Used TEL / TOKYO ELECTRON ACT 8 #9285377 for sale

URL successfully copied!

Tap to zoom

ID: 9285377

Vintage: 2006

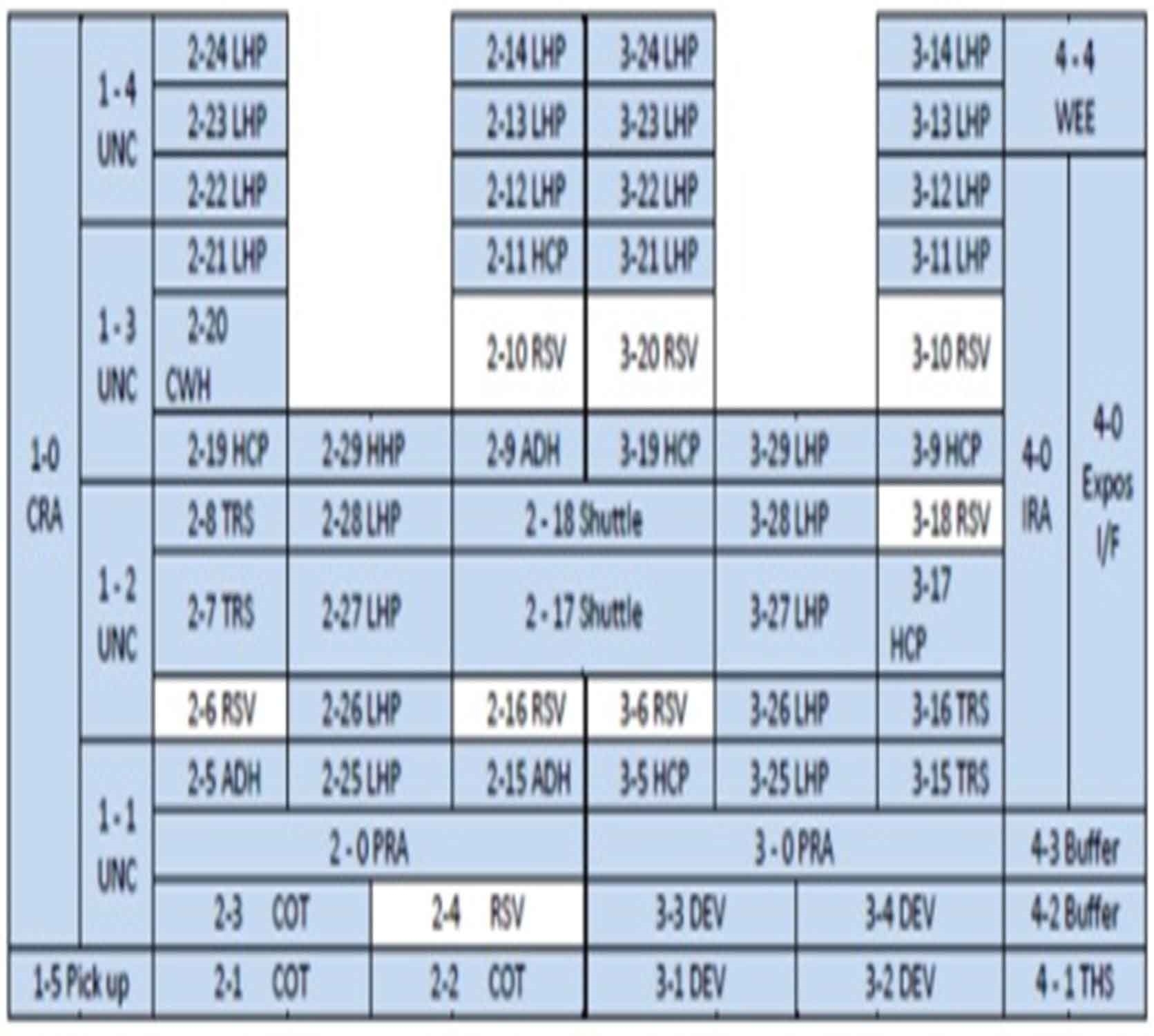

(3) Coater / (4) Developer system

NLD

Open cassette

2006 vintage.

TEL / TOKYO ELECTRON ACT 8 (TEAC-8)- Photoresist Equipment is a specialized piece of equipment designed to create photolithographic wafers for the production of semiconductor devices. Using an exposure mechanism, TEAC-8 forms patterns onto the surface of a wafer based on a digital image supplied by a computer. The TEAC-8 is compatible with light sensitive materials of various thickness, including those with low absorption rates. It features a 4K resolution which allows for an exceptionally high level of clarity in the lithographic pattern formation, as well as precise control of the exposure conditions. The TEAC-8 utilizes a complex network of hardware components to create an optimal natural environment for lithography. These components include a mechanical stage, lasers, mirrors and motorized shutter systems. This configuration allows for extreme accuracy when matching the exposure system to the optical lens, translating into smooth and consistent production of the photoresist pattern. The unit is capable of line widths ranging from 25 nanometers up to 2.5 microns (2.5 million nanometers). This wide range of exposure levels allows the TEAC-8 to meet the needs of many different types of lithographic application. It is also capable of producing 8 by 8 inch wafers, to meet the demands of wafer-fabrication production. In addition to its excellent exposure capabilities, TEAC-8 provides a full line of post-process options for cleaning and preparing the wafers. This includes on-site hard-bake, developing, cleaning, etching, and curing services. This all-in-one solution offers hardware and software solutions for an enhanced end-product. The TEAC-8 is an effective machine for producing high-quality wafers and has been proven to generate reliable results time and time again. Its performance has been proven in wafer fabrication across numerous industries, including medical device and chip production. With proper cleaning, maintenance, and handling this tool can easily extend the life of wafer production.

There are no reviews yet