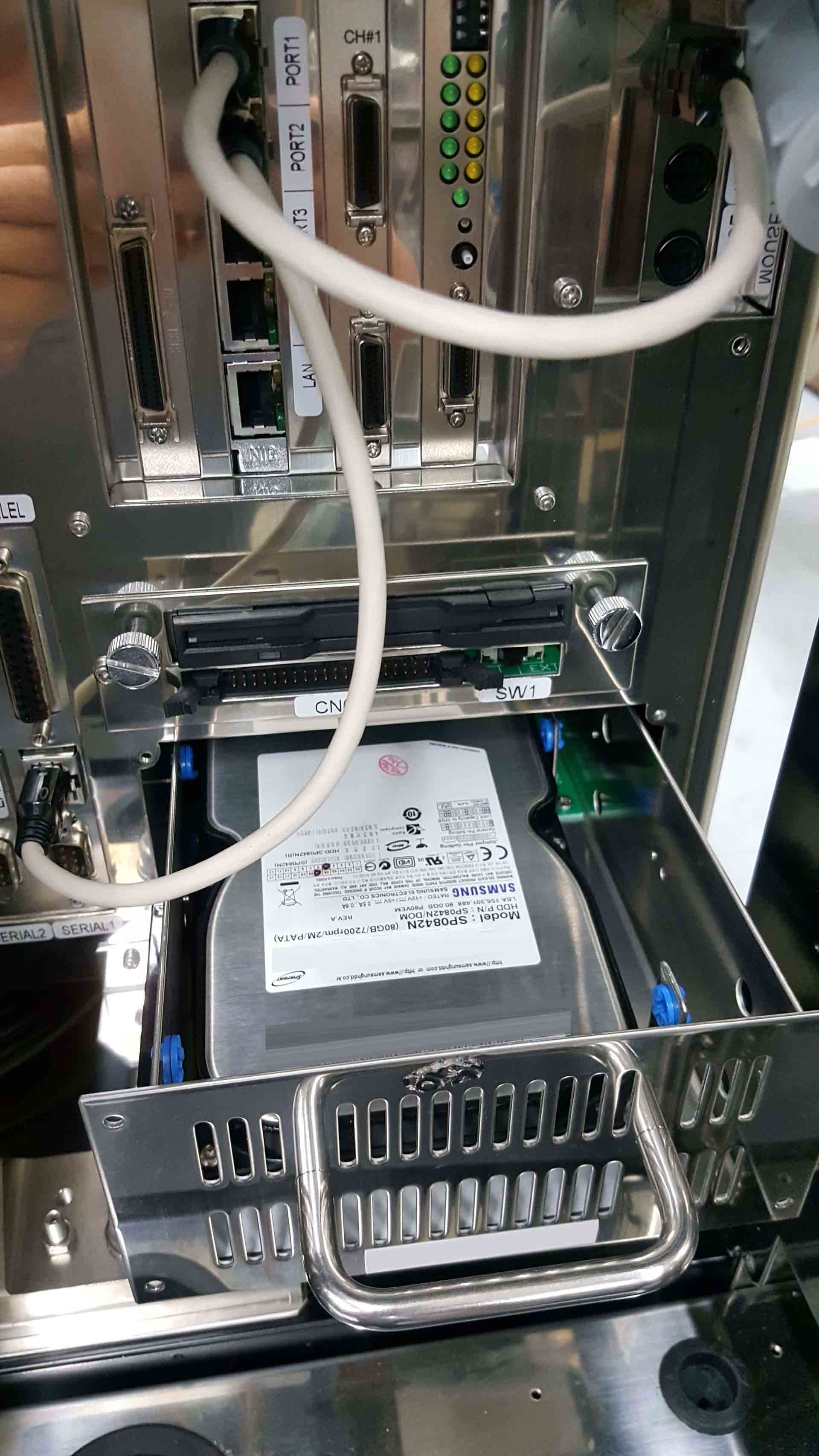

Hard Disk Drive (HDD)

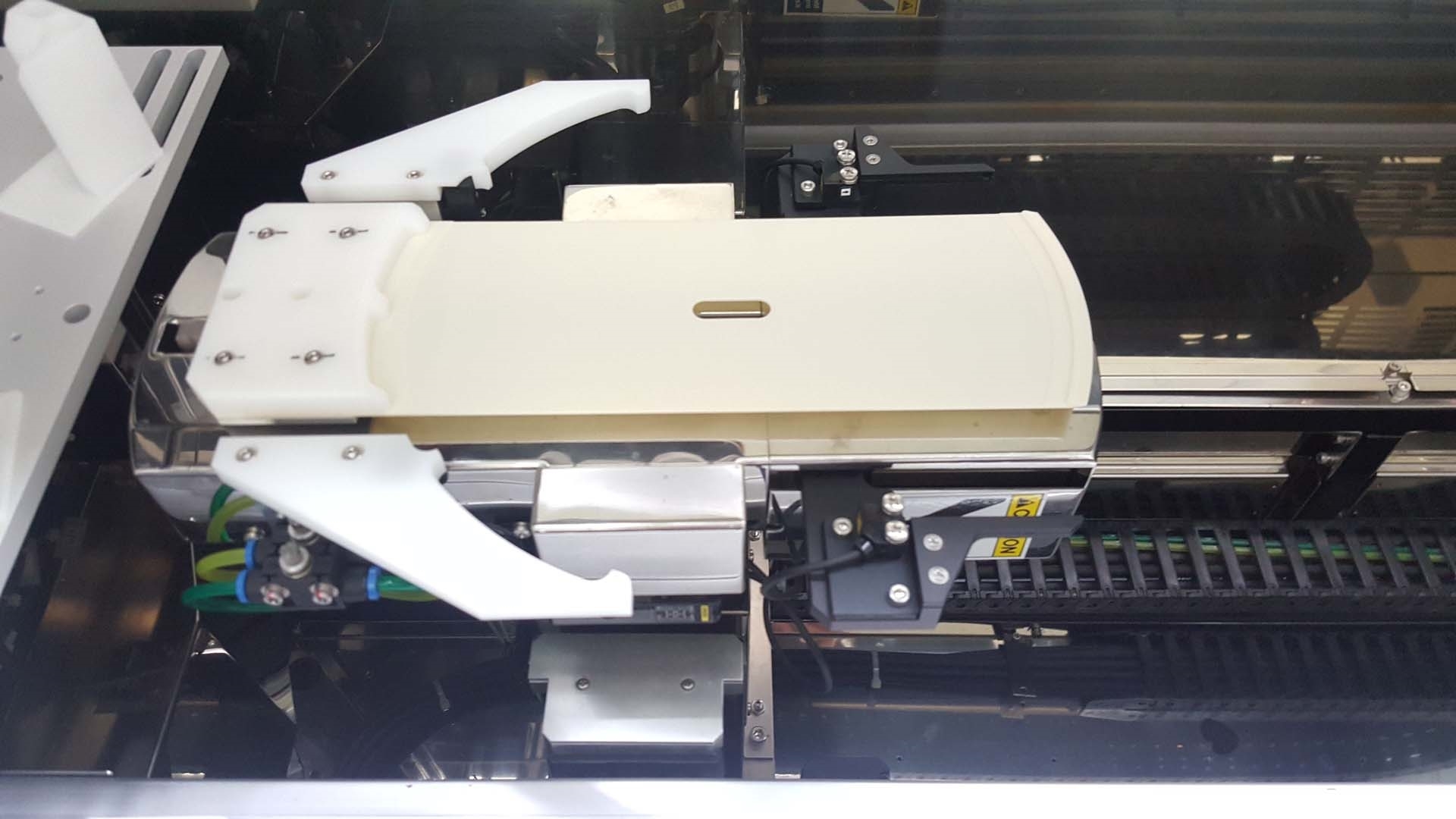

Loader

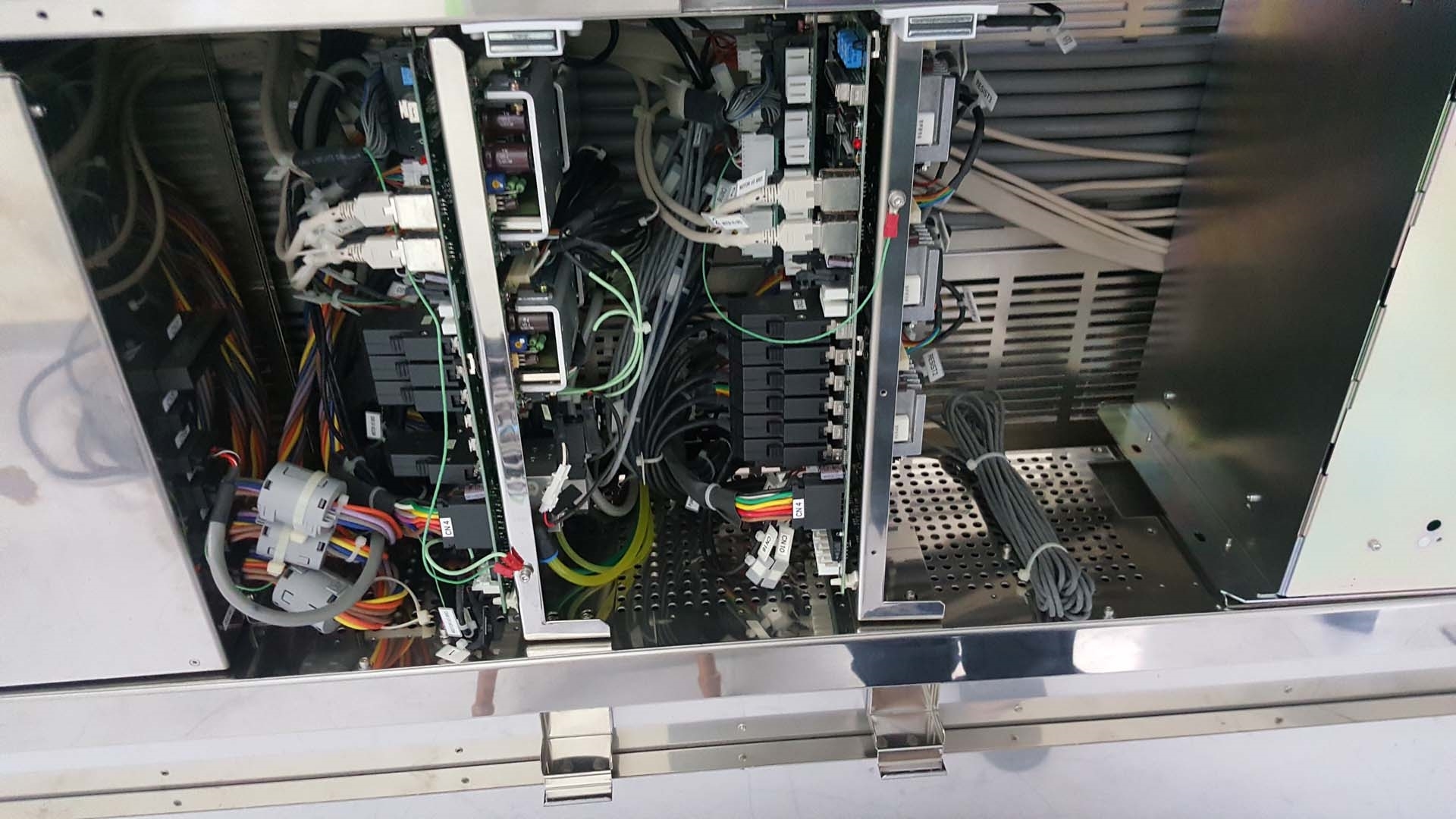

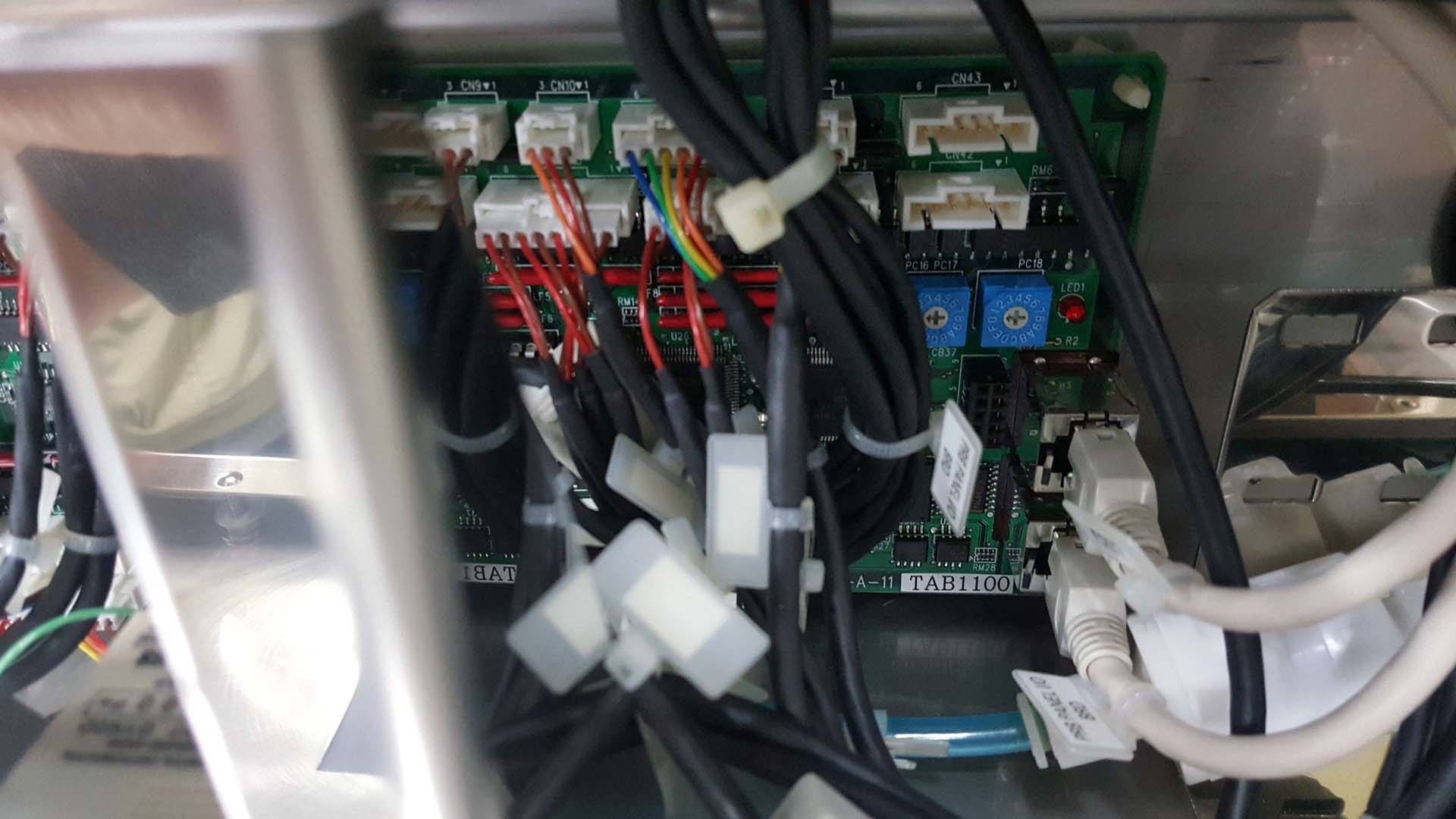

Main controller type: Type #3

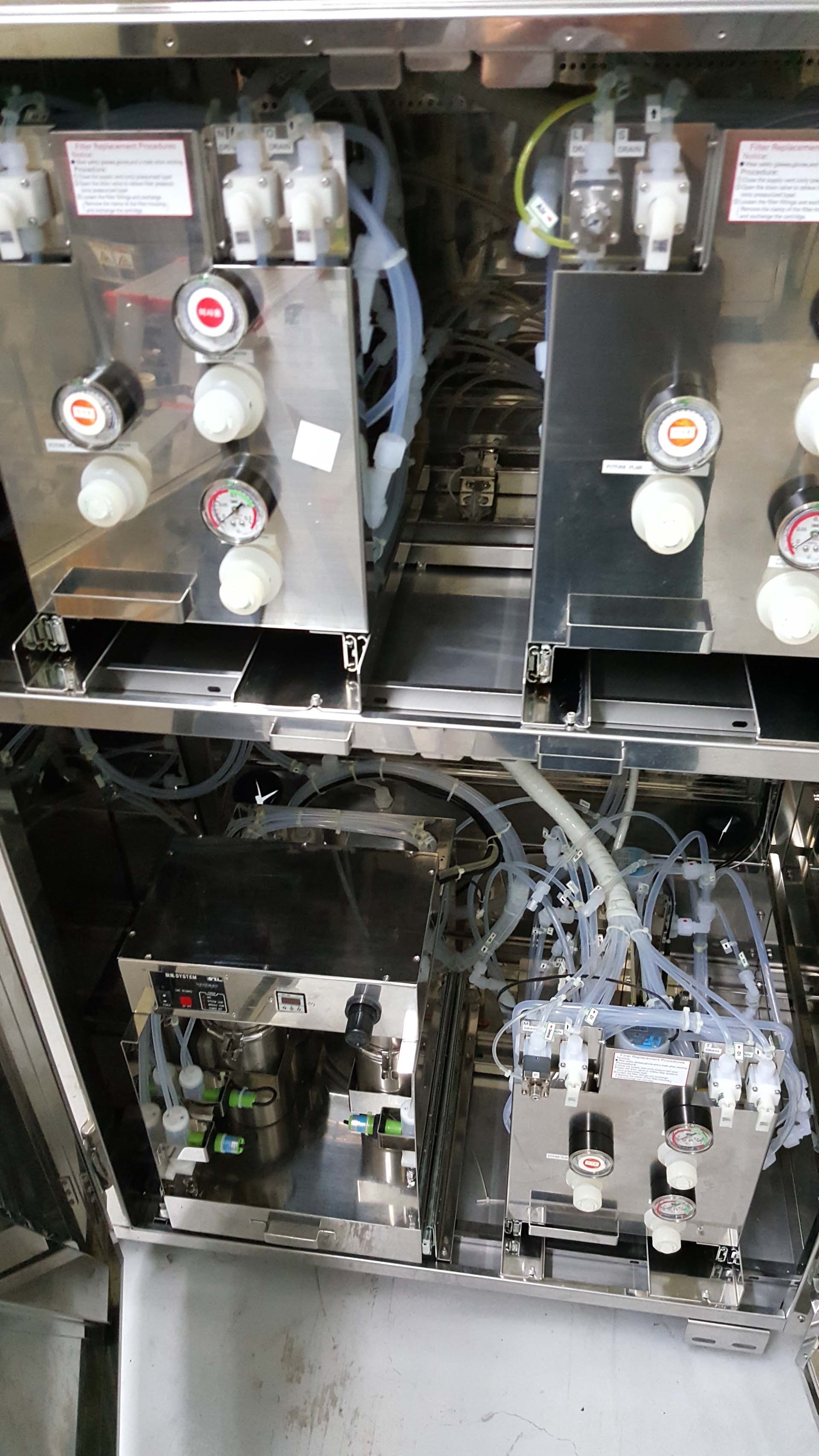

Coater:

(3) Nozzles

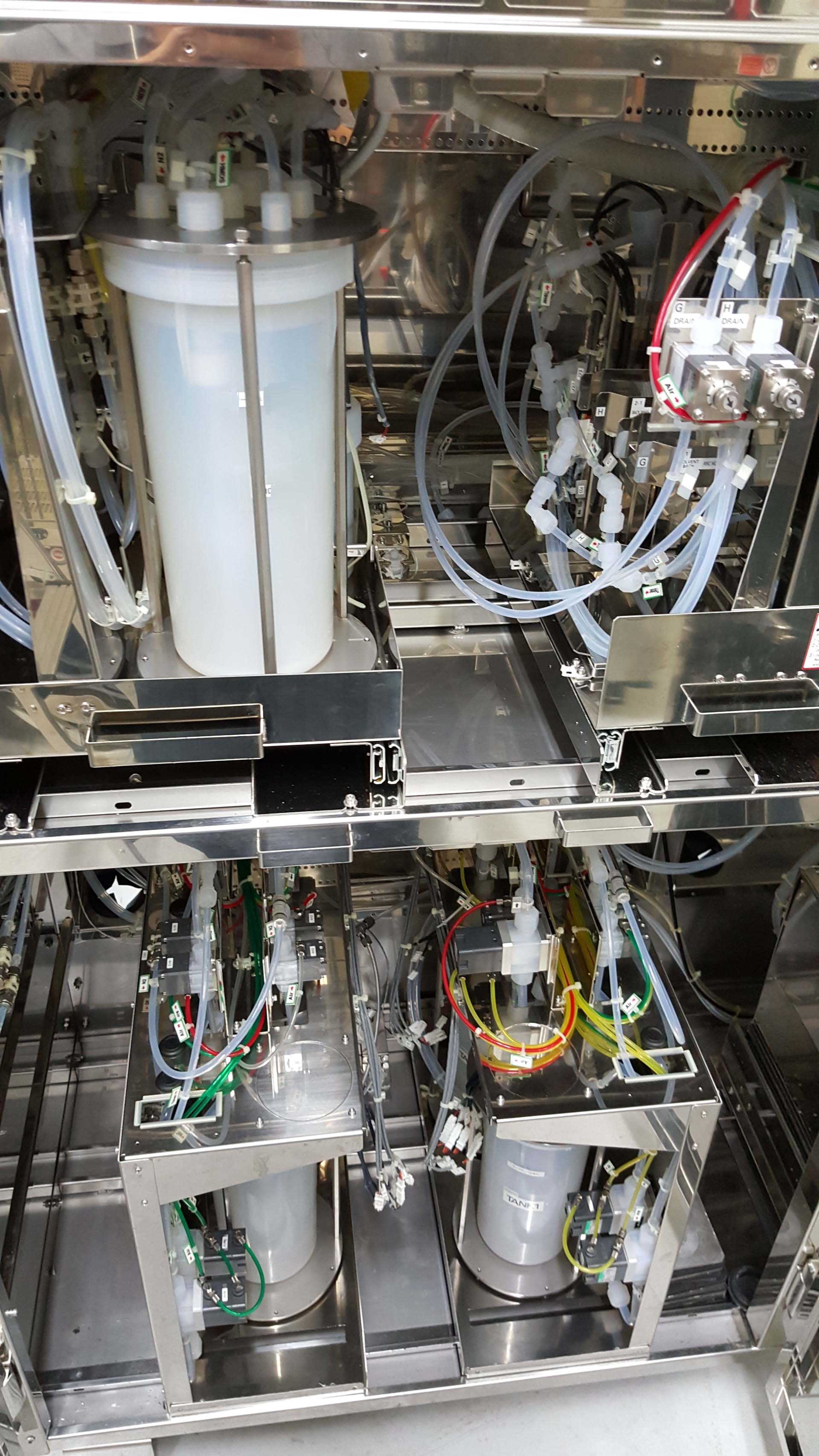

RRC Pump

(2) Buffer tanks: 3 L

Side rinse (EBR)

(2) Back side rinses

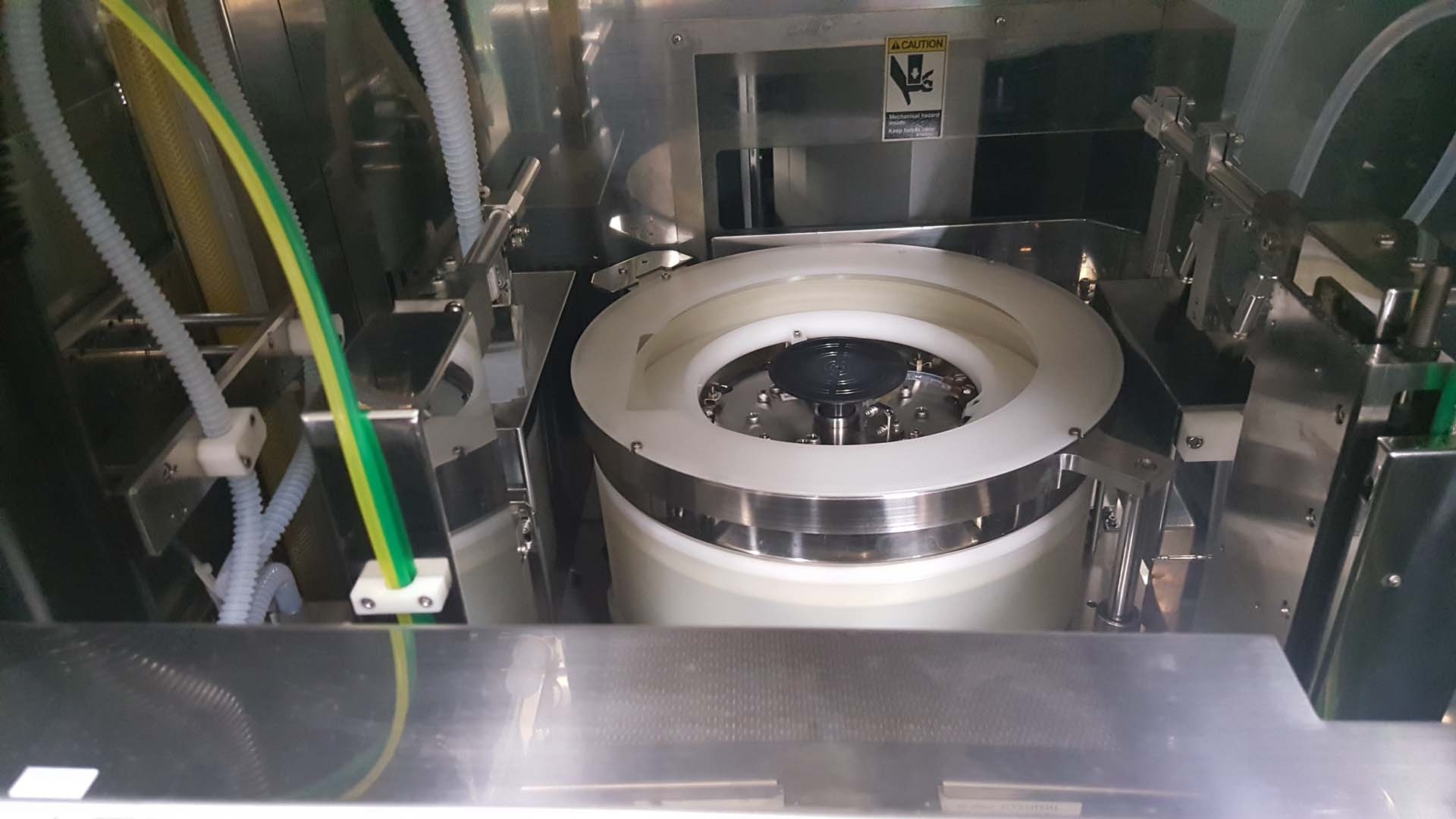

Developer:

H Nozzle type

(2) Buffer tanks: 3 L

(2) Rinse nozzles

(2) Back side rinses

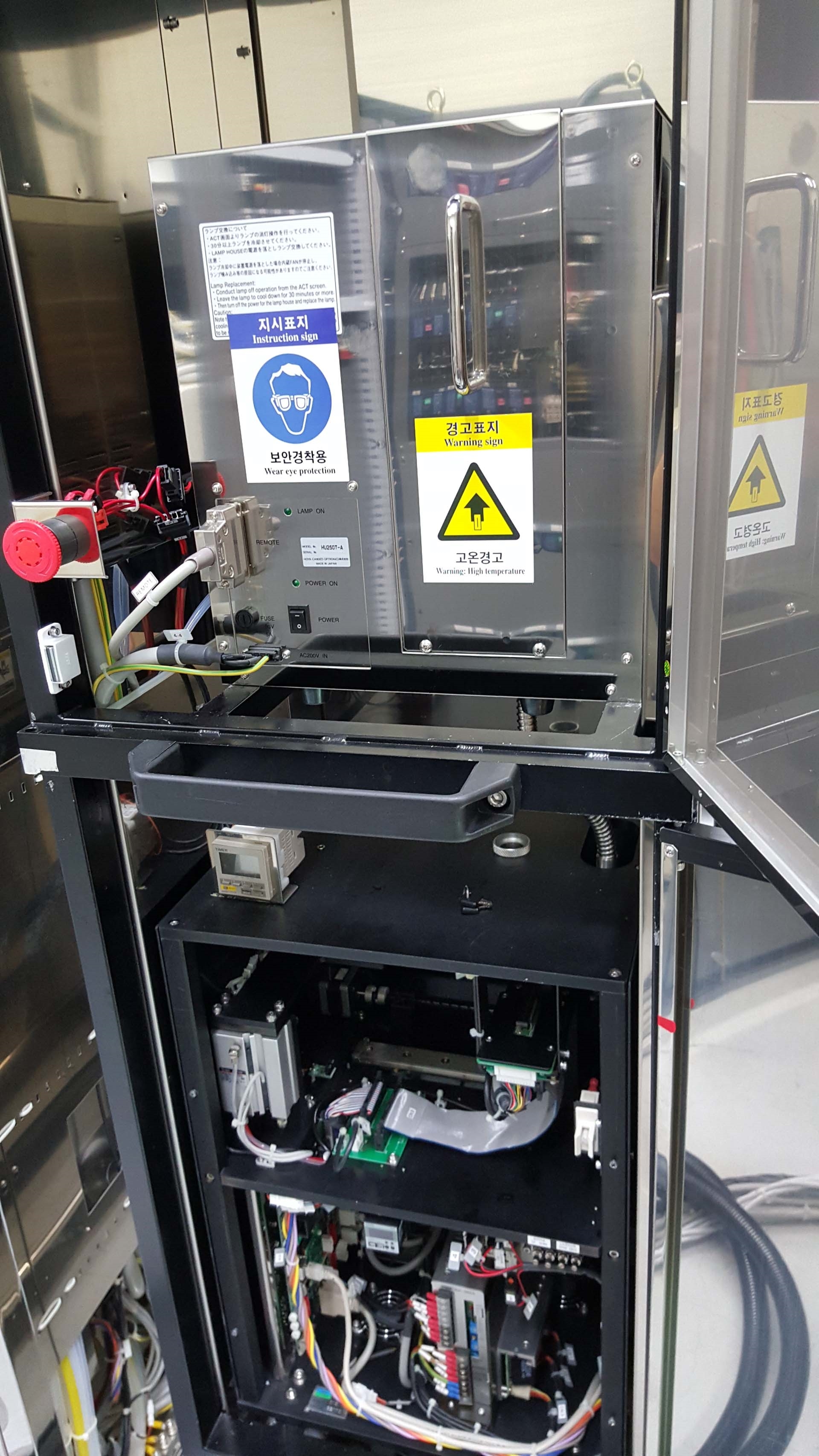

(2) Adhesion process stations (ADH )

(12) Low temperature Hot Plate stations (LHP)

(2) High Temperature Hot Plate Process Station (HHP)

(8) Chiller Plate Place (CPL)

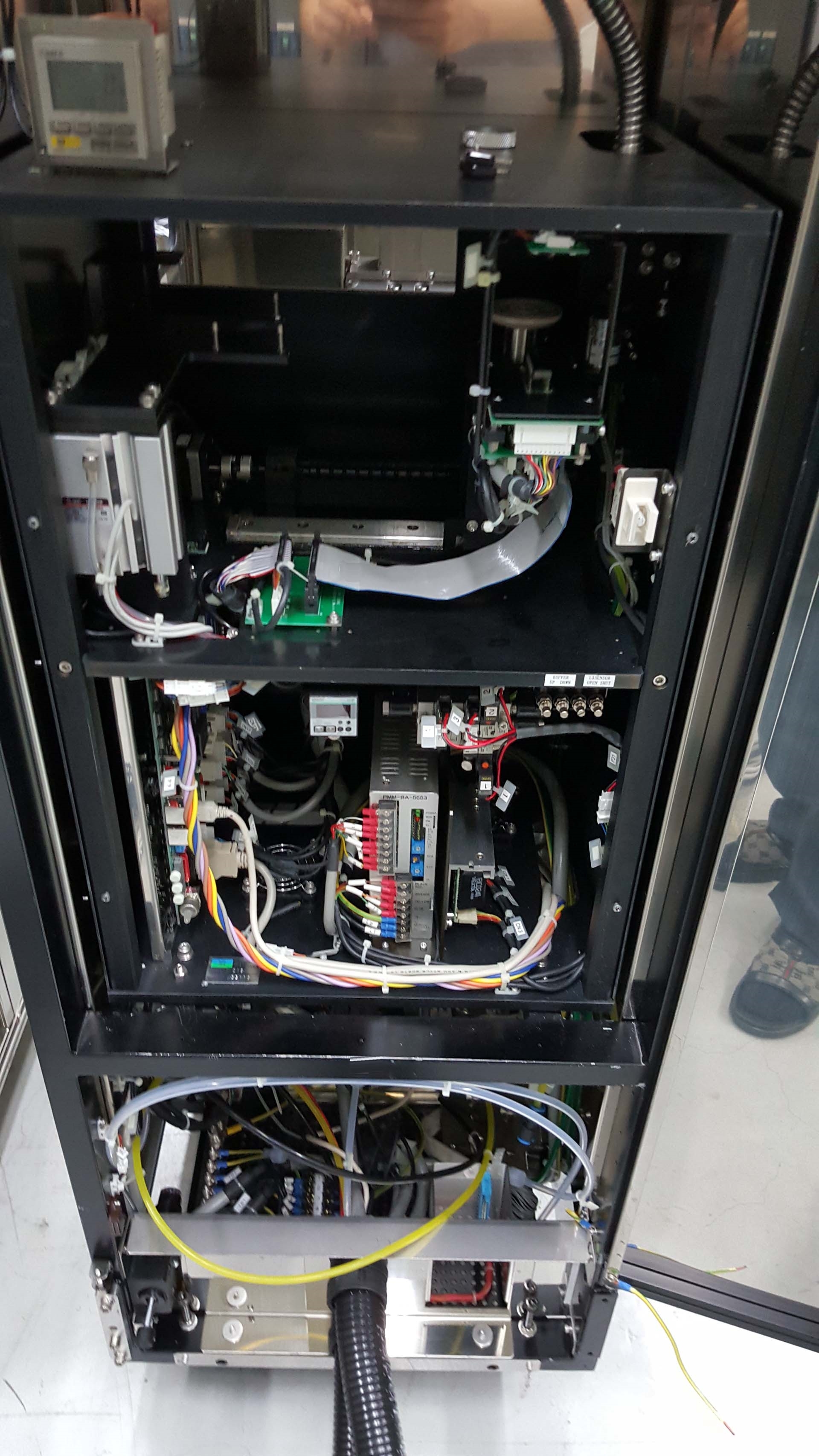

(4) Transition Stage (TRS)

(4) Chilling Hot Plate (CHP)

(2) Cup Washer Holder (CWH)

(2) Shuttle Module (SHU)

IFM

EIS Type: ASML

WEE

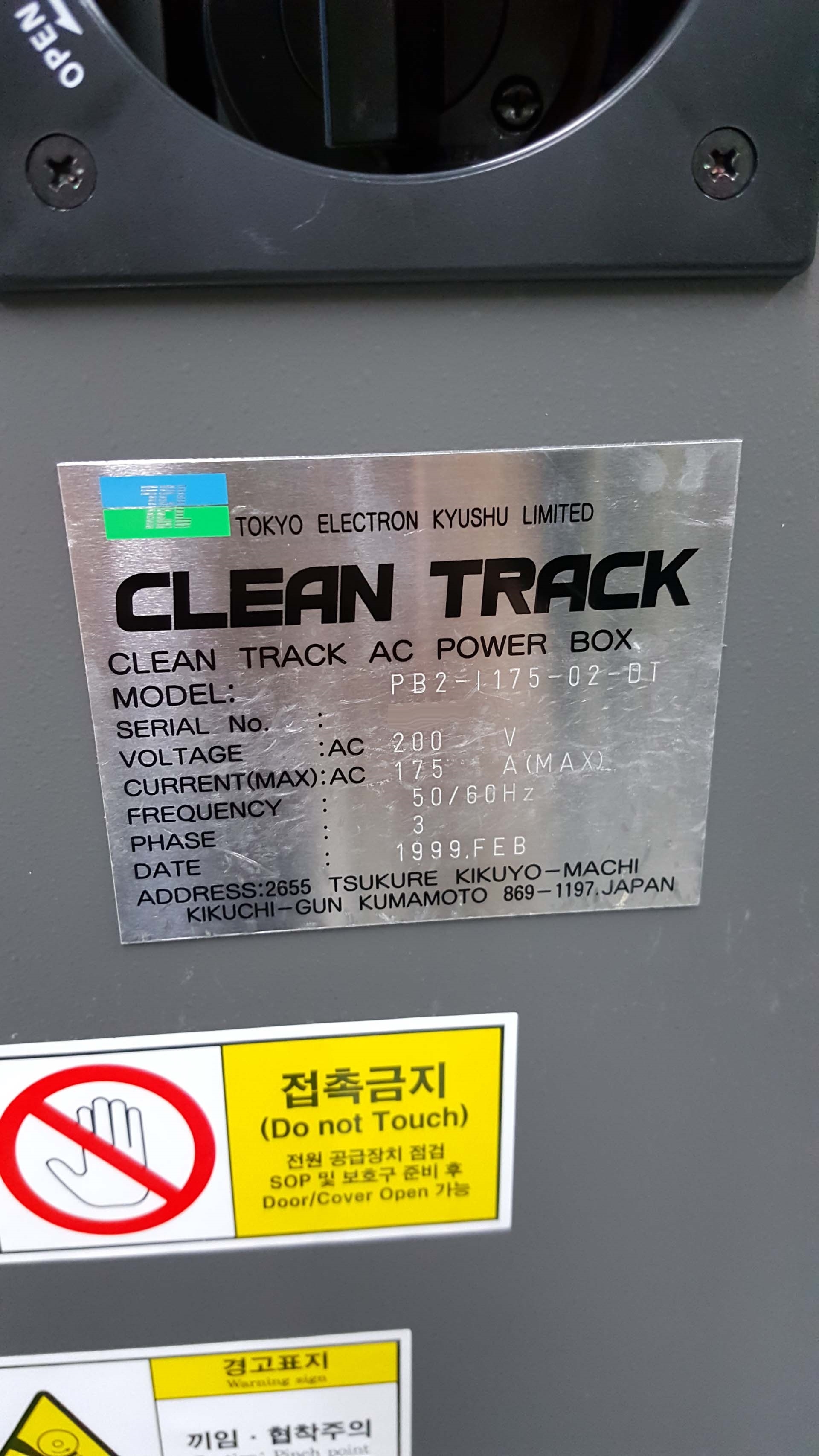

AC Power box

Chemical box

Temperature controller

T and H

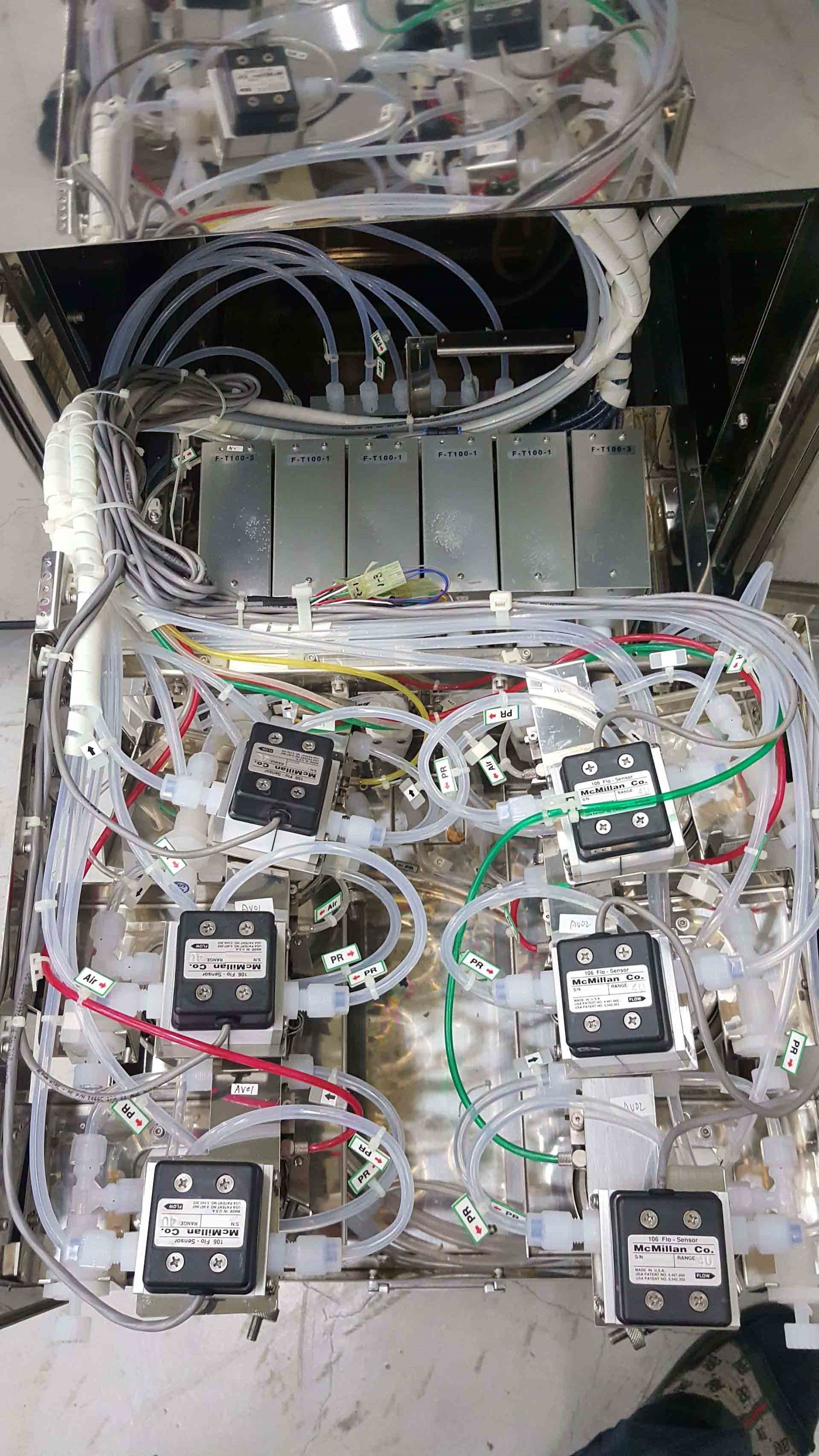

MFC.

TEL / TOKYO ELECTRON ACT 8 is a photoresist equipment designed for advanced wafer-level processes. The system offers high levels of flexibility, accuracy and efficiency through its combination of advanced automated capabilities and manual user-control. TEL ACT 8 comprises several integrated components, including a broadcast sprayer, photoresist coater, module, and multiple turret systems. The sprayer, which is used to fine-tune the photoresist, works according to a step-by-step process; first pre-mix the photoresist, then spray it evenly across the wafer using the controllable burst pressure and spray velocity. From there, the coater uses the set spray width and number of revolutions to maintain uniform film thicknesses - a key step in high-resolution processing. TOKYO ELECTRON ACT 8 module is used to heat, align, and focus the beam of the tool before the programmed exposure cycle begins. Heat and chemical-resistance can be fine-tuned using the module's high-powered optical vats, which also help to maintain a steady, uniform processing temperature. To further ensure accuracy and efficiency, the turret systems are designed for seamless integration between the camera and projector. The retractable turret arms facilitate fast and cost-effective changeover of modules, while the high-speed autofocus unit facilitates the precision alignment of cameras and projectors across a range of photoresist materials. Overall, ACT 8 provides users with an innovative photoresist solution, designed for advanced levels of accuracy and efficiency. The machine combines advanced automation capabilities with user-specified controls, allowing for maximum flexibility and reliability. With its unbiased and repeatable results, TOKYO ELECTRON ACT 8 tool also streamlines the photoresist process, reducing overhead costs and increasing potential return on investment.

There are no reviews yet