Used TEL / TOKYO ELECTRON ACT 8 #9282700 for sale

URL successfully copied!

Tap to zoom

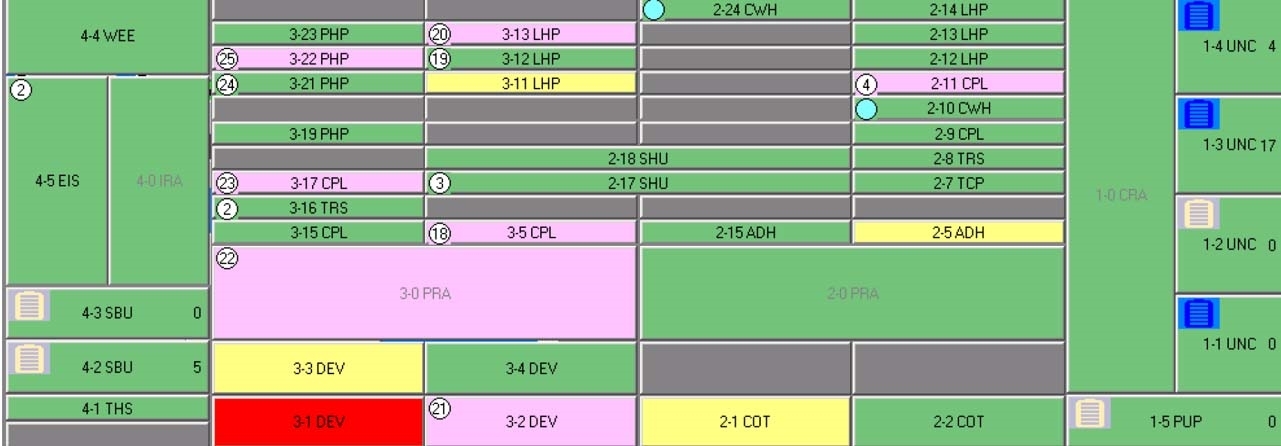

TEL / TOKYO ELECTRON ACT 8 is aphotoresist equipment that is designed to critically control the development process in semiconductor materials. It is a lithography system capable of fabricating integrated circuits and other complex materials with high density, high accuracy, and high yield. TEL ACT 8 photoresist unit's exposure stage is equipped with a Cold Cathode Lamp (CCL) capable of accommodating a single wafer at a time. The energy emitted from the lamp is measured in the Wafer Sensing Machine to ensure precise exposure of the wafer. The combination of CCL and Wafer Sensing Tool promise precise exposure by ensuring that all features of the pattern are accurately aligned on the substrate. The photo-aligning asset is also equipped with an autofocus model, allowing for quick and accurate alignment with the reticles used in the wafer projection. TOKYO ELECTRON ACT 8 also provides precise temperature control over the wafers during the development process. This ensures consistency of results across the batches and wafers, ensuring higher yield. The developers utilized are held in a tightly controlled environment using multiple temperature controlled zones, which further ensure the shelf lives of the chemicals and a higher quality of the developed resist. TEL / TOKYO ELECTRON ACT 8 is equipped with a gravure development station, the D-Station, which works in tandem with the developers mentioned above to accurately tint the developed semiconductor wafer. The D-Station contains several elements, such as a carrier, developer, and cylinder. This enables precise development of the pattern into the resist currently deposited on the semiconductor. Finally, ACT 8 is also equipped with a spray capsule for the post-exposure bake stages of the development process. This makes it easier to extend the process window by controlling the post-exposure bake process. Overall, ACT 8 is a state of the art photoresist equipment designed for precise exposure and development in the manufacture of integrated circuits and other complex materials. Its highly accurate exposure system, temperature controlled developer tanks, gravure development station, and spray capsule all work together to ensure high yields and a high level of accuracy in the development process.

There are no reviews yet